Low-temperature ductility and high-temperature-resistant storage stability auxiliaries for modified asphalt as well as preparation method for low-temperature ductility and high-temperature-resistant storage stability auxiliaries and modified asphalt

A technology of storage stability and modified asphalt, which is applied in building insulation materials, building components, buildings, etc., can solve the problem of poor interfacial compatibility of matrix asphalt, affecting low temperature performance indicators and high temperature storage stability, and affecting low temperature performance of modified asphalt Index and high temperature storage stability and other issues, to achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

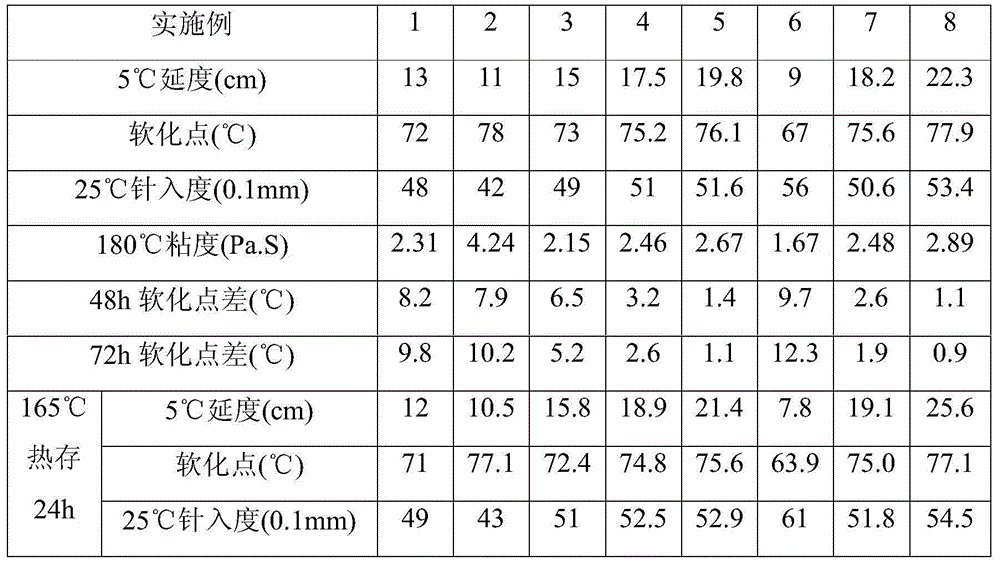

Examples

Embodiment 1

[0038] Weigh 20% 40-mesh rubber powder according to the weight ratio of the base asphalt, add it to the base asphalt and stir rapidly for 15 minutes, then stir and add 0.4% stabilizer, use a colloid mill to grind once (10 minutes), and incubate at 170-175 ° C After 4 hours, the modified asphalt was prepared and the properties of the modified asphalt were tested.

Embodiment 2

[0040] Weigh 25% 40-mesh rubber powder according to the weight ratio of the base asphalt, add it to the base asphalt and stir rapidly for 15 minutes, then add 0.4% stabilizer after stirring, use a colloid mill to grind once (10 minutes), and incubate at 170-175 °C After 4 hours, the modified asphalt was prepared and the properties of the modified asphalt were tested.

Embodiment 3

[0042] Pretreat rubber powder, softening oil, and activator in a high-speed mixer at 50-100°C for 10-30 minutes, meter them into the screw extruder, and continuously extrude fluid regenerated rubber from the die after reaction. Heat the rubber cracking oil to 140-170°C, weigh the diluent with a weight ratio of 75%, add the regenerated rubber to the rubber cracking oil, keep stirring for 30 minutes, keep the temperature at 150°C, and then use a high-speed emulsifying shear to shear The speed is 1000-10000 rpm and shearing for 20 minutes to prepare additives that can significantly improve the low-temperature ductility and high-temperature storage stability of modified asphalt. Take by weighing 20% of 40 mesh rubber powder and 5% of the above-mentioned additives according to the weight ratio of the base asphalt, add them into the base asphalt and stir rapidly for 15 minutes, then stir and add 0.4% stabilizer, and use a colloid mill to grind 1 time (10min), And incubate at 170-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com