Patents

Literature

67results about How to "Improve optical utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

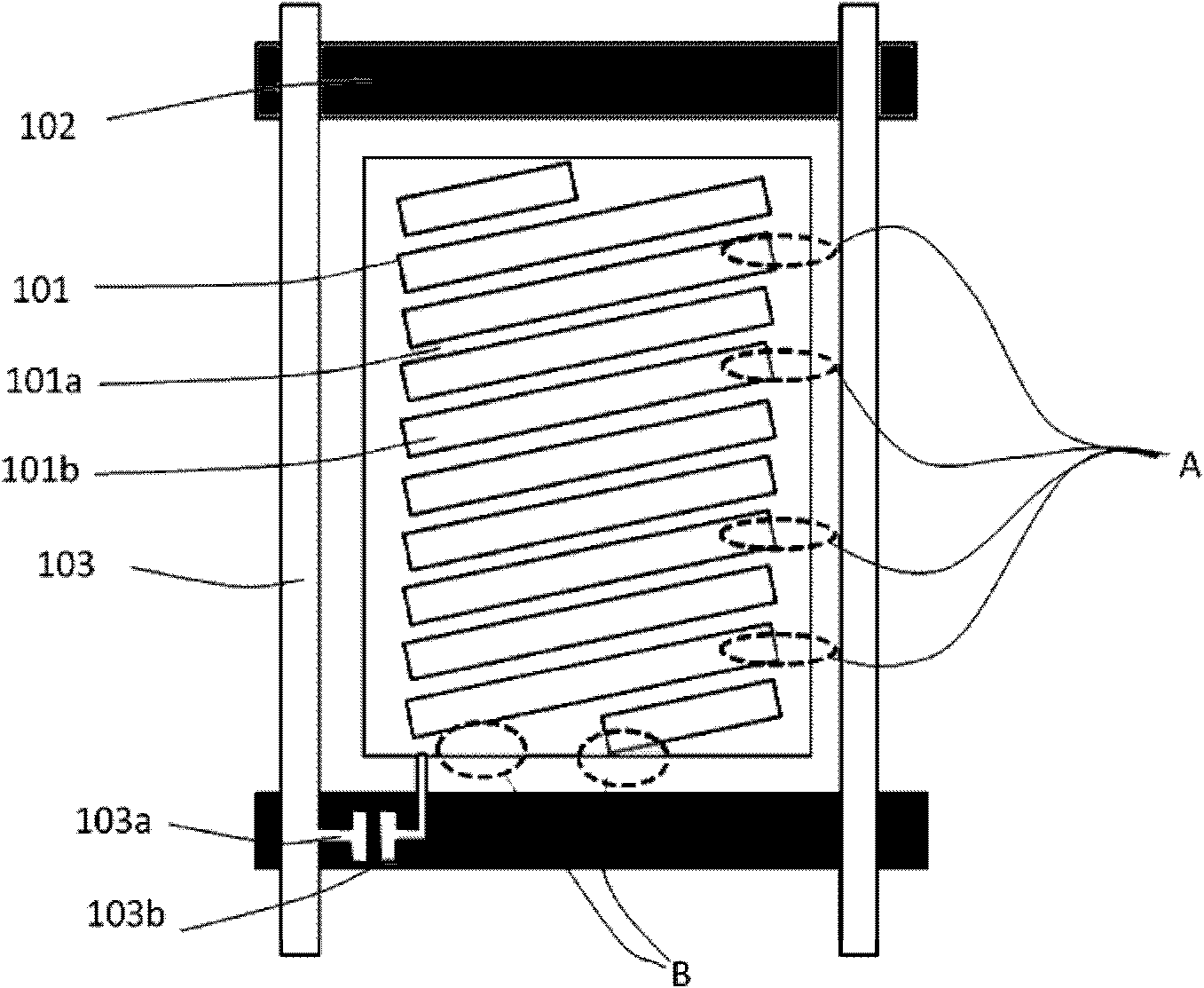

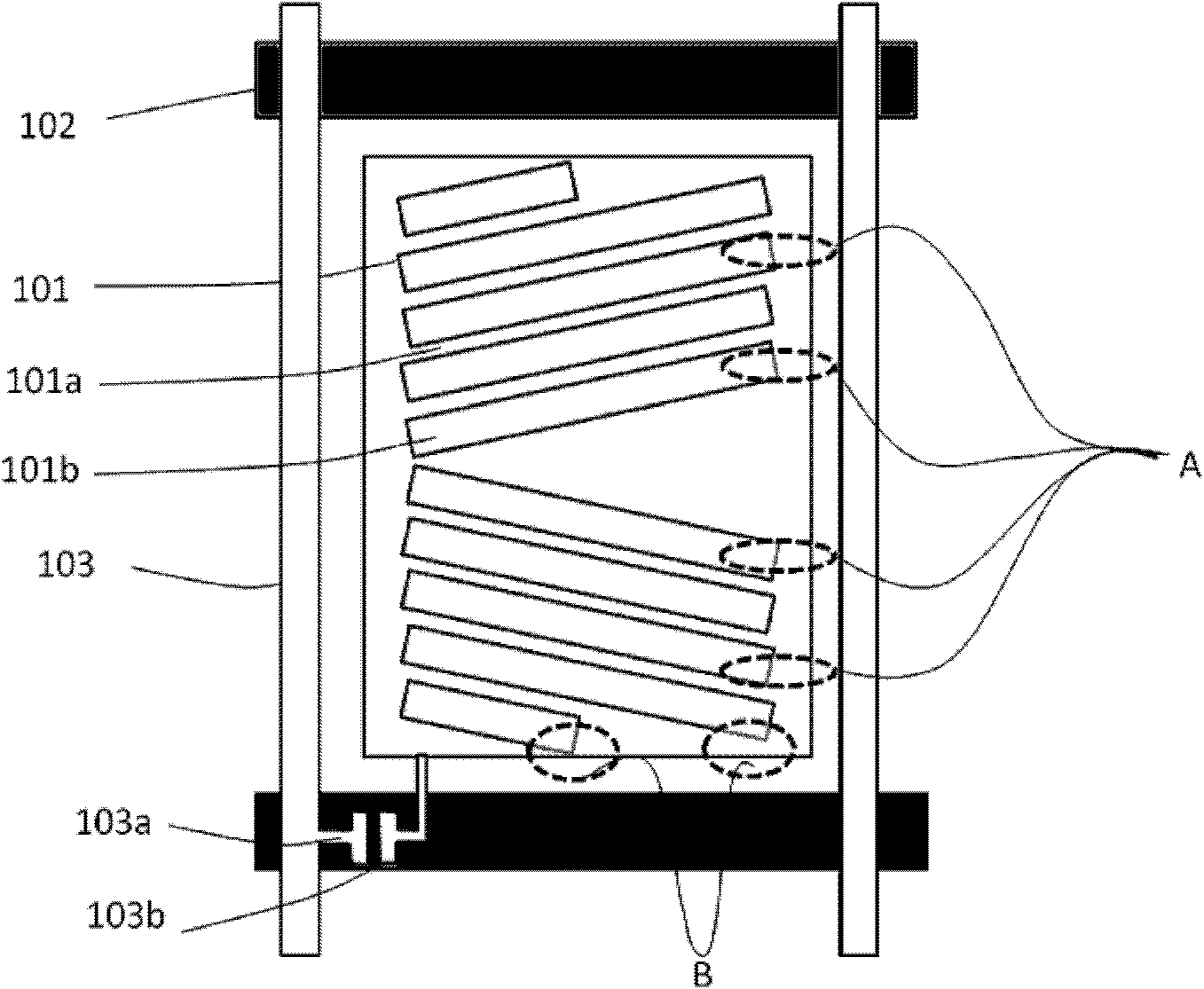

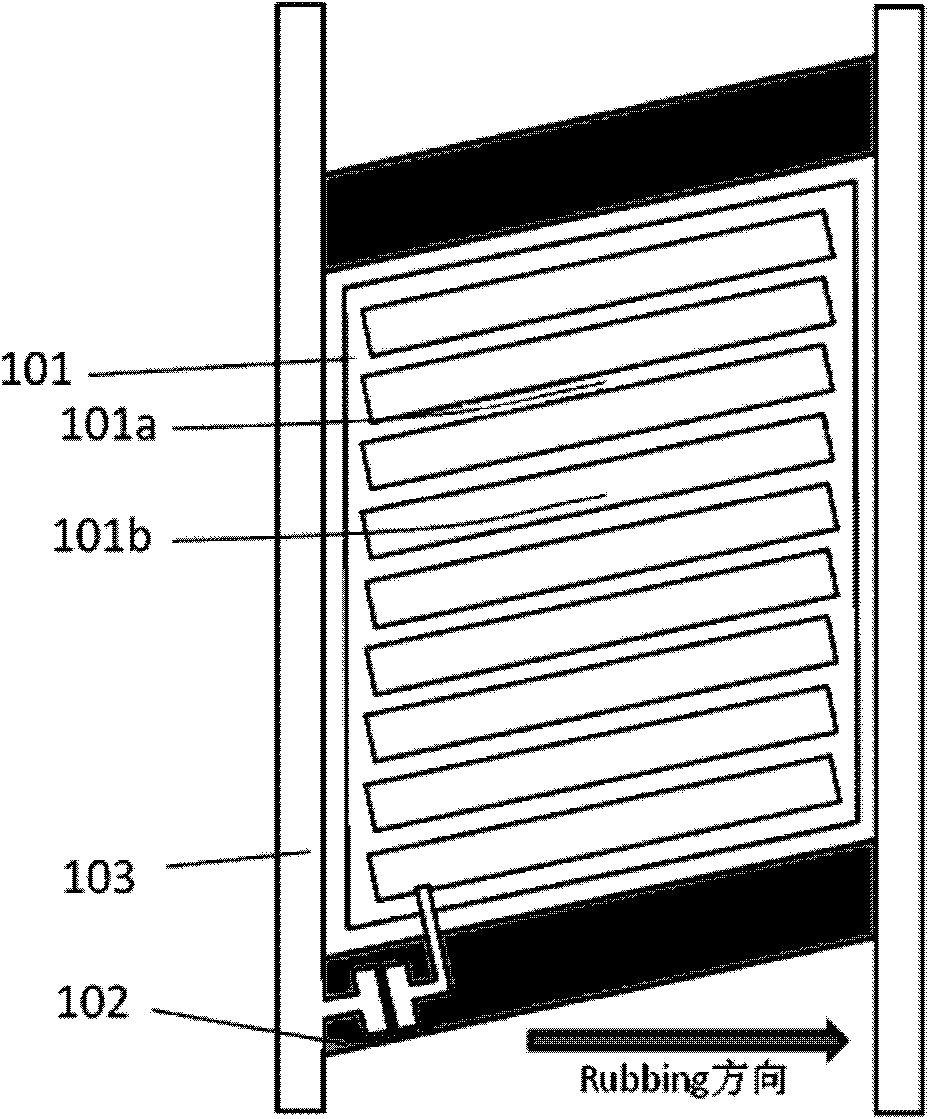

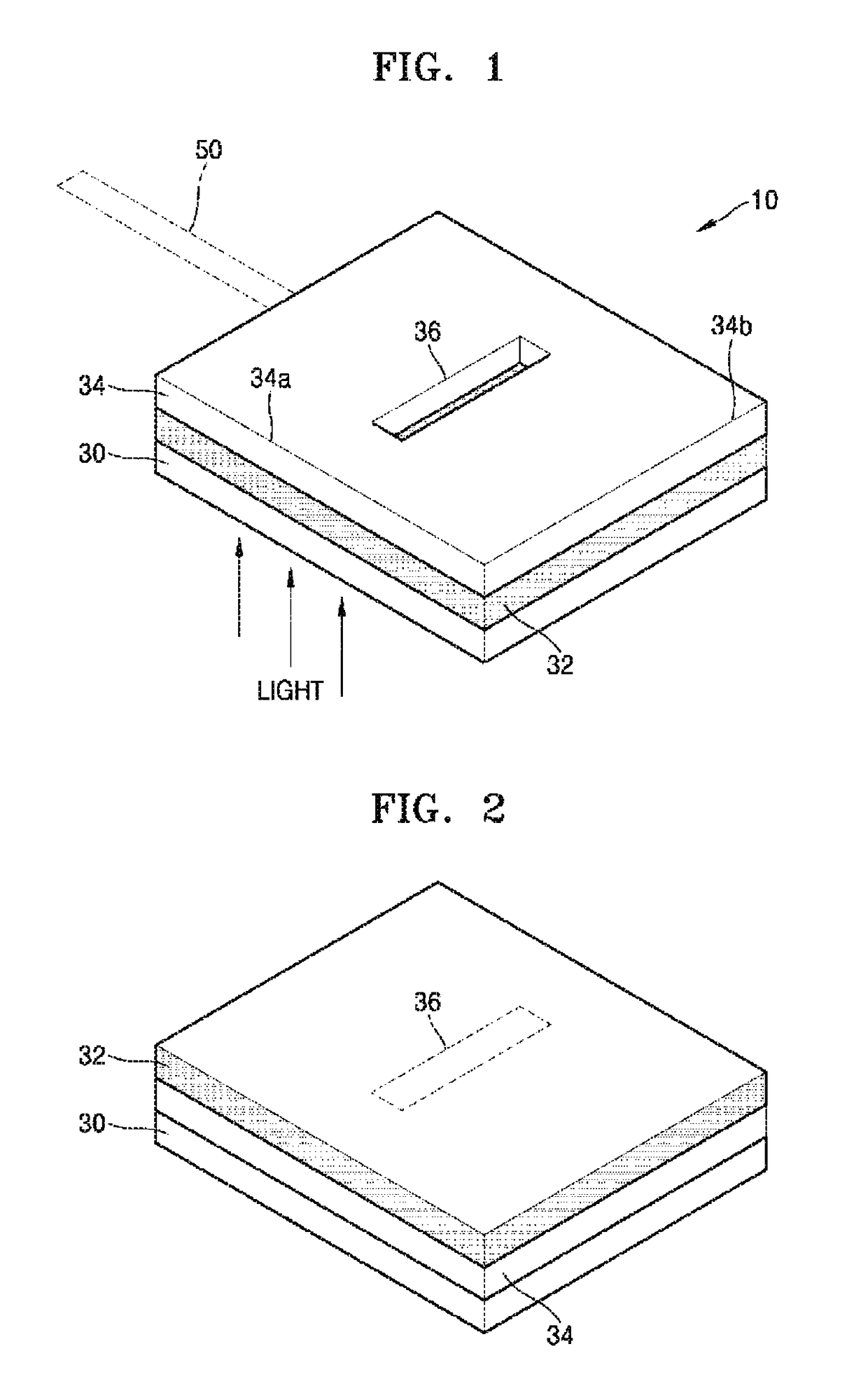

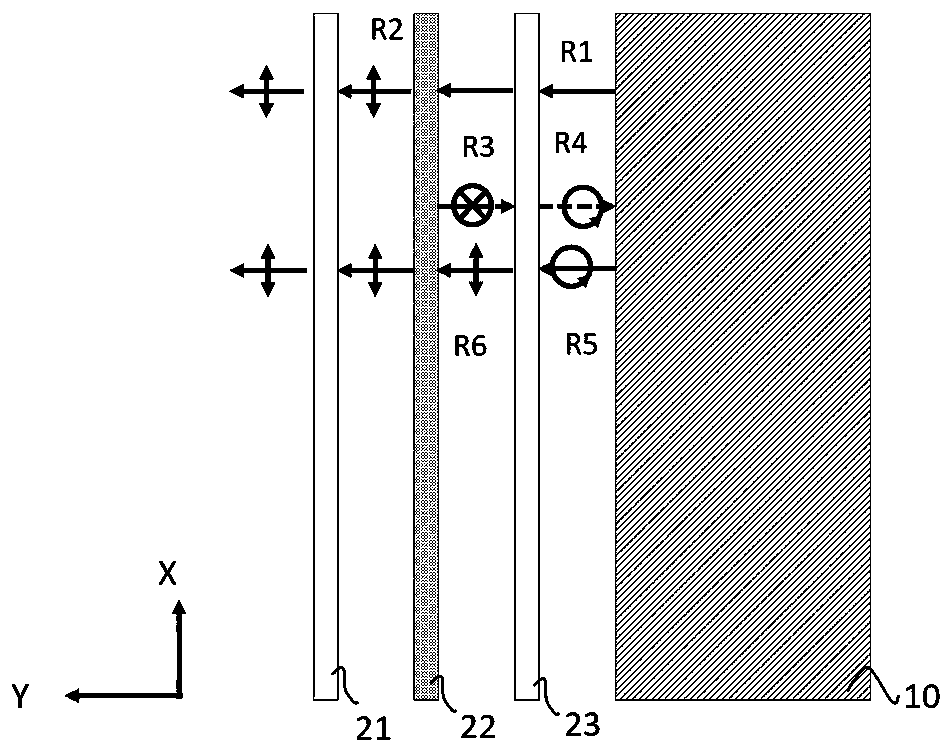

Thin film transistor (TFT) array substrate and display device

InactiveCN102629056AReduce liquid crystal alignment disorder areaIncrease opening ratioSolid-state devicesNon-linear opticsInsulation layerDisplay device

The invention discloses a thin film transistor (TFT) array substrate, which comprises grid lines and data lines, the grid lines and the data lines are formed on the substrate. The grid lines and the data lines cross to define sub-pixel units. Each sub-pixel unit comprises a thin film transistor device, a public electrode, a first pixel electrode layer and a second pixel electrode layer. The first pixel electrode layers or the second pixel electrode layers are connected with public electrodes, and the other ones are connected with source electrodes or drain electrodes of the thin film transistors, the first pixel electrode layers and the second pixel electrode layers are separated through insulation layers, and the second pixel electrode layers are arranged above the first pixel electrode layers. Images of strip pixel electrodes of the second pixel electrode layers are overlapped with images of the first pixel electrode layers, an inclined angle is arranged between the strip pixel electrodes and liquid crystal initial orientation, and the grid lines are parallel to the strip pixel electrodes close to the grid lines or the data lines are parallel to the strip pixel electrodes close to the data lines. The TFT array substrate and the display device guarantee that a liquid crystal orientation chaos phenomenon caused by effects of disorder electric fields at a pixel edge can not occur.

