Hyperbranched resin pigment dispersant, preparation method and color paste thereof, and applications of color paste

A technology of pigment dispersant and hyperbranched resin, which is applied in the direction of pigment paste, epoxy resin coating, anti-corrosion coating, etc. It can solve the problems of low dispersion efficiency of color paste, floating color of paint film, and large color difference of finished paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

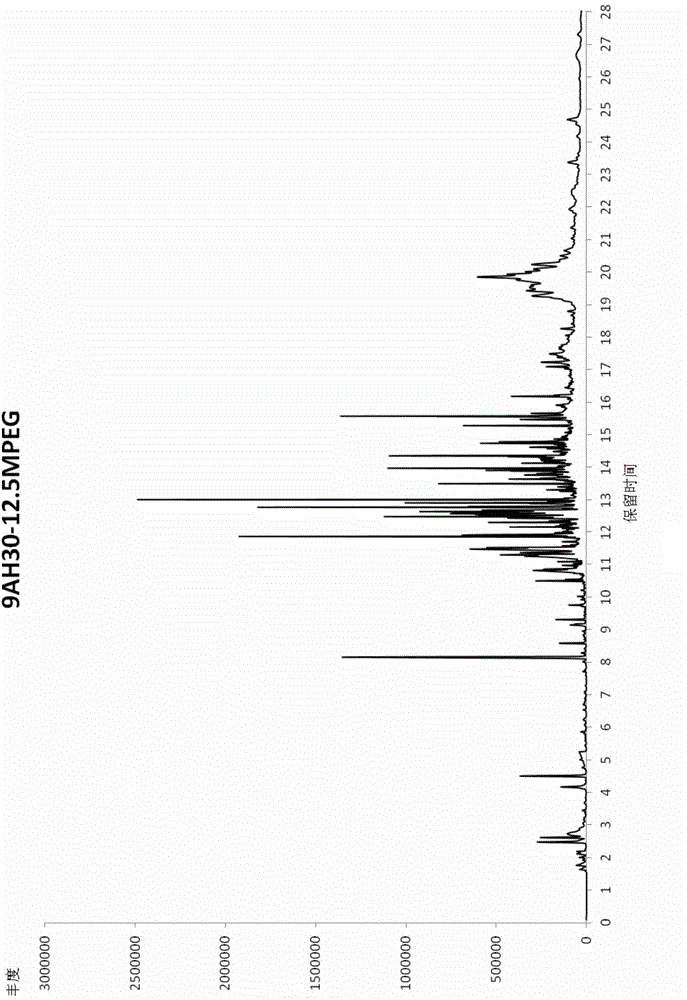

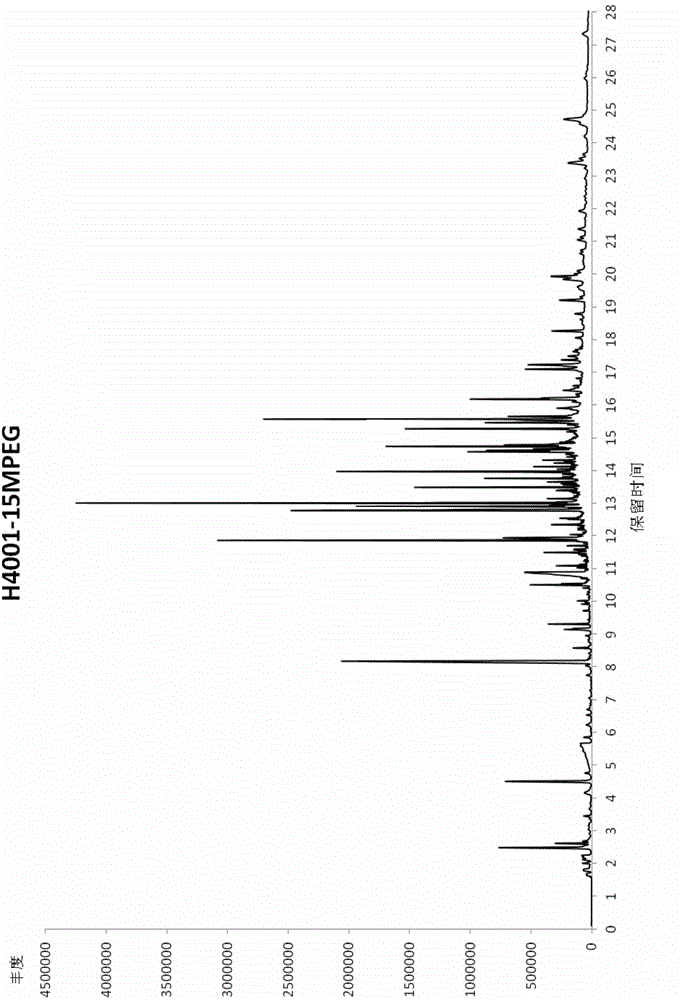

[0074] Embodiment 1 (9AH30-12.5% MPEG)

