Alloy steel shot preparation method and device therefor

A preparation device and alloy steel technology, which is applied in the field of devices for preparing alloy steel shots, can solve the problems of reducing product strength and long throwing distance, and achieve the effects of increased yield, reduced oxidation, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

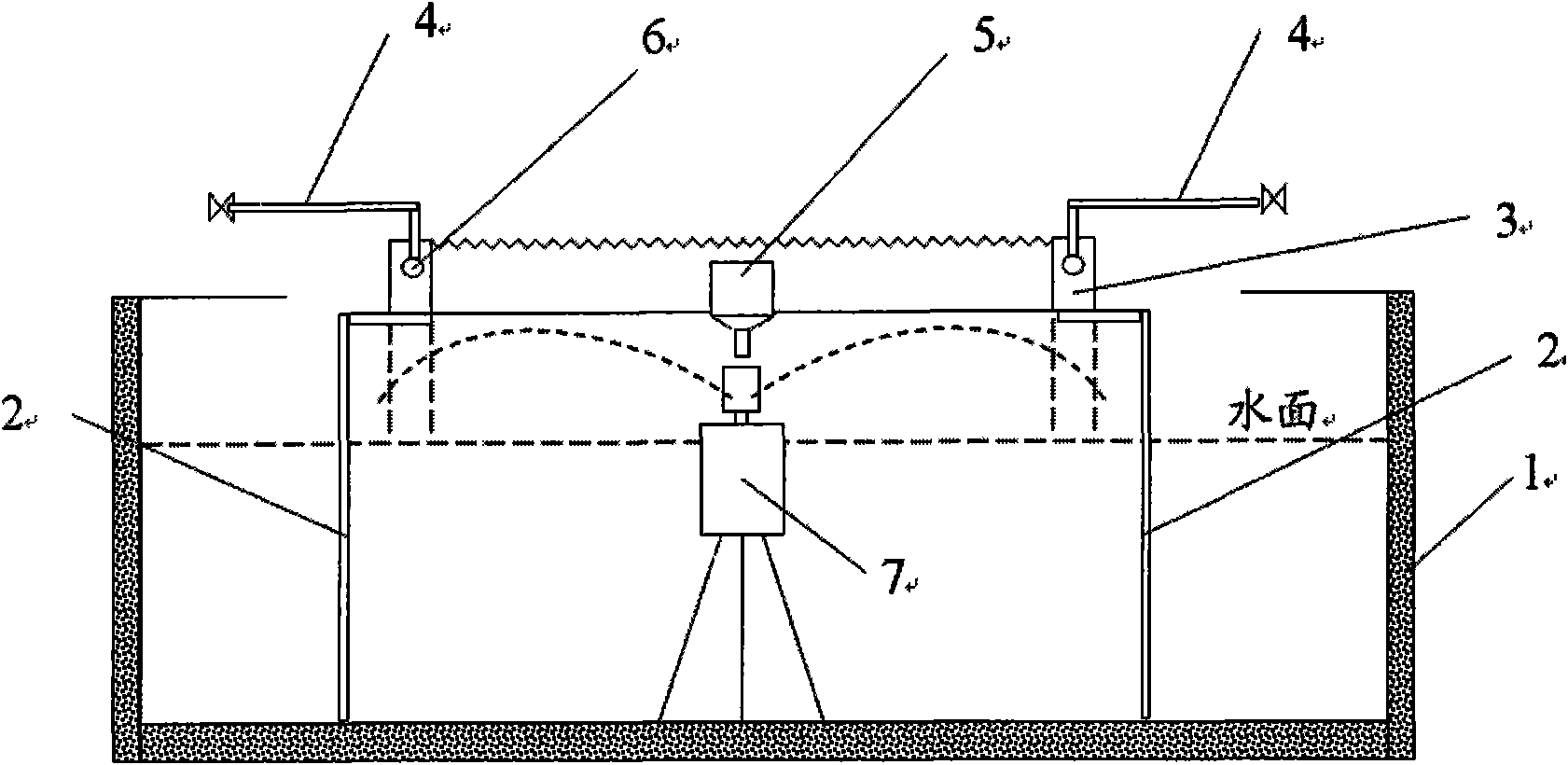

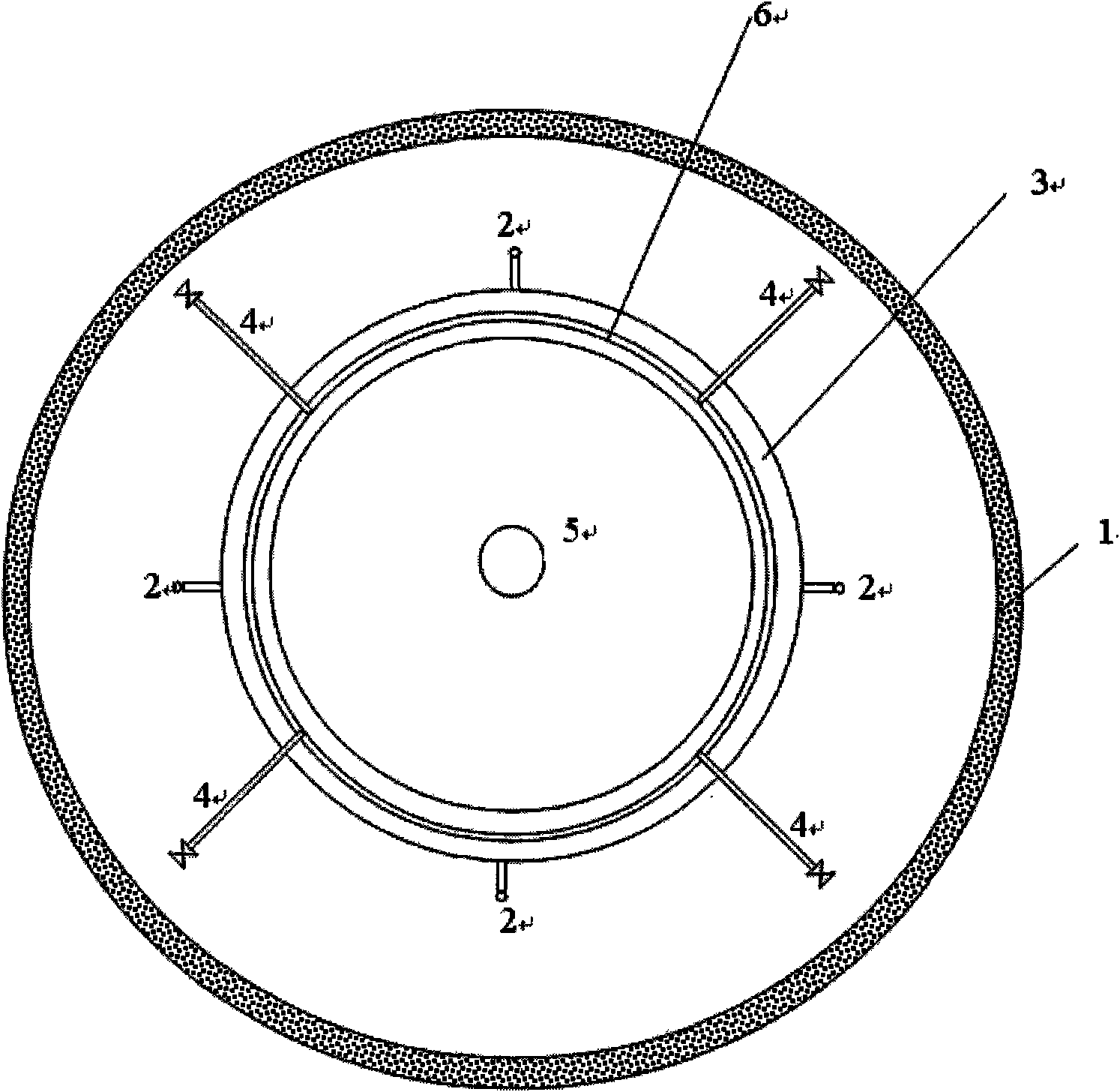

[0039] The speed of the centrifugal pellet making machine 7 is controlled at 850 rpm; the diameter of the annular water spray device is Ф6m, the width of the water tank is 300mm, and the depth is 300mm; the diameter of the water spray pipe is Ф32×3mm; a Ф3mm round hole is placed under the water spray pipe, and the distance is 20mm, there are 6 water inlet pipes, which are installed on the annular water spray pipe with a difference of 90°, and the total water inlet is 50m 3 / h, a total of 6 support frames are set up. After being thrown out of the centrifugal pelletizing cup, the molten alloy steel is cooled to become solid particles after flying for about 2.5m, and rapidly quenched and cooled at the 3m annular water curtain. The average particle size of the manufactured alloy steel shot is 1.5mm, and a tempering treatment is carried out in the subsequent heat treatment process. The average strength of the product is tested to reach HRC48.5, which meets the standard requirements...

Embodiment 2

[0041]The speed of the centrifugal pelletizing machine is controlled at 950 rpm; the diameter of the ring water spraying device is Ф4m, the width of the water tank is 200mm, and the depth is 300mm; the diameter of the water spray pipe is Ф25×3mm, and a Ф2mm round hole is placed under the water spray pipe with a distance of 20mm; There are 4 water inlet pipes in total, which are installed at 90° intervals on the annular water spray pipe, and the total water inlet is 30m 3 / h, a total of 4 support frames are set up. After being thrown out of the centrifugal pelletizing cup, the molten alloy steel is cooled to become solid particles after flying for about 1.5m, and rapidly quenched and cooled at the 2m annular water curtain. The average particle size of the manufactured alloy steel shot is 1.0mm, and a tempering treatment is carried out in the subsequent heat treatment process. After testing, the average strength of the product reaches HRC47.8, which meets the standard requiremen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com