Owner:BOE TECH GRP CO LTD +1

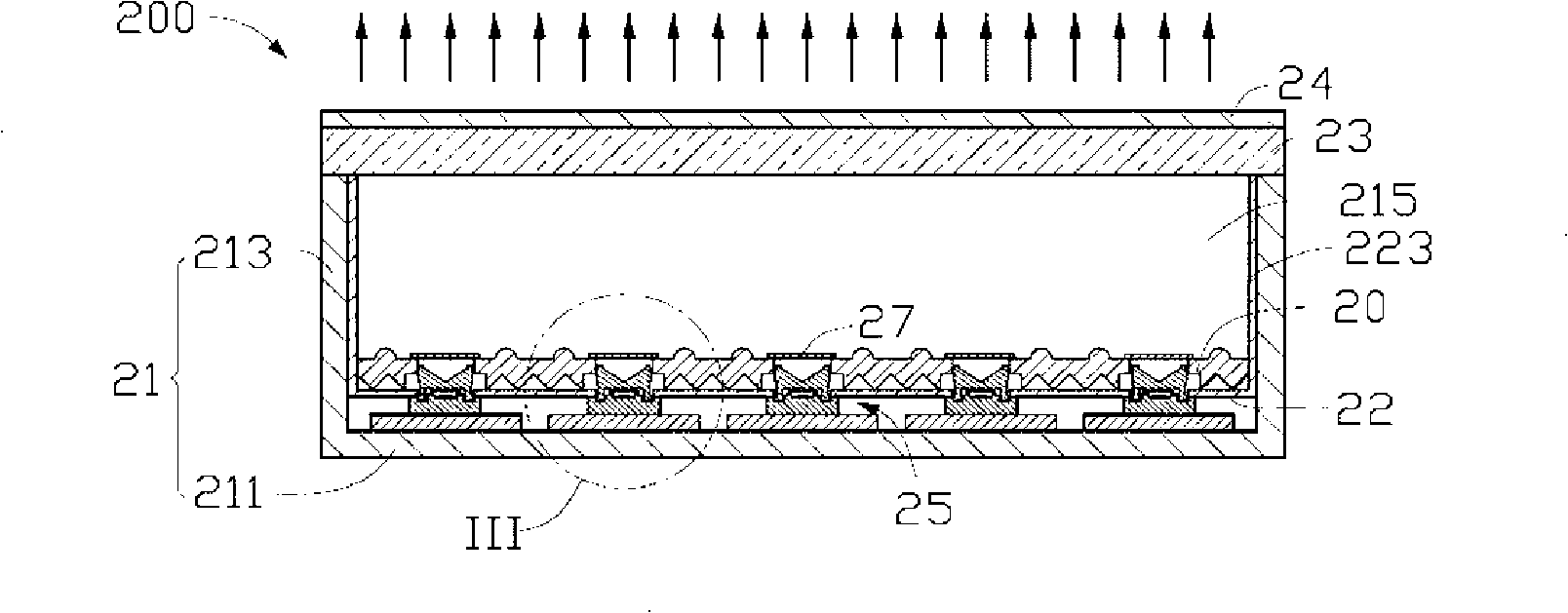

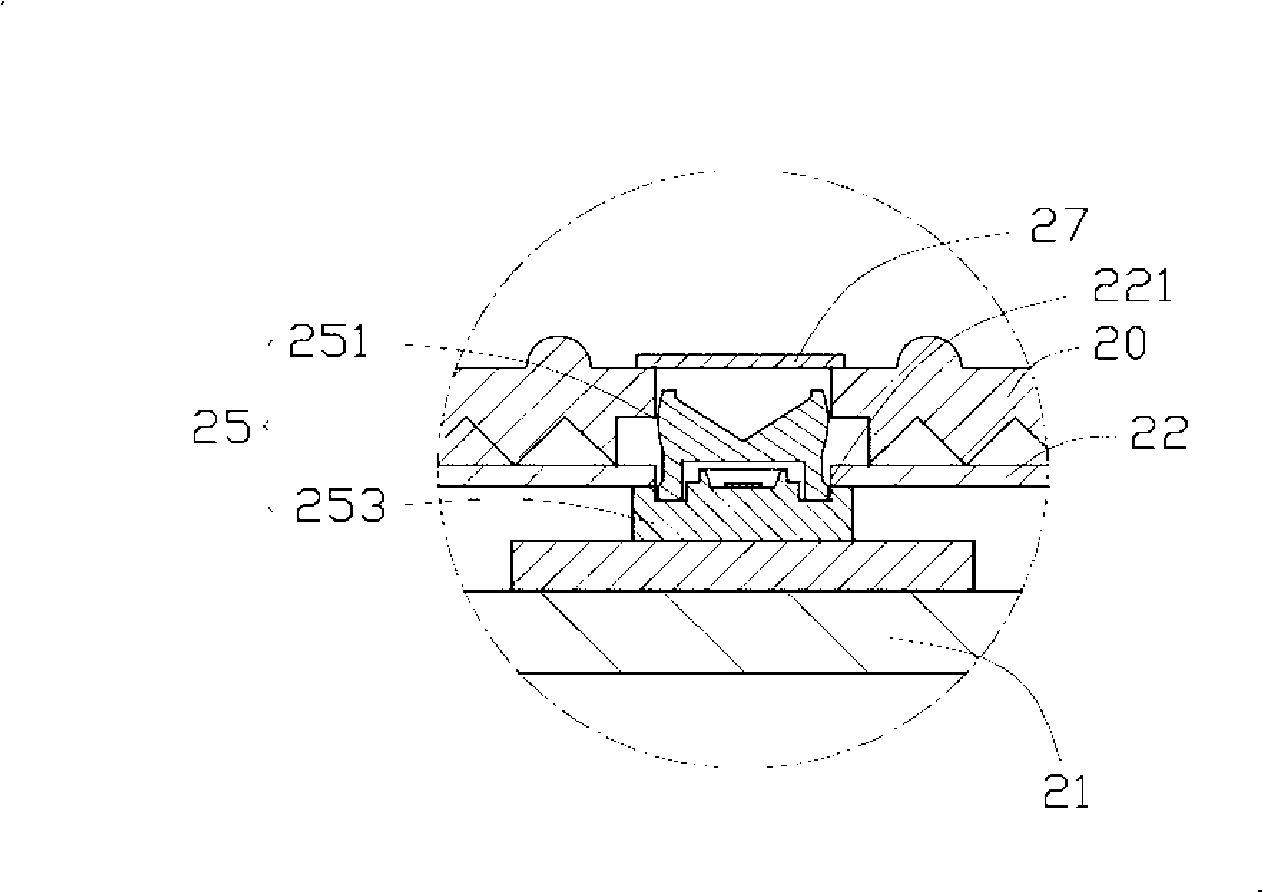

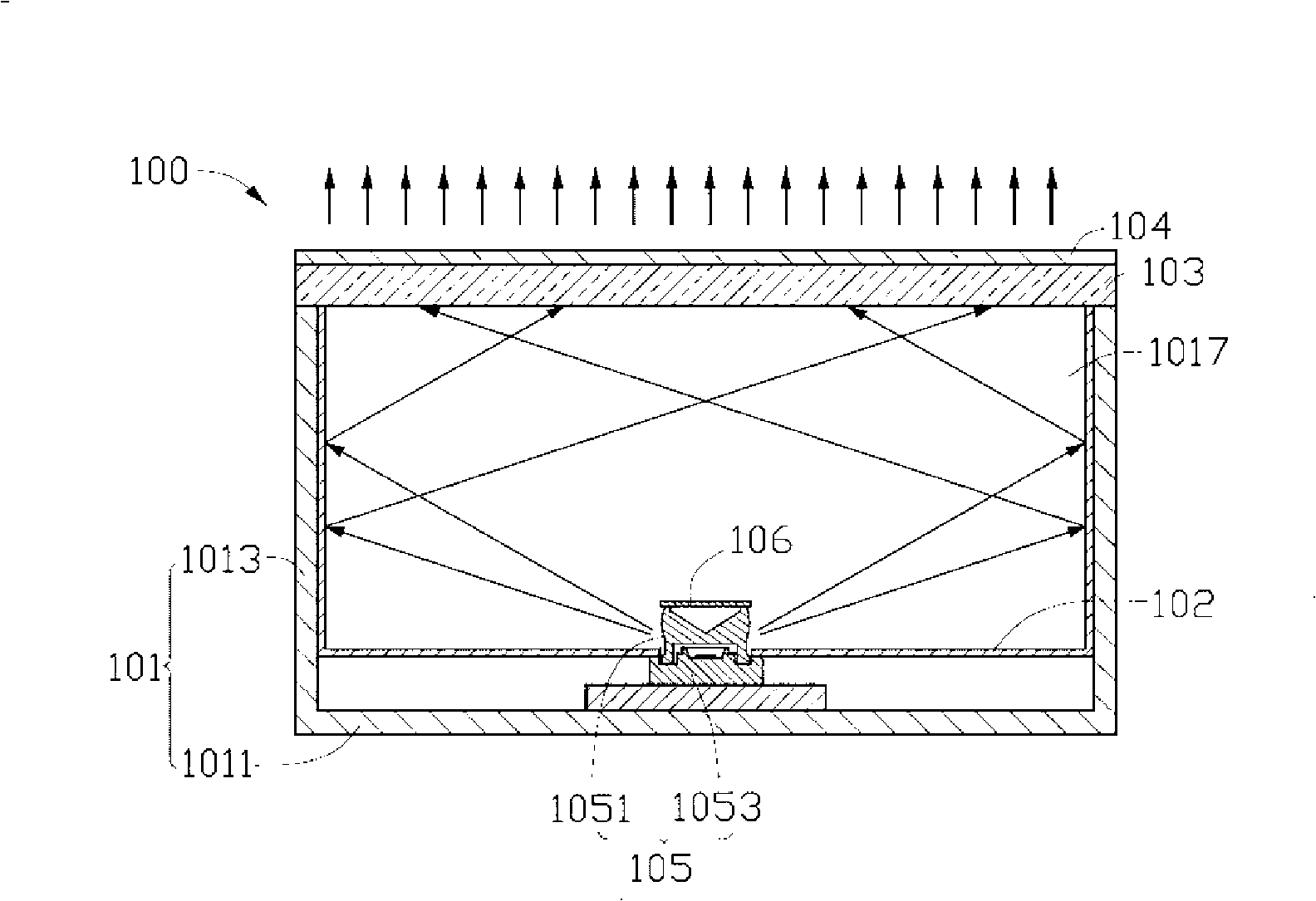

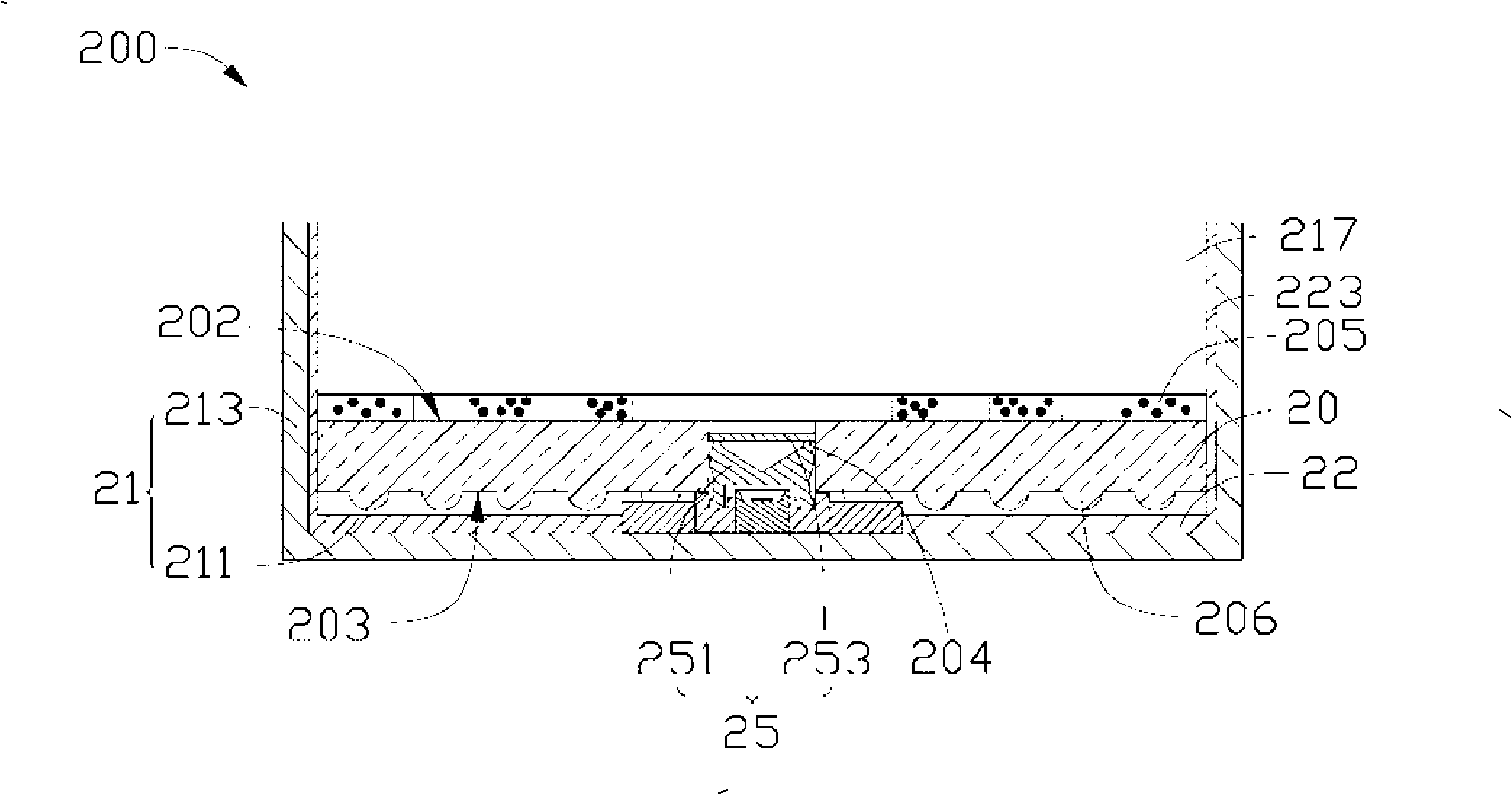

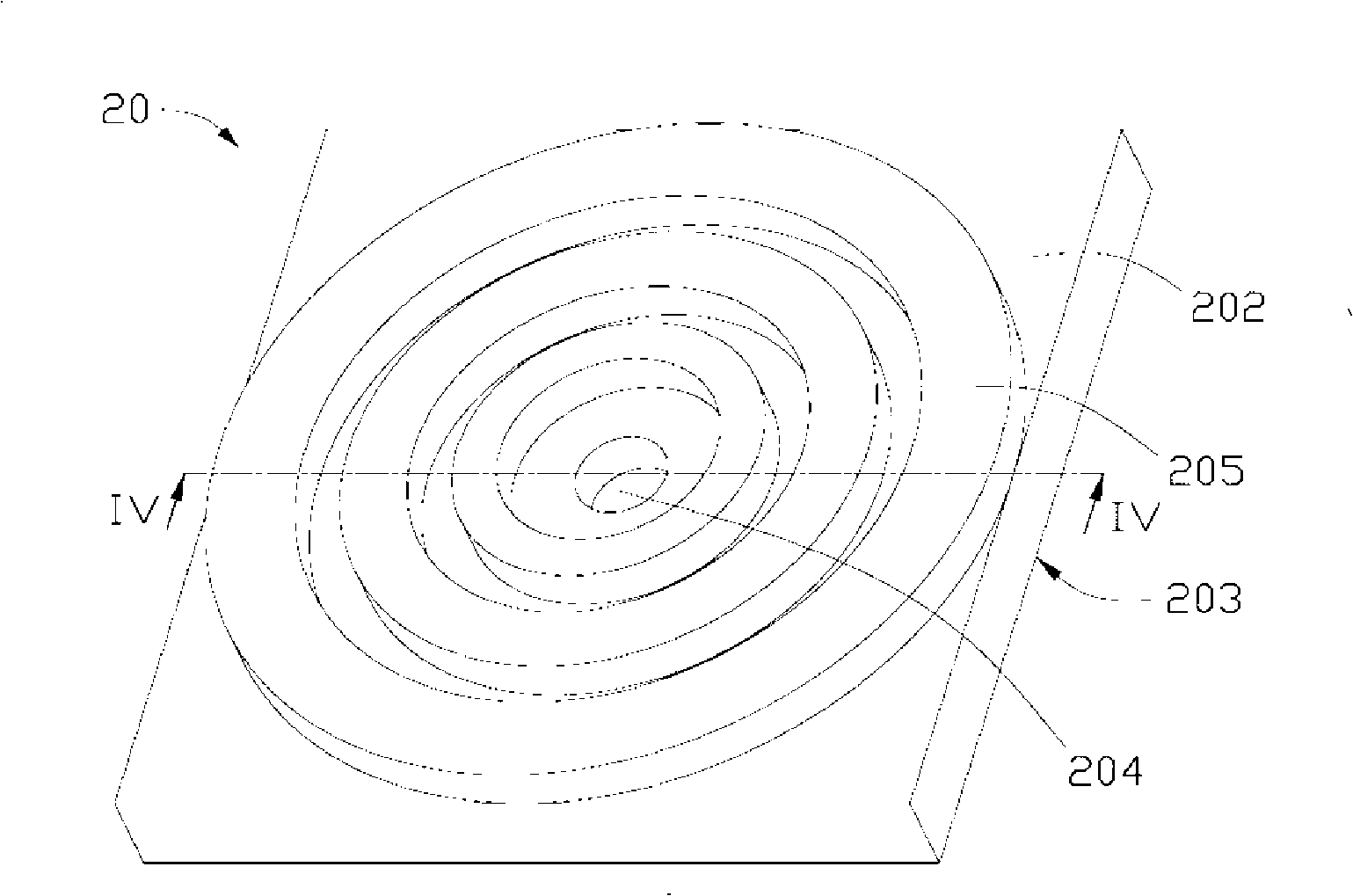

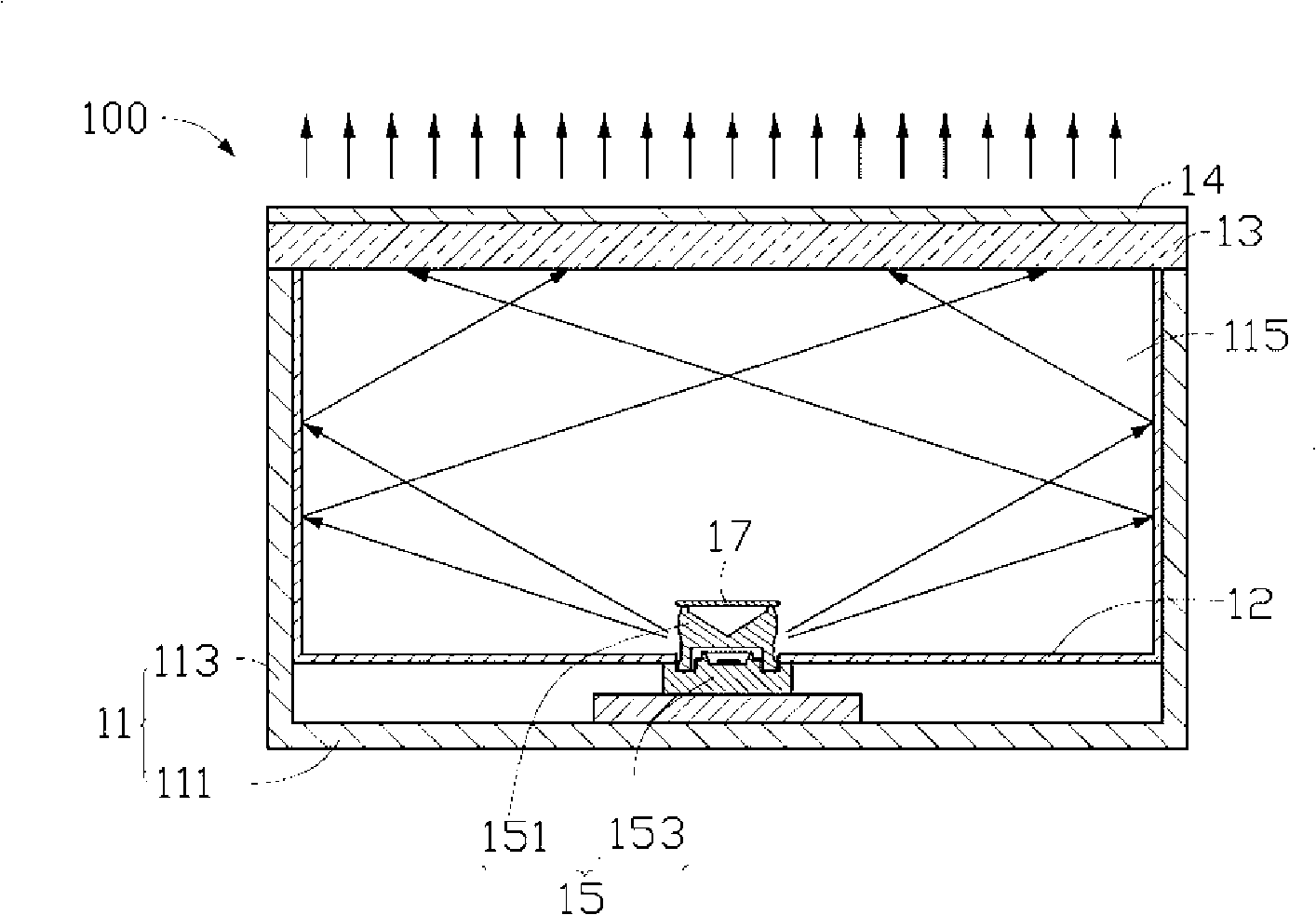

