Electrode plate for lead-acid battery and manufacturing method thereof

a technology of electrode plates and lead-acid batteries, which is applied in the direction of current conducting connections, cell components, cell component details, etc., can solve the problems of poor discharge performance, difficult handling at the assembling time, and a large voltage drop in the expansion portion, so as to reduce the risk of thinning the lug part by grinding it, reduce the risk of thinning the lug part, and remove the effect of easy and complete removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0041]

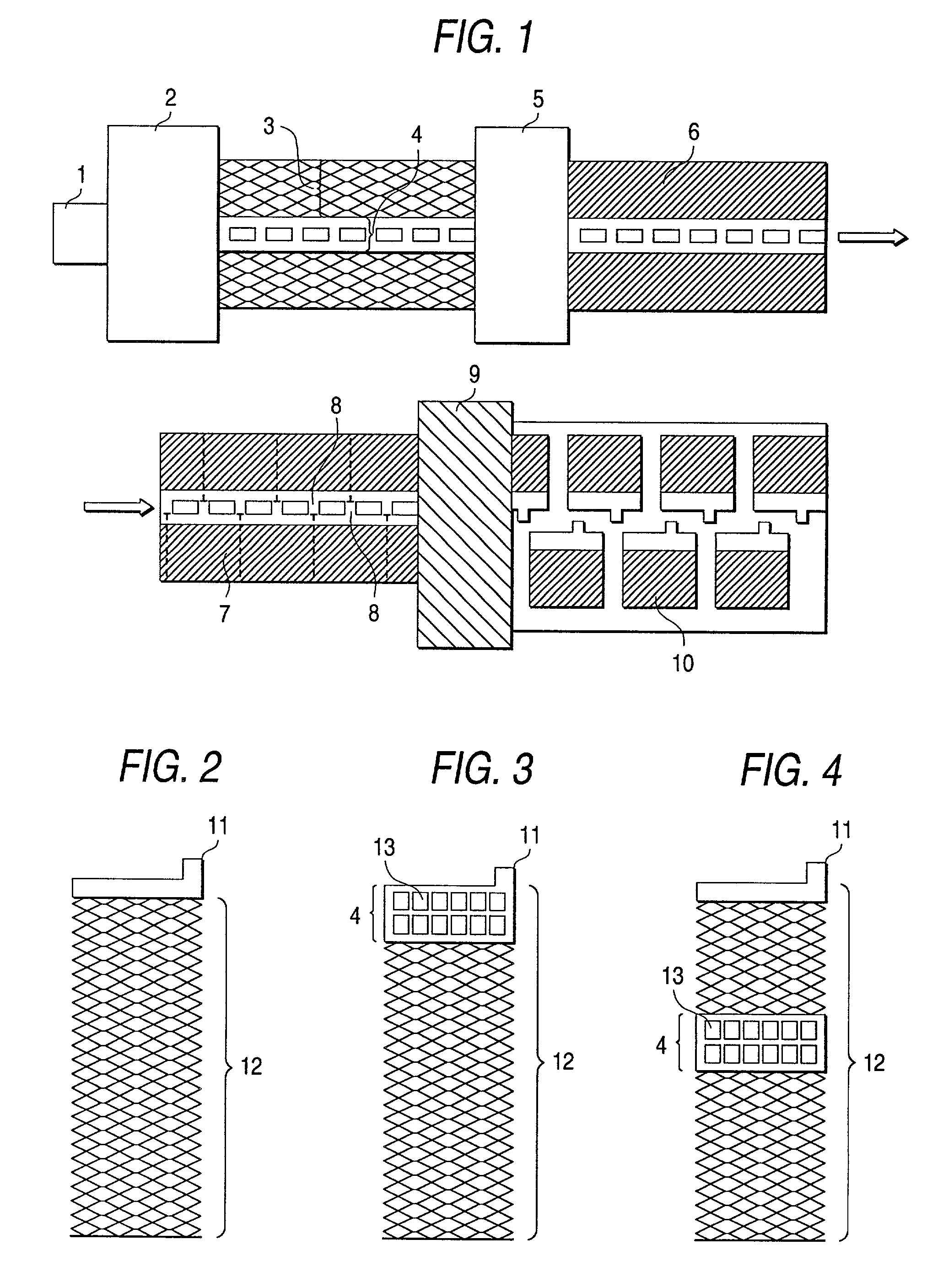

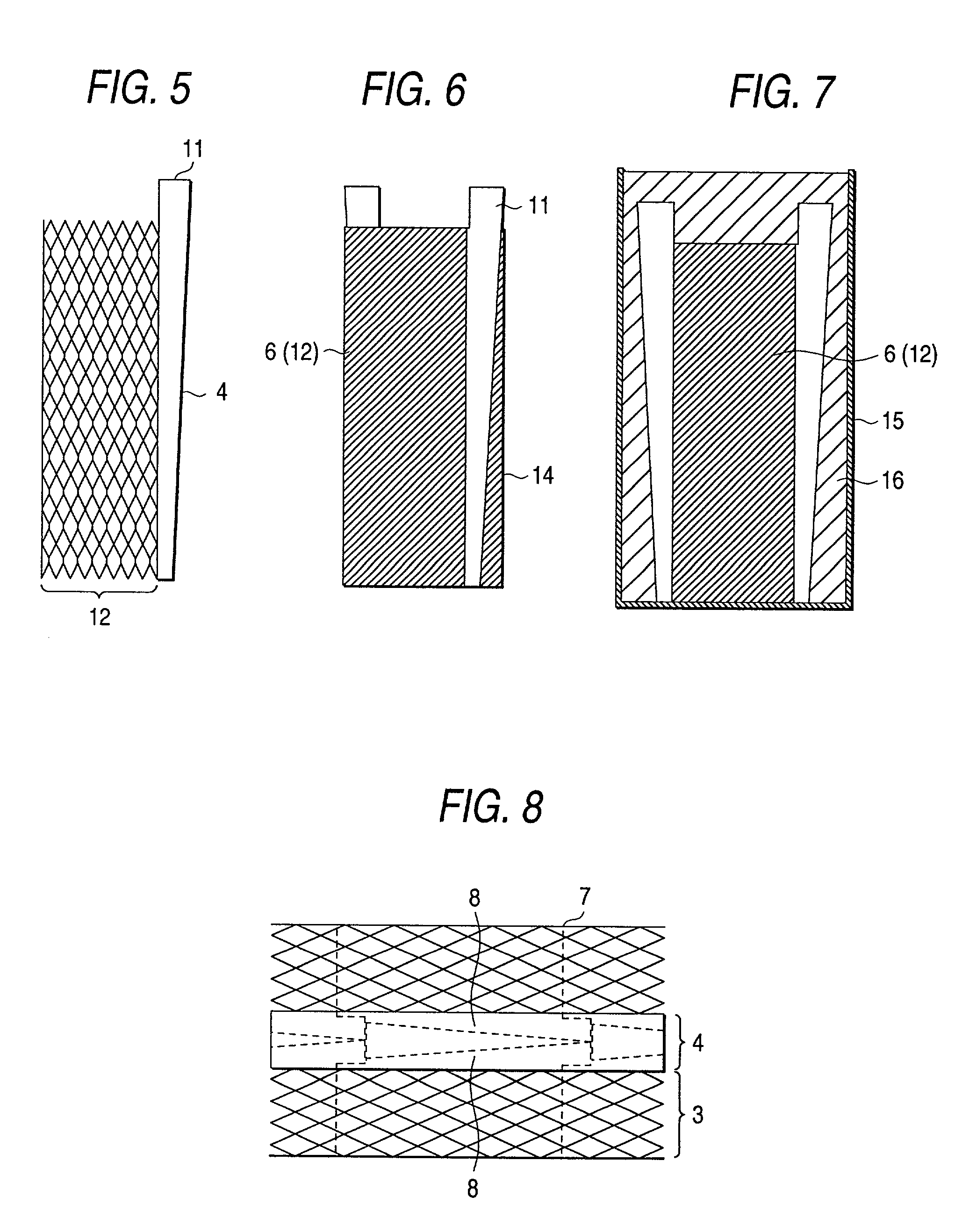

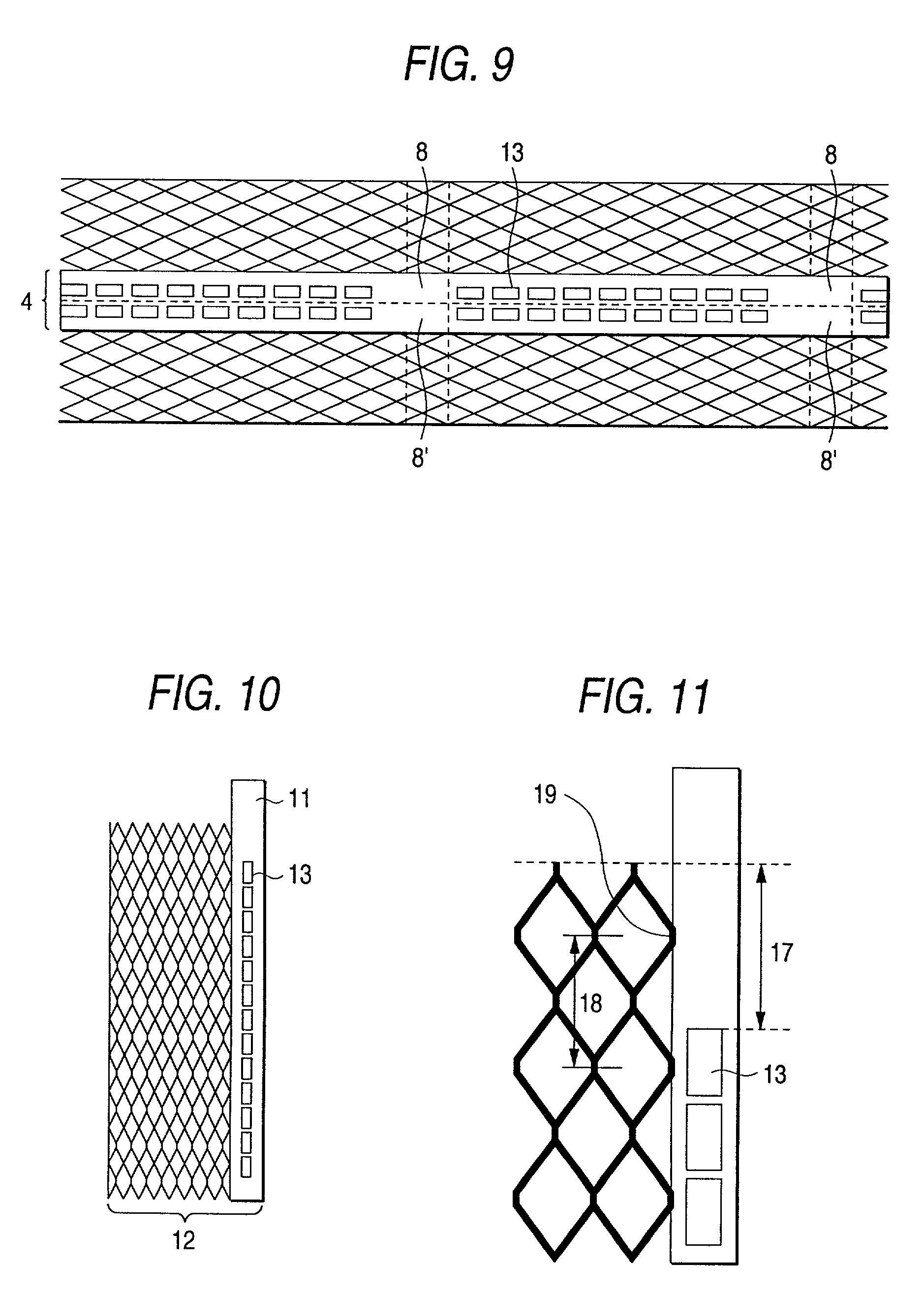

[0042] A sheet 2.0 mm thick manufactured by rolling a lead-calcium-tin alloy was consecutively expanded with a non-expansion port 4 left in the center as shown in FIG. 9. Subsequently, the non-expansion portion 4 of the expanded sheet was formed with openings 13 intermittently and a part of the expansion portion was cut at a position indicated by a dotted line 7, whereby a current collector lug part 8 was formed and an expanded grid body of the present invention (grid height H except lug part=400 mm, grid width W=140 mm) as shown in FIG. 