General shaft type tooth grinding auxiliary support

An auxiliary support, general-purpose technology, applied in the direction of gear teeth, gear cutting machines, components with teeth, etc., can solve the problems of low utilization rate, low tooth separation efficiency, and high speciality of auxiliary support, reducing labor intensity and high efficiency. Tooth separation accuracy, the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment:

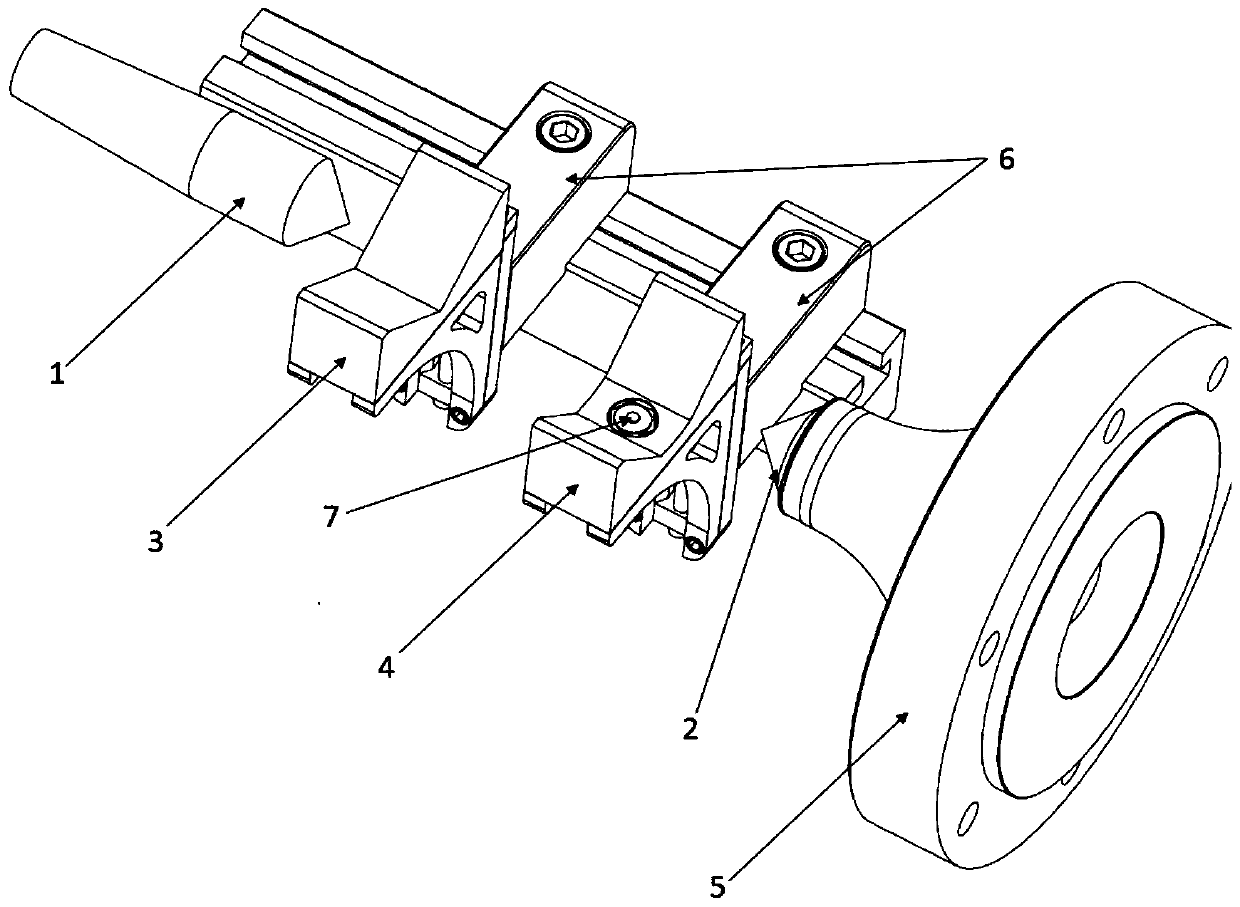

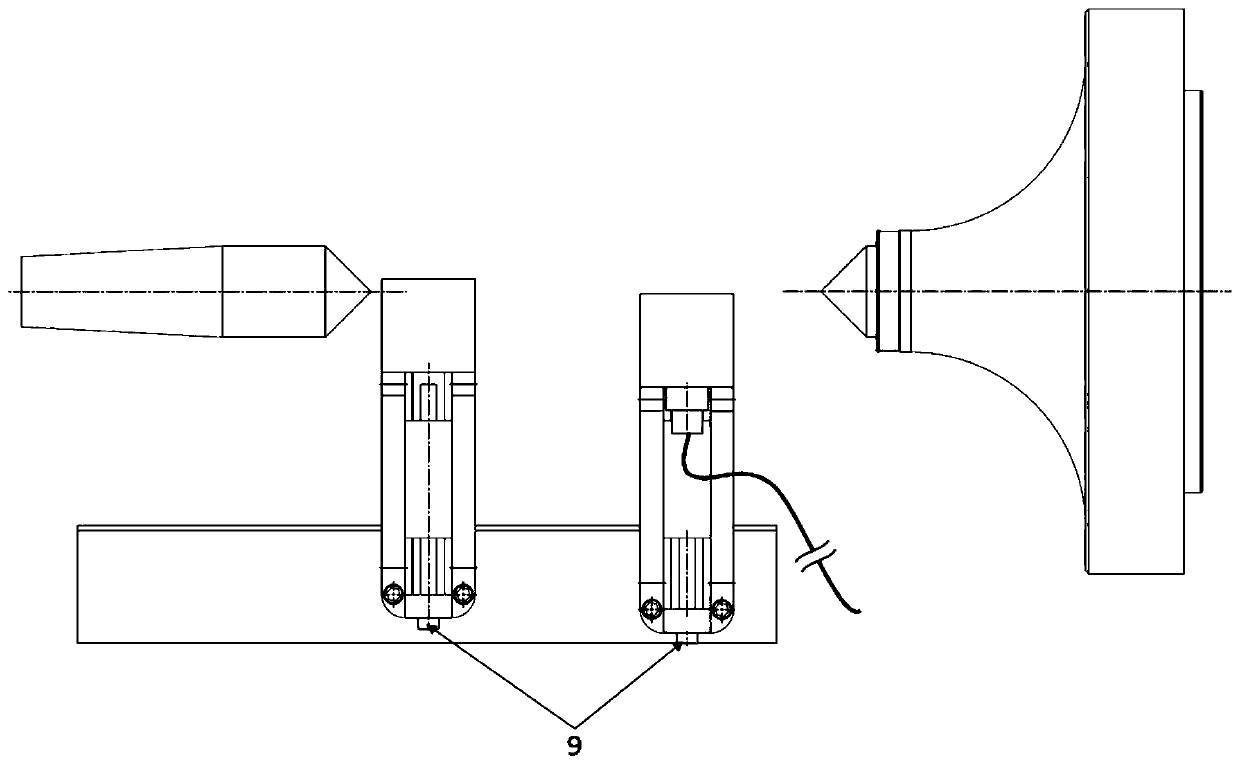

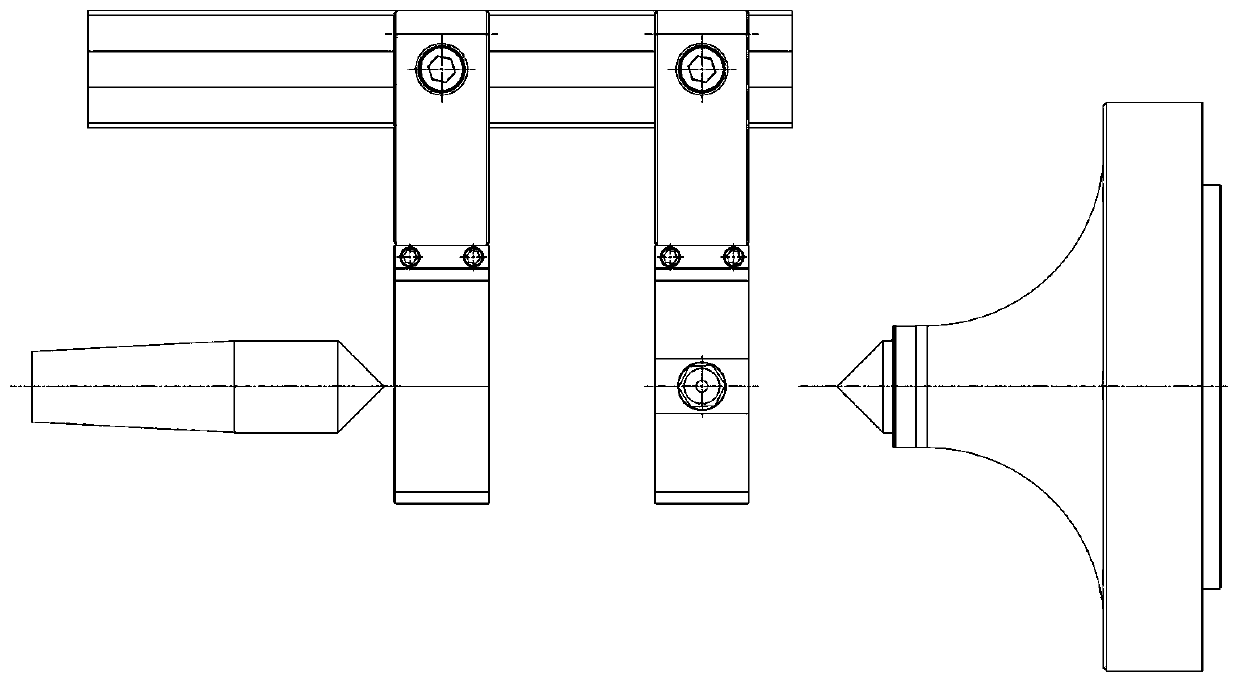

[0029] Such as Figure 1-4 As shown, the present invention provides a general-purpose shaft grinding auxiliary support, which consists of two bases 6, a slider 11, a V-shaped support block, a proximity sensor 7, an adjustment bolt 9, a T-shaped block 10, a left top 1, The right top 2 and the clip body 5 are formed. The two bases 6 are respectively arranged on the guide rails of the tailstock of the gear grinding machine, and through holes are provided in the two bases 6, and locking bolts are installed in the through holes to connect with the T-shaped block 10 to connect the two bases 6 with the tailstock of the gear grinding machine. The rails are fixed. The front ends of the two bases 6 are additionally provided with threaded through holes, and the slide block 11 is connected with the two bases 6 through a trapezoidal guide rail. The block 11 is connected with the toothed V-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com