Chemically-modified asphalt cement and preparation method thereof

A technology of chemical modification and asphalt glue, which is applied in building insulation materials, building components, buildings, etc., can solve problems such as increased project costs, higher technical level requirements for operators, monopoly of patented technology, etc., to improve high temperature stability , thermal storage stability, improve the effect of segregation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

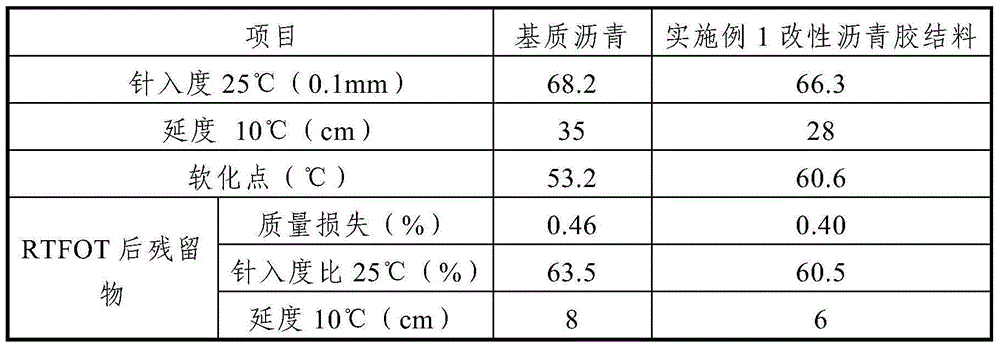

Embodiment 1

[0020] The chemically modified asphalt binder in this embodiment is made of the following raw materials in parts by weight: 100 parts of base asphalt, 1.2 parts of RET asphalt modifier, and 0.2 parts of polyphosphoric acid; the base asphalt is preferably 70# asphalt, and the RET Asphalt modifier is preferably the RET asphalt modifier produced by U.S. Dupont, and the preferred mass percentage concentration of the polyphosphoric acid is expressed in H 3 PO 4 Calculated as 110% polyphosphoric acid.

[0021] The method for preparing chemically modified asphalt binder in this example is as follows: heat the base asphalt to 175°C, then add the RET asphalt modifier to the base asphalt and stir for 60 minutes under the condition that the addition rate is 10 g / min, and then add more Polyphosphoric acid continued to stir for 40 minutes to obtain chemically modified asphalt binder.

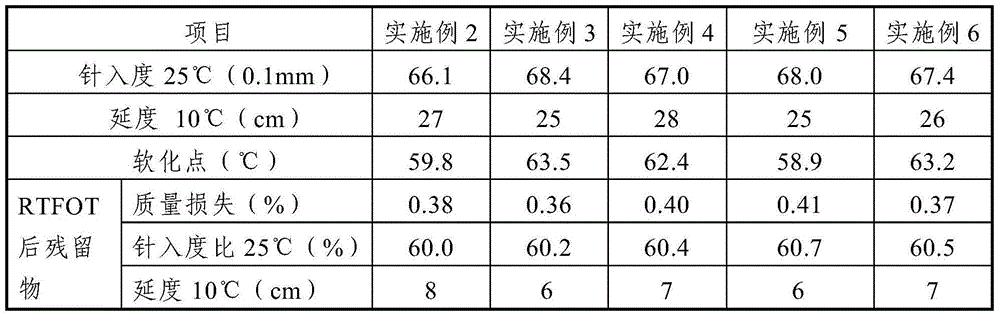

Embodiment 2

[0026] The chemically modified asphalt binder in this embodiment is made of the following raw materials in parts by weight: 100 parts of base asphalt, 1 part of RET asphalt modifier, and 0.2 part of polyphosphoric acid; the base asphalt is preferably 70# asphalt, and the RET Asphalt modifier is preferably the RET asphalt modifier produced by U.S. Dupont, and the preferred mass percentage concentration of the polyphosphoric acid is expressed in H 3 PO 4 Calculated as 110% polyphosphoric acid.

[0027] The method for preparing chemically modified asphalt binder in this example is as follows: heat base asphalt to 185°C, then add RET asphalt modifier to base asphalt and stir for 40 minutes under the condition that the addition rate is 10 g / min, and then add more Polyphosphoric acid continued to stir for 30 minutes to obtain chemically modified asphalt binder.

Embodiment 3

[0029] The chemically modified asphalt binder in this embodiment is made of the following raw materials in parts by weight: 100 parts of base asphalt, 1.8 parts of RET asphalt modifier, and 0.3 parts of polyphosphoric acid; the base asphalt is preferably 70# asphalt, and the RET Asphalt modifier is preferably the RET asphalt modifier produced by U.S. Dupont, and the preferred mass percentage concentration of the polyphosphoric acid is expressed in H 3 PO 4 Calculated as 110% polyphosphoric acid.

[0030] The method for preparing chemically modified asphalt binder in this example is as follows: heat the base asphalt to 180°C, then add the RET asphalt modifier to the base asphalt and stir for 50 minutes under the condition that the addition rate is 12 g / min, and then add more Polyphosphoric acid continued to stir for 35 minutes to obtain chemically modified asphalt binder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com