Lead-acid storage battery plate grid and forming surface treatment method

A lead-acid battery and surface treatment technology, applied in the direction of electrode carrier/current collector, etc., can solve the problems of easy to drop paste, poor adhesion of lead paste, affecting battery performance, etc., and achieve the effect of increasing roughness and improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

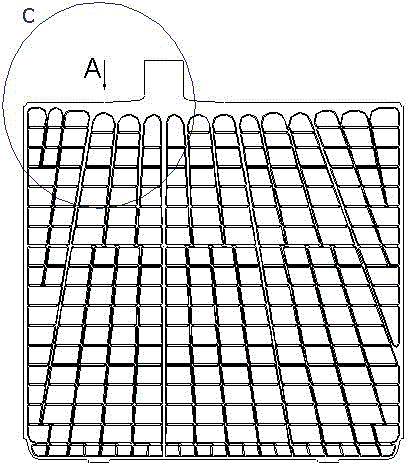

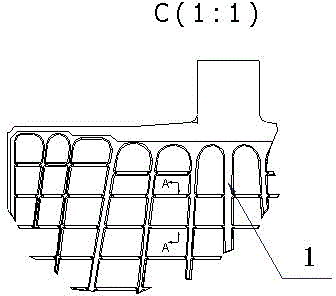

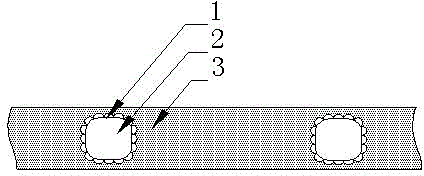

[0028] Such as figure 1 , figure 2 , image 3 shown. A lead-acid storage battery grid of the present invention comprises a grid skeleton 2 and lead paste 3 attached to the surface thereof. The thickness of the grid frame 2 is 0.3~2mm, and the surface 1 is a surface with a roughness of 3.2~12.6. 12.6 surfaces. The rough surface 1 of the grid skeleton is coated with lead paste. The grid thickness can be thinner than 1mm.

[0029] A kind of lead-acid battery grid forming and surface treatment method of the present invention comprises the following steps:

[0030] 1. prepare lead alloy: prepare pre-smelted lead alloy according to the standard, same as in the existing method;

[0031] ② Melting the lead alloy: Put the pre-smelted lead alloy into the lead melting pot, heat it to 350~500°C until the pre-smelted lead alloy is completely melted, which is the same as in the existing method;

[0032] ③ casting lead plate: inject the melted lead alloy pump into the continuous lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com