Low-temperature denitration catalyst and preparation method thereof

A low-temperature denitration and catalyst technology, applied in the field of denitration catalysts, can solve problems such as affecting the denitration efficiency of the catalyst and being unable to mix efficiently and uniformly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

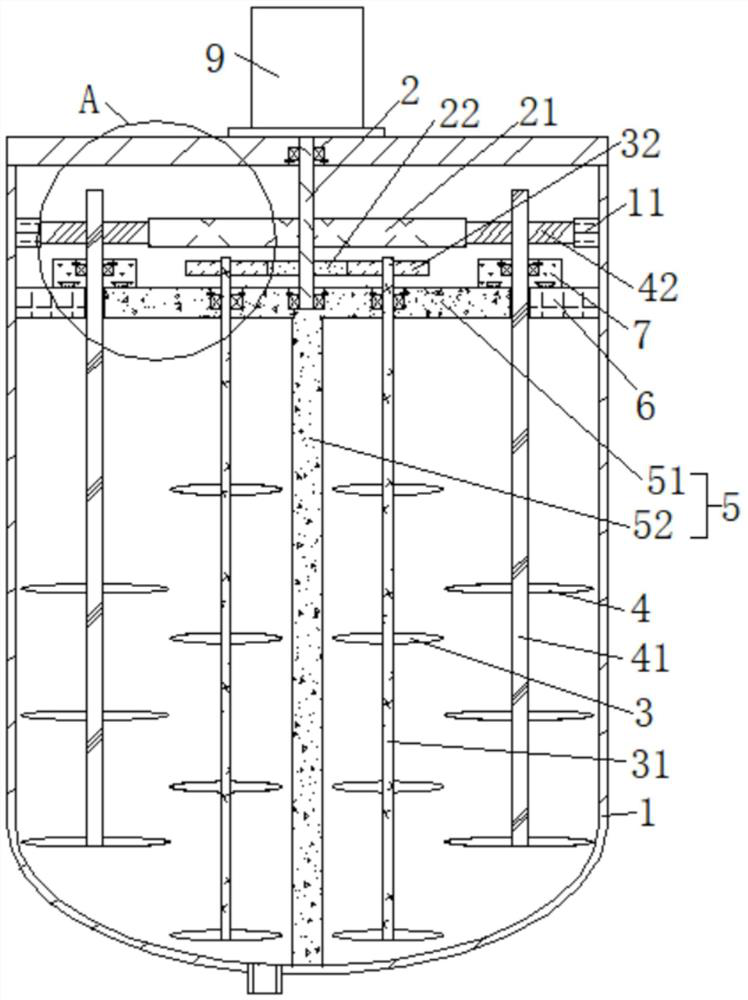

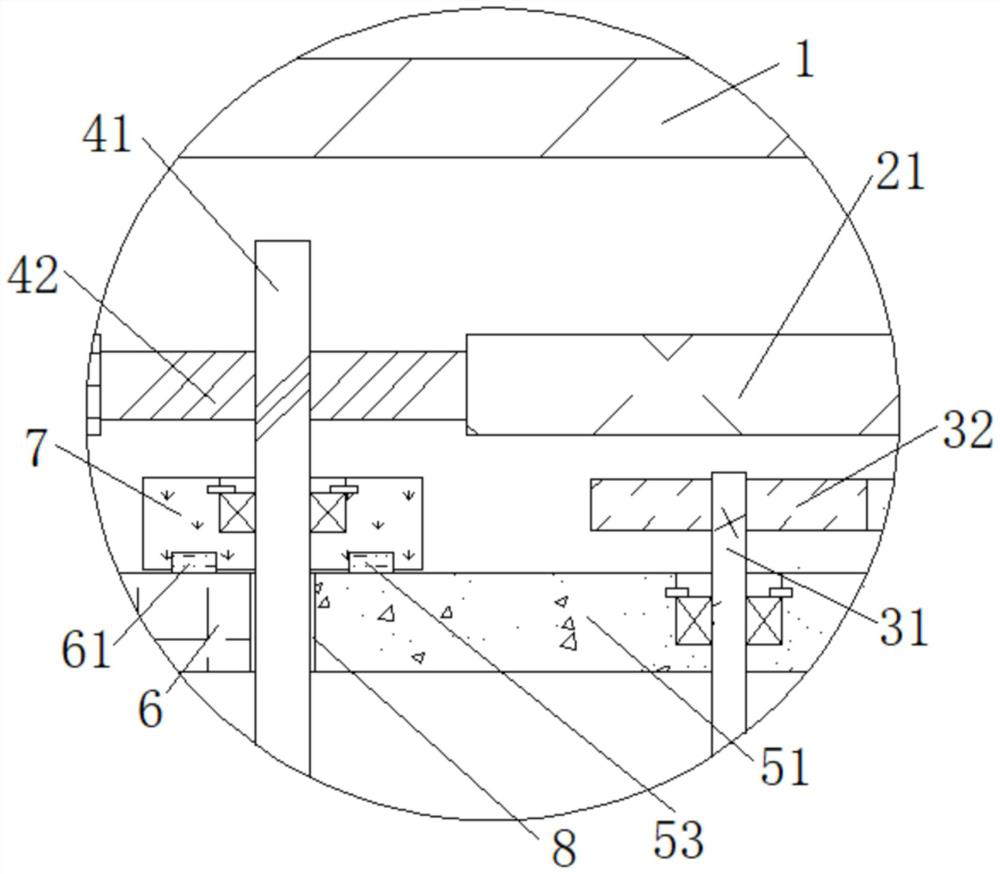

Image

Examples

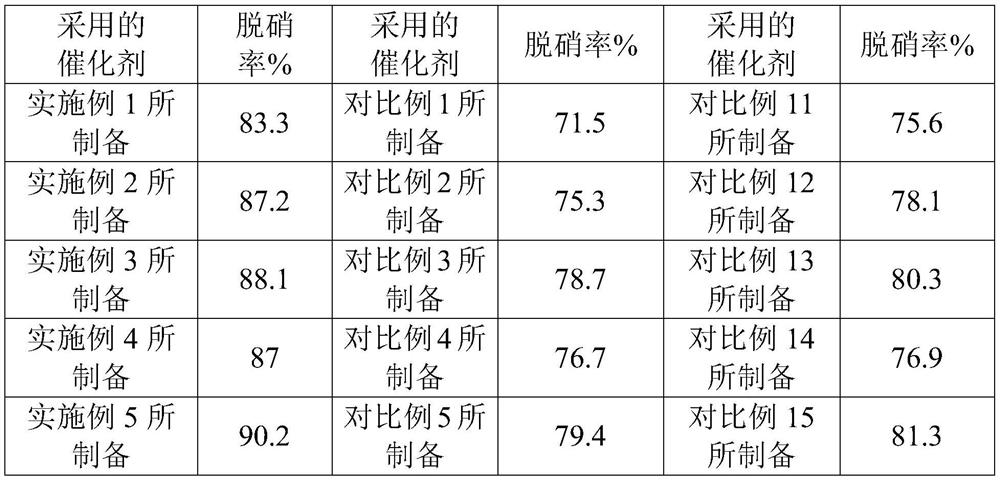

Embodiment 1

[0028] A low-temperature denitration catalyst, the low-temperature denitration catalyst includes a cordierite carrier and an active component coated on the carrier, the loading of the active component is 3wt%; the active component includes 3wt% V 2 o 5 , 10wt% MoO 3 , 2.5wt% SiO 2 , 82.2wt% TiO 2 and 2.3wt% phosphate ion, and the loading amount of vanadium element in the active component in the low-temperature denitration catalyst is 5.04wt%.

[0029] The preparation method of the low-temperature denitration catalyst comprises the following steps:

[0030] (a) Add deionized water into the stirring device, add titanium dioxide while stirring, then add oxalic acid-ammonium metavanadate mixed solution, ammonium heptamolybdate, wherein the mass concentration of oxalic acid-ammonium metavanadate mixed solution is 20% The oxalic acid solution and the ammonium metavanadate solution with a mass concentration of 30% are mixed according to a mass ratio of 1:1. After stirring and mix...

Embodiment 2

[0039] A low-temperature denitration catalyst, the low-temperature denitration catalyst includes a cordierite carrier and an active component coated on the carrier, the loading of the active component is 1.8wt%; the active component includes 6.5wt% V 2 o 5 , 3wt% MoO 3 , 3wt% SiO 2 , 86.5wt% TiO 2 and 1wt% phosphate ion, and the loading amount of vanadium element in the active component in the low-temperature denitration catalyst is 6.55wt%.