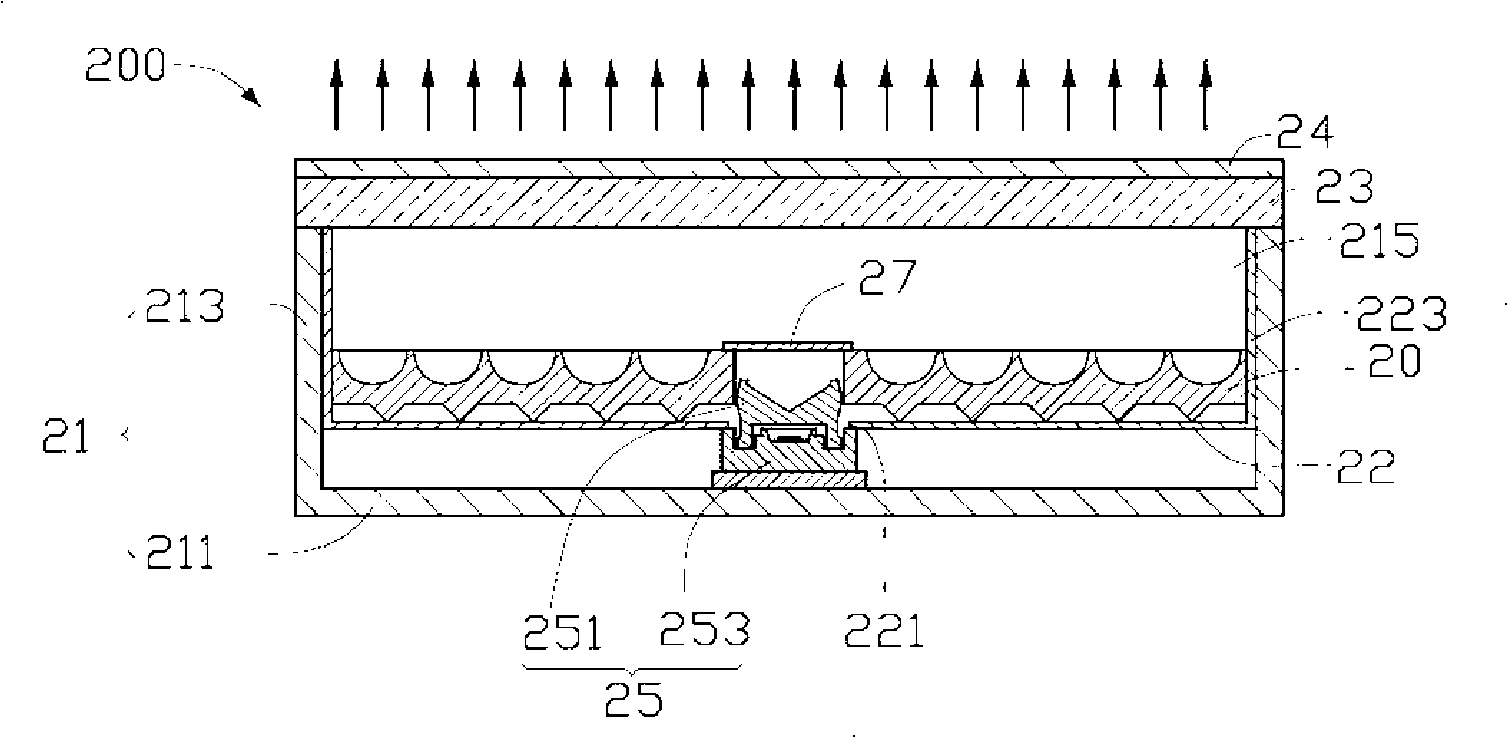

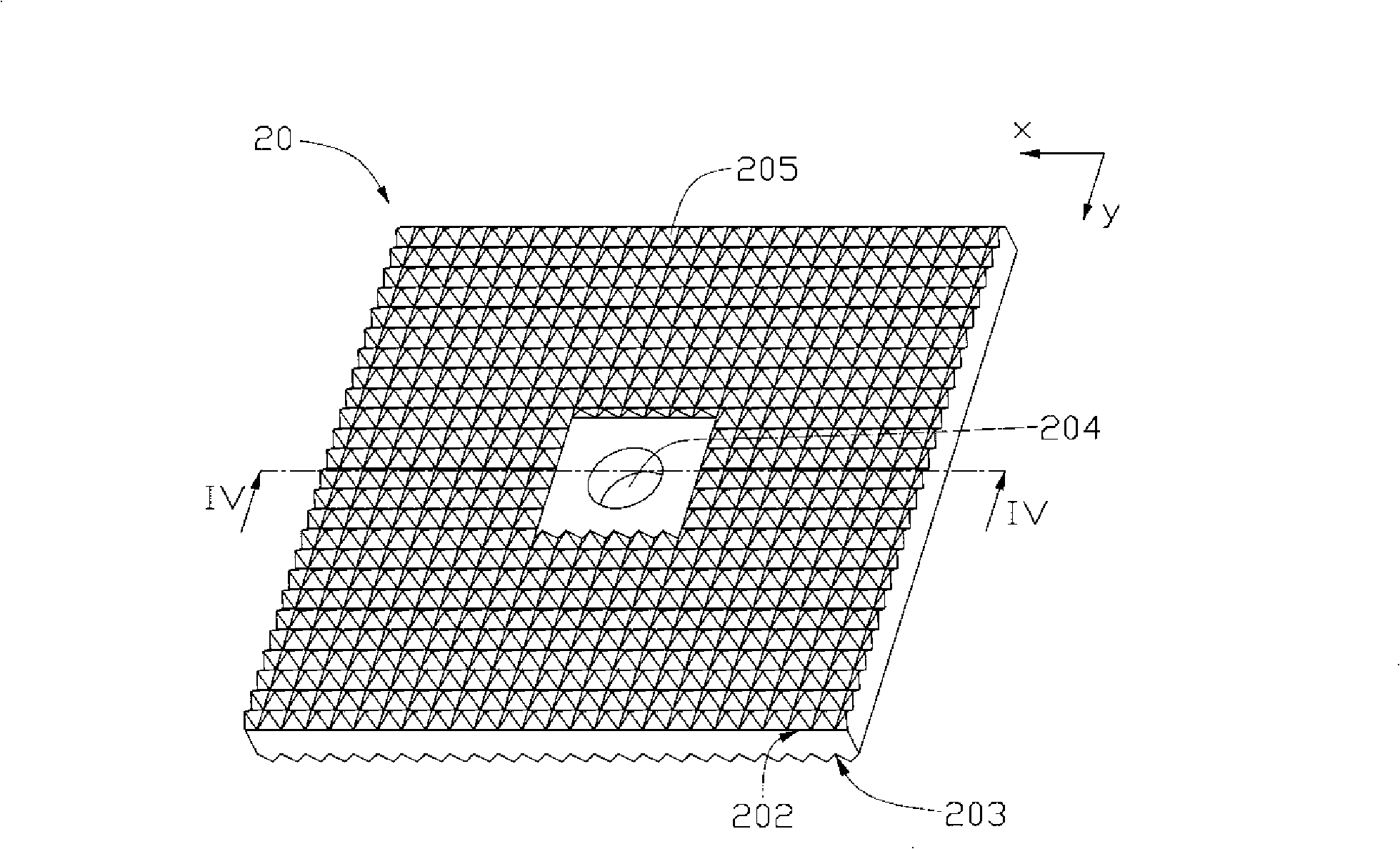

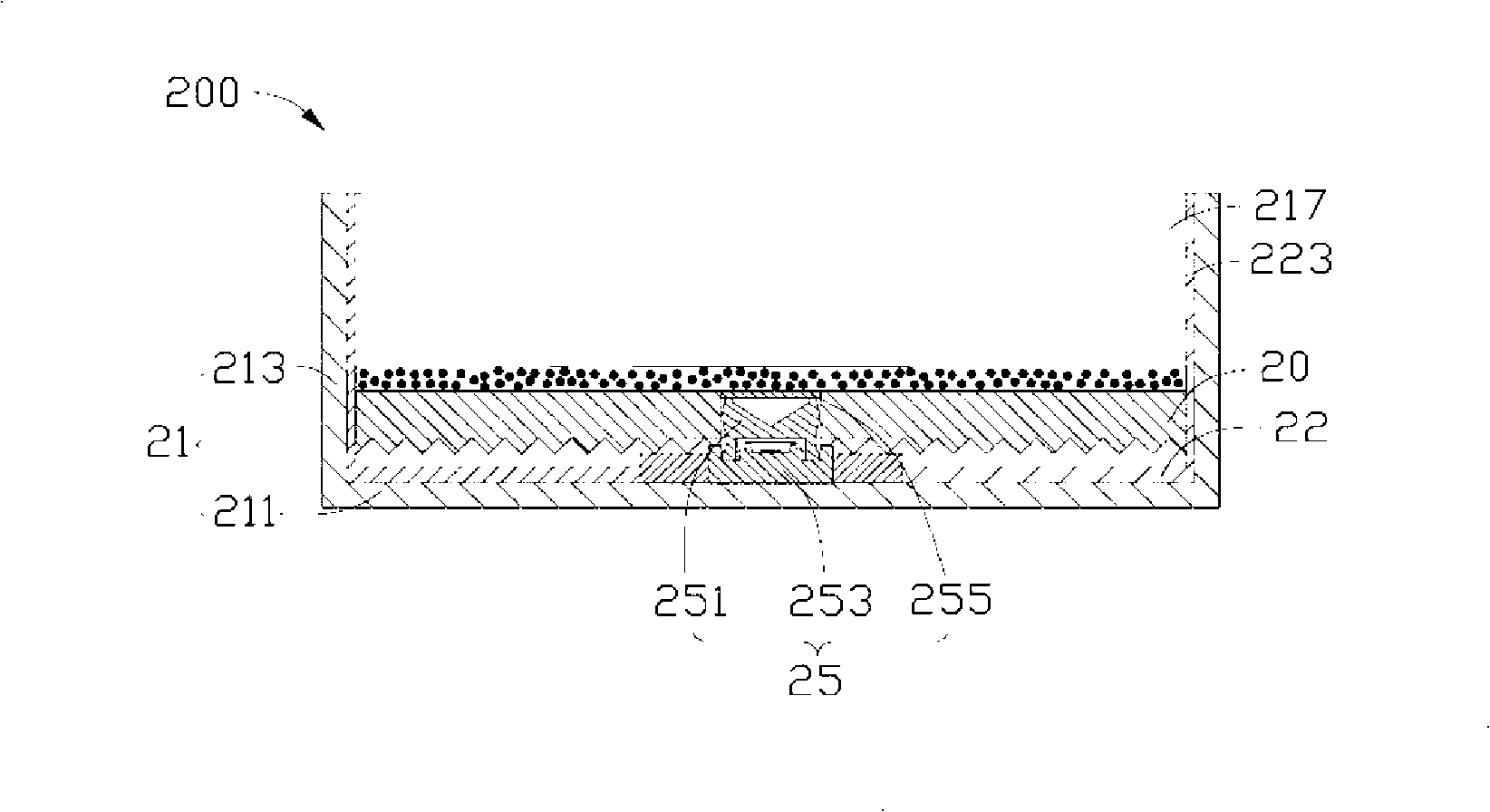

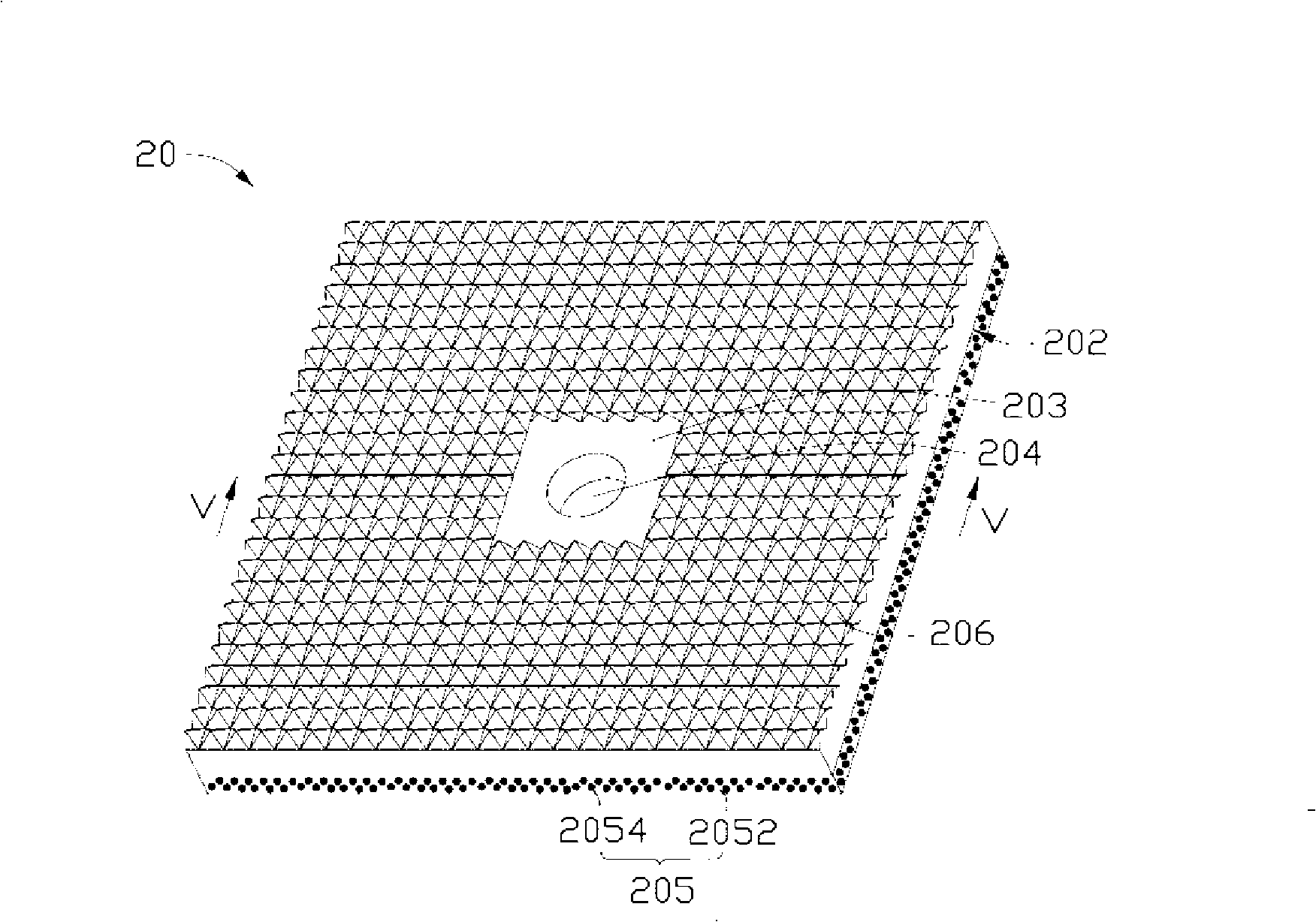

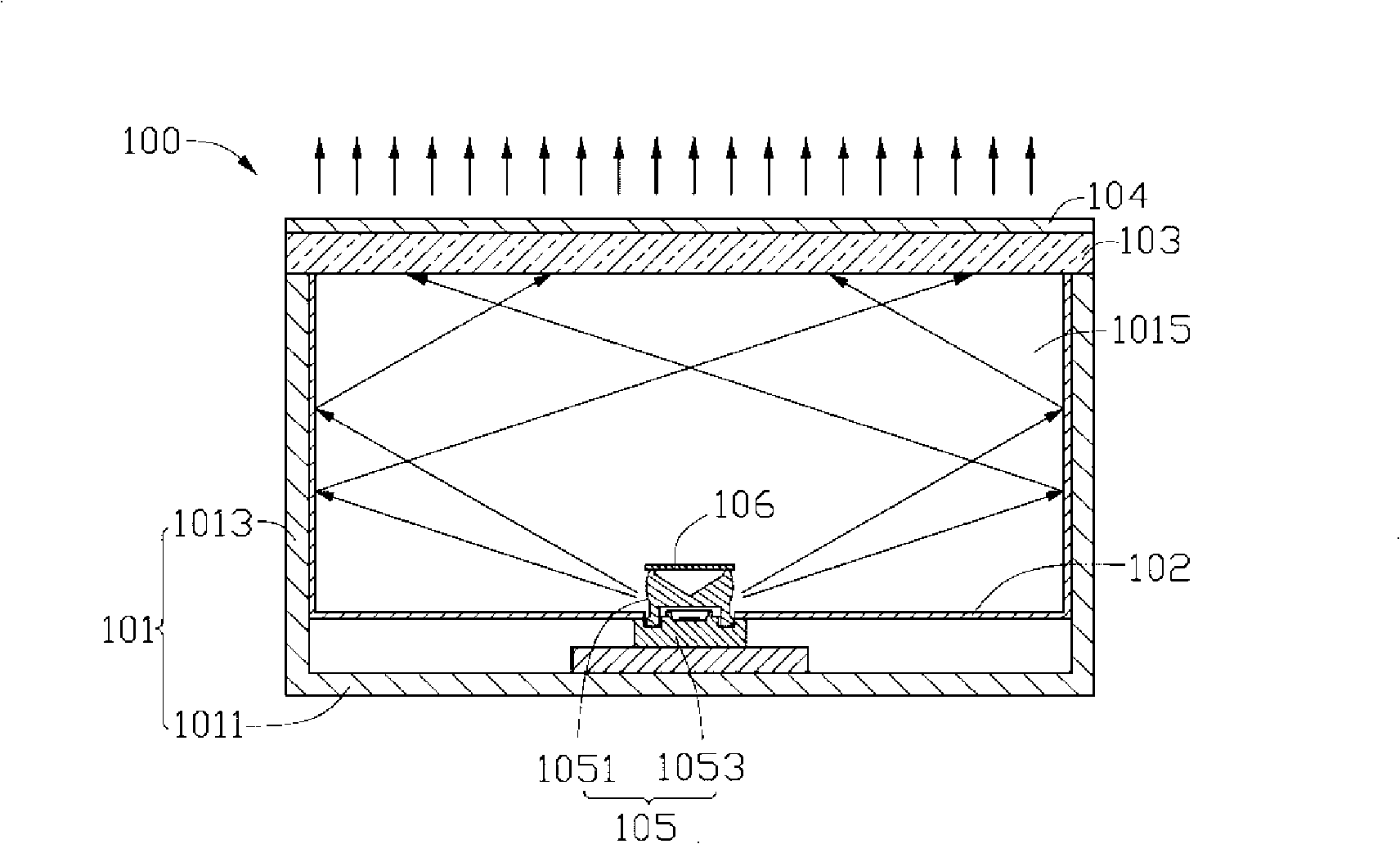

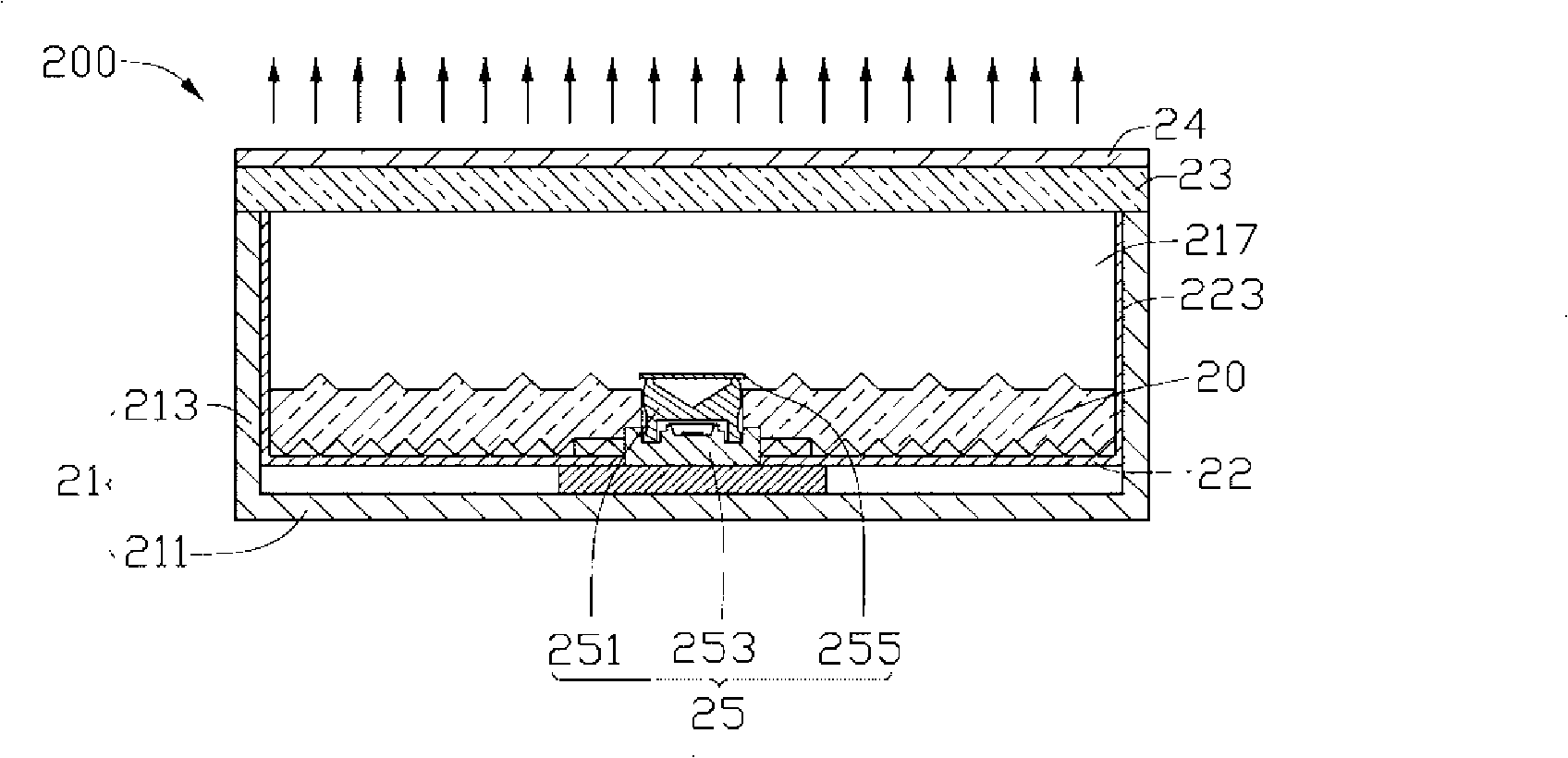

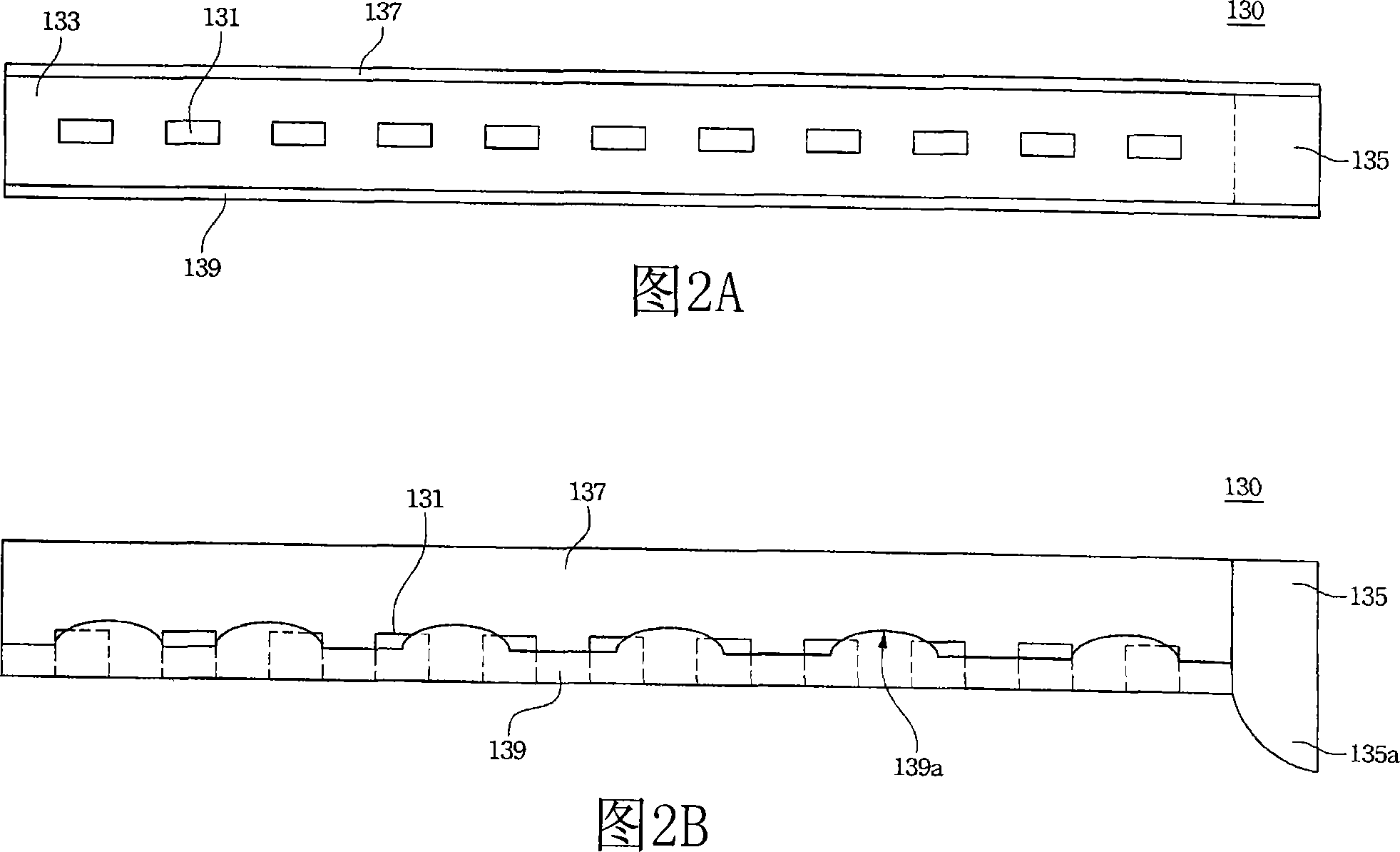

