A selective hydrogenation process for C4 stream with high butadiene content

A high-butadiene, selective hydrogenation technology, applied in the petrochemical field, can solve the problems of high operation difficulty, large investment, complex process, etc., and achieve the effects of inhibiting deposition, reducing temperature rise, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

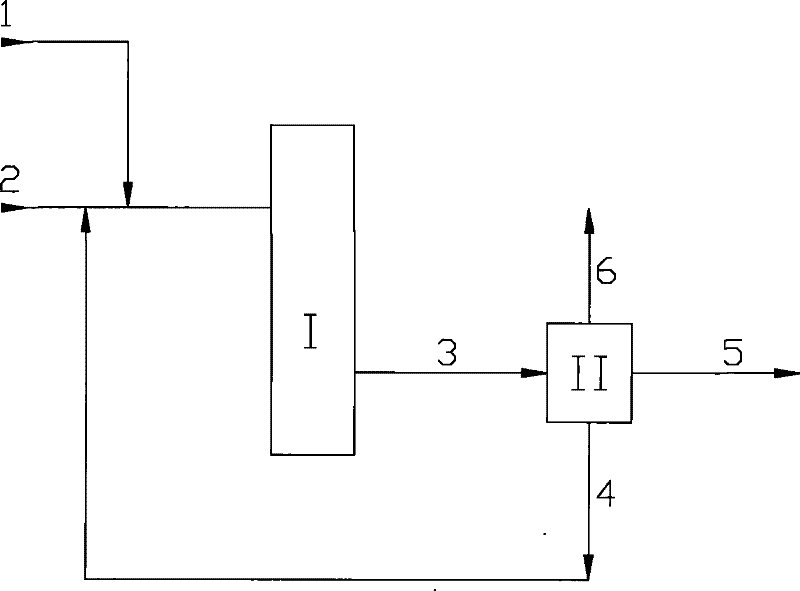

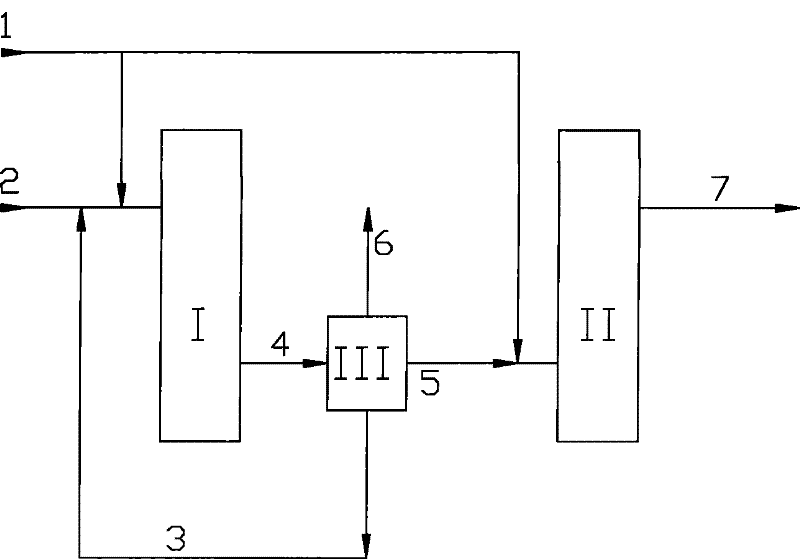

[0027] The raw material that present embodiment adopts is the mixed carbon four that hydrocarbon steam cracking device produces, and catalyst adopts multi-metal selective hydrogenation catalyst described in CN00107257.9, and catalyst carrier is Al O , metal component content is: palladium 0.2wt%, Copper 11.3wt%, silver 0.2wt%. The two-stage adiabatic fixed-bed process is adopted, the catalyst loading capacity of the first-stage reactor is 50ml, and the catalyst loading amount of the second-stage reactor is 20ml. Freshly mixed C4 and C4 recycled from the first stage reactor are mixed into the first stage reactor, part of the C4 at the outlet of the first stage reactor is recycled to the inlet of the first stage reactor, and the rest enters the second stage reactor, with a circulation ratio of 11.5. The second stage reactor serves as the terminal reactor. The first-stage reactor inlet temperature is 32°C, pressure is 2.0MPa, hydrogen / (butadiene+alkyne) is 0.77mol / mol, space vel...

Embodiment 2

[0033] The raw material used in this embodiment is mixed carbon dioxide produced by a hydrocarbon steam cracking device, the catalyst is a palladium / silver selective hydrogenation catalyst, the catalyst carrier is Al2O3, and the metal component content is: palladium 0.42wt%, silver 0.14wt%. The two-stage adiabatic fixed-bed process is adopted, the catalyst loading capacity of the first-stage reactor is 50ml, and the catalyst loading amount of the second-stage reactor is 20ml. Freshly mixed C4 and C4 recycled from the first stage reactor are mixed into the first stage reactor, part of the C4 at the outlet of the first stage reactor is recycled to the inlet of the first stage reactor, and the rest enters the second stage reactor, with a circulation ratio of 11.5. The second stage reactor serves as the terminal reactor. The first-stage reactor inlet temperature is 29°C, pressure is 2.0MPa, hydrogen / (butadiene+alkyne) is 0.756mol / mol, space velocity (LHSV) is 60h -1 ; The inlet t...

Embodiment 3

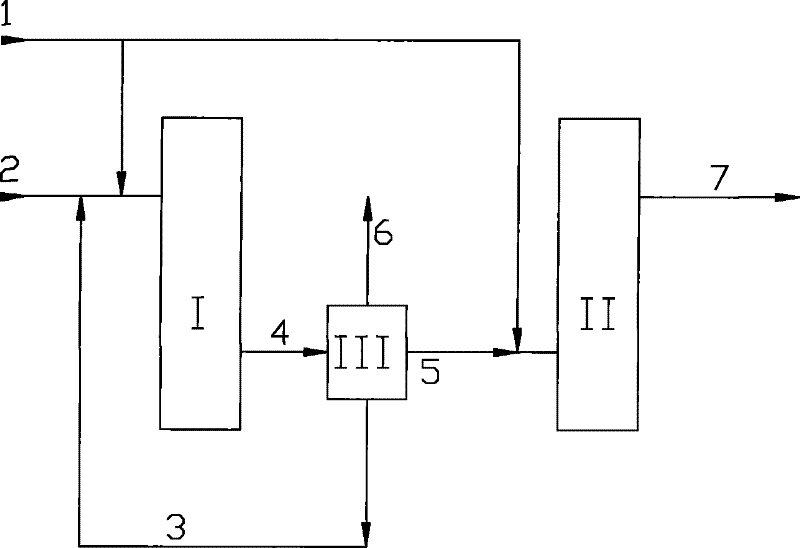

[0045] The raw material used in this embodiment is the homokyne carbon four discharged from the industrial butadiene extraction device, and the catalyst is the same catalyst as in Example 2. The three-stage adiabatic fixed-bed process is adopted, the catalyst loading volume of the first-stage reactor is 100ml, the catalyst loading volume of the second-stage reactor is 100ml, and the catalyst loading volume of the terminal reactor is 30ml. Fresh high alkyne C4 and C4 recycled from the second stage reactor are mixed and mixed with a certain amount of hydrogen, and then enter the first stage reactor. After the outlet material of the first stage reactor is cooled, a certain amount of hydrogen is added to the second stage reactor. The reactor outlet part C4 circulates to the first-stage reactor inlet, and the rest enters the third-stage reactor, with a circulation ratio of 19. The three-stage reactor serves as the terminal reactor. The first-stage reactor inlet temperature is 29°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com