Bimetallic composite wire rod high-efficient production line

A composite wire and production line technology, applied to other manufacturing equipment/tools, instruments, computer control, etc., can solve the problems of lower product production efficiency, long downtime, copper strip drilling, etc., to improve production efficiency and reduce production costs , metallurgical bonding firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

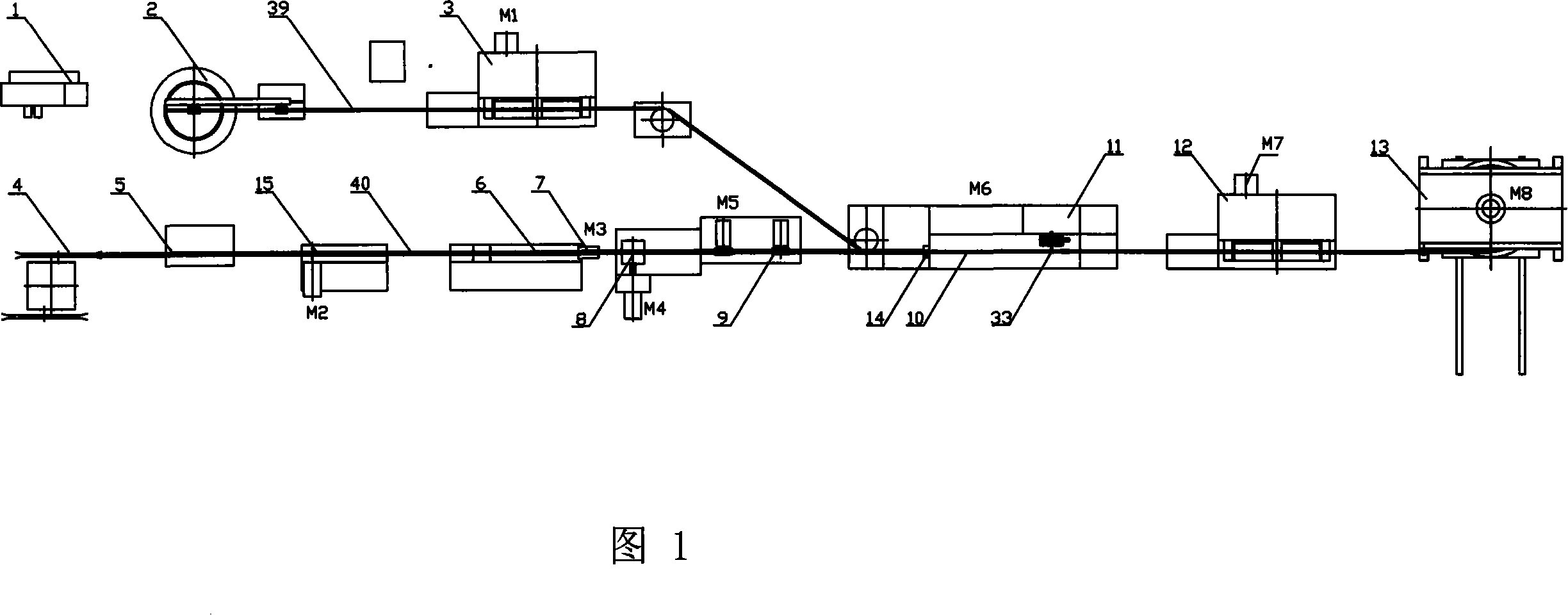

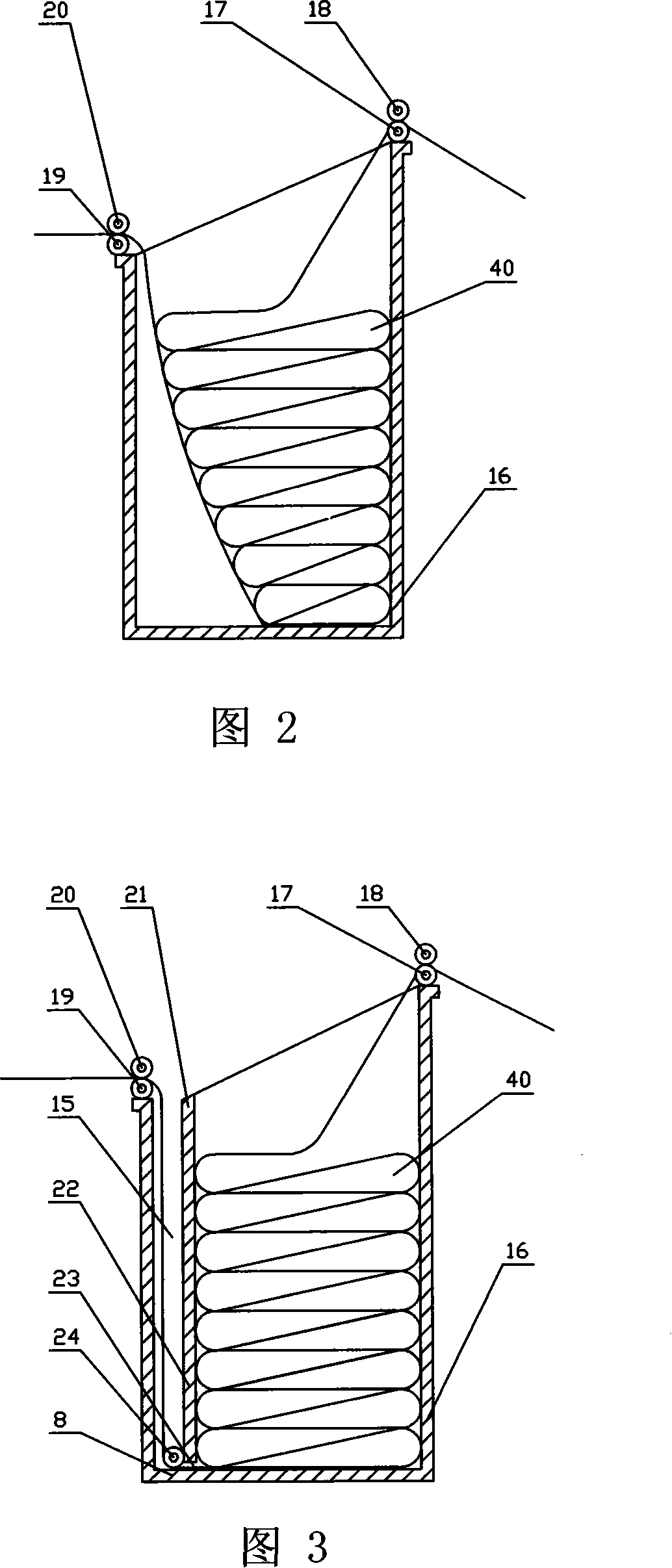

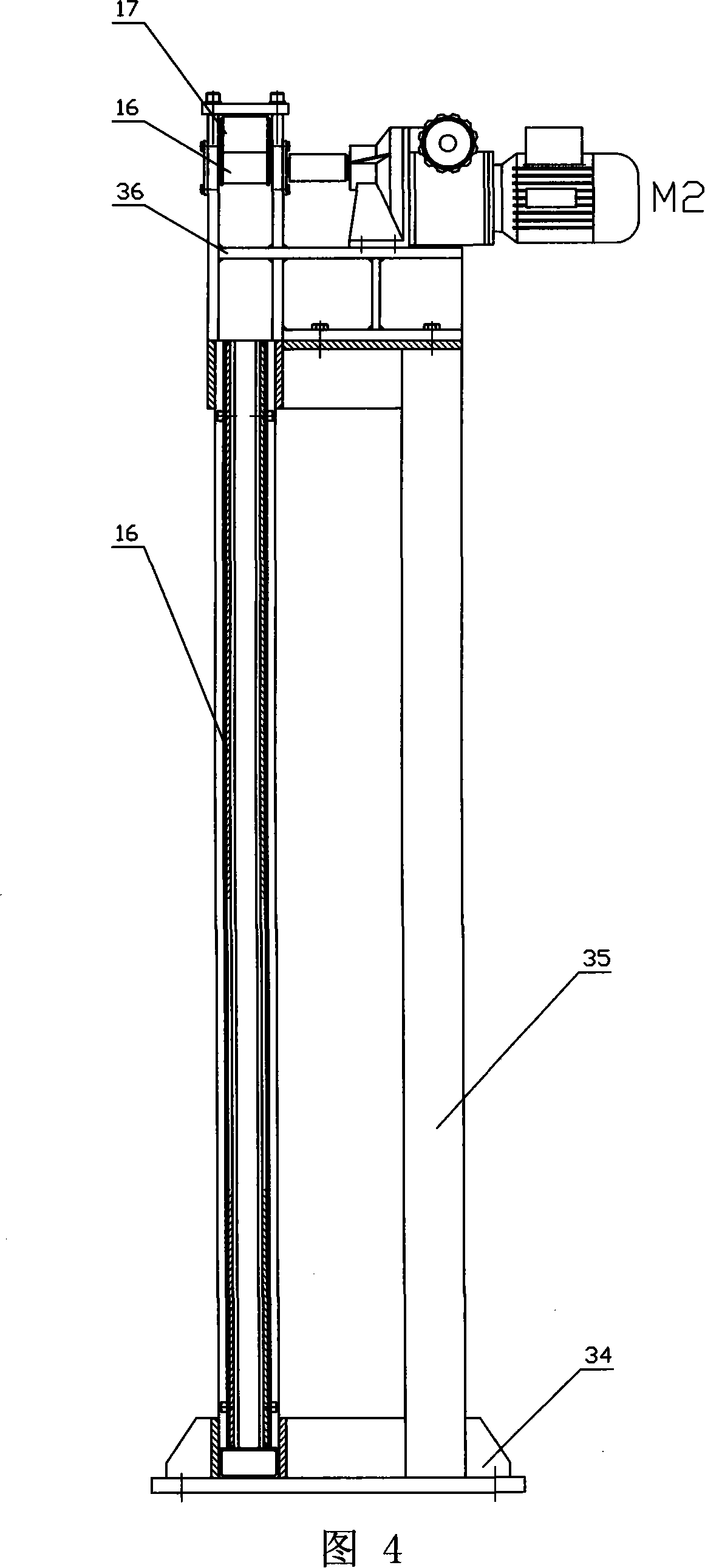

[0026] As shown in Figure 1: there are aluminum rod butt welding machine 1 (resistance butt welding machine), aluminum rod discharging rack 2, and aluminum rod drawing machine 3 which are arranged in sequence, which are the same as the prior art; There are copper strip unloading rack 4 with the same technology, copper strip butt joint machine 5 (TIG argon arc welding machine), copper strip cleaning tank 6, copper strip drying machine 7, copper strip grinding machine 9 and overmolding machine arranged in