Automotive seat slide rail

A technology of sliding rails and sliding rails for automobile seats, which is applied in the direction of movable seats, etc., to achieve the effects of easy assembly, simple structure of the sliding rails, and good quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

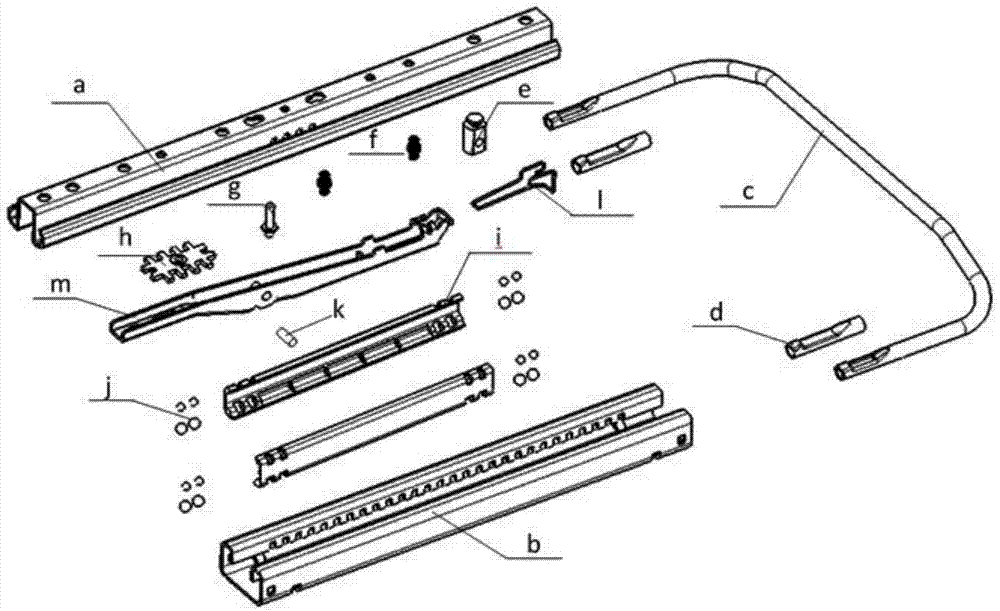

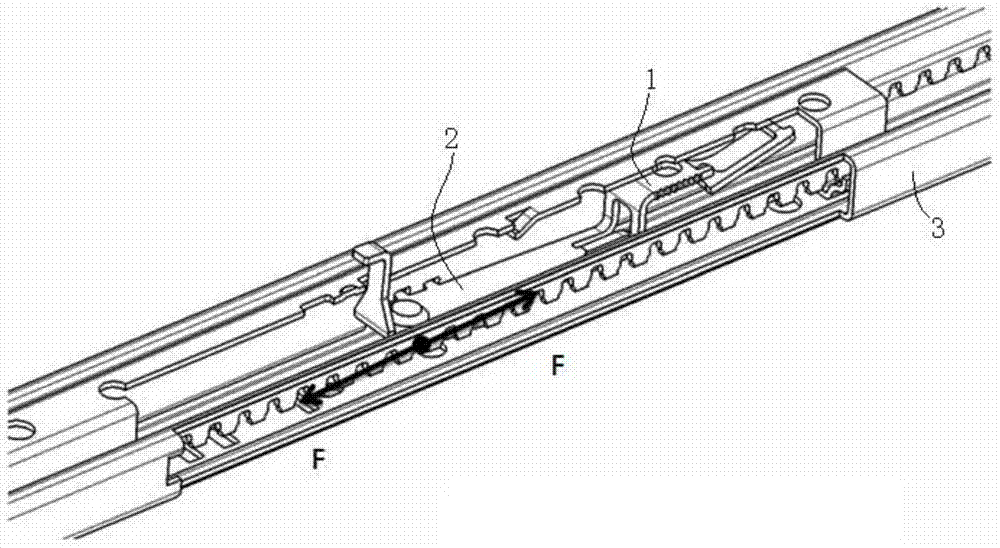

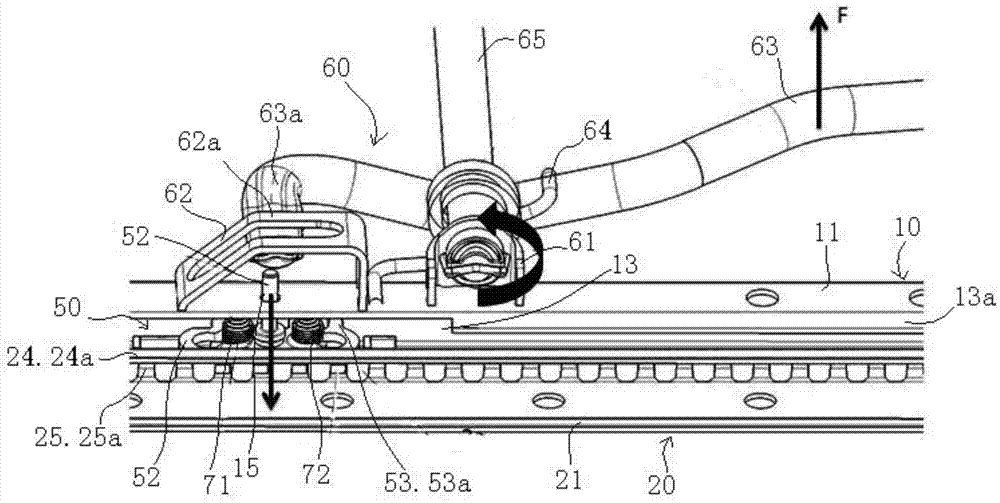

[0091] see Figure 3 to Figure 8 , the car seat slide rail given in the figure includes an upper slide rail 10, a lower slide rail 20, a spring component, a locking component 50 and an unlocking component.

[0092] See especially Figure 7 and Figure 8 , the upper slide rail 10 has an upper wall portion 11 connected to the seat cushion frame (not shown in the figure) and two outer flanges 12, 12a and two inner flanges 13, 13a, the two inner flanges 13, 13a of the upper slide rail 10 are formed by folding down from both sides of the upper wall portion 11, and the two outer flanges 12, 12a of the upper slide rail 10 are respectively formed by the two sides of the upper slide rail 10. The bottoms of the strip inner flanges 13, 13a are folded outwards and upwards. Four upper teeth windows 14, 14a are respectively configured on the two inner flanges 13, 13a of the upper slide rail 10 (in conjunction with referring to Figure 4 , Figure 6 ).

[0093] See also in particular ...

Embodiment 2

[0104] see Figure 11 , the car seat slide rail shown in the figure includes an upper slide rail 100 , a lower slide rail 200 , a spring component 300 , a locking component 400 and an unlocking component 500 .

