Laser surface strengthening method for improving surface quality and performance of high-carbon steel component

A surface quality and surface strengthening technology, which is applied in the coating process and coating of metal materials, can solve the problems of large heat-affected zone range of components, large hardening tendency, and decrease of plasticity and toughness of components, so as to reduce thermal influence The effect of reducing the tendency of overheating and reducing the tendency of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for surface treatment of high-carbon steel components. It is worth mentioning that the surface treatment of this embodiment refers to performing surface strengthening treatment on high-carbon steel components, including the following steps:

[0036] 1. Surface pretreatment

[0037] Pretreatment of the high carbon steel components as a whole, specifically including manual grinding with an angle grinder to remove rust and oxide film on the surface and cleaning the surface.

[0038] 2. Powder

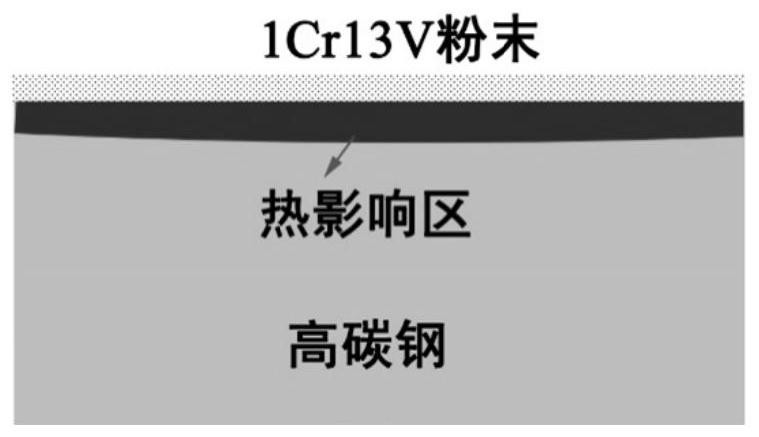

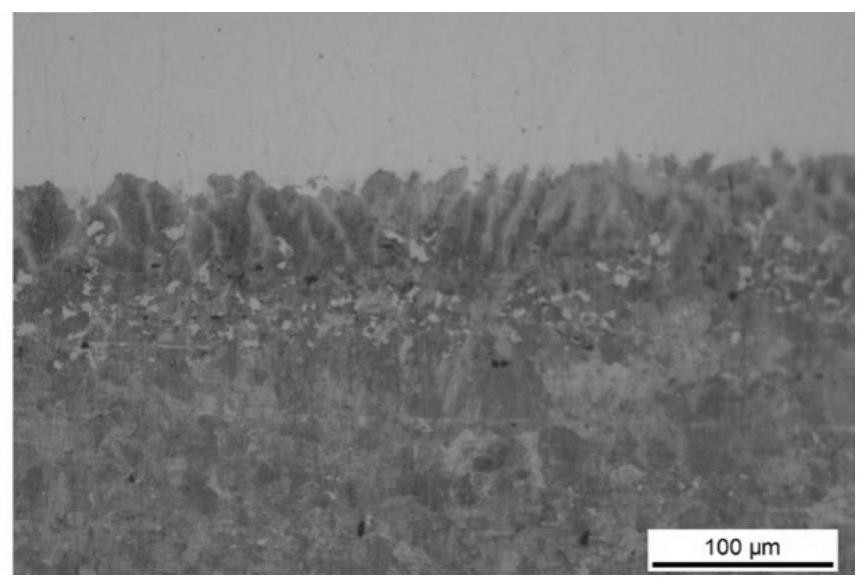

[0039] Such as figure 1 As shown, a layer of 1Cr13V stainless steel powder is laid on the whole high carbon steel member. 1Cr13V stainless steel powder is prepared by quenching + low temperature (230°C-370°C) tempering heat treatment of 1Cr13 stainless steel powder. 1Cr13 stainless steel powder is commonly used martensitic stainless steel , the price is cheap and easy to obtain, the performance of 1Cr13V stainless steel powder is equivalent to tha...

Embodiment 2

[0054] This embodiment provides a method for surface treatment of high-carbon steel components. It is worth mentioning that the surface treatment in this embodiment refers to the surface repair of high-carbon steel components with surface damage such as abrasion and surface cracks. , compared with embodiment 1, this embodiment comprises the following steps:

[0055] 1. Surface pretreatment

[0056] For the surface damage of high carbon steel components such as abrasion and surface cracks, the damage assessment is first carried out. After determining the position and size of the area to be clad, the groove to be clad is roughly machined by mechanical processing to remove the surface damage, and then angle grinding is used to The machine will grind the groove to be clad to remove rust and oxide film.

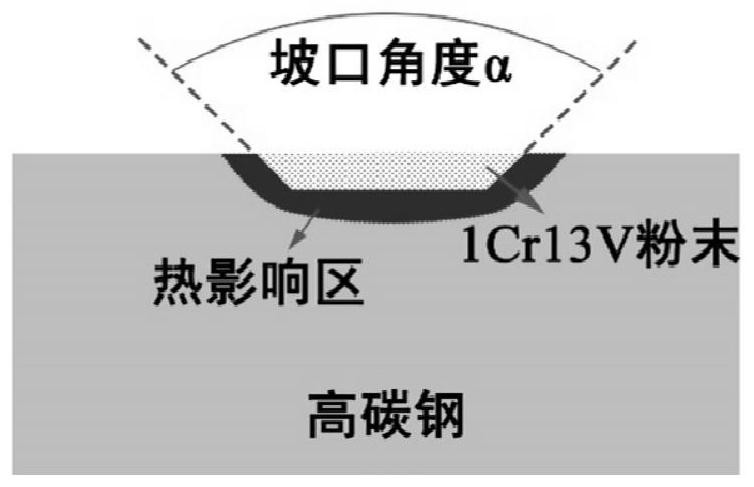

[0057] 2. Groove processing

[0058] Groove processing is performed on the grooves of high carbon steel components to be clad to remove surface damage, and the groove processing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com