Efficient mixer

A kind of mixer, high-efficiency technology, applied in the direction of mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve the problems of dust pollution, volatile oar liquid, low efficiency, etc., achieve efficient mixing, increase mixing speed, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

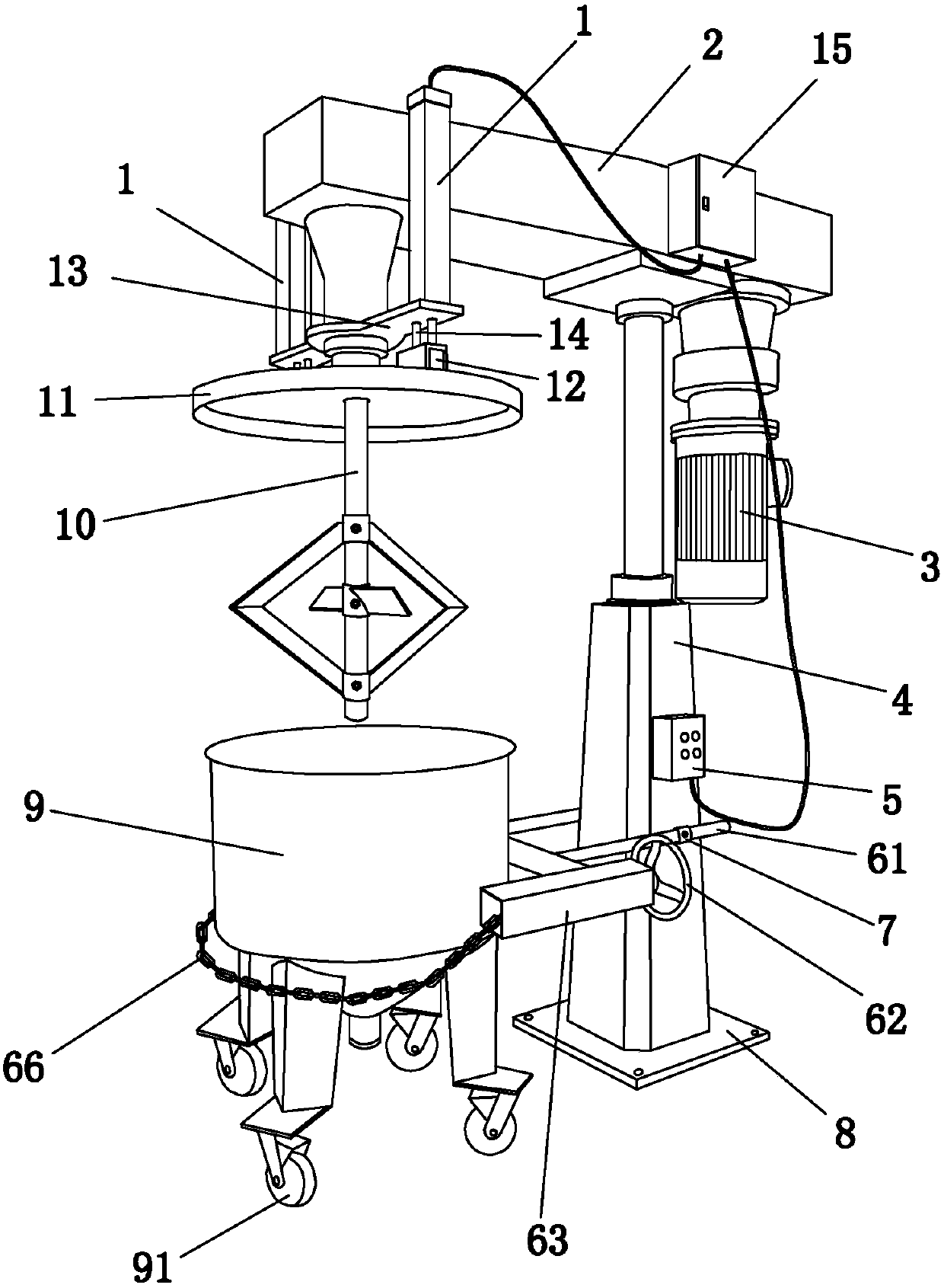

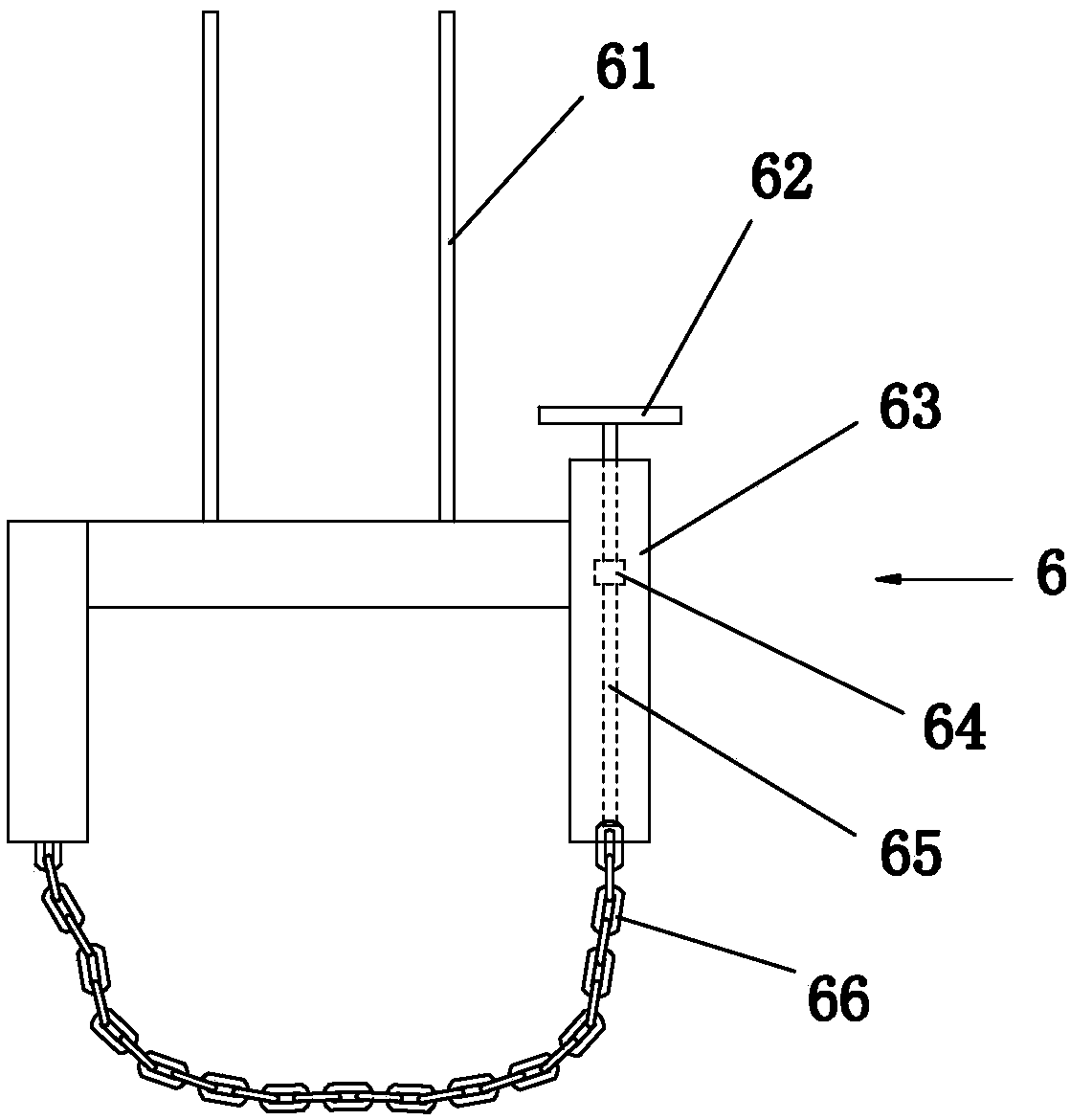

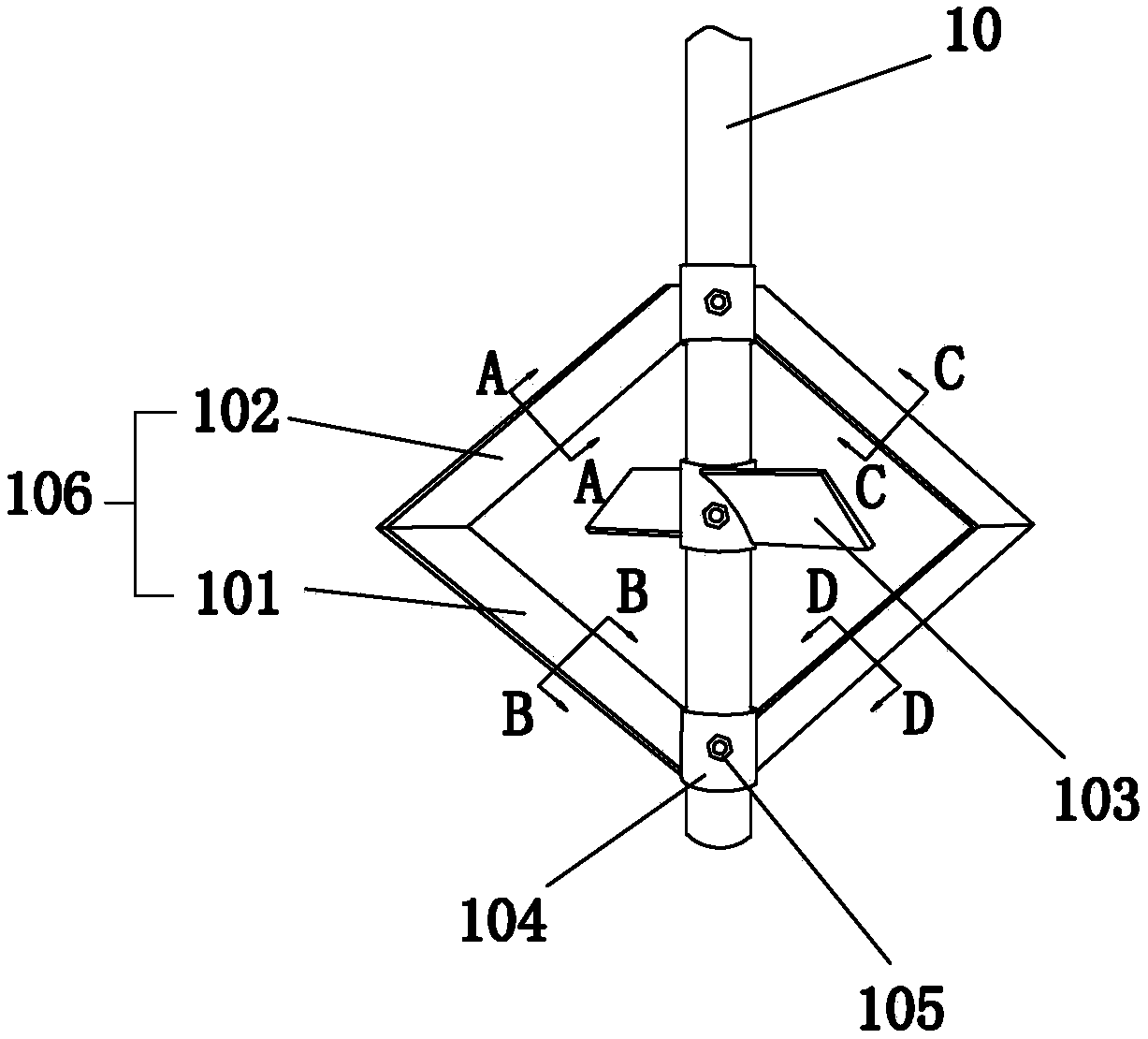

[0027] like figure 1 and figure 2 A high-efficiency mixer shown includes a mixer body, a stirring rod 10 and a motor 3, and the mixer body includes a sealing cover 11, two electric telescopic rods 1, a fixing seat 8, a hydraulic telescopic rod 4, a mounting frame 2 and a mixing bucket fixed Frame 6.

[0028] The lower end of the fixing seat 8 is a horizontal plate, on which a fixing hole is arranged, and it is fixed on a horizontal mounting surface by bolts. The hydraulic telescopic rod 4 is vertically fixed upwards on the fixed seat 8, and the hydraulic telescopic rod includes necessary devices for hydraulic control such as a hydraulic oil tank and an oil circuit. The mounting frame 2 is fixed horizontally on the upper movable end of the hydraulic telescopic rod 4, the hydraulic telescopic rod 4 drives the mounting frame 2 to move up and down, the stirring rod 10 is installed vertically downward on the front end of the mounting frame 2, and the motor 3 is mounted verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com