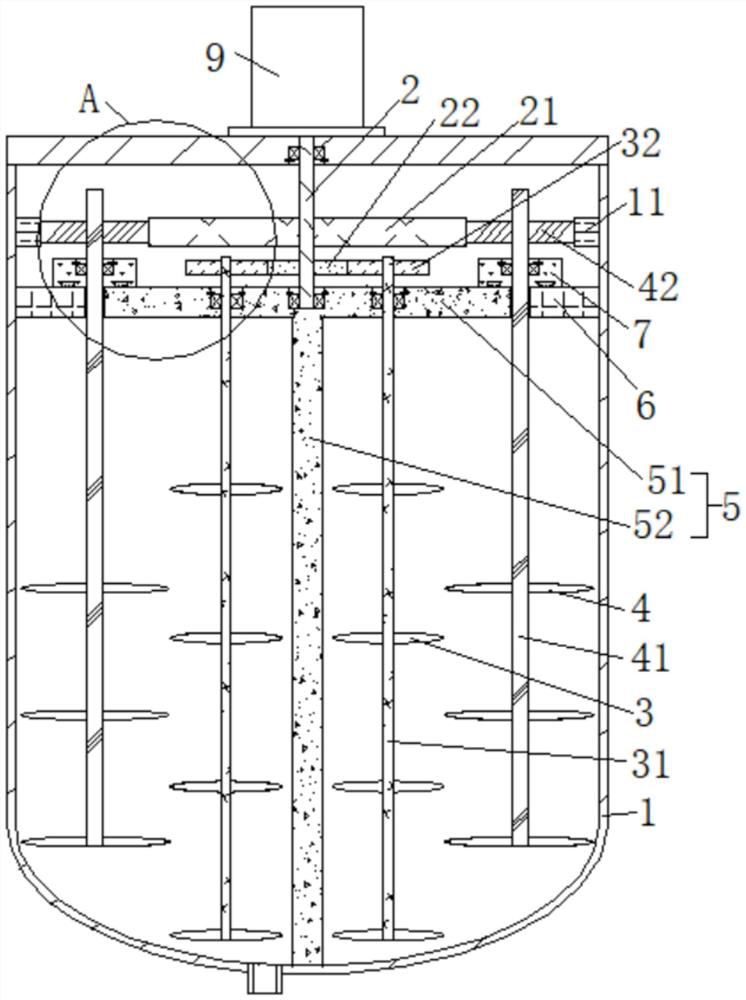

Stirring device for preparing low-temperature denitration catalyst

A stirring device and low-temperature denitrification technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve problems such as inability to mix efficiently and uniformly, affect catalyst denitrification efficiency, etc., achieve efficient, rapid and uniform mixing, improve Effect of denitrification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

