Electrical smoking system and method

A technology of electric smoking, cigarettes, applied in the direction of combustion methods, smoker's supplies, tobacco, etc., which can solve the problem of unattractiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

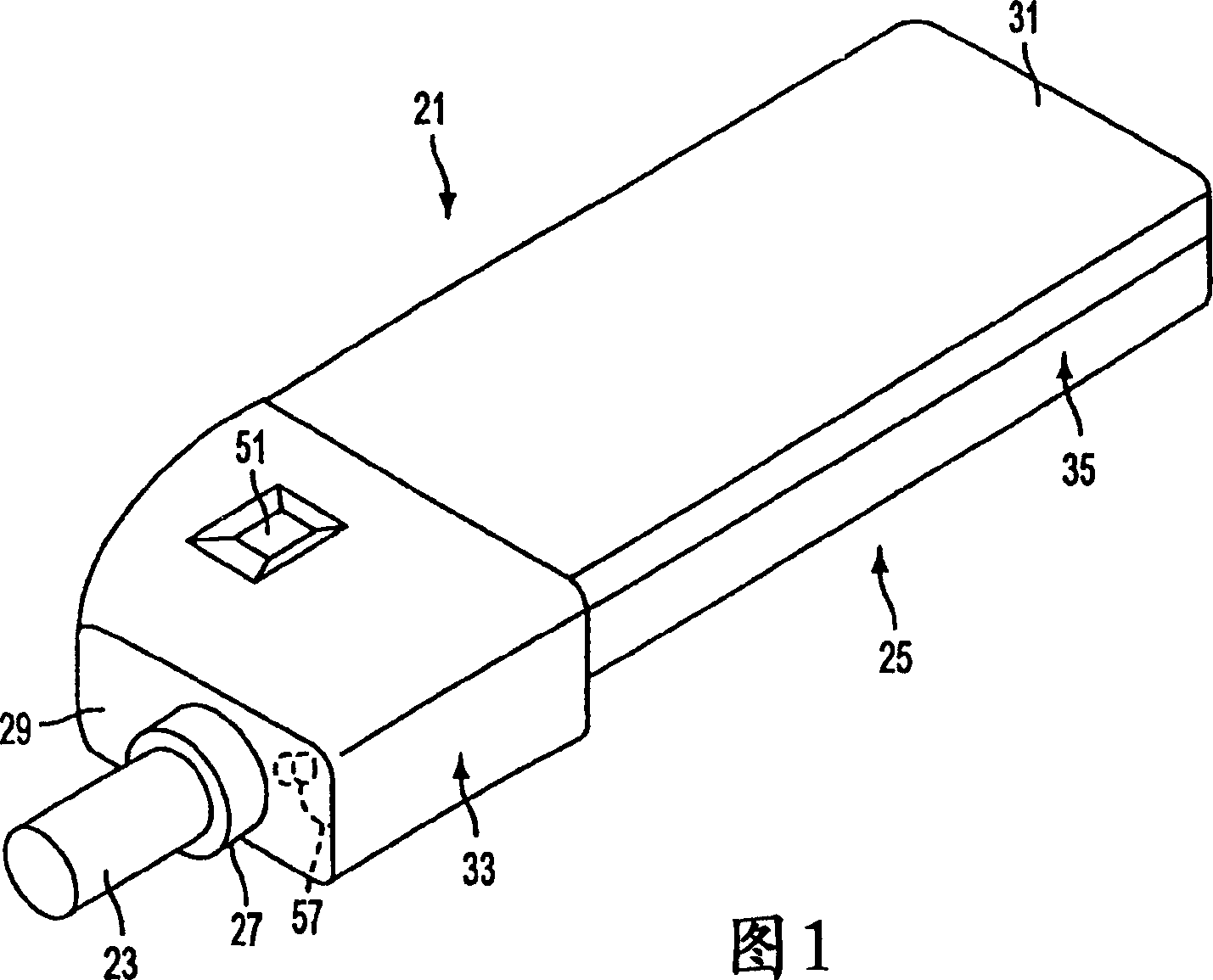

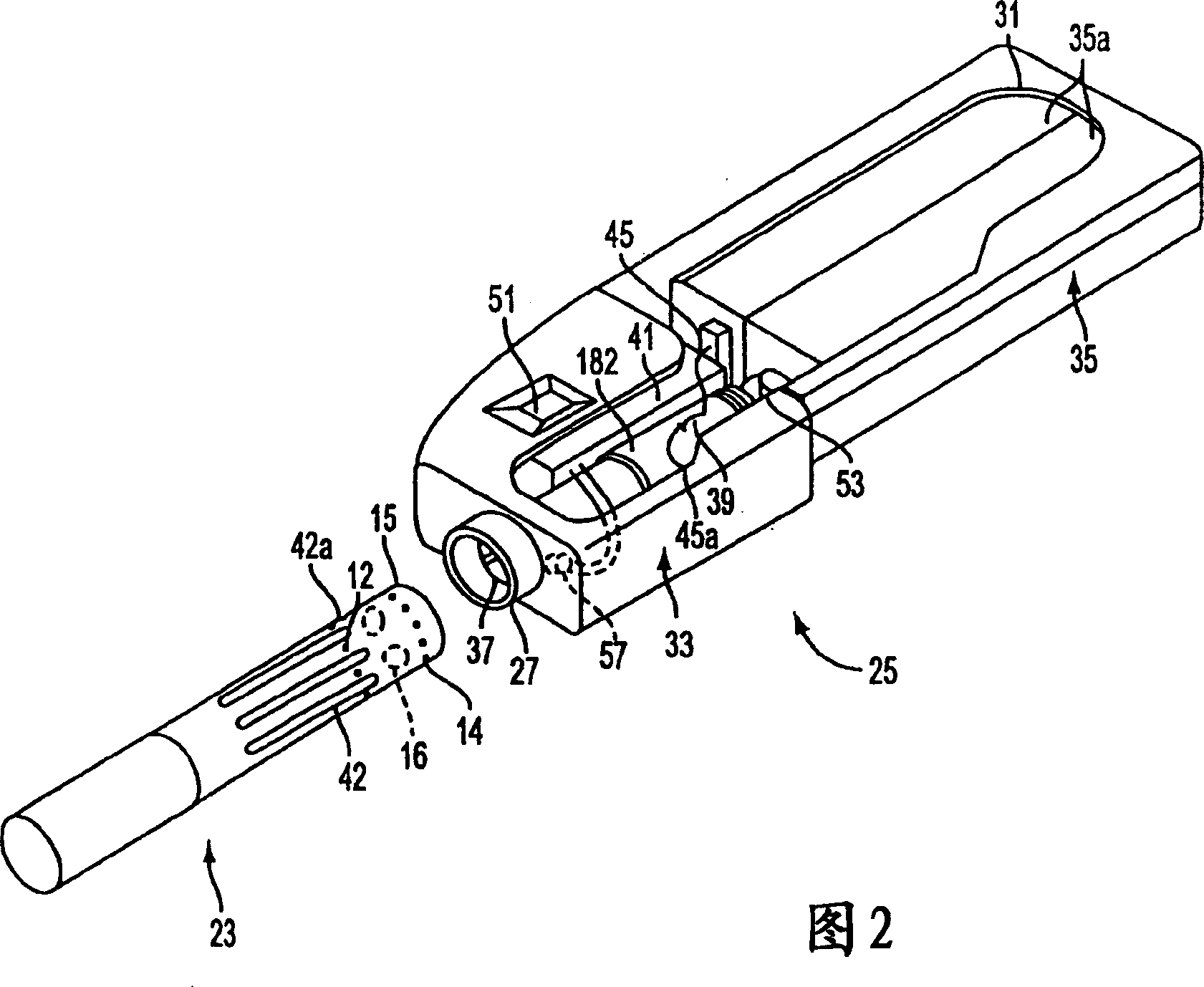

[0016] Referring to FIGS. 1 and 2 , the preferred embodiment of the present invention provides a smoking system 21 which preferably includes a partially filled filter cigarette 23 and a reusable lighter 25 . The cigarette 23 is adapted to be inserted into or removed from a cigarette receptacle 27 provided on the front end 29 of the lighter 25 . Once the cigarette 23 is inserted, the smoking system 21 is used in the same manner as a normal cigarette, but without lighting or smoldering the cigarette 23 . After one or more puffs, the cigarette 23 is discarded.

