High-temperature-resisting aqueous aluminum-plating transferring paint composition and preparation method thereof

A technology for transferring coatings and compositions, applied in fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor leveling and transfer performance, difficult to solve compatibility problems, etc., and achieve stable and stable supply of raw materials. , the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

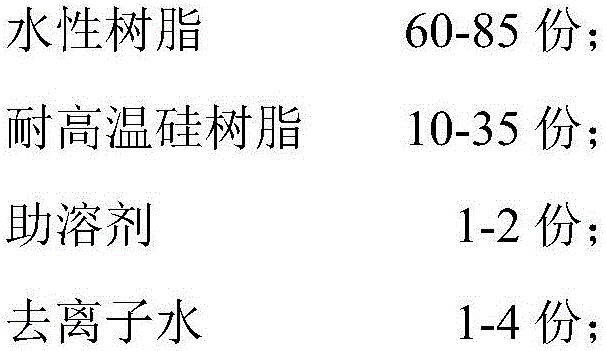

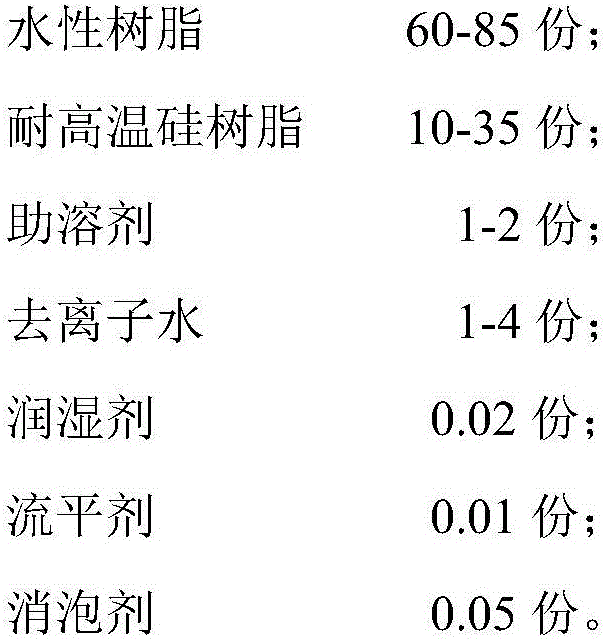

Embodiment 1

[0029] This embodiment provides a water-based high-temperature-resistant aluminized transfer coating composition and a preparation method thereof. The coating composition includes the following components by weight: 83Kg water-based resin, 14Kg high-temperature-resistant silicone resin, 2Kg cosolvent, 1Kg Deionized water, 0.02Kg wetting agent, 0.01Kg leveling agent and 0.05Kg defoamer. Among them, the water-based resin is a water-based acrylic emulsion, with a solid content of 20wt%, a Tg of 0-30°C, and a molecular weight of ≥200,000; the high-temperature resistant silicone resin is a methylphenyl silicone resin, which is an anionic aqueous solution of weak alkalinity, with a solid content of 40wt %; cosolvent is isopropanol; wetting agent is sodium dodecylbenzenesulfonate; leveling agent is polyether modified polysiloxane; defoaming agent is modified silicone emulsion.

[0030] The preparation method comprises the following process steps:

[0031] (1) prepare materials accor...

Embodiment 2

[0036] This embodiment provides a water-based high-temperature-resistant aluminized transfer coating composition and a preparation method thereof. The coating composition includes the following components by weight: 80Kg water-based resin, 15Kg high-temperature-resistant silicone resin, 1Kg cosolvent, 4Kg Deionized water, 0.02Kg wetting agent, 0.01Kg leveling agent and 0.05Kg defoamer, wherein the water-based resin is water-based polyurethane emulsion with a solid content of 23wt%, a Tg of 0-30°C, and a molecular weight of ≥200,000; high temperature resistance The silicone resin is a silicone polyurethane resin, which is a weakly alkaline anionic aqueous solution with a solid content of 35wt%; the cosolvent is isopropanol; the wetting agent is sodium dodecylbenzenesulfonate; the leveling agent is polyether modified non-toxic polysiloxane; the defoamer is a modified silicone emulsion.

[0037] The preparation method comprises the following process steps:

[0038] (1) Prepare m...

Embodiment 3

[0043] This embodiment provides a water-based high-temperature-resistant aluminized transfer coating composition and a preparation method thereof. The coating composition includes the following components by weight: 70Kg water-based resin, 25Kg high-temperature-resistant silicone resin, 1Kg cosolvent, 4Kg Deionized water, 0.02Kg wetting agent, 0.01Kg leveling agent and 0.05Kg defoamer, wherein the water-based resin is acrylic modified polyurethane with a solid content of 30wt%, a Tg of 0-30°C, and a molecular weight of ≥200,000; The high temperature resistant silicone resin is epoxy modified silicone resin, which is weakly alkaline anionic aqueous solution with a solid content of 40wt%; the cosolvent is ethanol; the wetting agent is sodium dodecylbenzenesulfonate; the leveling agent is polystyrene Ether-modified polysiloxane; the defoamer is a modified silicone emulsion.

[0044] The preparation method comprises the following process steps:

[0045] (1) Prepare materials acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com