Powder-combustible vortex burner

A technology of swirl burners and burners, which is applied in the direction of burners, burners, and combustion methods for burning powder fuels. It can solve the problems of no ignition device, cumbersome, damage, etc., so as to prolong the service life and have a wide range of applications. , to avoid the effect of ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

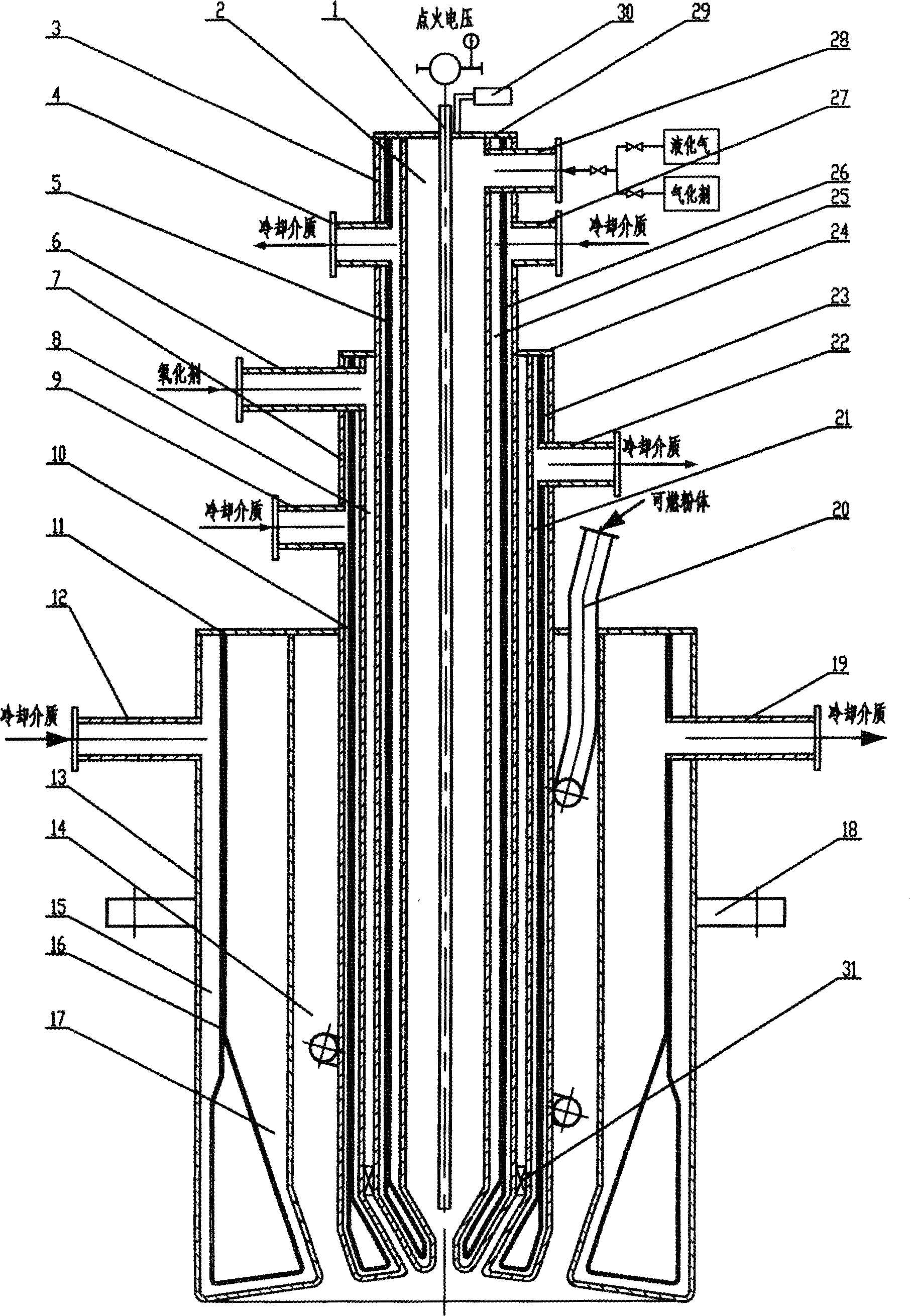

[0016] like figure 1 As shown, the center of the burner of the present invention is provided with a primary cooling jacket 3, the center of the primary cooling jacket 3 is inserted into the ignition rod 1, and a flame monitoring device 30 is arranged on the end cover 29 of the primary cooling jacket; and connected to a pipe, which is connected with the inlet 28, and the inlet 28 is connected with the primary air duct 2, and the fuel gas and gasification agent are switched through the valve; the oxidant flows in from the oxidant inlet 6, and is sprayed out after passing through the secondary air duct 8; Out of the cooling jacket 3 is a secondary cooling jacket 7, the outer wall of the secondary cooling jacket 7 is spirally wound with 2 to 5 pulverized coal pipes 20, and the pulverized coal is sprayed out through the pulverized coal pipe swirling flow; the outermost layer of the burner is arranged for tertiary cooling Jacket 13; after the cooling medium enters the channel from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com