[0040] The preparation method of the low-temperature denitration catalyst comprises the following steps:

[0041] (a) Add deionized water into the stirring device, add titanium dioxide while stirring, then add oxalic acid-ammonium metavanadate mixed solution, ammonium heptamolybdate, wherein the mass concentration of oxalic acid-ammonium metavanadate mixed solution is 20% The oxalic acid solution and the ammonium metavanadate solution with a mass concentration of 30% are mixed according to a mass ratio of 1:1. After stirring and mixi...

Embodiment 3

[0046] A low-temperature denitration catalyst, the low-temperature denitration catalyst includes a cordierite carrier and an active component coated on the carrier, the loading of the active component is 1.1wt%; the active component includes 11.5wt% V 2 o 5 , 12wt% MoO 3 , 3.7wt% SiO 2 , 70wt% TiO 2 and 2.8wt% phosphate ion, and the loading amount of vanadium element in the active component in the low-temperature denitration catalyst is 7.09wt%.

[0047] The preparation method of the low-temperature denitration catalyst comprises the following steps:

[0048] (a) Add deionized water into the stirring device, add titanium dioxide while stirring, then add oxalic acid-ammonium metavanadate mixed solution, ammonium heptamolybdate, wherein the mass concentration of oxalic acid-ammonium metavanadate mixed solution is 20% The oxalic acid solution and the ammonium metavanadate solution with a mass concentration of 30% are mixed according to a mass ratio of 1:1. After stirring and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com