[0075] (a) Synthesis of 9AH30

[0076] Under the protection of nitrogen, after heating 320 grams of H4001 to 120 degrees, 39.59 grams of HHPA were added with stirring. Insulate and react for about 1 hour. After the infrared spectrum shows that the absorption peak of the acid anhydride disappears, add 61.63 grams of CarduraE10, heat up to 140 degrees, and insulate for about 5 hours until the acid value is less than 10mgKOH / g. The product 9AH30 has a solid content of about 67%.

[0077] (b) Synthesis of IPDI-MPEG750 adduct

[0078] Under nitrogen protection and at room temperature, to 61.75 gram IPDI, in the mixture of 62.5 gram butyl acetate (BA) solvents and 0.312 gram DBTDL catalyst, slowly add the mixed solution of 312.5 gram MPEG750 and butyl acetate (the weight of MPEG750 and butyl acetate The ratio is 4:1), about 1.5 hours to add. React at room temperature for about 2-3 hours until the content of the isocyanate functional grou...

Embodiment 2

[0089] (a) Synthesis of 9AH30

[0090] Same as Example 1

[0091] (b) Synthesis of IPDI-MPEG750 adduct

[0092] Same as Example 1

[0093] (c) Synthesis of 9AH30-25% MPEG

[0094] Under the protection of nitrogen, heat 230 g of 9AH30 to 80 degrees, then add 0.230 g of DBTDL, stir for 5 minutes, then add 183.8 g of newly prepared IPDI-MPEG750 adduct with slow stirring. Insulate and react for about 5 hours until NCOwt% is less than 0.1wt%. The resulting product had a solids content of about 69%.

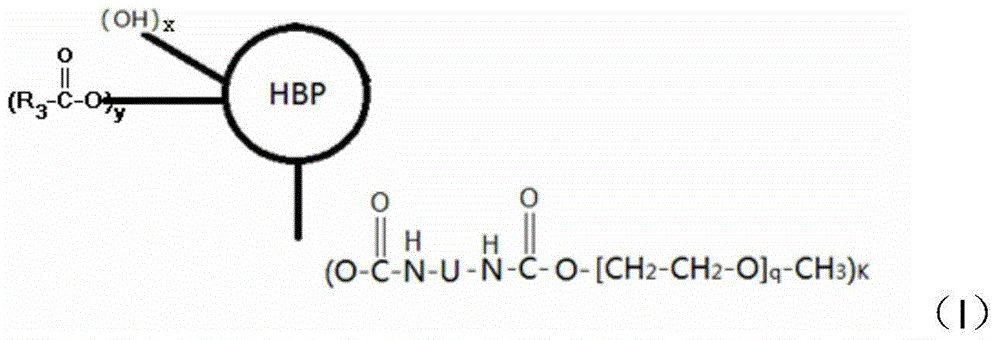

[0095] The structural formula of gained product 9AH30-25%MPEG is

[0096]

[0097] In the formula R 1 It is a carbon six-membered ring skeleton; R 2 Corresponding formula (III) structure, where R 5 +R 6 = 7 C; R 3 It is a C6-C15 saturated fatty acid carbon chain skeleton, the average value of y is 22, the average value of x+n+k is: 64-22=42, and the relative ratio of k, n, x is: 25%, 30% , 45%.

Embodiment 3

[0099] (a) Synthesis of 9AH30

[0100] Same as Example 1

[0101] (b) Synthesis of IPDI-MPEG750 adduct

[0102] Same as Example 1

[0103] (c) Synthesis of 9AH30-50% MPEG

[0104]Under the protection of nitrogen, heat 160 grams of 9AH30 to 80 degrees, then add 0.160 grams of DBTDL, stir for 5 minutes, then add 255.8 grams of newly prepared IPDI-MPEG750 adduct with slow stirring. Insulate and react for about 8 hours until NCOwt% is less than 0.1wt%. The resulting product had a solids content of about 70%.

[0105] The structural formula of gained product 9AH30-50%MPEG is

[0106]

[0107] In the formula R 1 It is a carbon six-membered ring skeleton; R 2 Corresponding formula (III) structure, where R 5 +R 6 = 7 C; R 3 It is a C6-C15 saturated fatty acid carbon chain skeleton, the average value of y is 22, the average value of x+n+k is: 64-22=42, and the relative ratio of k, n, x is: 50%, 30% , 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com