Impact flow-rotary filler bed device and using method

A technology of rotating packed bed and impingement flow, applied in the chemical method of reacting liquid with liquid, mixing method, chemical method of reacting liquid with gas medium, etc., can solve the problems of uneven mixing and long mixing time, etc. Achieve the effect of high mixing effect, fast mixing speed and good micro-mixing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

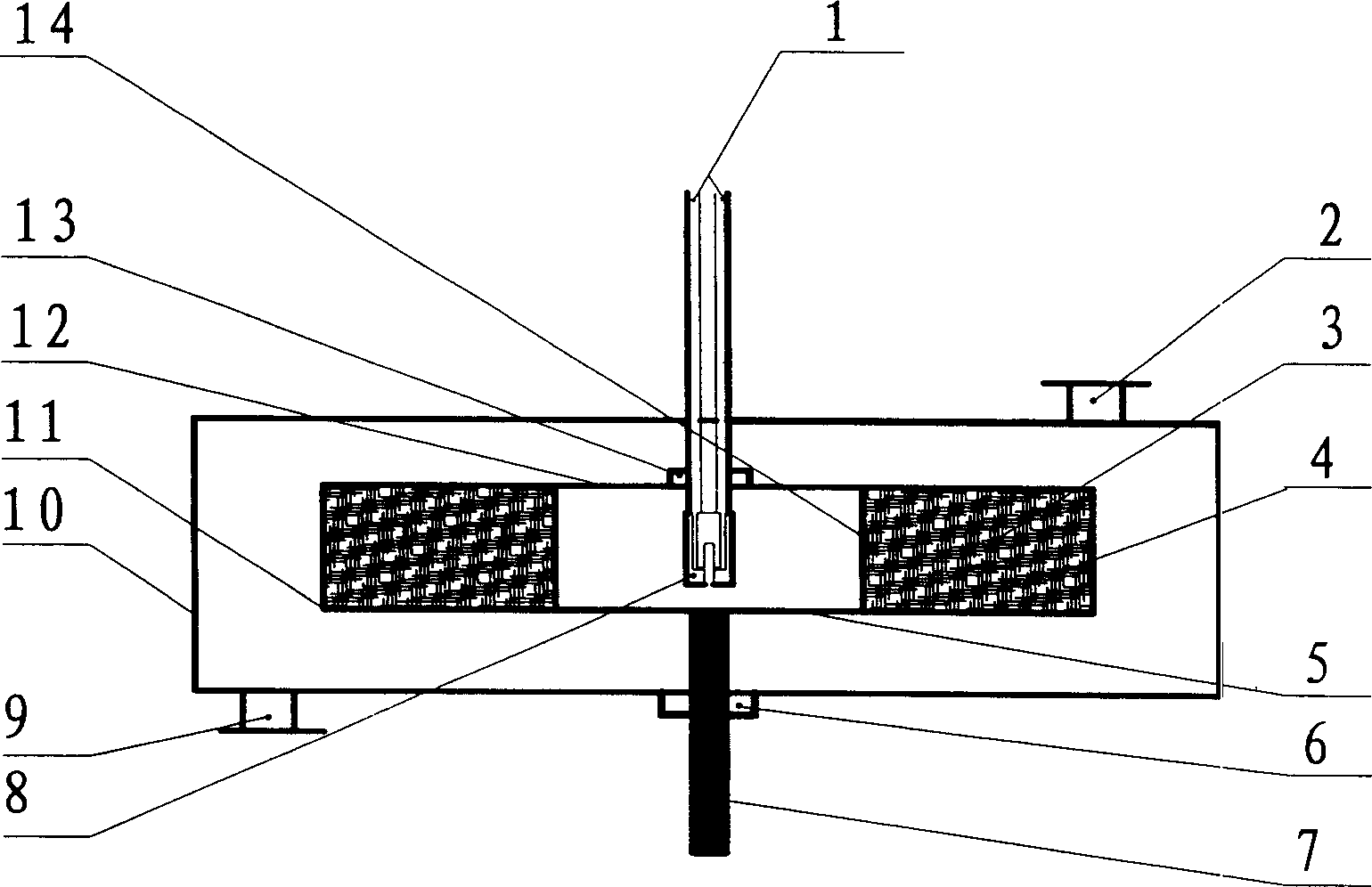

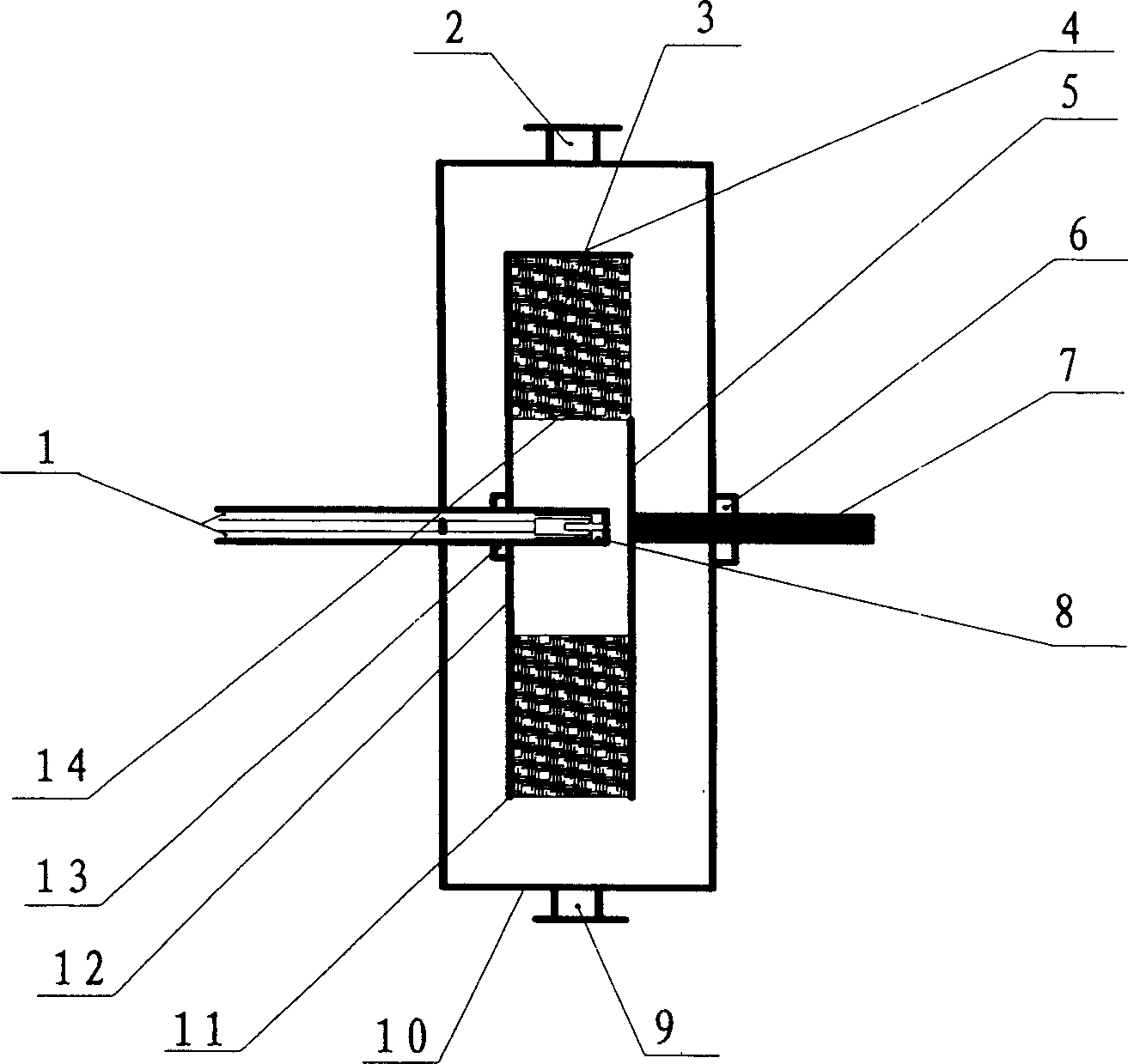