[0105] see in conjunction Figure 12 , Figure 13 , Figure 16 and Figure 17 , the upper slide rail 100 has an upper wall portion 110 connected to the seat cushion frame (not shown in the figure) and two outward turning edges 120, 120a and two inner turning edges 130, 130a, the two inner flanges 130, 130a of the upper slide rail 100 are formed by folding down from both sides of the upper wall portion 110, and the two outer flanges 120, 120a of the upper slide rail 100 are respectively formed by the two sides of the upper slide rail 100. The bottoms of the strip inner flanges 130, 130a are folded outwards and upwards. Four upper teeth windows 140 , 140 a are respectively arranged on the two inner flanges 130 , 130 a of the upper slide rail 100 . In addition, on t...

Embodiment 3

[0122] Except that the structure of the upper wall part 110 in the upper slide rail 100 is slightly different from that of Embodiment 2 and the spring part is slightly different in the car seat slide rail of this embodiment, and the installation part 310 of the spring part is different from the upper wall part 100 of the upper slide rail 100. Except for the installation method of the wall part 110, the remaining parts are the same as in the second embodiment.

[0123] Only the differences between this embodiment and Embodiment 2 will be described below, and for the similarities, refer to the relevant description of Embodiment 2.

[0124] see Figure 50 and 51 , the spring part 300' of this embodiment is a special-shaped spring part, and the special-shaped spring part has a mounting part 310', elastic parts 320', 330', and the elastic part 320' is hollowed out and connected with the mounting part 310'. The junction begins to extend outward in waves.

[0125] The elastic part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com