High-precision tooth separating machine

A gear separation machine, high-precision technology, applied in metal sawing equipment, tool manufacturing of sawing machine devices, metal processing equipment, etc. , Good uniformity, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

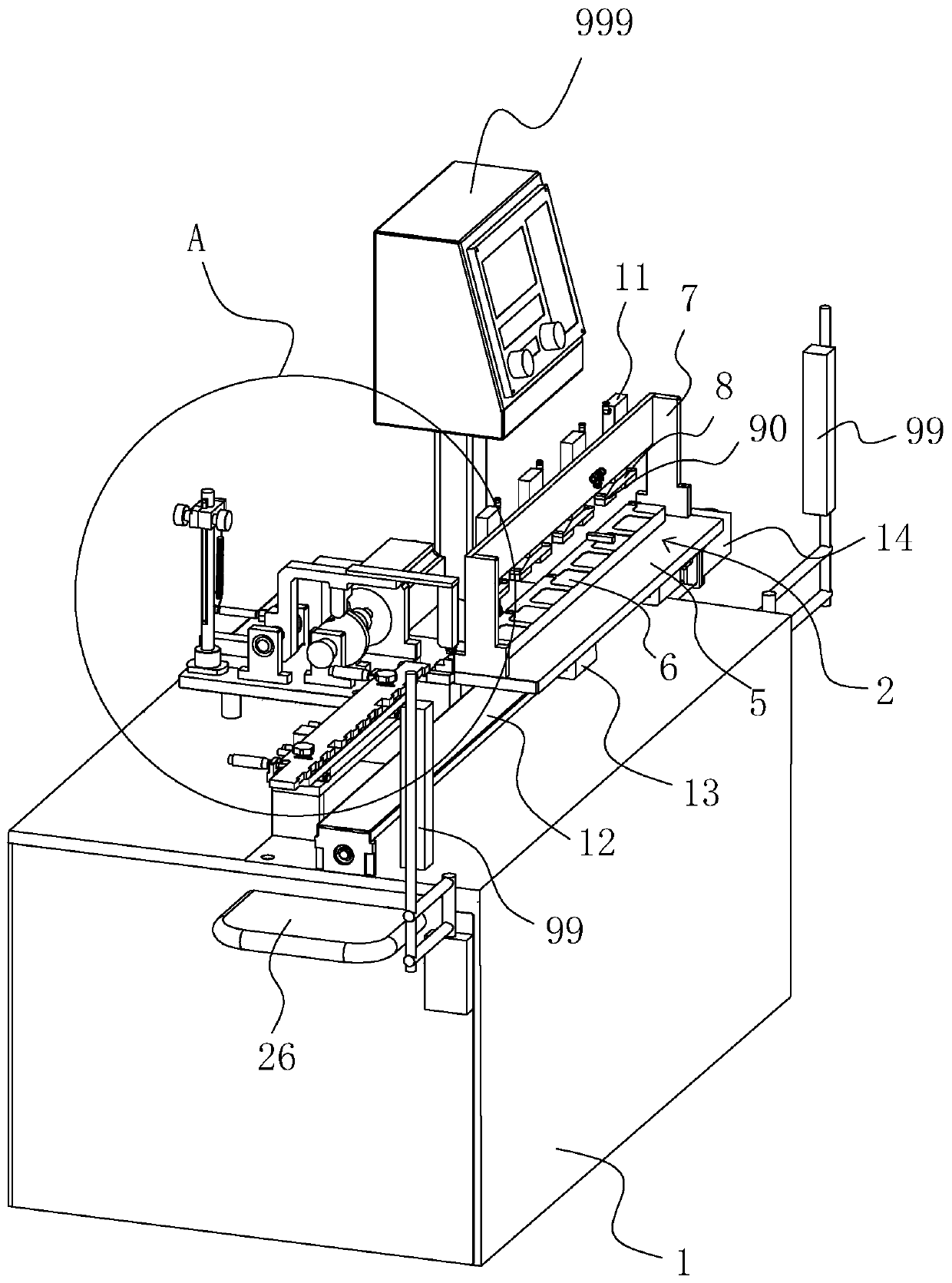

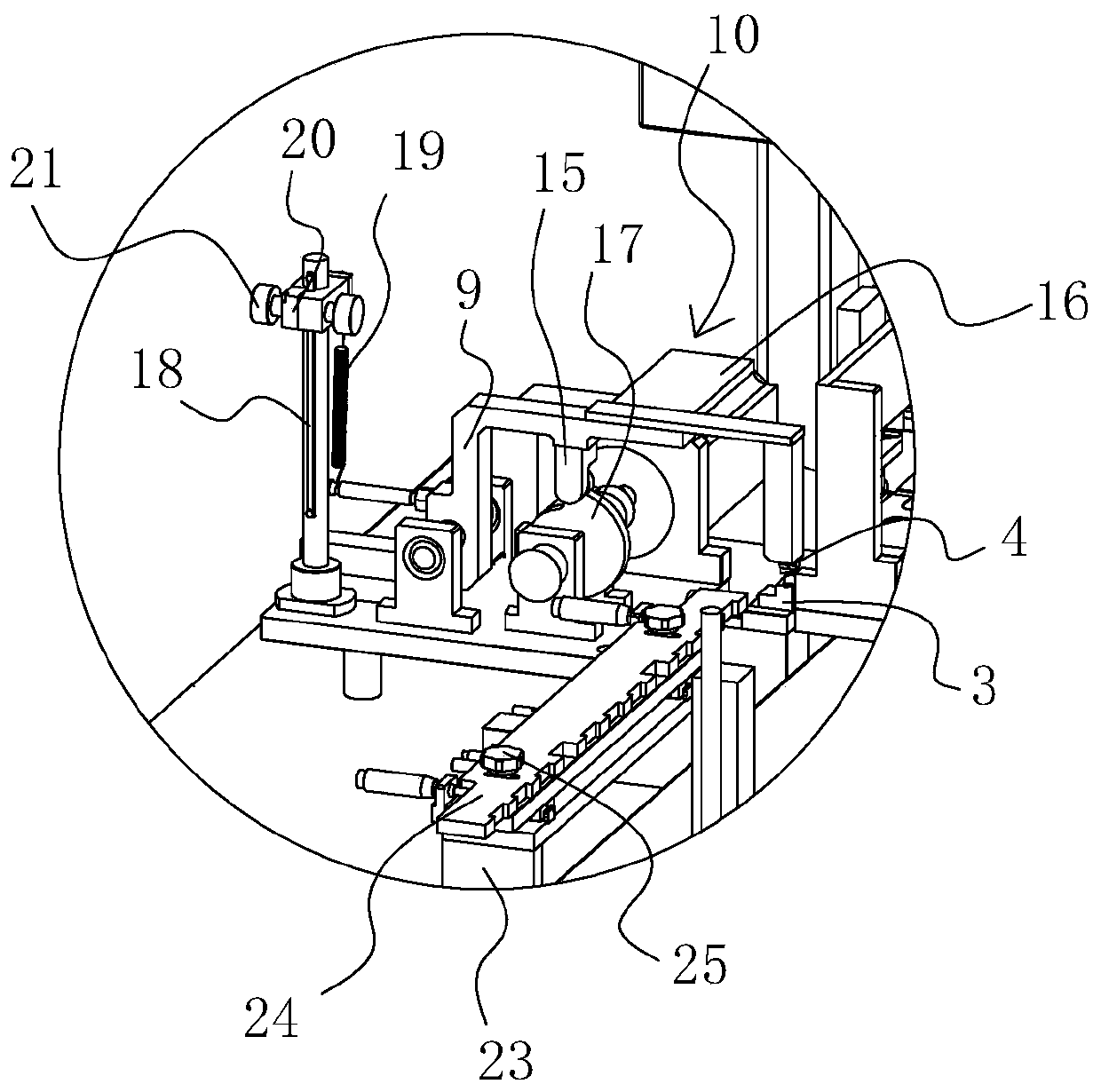

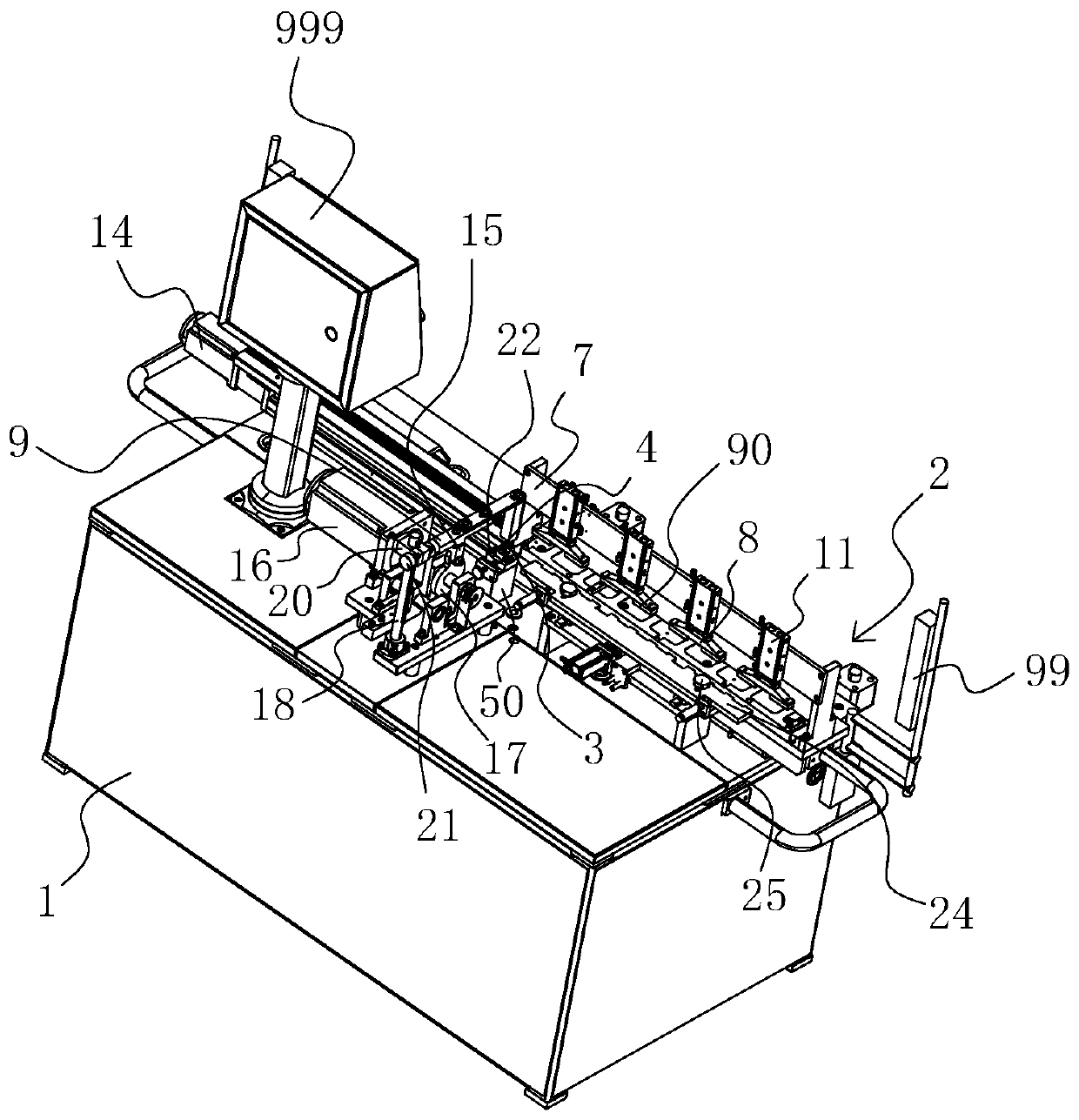

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 , figure 2 , image 3 As shown, a high-precision gear splitting machine includes an operating table 1, and the operating table 1 is provided with a saw blade fixing assembly 2 for fixing the saw blade and can reciprocate along a straight line. A lower split tooth mold 3 is provided, and an upper split tooth mold 4 that can perform reciprocating linear motion along the direction perpendicular to the plane where the saw blade is located is arranged above the lower split tooth mold 3. The saw blade fixing assembly 2 is connected with the lower tooth mold respectively The positions of the divided tooth mold 3 and the upper divided tooth mold 4 are corresponding.

[0028] In this embodiment, the shape of the upper split tooth mold 4 is compatible with the shape of the lower split tooth mold 3. The user places the saw blade in the saw blade fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com