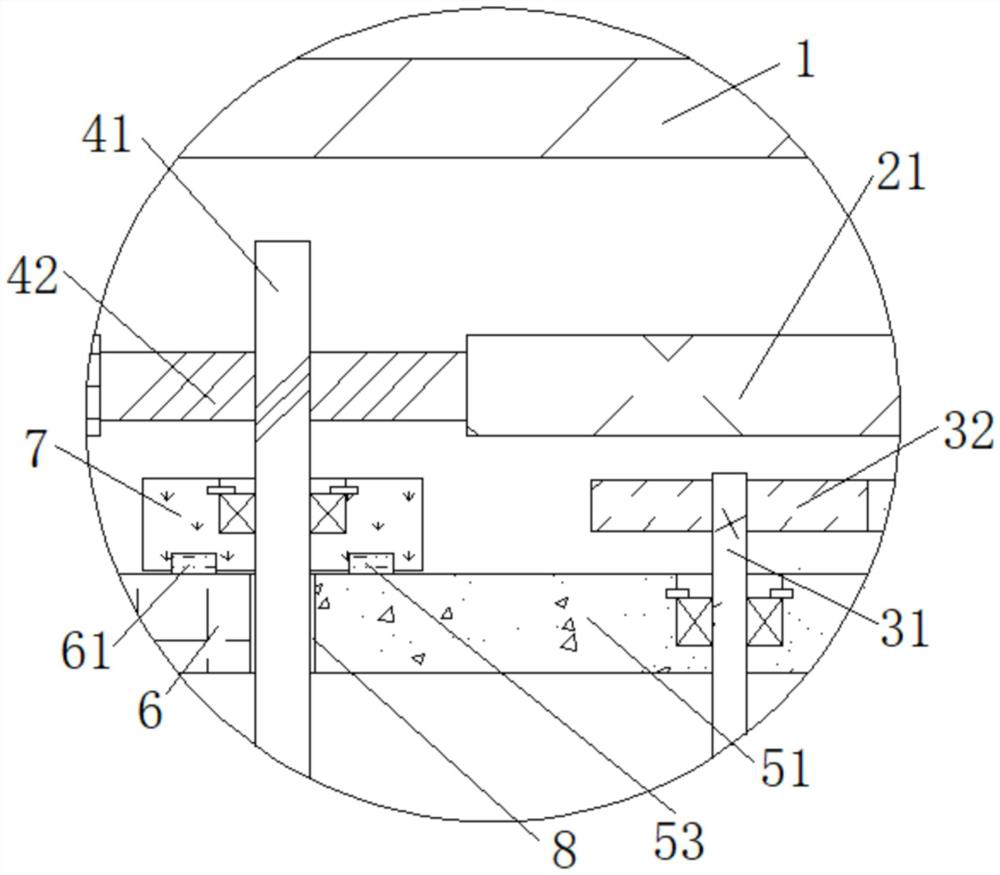

Method used

Image

Examples

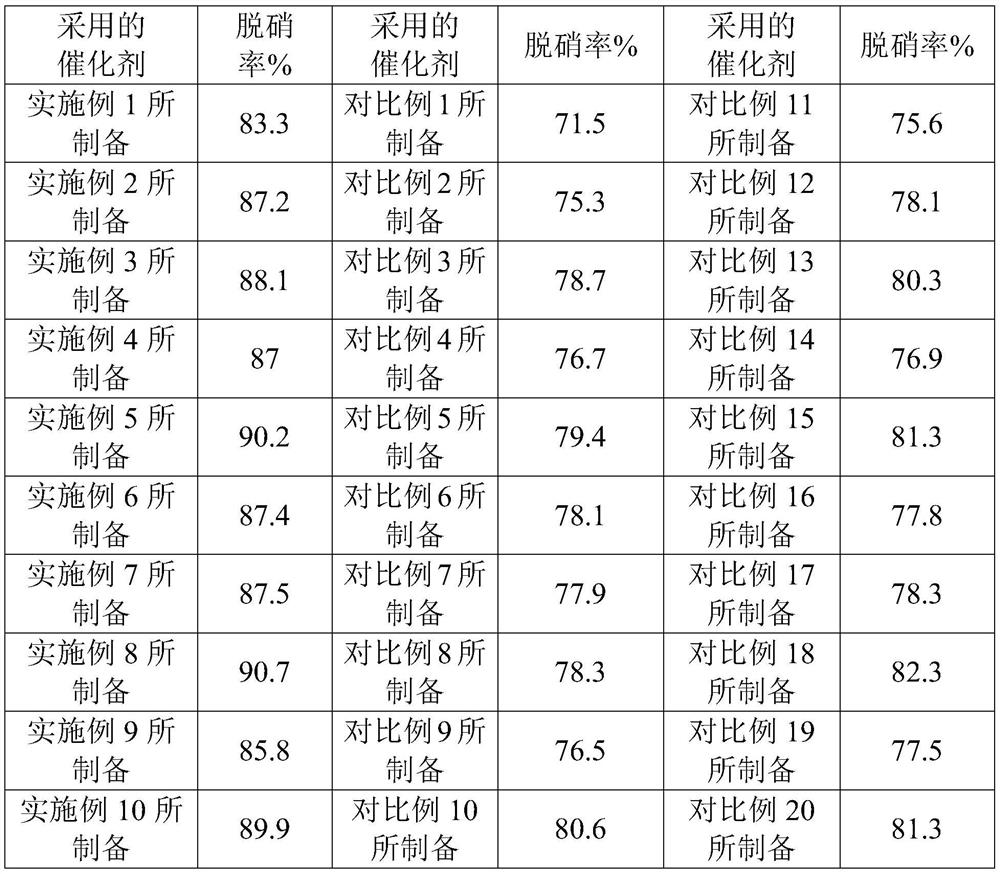

Embodiment 1

[0026] A low-temperature denitration catalyst, the low-temperature denitration catalyst comprises a cordierite carrier and an active component coated on the carrier, and the loading amount of the active component is 3wt%; the active component comprises 3wt% of V 2 O 5 , 10wt% MoO 3 , 2.5wt% SiO 2 , 82.2wt% TiO 2 and 2.3wt% of phosphate ions, and the loading amount of vanadium element in the active component in the low-temperature denitration catalyst is 5.04wt%.

[0027] The preparation method of the low-temperature denitration catalyst comprises the following steps:

[0028] (a) adding deionized water to the stirring device, adding titanium dioxide while stirring, then adding oxalic acid-ammonium metavanadate mixed solution and ammonium heptamolybdate, wherein the oxalic acid-ammonium metavanadate mixed solution is 20% by mass concentration The oxalic acid solution and the ammonium metavanadate solution with a mass concentration of 30% are mixed at a mass ratio of 1:1 to ...

Embodiment 2

[0033] A low-temperature denitration catalyst, the low-temperature denitration catalyst comprises a cordierite carrier and an active component coated on the carrier, the loading of the active component is 1.8 wt %; the active component comprises 6.5 wt % of V 2 O 5 , 3wt% MoO 3 , 3wt% SiO 2 , 86.5wt% TiO 2 and 1 wt % of phosphate ions, and the loading amount of vanadium element in the active component in the low-temperature denitration catalyst is 6.55 wt %.

[0034] The preparation method of the low-temperature denitration catalyst comprises the following steps:

[0035] (a) adding deionized water to the stirring device, adding titanium dioxide while stirring, then adding oxalic acid-ammonium metavanadate mixed solution and ammonium heptamolybdate, wherein the oxalic acid-ammonium metavanadate mixed solution is 20% by mass concentration The oxalic acid solution and the ammonium metavanadate solution with a mass concentration of 30% are mixed at a mass ratio of 1:1 to form...

Embodiment 3

[0040] A low-temperature denitration catalyst, the low-temperature denitration catalyst comprises a cordierite carrier and an active component coated on the carrier, the loading of the active component is 1.1 wt %; the active component comprises 11.5 wt % of V 2 O 5 , 12wt% MoO 3 , 3.7wt% SiO 2 , 70wt% TiO 2 and 2.8wt% of phosphate ions, and the loading amount of vanadium element in the active component in the low-temperature denitration catalyst is 7.09wt%.

[0041] The preparation method of the low-temperature denitration catalyst comprises the following steps:

[0042] (a) adding deionized water to the stirring device, adding titanium dioxide while stirring, then adding oxalic acid-ammonium metavanadate mixed solution and ammonium heptamolybdate, wherein the oxalic acid-ammonium metavanadate mixed solution is 20% by mass concentration The oxalic acid solution and the ammonium metavanadate solution with a mass concentration of 30% were mixed at a mass ratio of 1:1 to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com