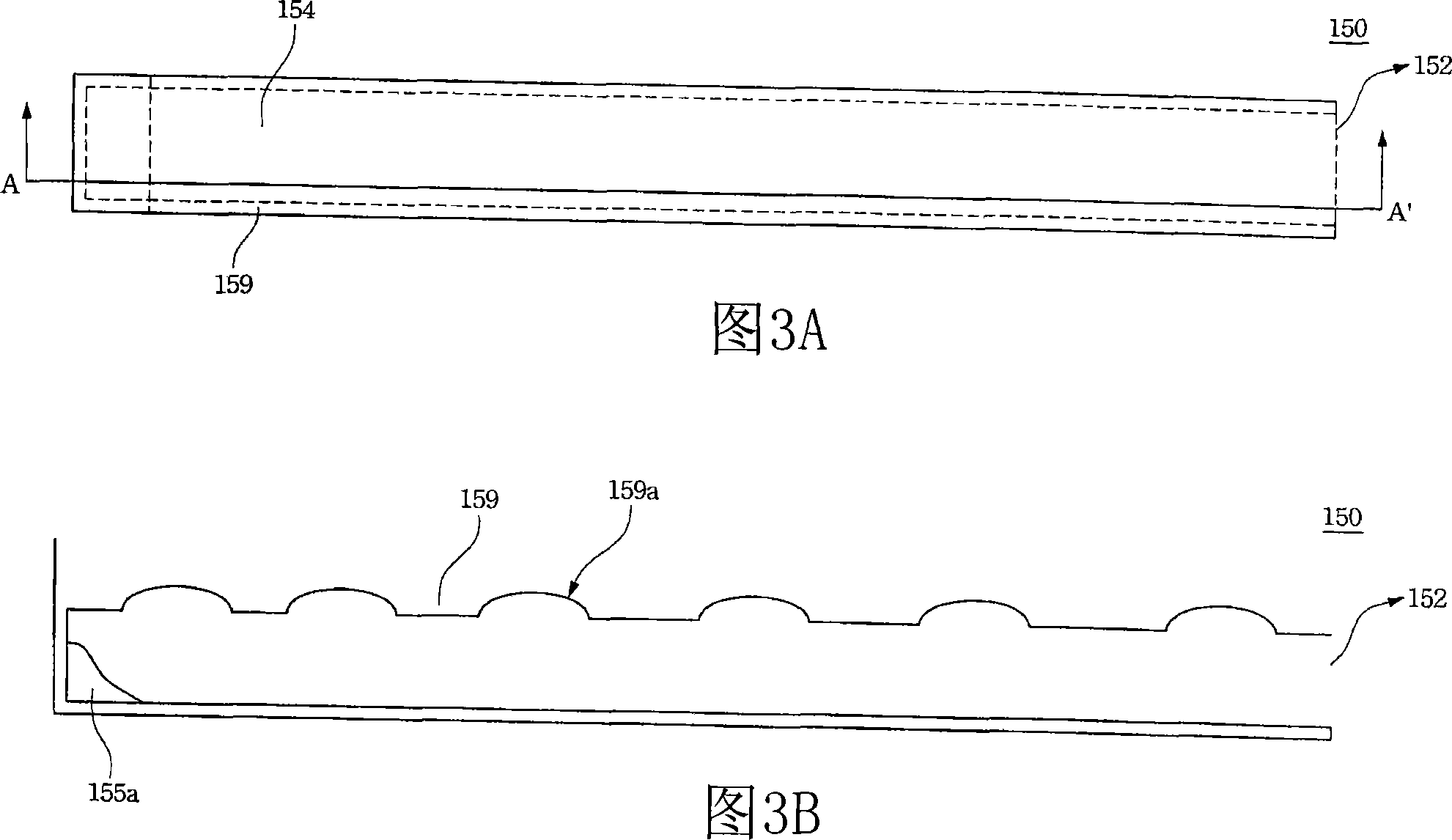

Back light module and optical plate

InactiveCN101295037AImprove optical utilizationReduce thicknessOptical light guidesNon-linear opticsEngineeringLight emission

The invention relates to an optical plate which comprises at least one optical plate unit including a first surface and a second surface opposite to the first surface. A plurality of V-shaped strip bulges are formed on the first surface. A plurality of spherical bulges are formed on the second surface, and at least one of the first surface and the second surface is provided with a light source containing part. The invention also provides a backlight module which adopts the optical plate, and the backlight module has the advantage of even light emission.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