10 was manufactured. The openings were made by stamping about 45% of the non-expansion portion when electrode plates were separated. Considering the electrical conductivity, the strength, the active material mass, and the mass of each electrode plate, a proper percentage of the openings is 30% to 70% to the non-expansion portion per electrode plate. This time, each opening was made rectangular, but the shape may be changed as desired depending...

second embodiment

[0057]

[0058] In the first embodiment, it was found that the grid body of the invention has excellent discharge performance and life performance. An example of a method of actually manufacturing electrode plates consecutively will be discussed. FIG. 24 shows a sequence of steps.

[0059] To manufacture the expanded electrode plate shown in FIG. 10, a lead-calcium-tin alloy rolled sheet 2 mm thick and 130 mm wide was expanded to both sides with a non-expansion portion left in the center by a reciprocation-type expanding machine. Next, openings were stamped to provide the shape shown in FIG. 9. If the expanded sheet is cut in the length direction, electrode plates can be taken out two at a time; paraffin as a parting agent of an active material was applied only to a part 8' corresponding to electrode plate lug part of one series of electrode plates. The sheet was passed through a pasting machine 5 for filling active material paste 6 into the full face of the sheet. At the pasting process,...

third embodiment

[0062]

[0063] In the sequence of the electrode plate manufacturing steps described in the second embodiment, the timing of removing the active material on the electrode plate lug part using the grid body of the invention was studied. The active material removal timings listed below are possible and thus an experiment was conducted at the timings. Before an active material was pasted into an expansion sheet, paraffin was applied to the part which becomes a lug part as a parting agent.

[0064] 1) Just after filling, 2) after passing through flash drying furnace, 3) after completion of curing, and 4) just before assembling.

[0065] The Results Are as Follows:

[0066] 1) Just after pasting: The active material was soft, a rotating brush of a grinding machine was clogged with the active material, and it became hard to remove the active material with time.

[0067] 2) After passing through flash drying furnace: The active material became hard as compared with that just after pasting, and can be eas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com