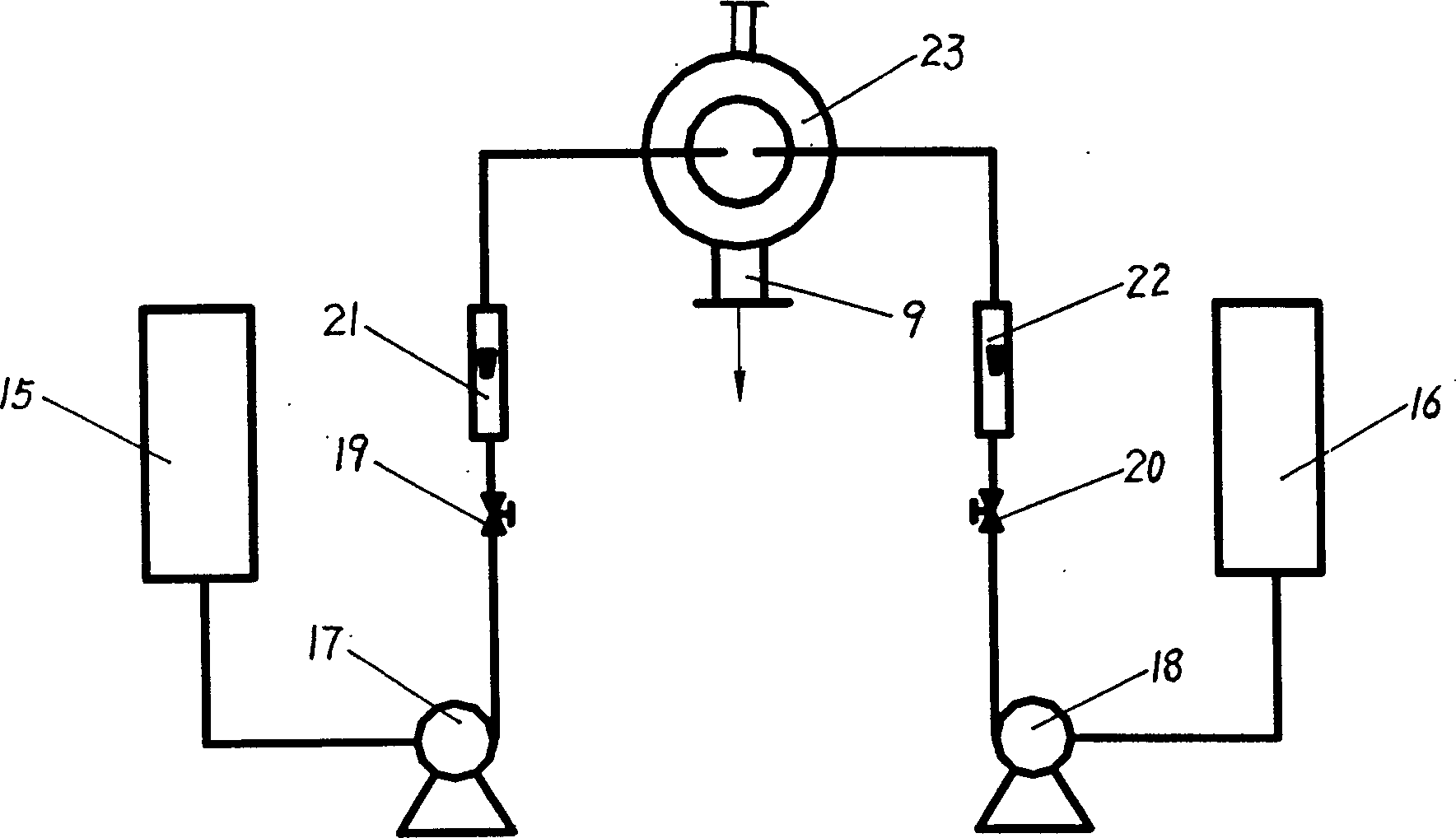

[0016] Such as figure 1 Shown, impinging flow of the present invention-rotary packed bed device is a vertical structure, and it comprises the hollow ring that is surrounded by annular inner baffle plate 12, circular outer baffle plate 5, inner ring plate 14 and outer ring plate 4 Type drum 11, wire mesh filler 3, rotating shaft 7 and housing 10, wire mesh filler 3 is installed in the hollow ring-shaped cavity of drum 11, and rotating shaft 7 is located at the center of circular outer baffle plate 5 And through the housing 10, wherein: it also includes an impingement flow device consisting of two feed pipes 1 and a nozzle 8 arranged at the bottom of the feed pipe 1 to form an impingement flow, a gas outlet 2 and a liquid outlet 9; A hollow circular drum 11 surrounded by an annular inner baffle 12, a circular outer baffle 5, an inner ring 14, and an outer ring 4 is arranged in the middle of the housing 10, and one end of the nozzle 8 of the impinging flow device It is placed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com