Graphene-lead alloy as well as preparation method and application thereof

A graphene and lead alloy technology, applied in the direction of electrode carriers/current collectors, electrical components, circuits, etc., to achieve the effects of good fluidity and creep resistance, less water loss, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: Preparation of graphene alloy plate and grid alloy thereof

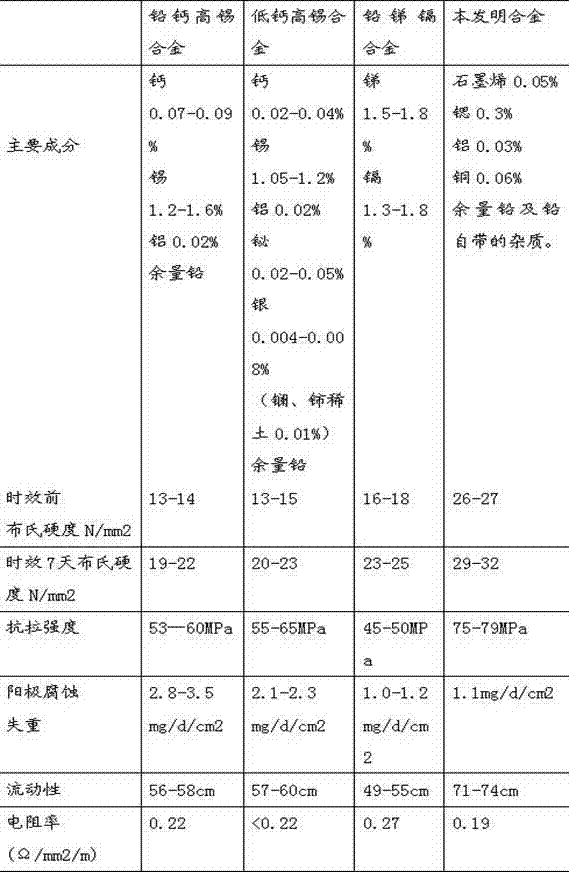

[0044] Table 1 is the consumption (weight percentage) of following each embodiment

[0045] Composition / Content Graphene tin aluminum strontium copper Example 1 0.1 0.1 0 0 0 Example 2 0.05 0.4 0 0 0 Example 3 0.02 1.6 0.03 0 0 Example 4 0.02 0 0 0.05 0 Example 5 0.02 0 0.03 0.26 0 Example 6 0.05 0 0 1.2 0 Example 7 0.0015 0.4 0 0.26 0.05 Example 8 0.05 0.36 0.03 0.3 0.06 Example 9 0.01 0.25 0.02 0.35 0.09

[0046] Note: the balance of each embodiment in table 1 is lead;

[0047] Preparation method: Disperse natural graphite in water, heat it under an oxidizing agent such as sulfuric acid at a temperature of 30-99°C for 1-48 hours to obtain graphene oxide; disperse it with ultrasonic waves and wash it, then add tin oxide and or strontium oxide and or oxidation Copper and or alumin...

Embodiment 2

[0050] Embodiment 2: the preparation of graphene alloy and grid alloy thereof

[0051] See Table 1 for dosage.

[0052] See Example 1 for the preparation method.

[0053] The grid prepared in this embodiment has high hardness, good fluidity and strong corrosion resistance. The cycle life is better.

Embodiment 3

[0054] Embodiment 3: the preparation of graphene alloy and grid alloy thereof

[0055] See Table 1 for dosage.

[0056] See Example 1 for the preparation method.

[0057] The grid prepared in this embodiment has suitable hardness, good fluidity and weak corrosion resistance. The creep resistance of the grid is relatively weak, and the cycle life is relatively short.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com