Preparation method and product of modified asphalt

A technology of modified asphalt and matrix asphalt, applied in building components, building insulation materials, buildings, etc., can solve the problems of affecting the softening point of asphalt, easily polluting the environment, etc. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of modified asphalt, comprises the following steps:

[0028] (1) Heat the base asphalt to 160°C to 190°C, based on 100 parts by mass of the base asphalt, add 2 to 8 parts of styrene-butadiene-styrene block copolymer (SBS) , 0 to 9 parts of compatibilizer are mixed with base asphalt, and sheared at a speed of 4000rpm to 8000rpm for 0.5h to 3h to make them fully mixed;

[0029] (2) spreading the modified asphalt primary material with a thickness of 3 mm to 10 mm;

[0030] (3) Utilize the electron beam that the dosage is 30kGy~800kGy (that is, the electron beam energy that per kg modified asphalt raw material absorbs is 30kJoule~800kJoule) electron beam is irradiated to the modified asphalt primary material after spreading, obtains described modified asphalt.

[0031] Between the step (1) and the step (2), it is also possible to: stir and develop the modified asphalt primary material at a speed of 100rpm-300rpm for 2h-8...

Embodiment 1

[0037] A modified bitumen, including SBS 1301 and No. 50 base bitumen, prepared by electron beam irradiation. The SBS1301 is dispersed in the base asphalt, and its addition amount is 2.5 parts based on 100 parts by mass of the base asphalt. The SBS 1301 has a linear structure with a molecular weight of 80,000 to 110,000, an average polystyrene segment content of 30 wt%, and an irradiation dose of 60 kGy.

[0038] The preparation method of described modified asphalt specifically comprises the following steps:

[0039] (1) Heat 500g of base asphalt to 160°C, add 12.5g of SBS 1301 to the base asphalt, cut at 4000rpm for 0.5 hours, so that SBS is evenly dispersed in the base asphalt; raise and keep the temperature at 170°C, 150rpm Continue mechanical stirring for 3 hours to obtain the primary material of SBS modified asphalt;

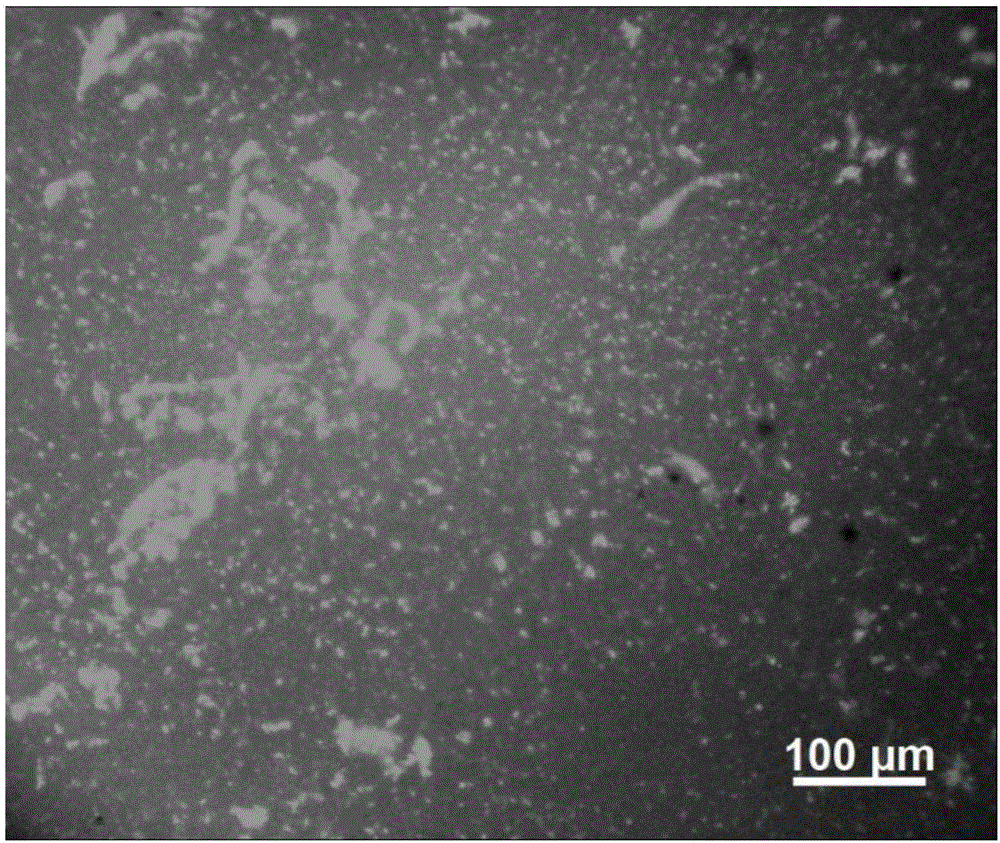

[0040] (2) spreading the SBS modified asphalt primary material that step (1) obtains, obtaining the SBS modified asphalt spreading material that thicknes...

