Cosmetics raw material agitation device

A technology of stirring device and cosmetics, which is applied to mixers with rotating stirring devices, accessories of mixers, transportation and packaging, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

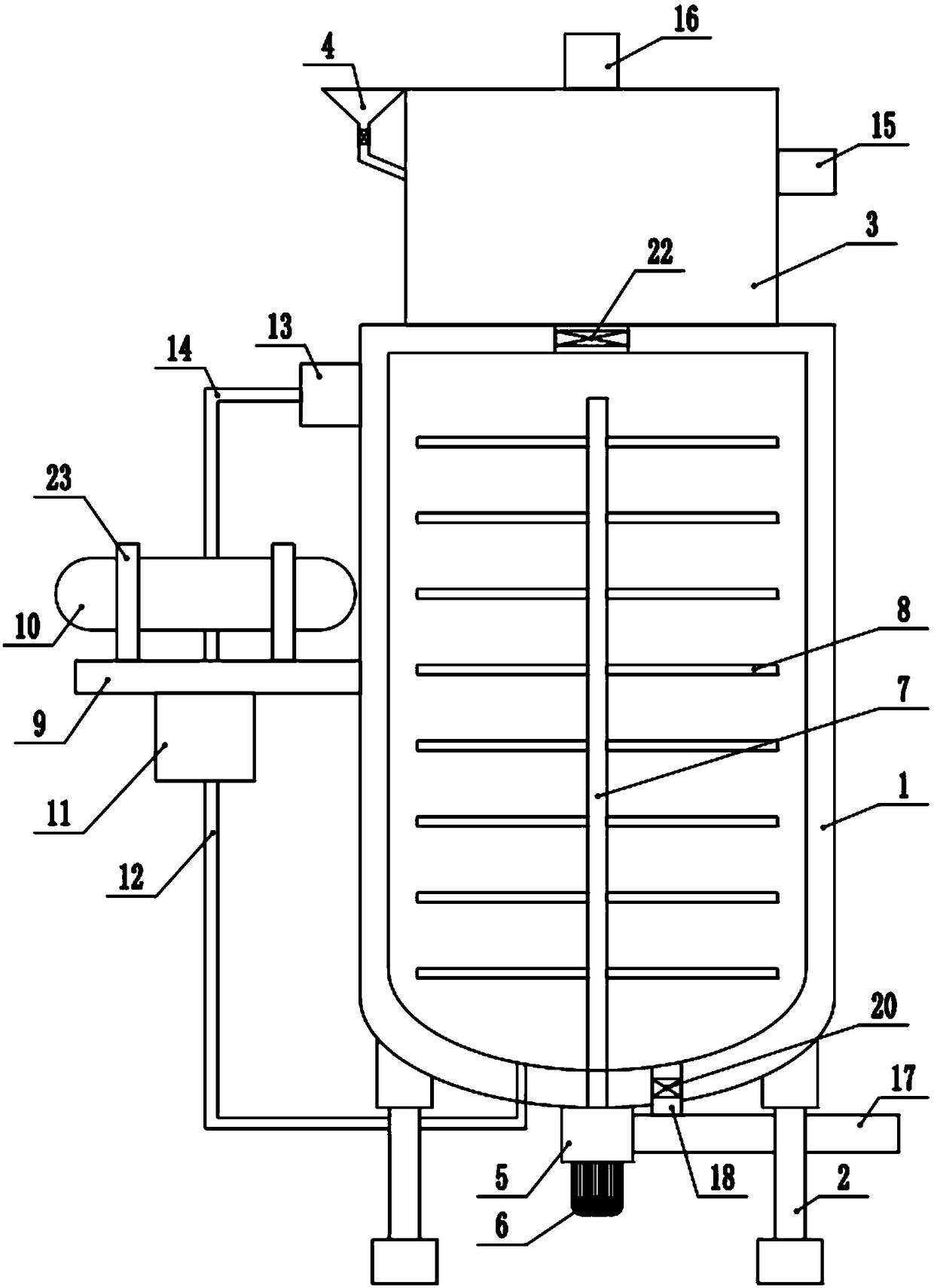

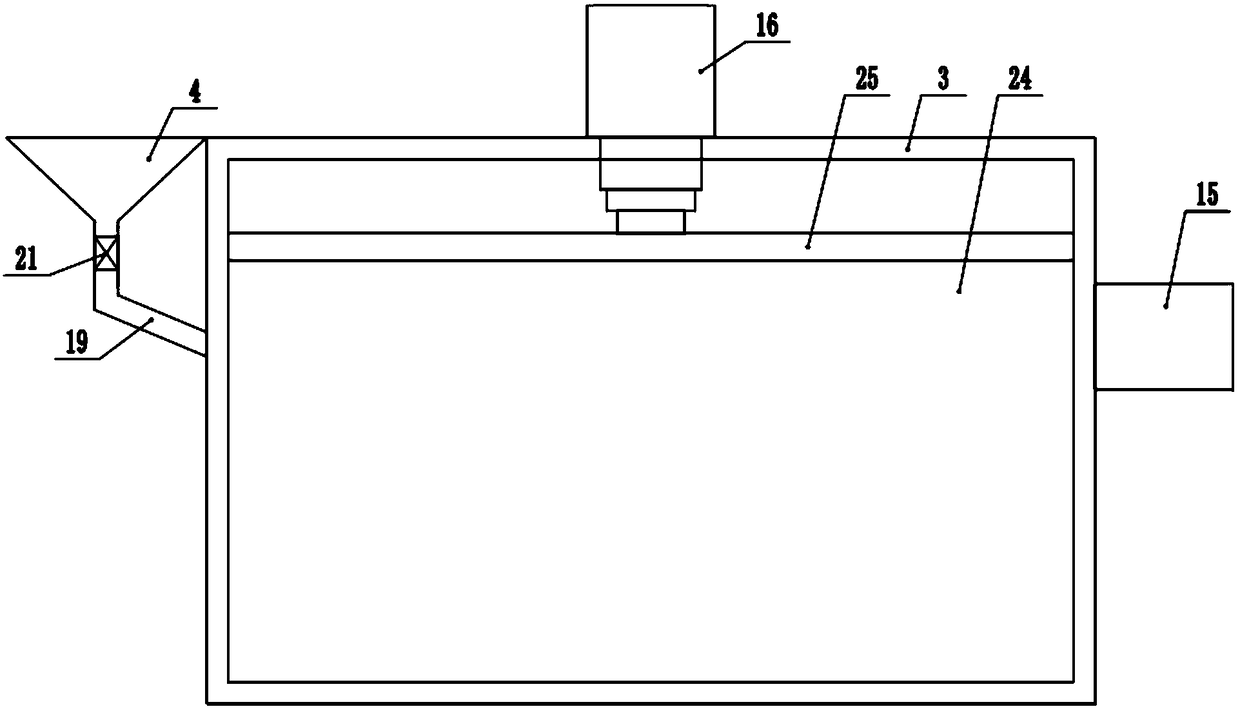

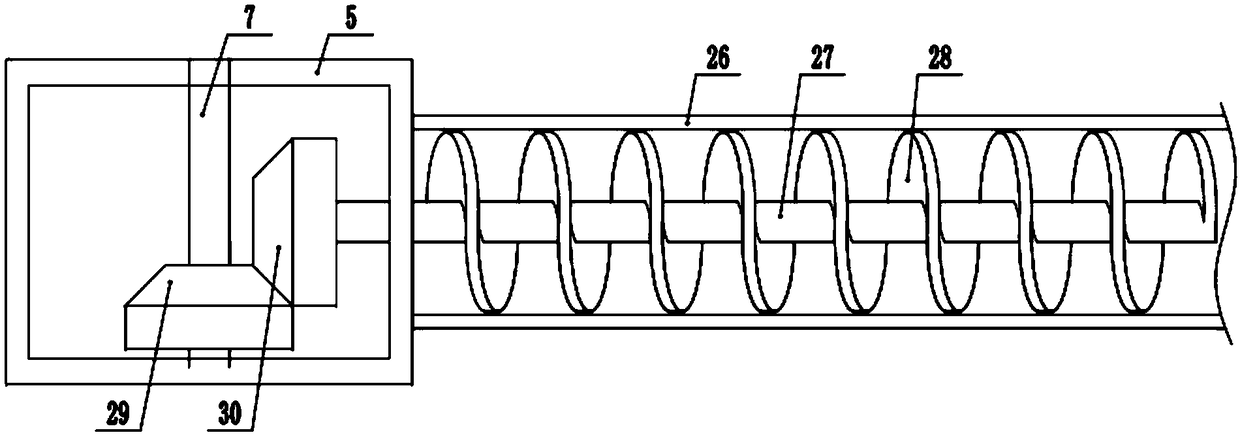

[0023] see figure 1 , a cosmetic raw material stirring device, the bottom end of the stirring tank 1 is fixedly connected to the support leg 2, the top of the stirring tank 1 is fixedly provided with a pretreatment box 3, and the side of the pretreatment box 3 is fixedly provided with an inlet Hopper 4, the bottom end of the mixing tank 1 is fixedly connected to the bottom block 5, the bottom end of the bottom block 5 is fixedly connected to the driving motor 6, the output shaft of the driving motor 6 is fixedly connected to the rotating shaft 7, and the rotating shaft 7 passes through the bottom block 5 and is placed inside the stirring tank 1, the rotating shaft 7 is fixedly connected to the stirring paddle 8, one side of the stirring tank 1 is fixedly connected to a fixed plate 9, and the top of the fixed plate 9 is provided with an air Tank 10, inert gas is stored in the gas tank 10, the bottom end of the fixed plate 9 is fixedly connected with the first gas pump 11, the i...

Embodiment 2

[0027] see figure 1 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the outside of the gas tank 10 is fixedly connected to the fixed frame 23, the fixed frame 23 is fixedly connected to the fixed plate 9, and the top of the stirring tank 1 A discharge channel is provided, and a third electric valve 22 is arranged in the discharge channel, and a first electric valve 20 is fixedly provided on the discharge pipe 18 .

[0028] In the implementation process of the present invention, the cosmetic raw materials are first put into the pretreatment box 3 through the feed hopper 4, then the second electric valve 21 and the third electric valve 22 are closed, the third air pump 15 is started, and the pretreatment box 3 is pumped. Vacuum treatment, then start the second air pump 13 to evacuate the mixing tank 1, then open the third electric valve 22, start the hydraulic telescopic rod 16 to make it stretch, so that the pressing plate 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com