Anti-aging agent and anti-aging asphalt

An anti-aging agent and anti-aging technology, which is applied in the field of road petroleum asphalt, can solve problems such as the complex chemical composition and structure of asphalt, the cost of toxic raw materials of anti-aging agents, and restrictions on the promotion and application of asphalt, so as to improve the performance of heat-oxidative aging resistance and Thermal storage stability, avoidance of thermo-oxidative aging, effect of suppressing thermo-oxidative aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take by weight 10 parts of nano carbon black, 40 parts of p-phenylenediamine, 10 parts of p-cresol, 10 parts of C5 petroleum resin, and 30 parts of rubber oil.

[0041] Put the above-mentioned C5 petroleum resin, nano-carbon black and rubber oil in a metal container, and use a stirrer to stir at a rate of 500rpm for about 10min at 100±5°C; maintain the above temperature, add p-phenylenediamine and p-cresol, and Stir at a speed of 500 rpm for about 10 minutes to obtain an anti-aging agent.

[0042] Heat base asphalt A (penetration of 80dmm at 25°C, softening point of 49°C) to 145-150°C, add the above anti-aging agent, and stir at a speed of 750rpm for about 30min to obtain anti-aging asphalt, in which the anti-aging agent The mass content is about 1%.

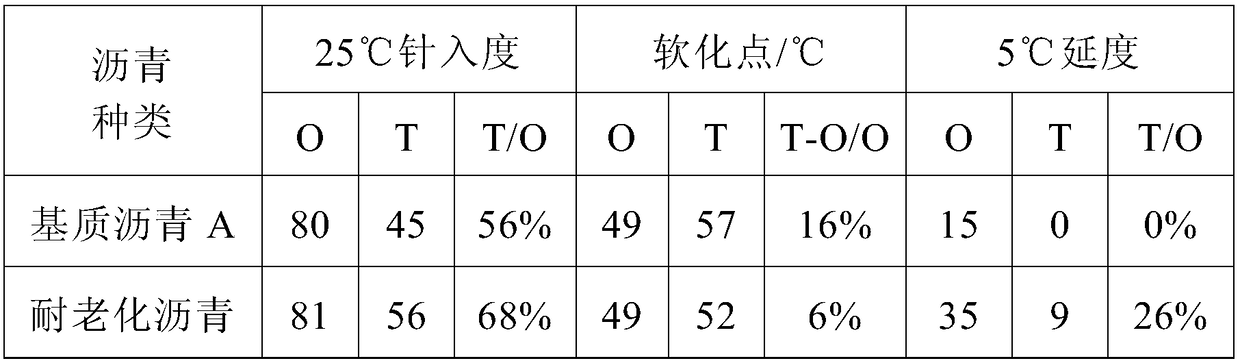

[0043] The comparison results of the penetration (0.1mm), softening point (°C) and ductility (cm) at 5°C of base asphalt A and aging-resistant asphalt before and after TFOT aging are shown in Table 1.

[0044] Table 1 C...

Embodiment 2

[0050] Take by weight 15 parts of nano-carbon black, 40 parts of p-phenylenediamine, 15 parts of p-cresol, and 30 parts of rubber oil.

[0051] Put the above-mentioned nano-carbon black and rubber oil in a metal container, and stir with a stirrer at a rate of 500rpm for about 10min at 100±5°C; Stir at a high speed for about 10 minutes to obtain an anti-aging agent.

[0052] Heat base asphalt B (penetration of 70dmm at 25°C and softening point of 50°C) to 145-150°C, add the above-mentioned anti-aging agent, and stir at a speed of 750rpm for about 30 minutes to obtain an aging-resistant asphalt. The mass content of the agent is about 0.5%.