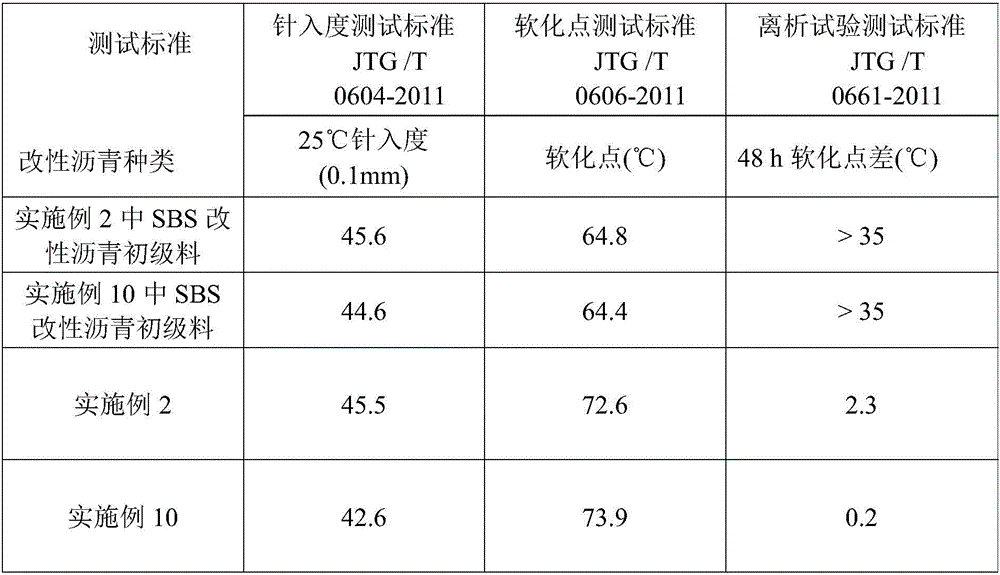

Embodiment 2

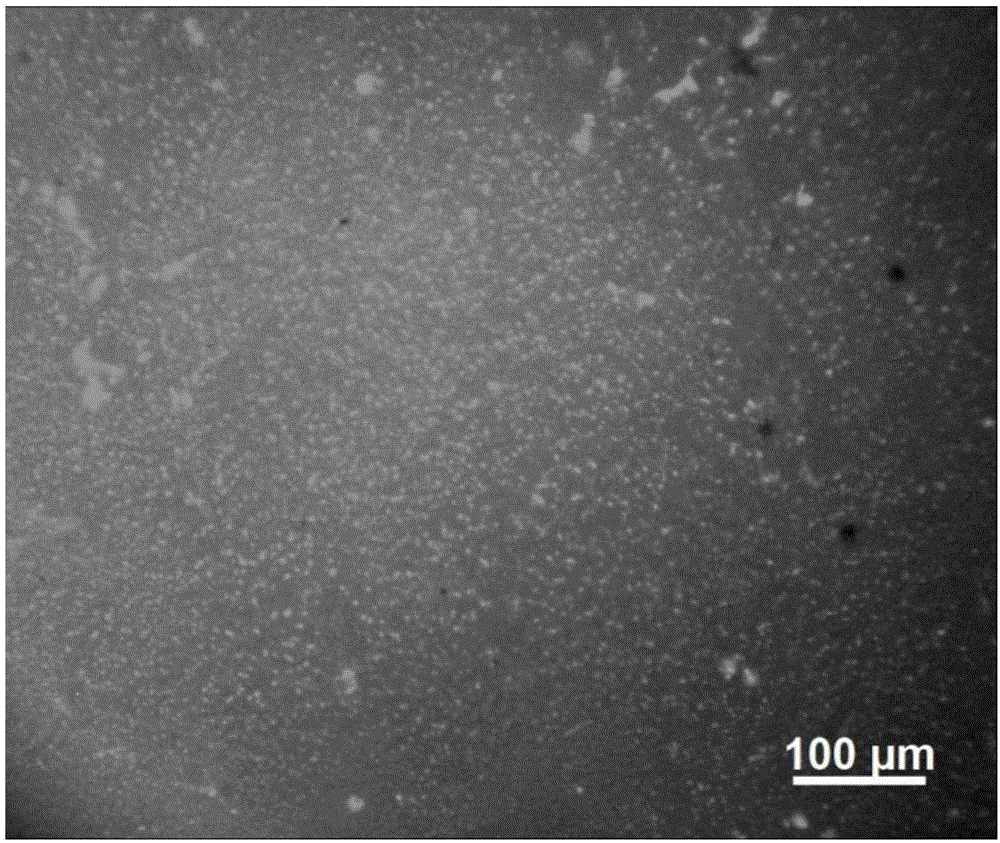

[0043] A modified bitumen, including SBS 1301-1 and No. 70 base bitumen, prepared by electron beam irradiation. The SBS 1301-1 is dispersed in the base asphalt, and its addition amount is 5.0 parts based on 100 parts by mass of the base asphalt. The SBS 1301-1 has a linear structure with a molecular weight of 100,000 to 130,000, an average content of polystyrene segments of 30 wt%, and a radiation dose of 390 kGy.

[0044] The preparation method of described modified asphalt specifically comprises the following steps:

[0045] (1) Heat 500g of base asphalt to 165°C, add 25.0g of SBS 1301-1 to the base asphalt, and cut at 4500rpm for 1.0 hour, so that SBS is evenly dispersed in the base asphalt, and the primary material of SBS modified asphalt is obtained;

[0046] (2) spreading the SBS modified asphalt primary material that step (1) obtains, obtaining the SBS modified asphalt spreading material that thickness is 4mm;

[0047] (3) The SBS modified asphalt spreading material o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com