sequence 10. Welding device 11, composite wire billet drawing machine 12, wire take-up machine 13, etc. An aluminum rod peeling device 14 is provided between the aluminum rod drawing machine 3 and the overmolding machine 10, and the copper strip butt joint machine 5 and A copper tape storehouse 15 is arranged between the copper tape cleaning tanks 6 . Aluminum rod peeling device 14 is as shown in Figure 5: can be separately arranged or be installed in the die hole of the inner ...

Embodiment 2

[0028] As shown in Figure 1: other is identical with embodiment 1, just is provided with copper strip trimming machine 8 between copper strip drying machine 7 and copper strip grinding machine 9, so that copper strip is more orderly, standard. And copper strip warehouse 15 as shown in Figure 3: be on the basis of embodiment 1, be provided with vertical dividing plate 21 in box-shaped warehouse body 16, between the bottom plate 22 of vertical dividing plate 21 and box-shaped warehouse body 16 There is a guide opening 23 between them, and a guide wheel 24 is arranged at the guide opening 23 .

Embodiment 3

[0030] As shown in Figure 6, on the basis of Embodiment 1, a PLC control unit such as a single-chip microcomputer or a computer is provided, that is, a single-chip microcomputer IC1 is provided, and the output of the single-chip microcomputer IC1 is passed through a frequency converter 25, a frequency converter 26, a frequency converter 28, and a frequency converter respectively. 29, frequency converter 30, frequency converter 31, frequency converter 32 and aluminum rod drawing machine motor M1, copper tape library motor M2, copper tape drying machine motor M3, copper tape grinding machine M5, overmolding machine drive motor M6 , composite wire billet drawing machine motor M7, take-up machine M8 join; the output of described single-chip microcomputer IC1 joins with welding device 11, and the output of welding device 11 joins with welding torch through current transformer, and the output end of current transformer Connect with the input terminal of the single-chip microcomputer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com