Throttling-governing butterfly valve

A throttling adjustment and butterfly valve technology, which is applied in the direction of lifting valves, valve devices, sliding valves, etc., can solve the problems of slightly opening butterfly valves, the inability to accurately adjust the flow rate, and the inability to fine-tune the flow rate of butterfly valves, etc., to achieve accurate flow adjustment and overall structure Simple, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

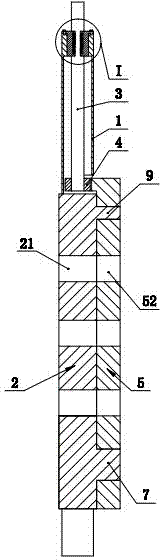

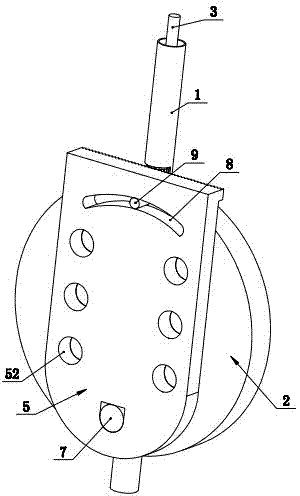

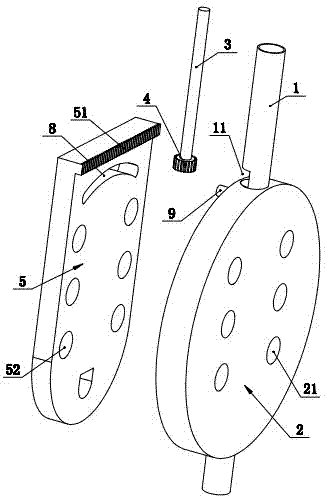

[0014] Such as figure 1 , 2 , 3, 4, and 5 show a throttling regulating butterfly valve, including a valve stem 1, a butterfly plate 2, a gear shaft 3, a gear 4 and a throttle plate 5, and the butterfly plate 2 is mounted on the valve stem 1 On the lower end, the gear shaft 3 is installed in the valve stem 1, and an axial limit is formed between the upper end of the gear shaft 3 and the upper port of the valve stem 1, and the upper end of the gear shaft 3 is clamped with a Axial limiting sleeve 6, said axial limiting sleeve 6 is fixedly mounted on the upper port of valve stem 1 through locking screw 61, and a seal is also provided between said axial limiting sleeve 6 and gear shaft 3 Packing 62, of course, the upper end of the gear shaft 3 and the upper port of the valve stem 1 can also be fixed in an axial position through other connection structures, the gear 4 is fixed on the lower end of the gear shaft 3, and The valve stem 1 is correspondingly provided with a notch 11 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com