Method for waste lead-acid cell resourcization and lead-acid cell cyclic production

A lead-acid battery and a production method technology are applied in the field of recycling waste lead-acid batteries and the recycling production of lead-acid batteries, which can solve problems such as endangering human health, lack of environmental protection awareness, environmental pollution, etc., and achieve pollution elimination and retention. The effect of usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

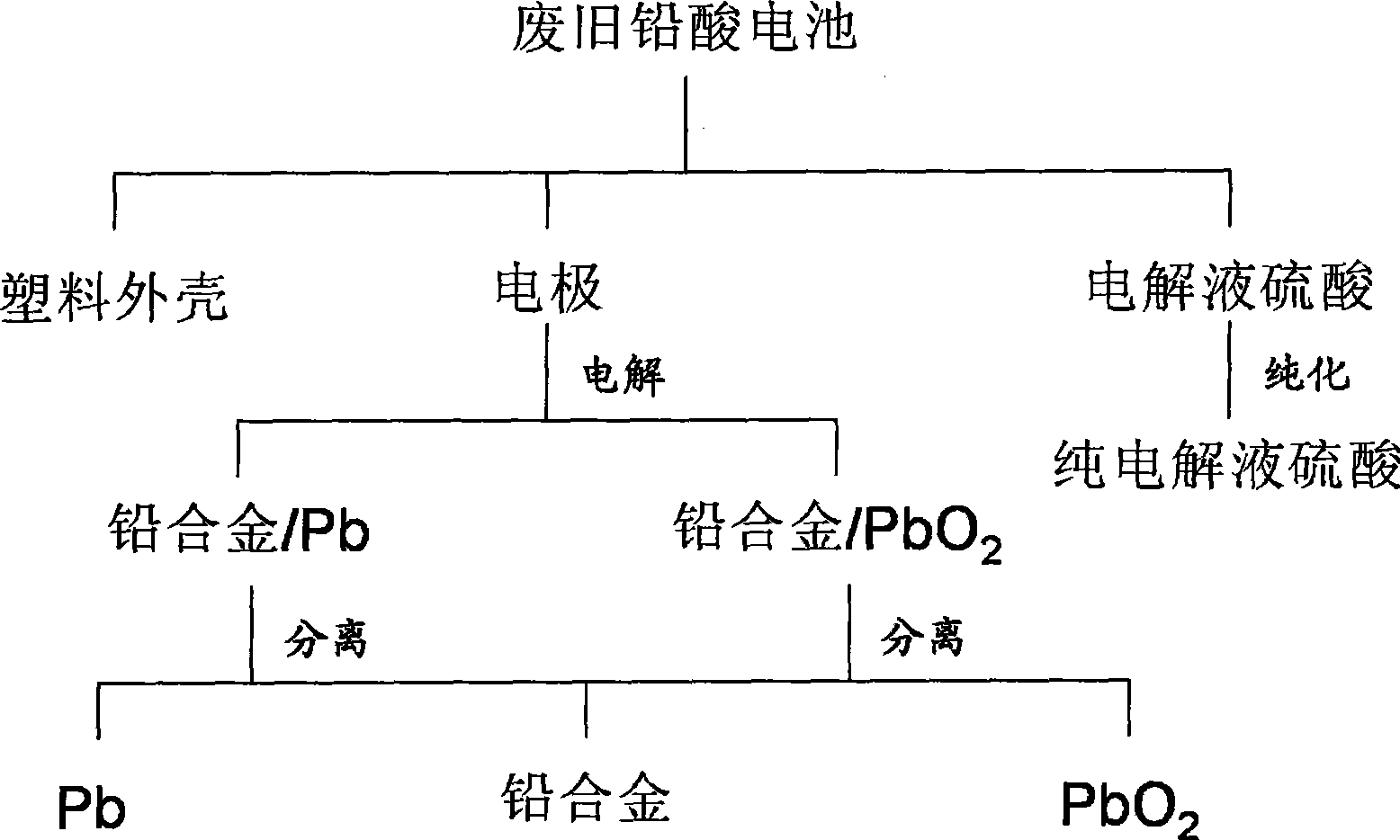

[0018] The resourceful separation of waste and old lead-acid battery components of the present invention and the method for new lead-acid battery production are:

[0019] 1. Disassembly of the battery

[0020] Use a machine to cut open the plastic case of the battery that has drained the residual electricity, pour out the electrolyte sulfuric acid, and take out the electrodes. Filter out the solids in the sulfuric acid, adjust the concentration and remove impurities, and use it directly in new batteries. The plastic case is crushed and granulated to produce new battery cases.

[0021] 2. Separation of positive and negative electrodes

[0022] Generally, the positive and negative plates of lead-acid batteries are connected together, so the two can be easily separated by mechanical means. Rinse off the separator components attached to the electrode surface with water flow.

[0023] 3. Treatment of pole pieces and regeneration of new electrode materials

[0024] Place the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com