Discharge coil for electromagnetic riveter and production method thereof

The technology of discharge coil and electromagnetic riveting gun is applied in the production of discharge coil and the field of discharge coil for electromagnetic riveting gun. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

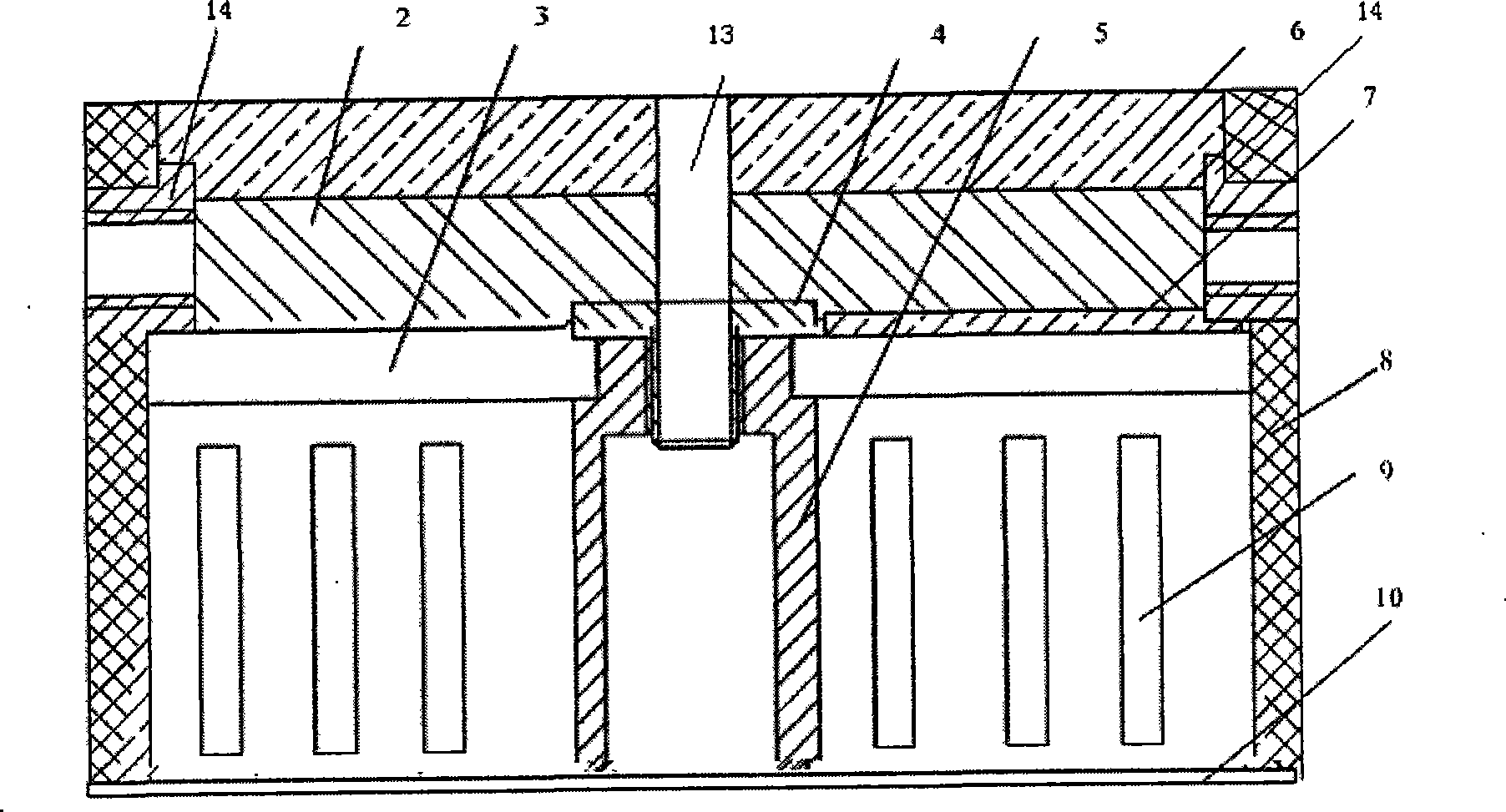

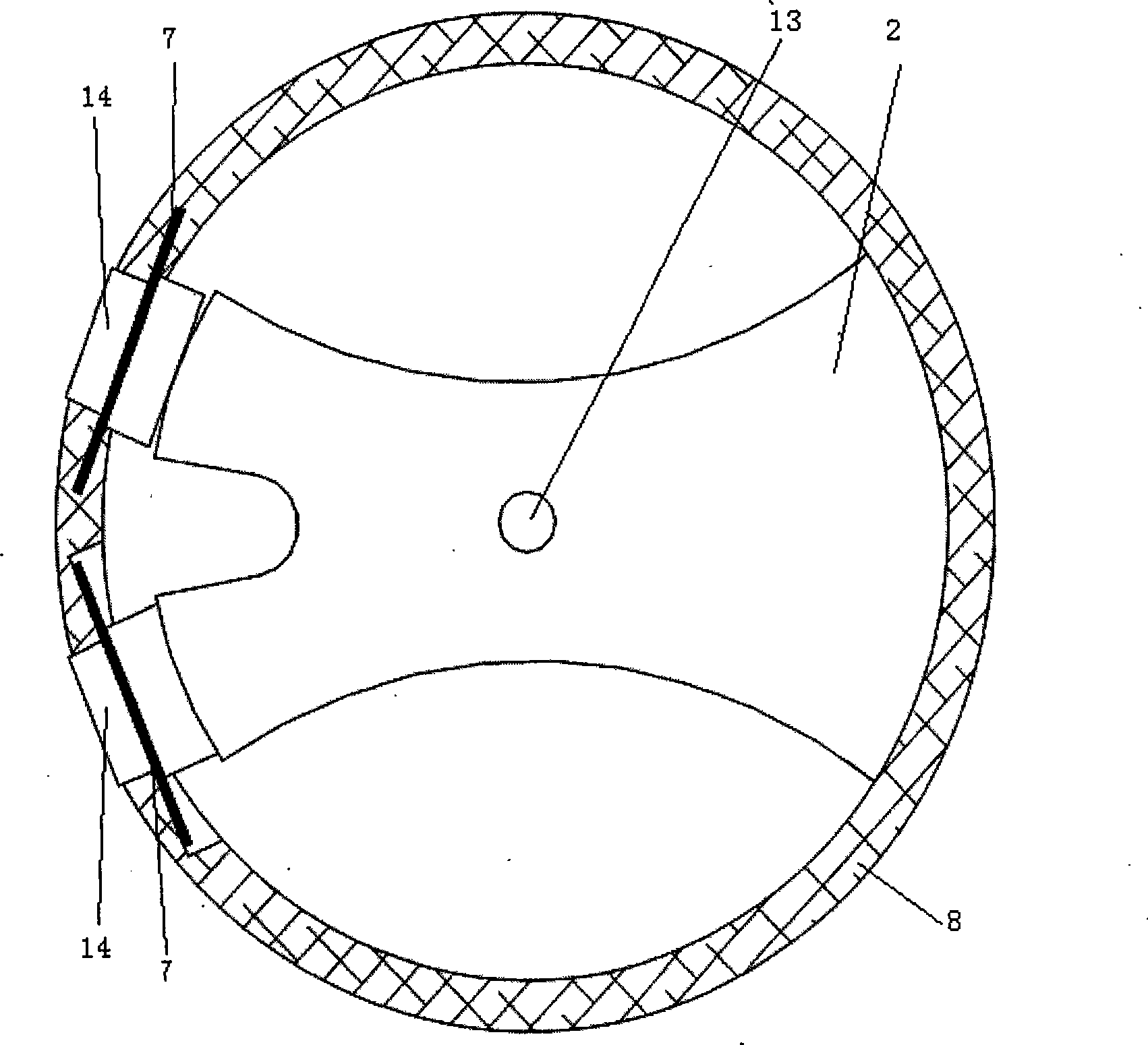

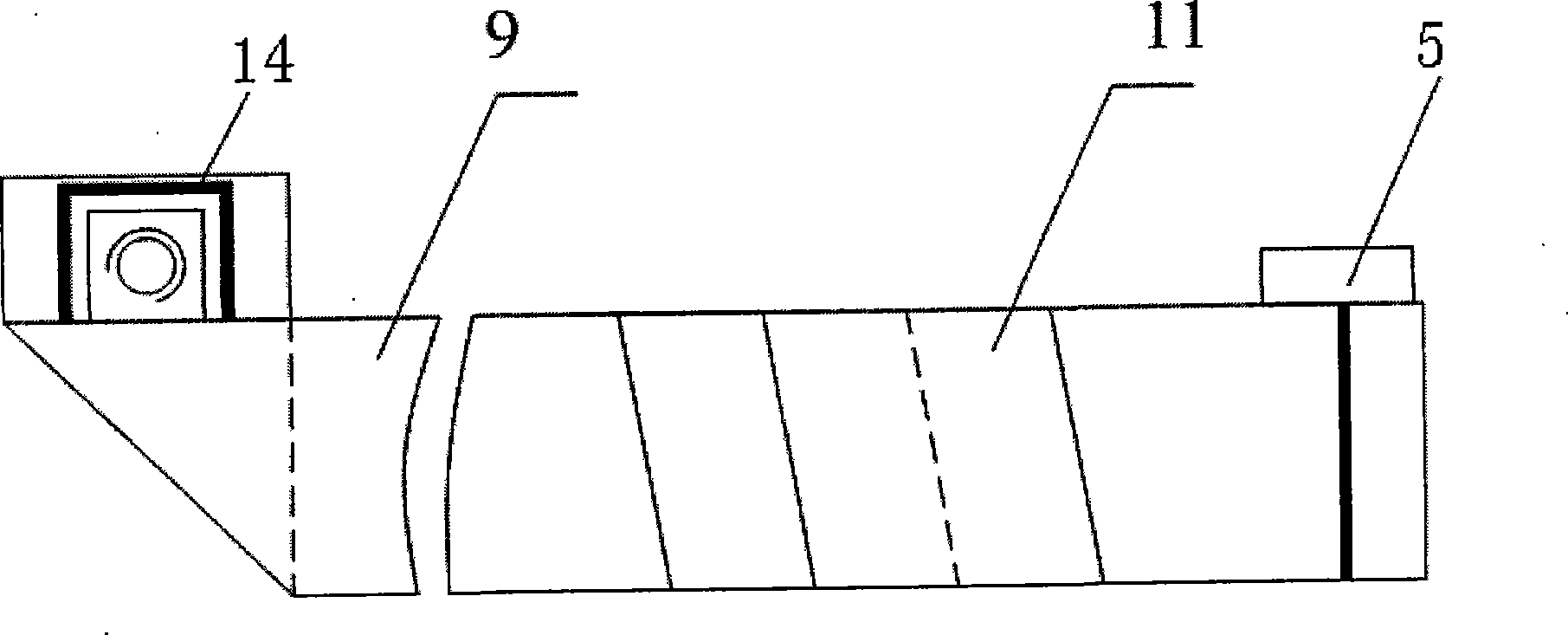

[0026] The discharge coil includes a support plate 2 , an insulating plate 3 , a compression bolt 4 , a core tube 5 , an insulating layer 6 , a shell 8 , a copper strip 9 , a separator 10 , a glass fiber cloth 11 and a countersunk nut 14 . There are two countersunk nuts 14, the head is square, the screw part is circular, the screw part passes through the shell 8 from the inside to the outside and is flush with the shell, and the inner wall of the shell 14 has a shape that matches the shape of the head of the countersunk nut 14. square hole. The center of the coil is a core tube 5 made of copper. The core tube 5 is used as a bushing for winding the coil. Around the core tube 5 is a layer of copper tape 9 wrapped in glass fiber cloth 11. The continuous copper tape 9 is inside the shell 8. Form a pie-shaped garden disc, the upper end of the core tube 5 has a boss, the inner wall of the boss is a thread that matches the compression bolt 4, the starting end of the copper strip 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com