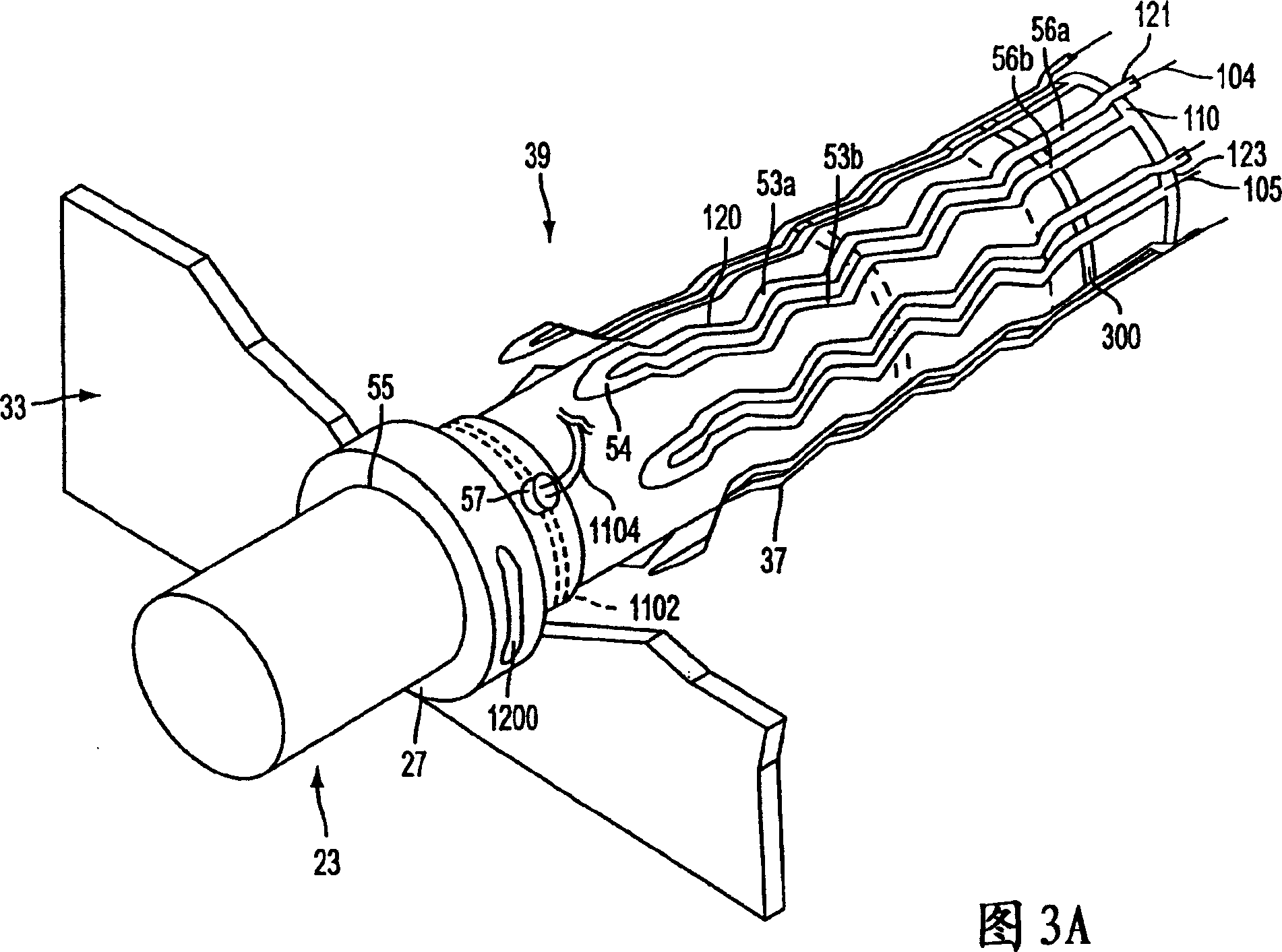

[0017] Preferably, the cigarette 23 provides 8 puffs (puff cycles) or more per cigarette, however this is a matter of design and the total number of puffs can be adjusted for fewer or more puffs suction. In a preferred embodiment, adjacent to the free end 15 of the cigarette 23, the cigarette 23 includes at least one circumferential perforated ring 12, and preferably also a second perforated ring or rings 14, beneath th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com