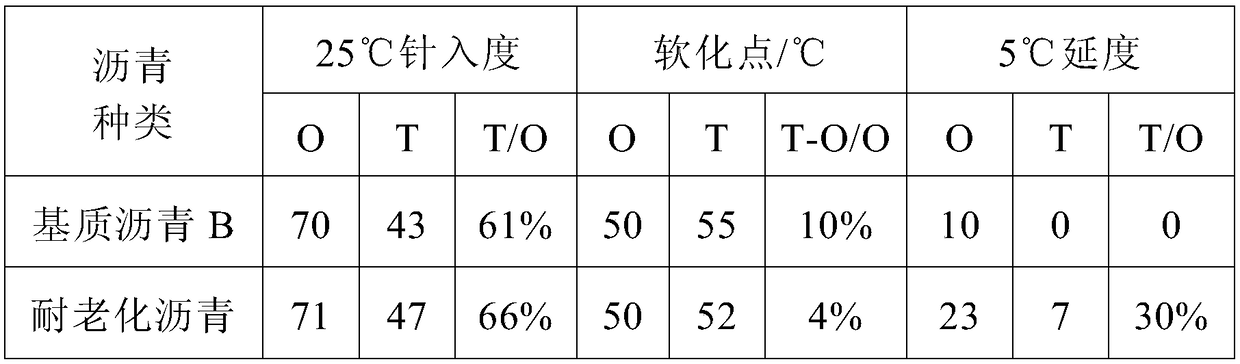

[0053] The comparison results of the penetration (0.1mm), softening point (°C) and ductility (cm) at 5°C of base asphalt B and aging-resistant asphalt before and after TFOT aging are shown in Table 2.

[0054] Table 2 Comparison of base asphalt B and aging-resistant asphalt before and after TFOT

[0055]

[0056] According to the above...

Embodiment 3

[0059] Take by weight 20 parts of nano carbon black, 45 parts of p-phenylenediamine, 5 parts of p-cresol, and 30 parts of rubber oil.

[0060] Put the above-mentioned nano-carbon black and rubber oil in a metal container, and stir with a stirrer at a rate of 500rpm for about 10min at 100±5°C; maintain the above temperature, and continue to add p-phenylenediamine and p-cresol, and continue to Stir at a high speed for about 10 minutes to obtain an anti-aging agent.

[0061] Heat base asphalt C (penetration of 50dmm at 25°C, softening point of 62°C) to 145-150°C, add the above anti-aging agent, and stir at a speed of 750rpm for about 30 minutes to obtain an aging-resistant asphalt. The mass content of agent is about 1%.

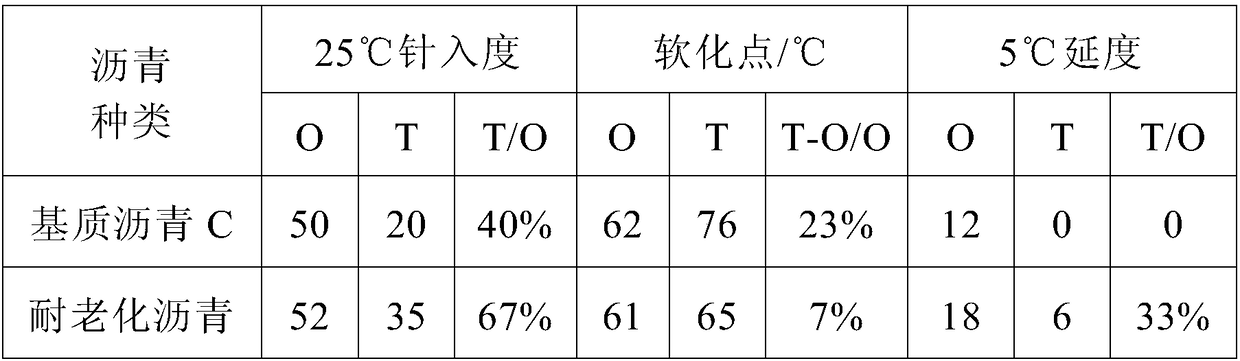

[0062] The comparison results of the penetration (0.1mm), softening point (°C) and ductility (cm) at 5°C of base asphalt C and aging-resistant asphalt before and after TFOT aging are shown in Table 3.

[0063] Table 3 Comparison of base asphalt C and aging-res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com