Method for manufacturing photovoltaic solder strip

A technology for photovoltaic ribbons and production methods, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of high processing and production costs, improve production efficiency, have a wide range of coating thicknesses, and increase optical utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

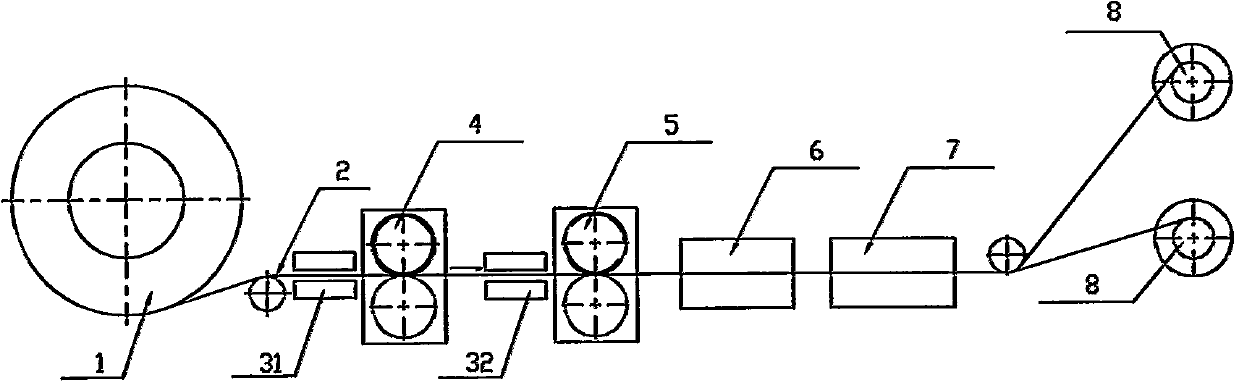

[0024] Such as figure 1 Shown, a kind of production method of photovoltaic ribbon, the process step of this method is as follows:

[0025] a) The raw copper strip 2 is unwound at a constant speed through the master material unwinding 1, and is transferred to the embossing device 4 through the first positioning guide device 31, and the raw copper strip 2 is embossed through the embossing device 4, so that the copper forming a structure with reflective grooves on the surface of belt 2 to obtain the first semi-finished product;

[0026] b) It is then transferred to the cutting device 5 by the second positioning guide device 32, and the first semi-finished product is cut into multiple copper strips with required width by the cutting device 5;

[0027] c) The slit copper strip is annealed through the annealing device 6 to form a second semi-finished product;

[0028] d) Then the second semi-finished product enters the electroplating device 7, reasonably selects the coating metal,...

Embodiment 2

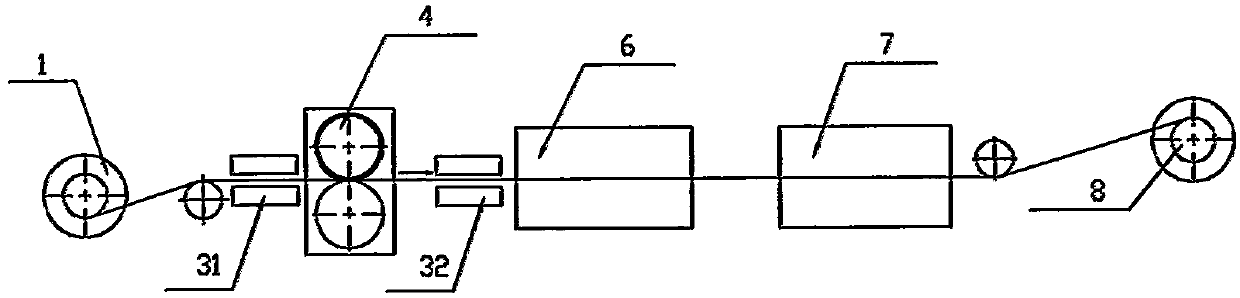

[0031] Such as figure 2 Shown, a kind of production method of photovoltaic ribbon, the process step of this method is as follows:

[0032] a) The raw copper strip with the required width is transferred to the embossing device 4 through the first positioning and guiding device 31, and the raw copper strip is embossed through the embossing device 4 to form reflective grooves on the surface of the copper strip structure to obtain the first semi-finished product;

[0033] b) then transported by the second positioning guide device 32 to the annealing device 6 for annealing treatment to form a second semi-finished product;

[0034] c) Then the second semi-finished product enters the electroplating device 7, reasonably selects the coating metal, and controls the thickness of the coating to be 1 μm to 30 μm, and performs electroplating treatment on the second semi-finished product to obtain the required photovoltaic ribbon;

[0035] d) Finally, the obtained photovoltaic ribbon is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com