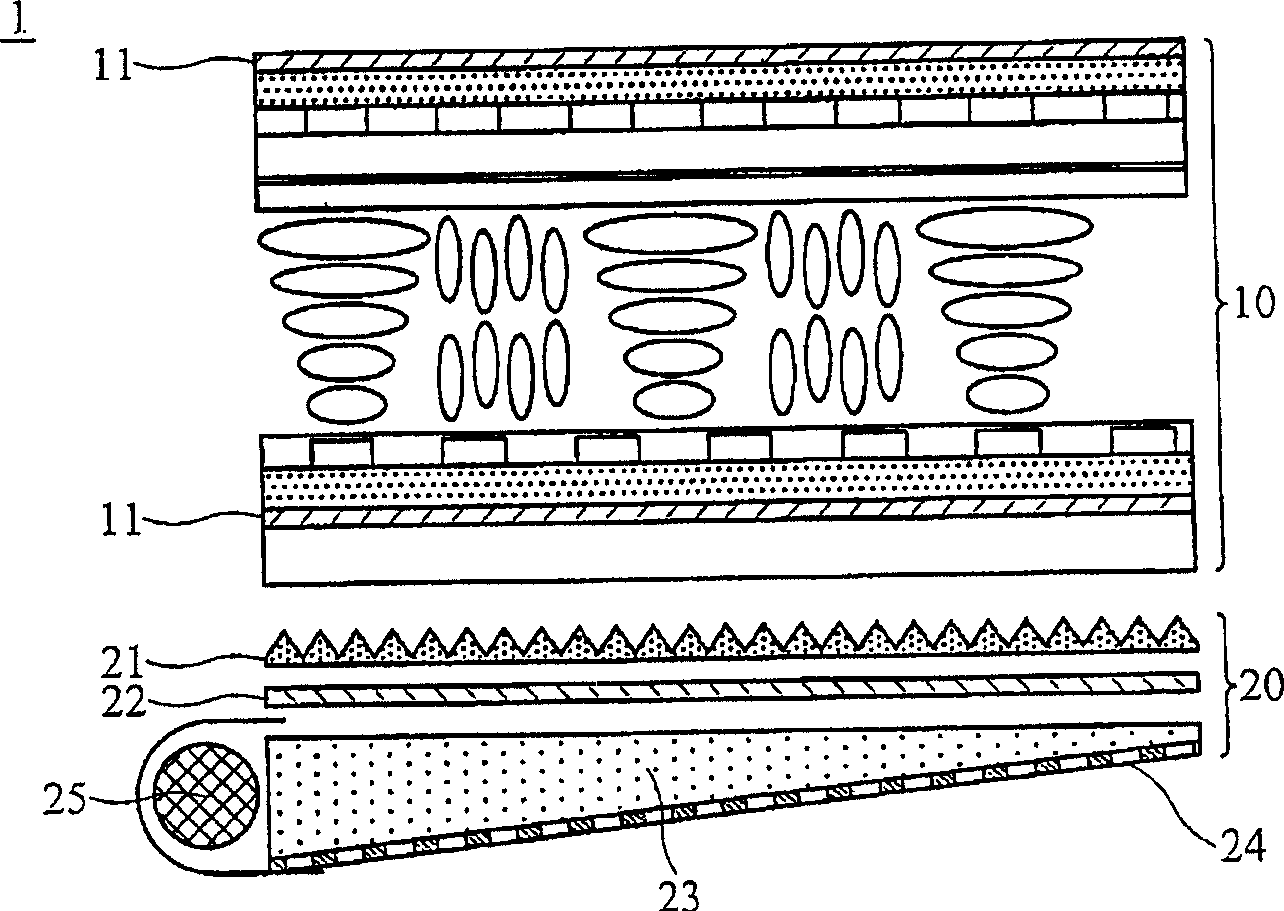

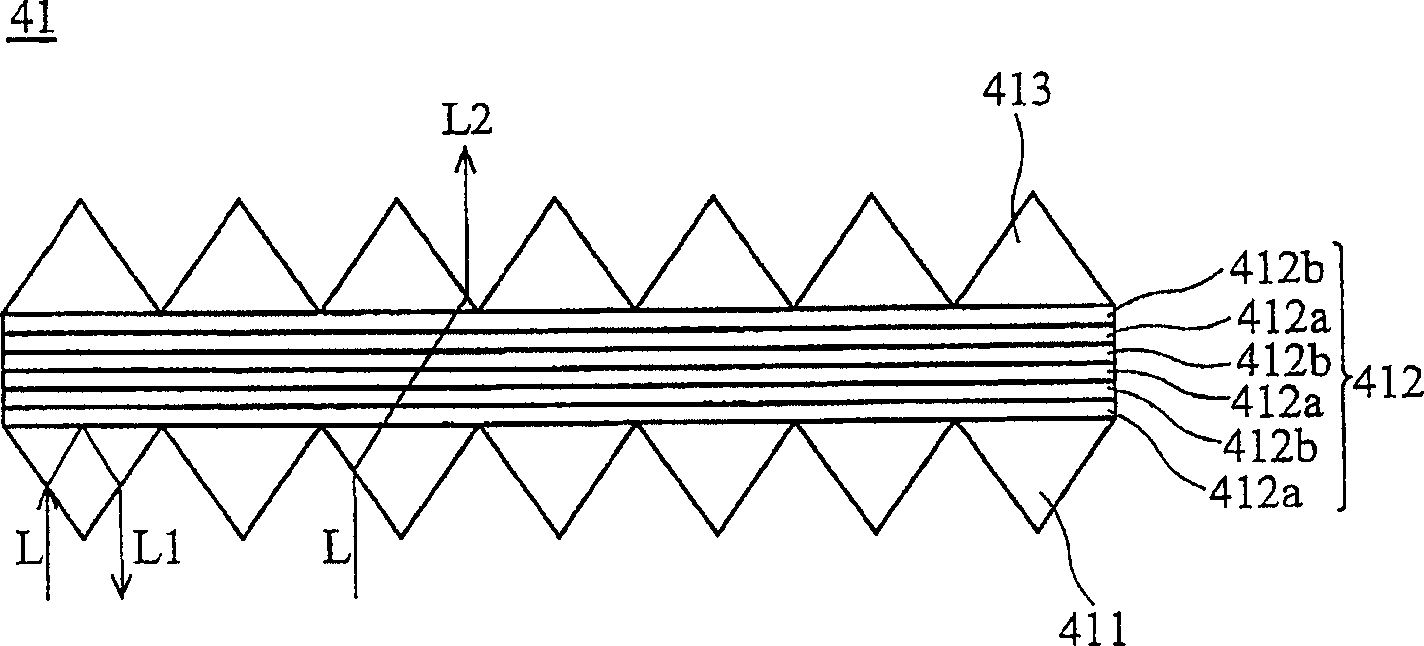

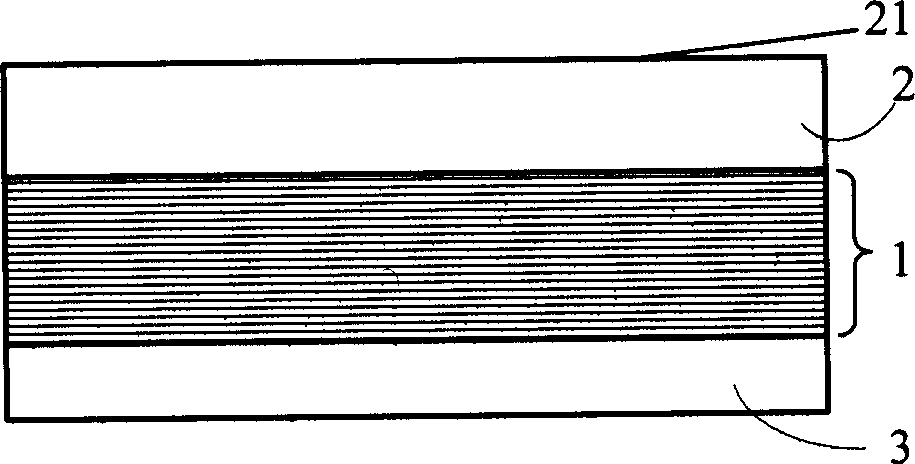

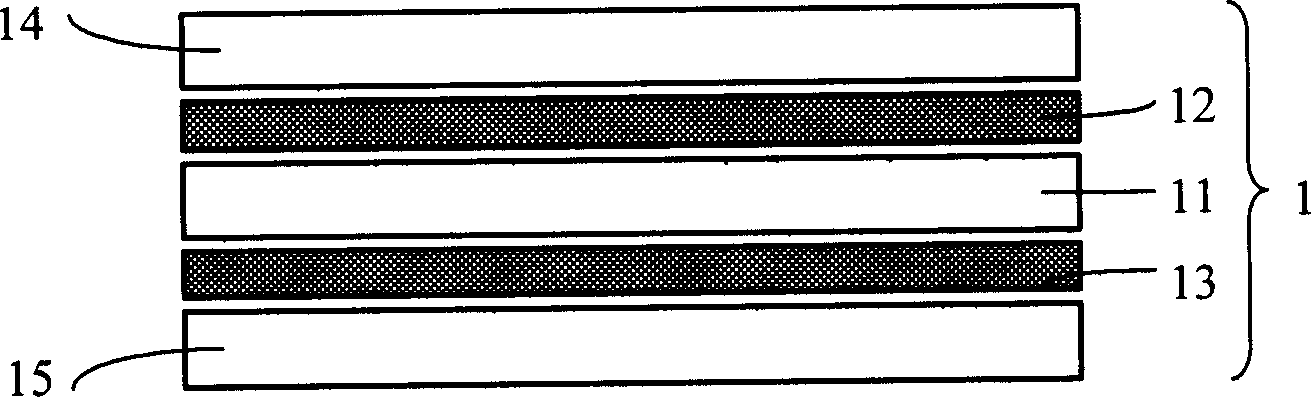

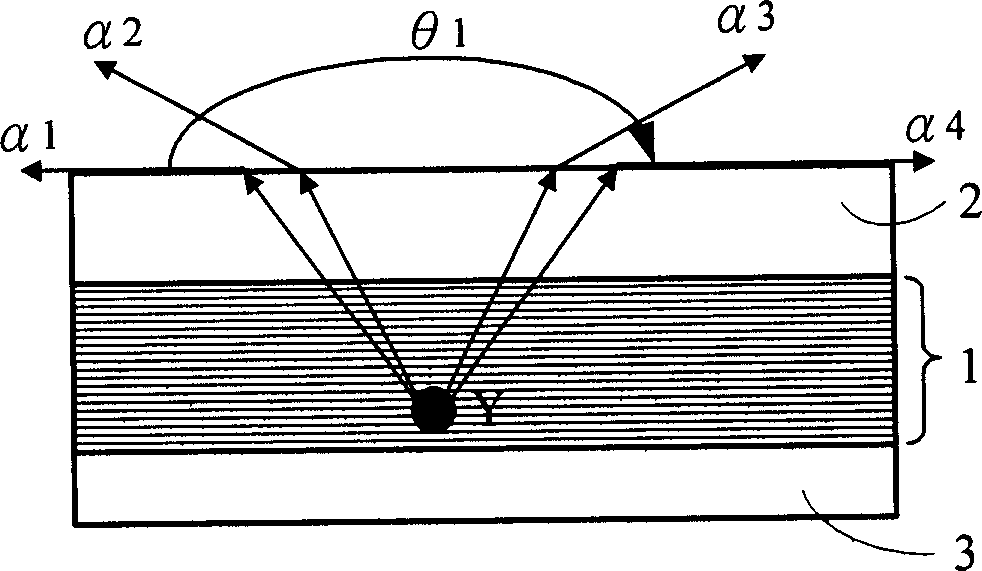

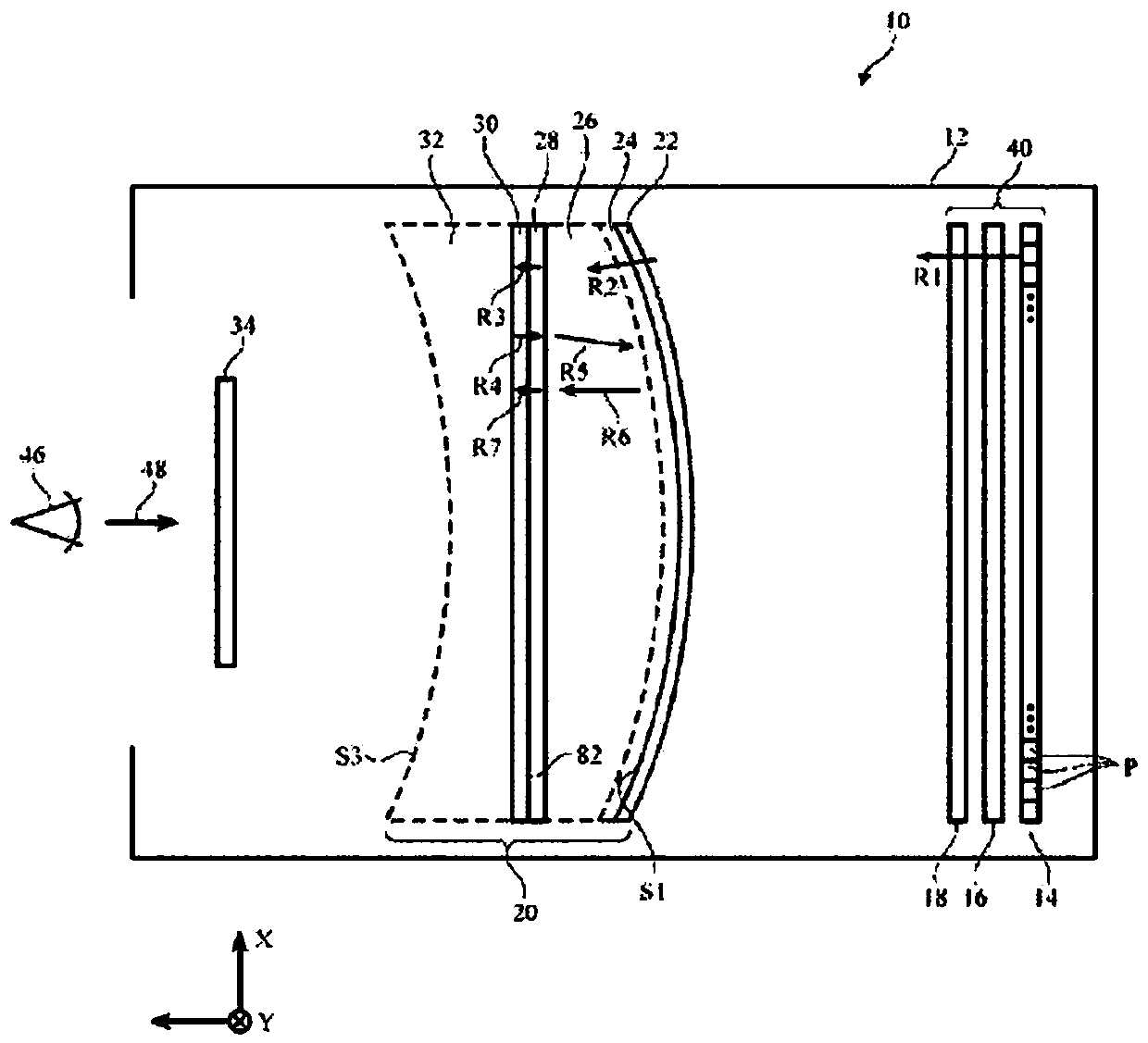

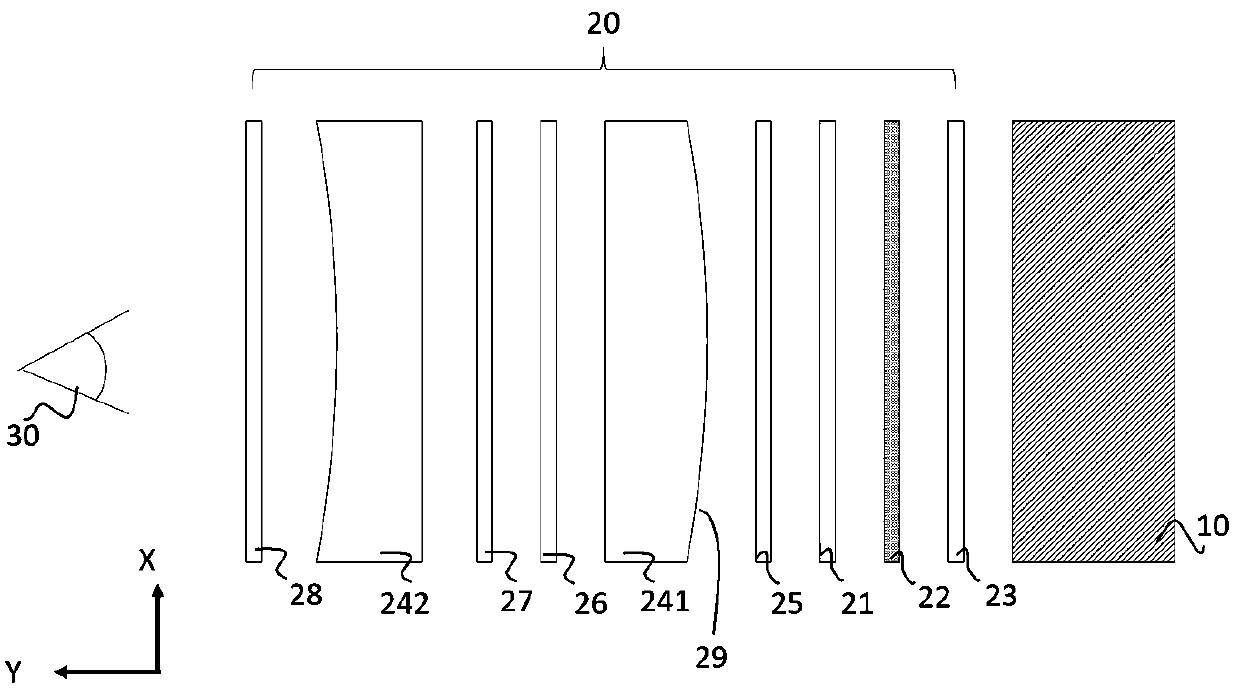

LCD modular and polarized optical brightening membrane

ActiveCN1601347AImprove optical utilizationPrismsPolarising elementsLiquid-crystal displayRefractive index

The invention relates to a liquid crystal display module and its polarized optical brightening film, in which the polarized optical brightening film includes a first prism, a thin-film and a second prism. Said thin-film is placed on first prism, and has at least a first refraction layer and at least a second refraction layer, the first refraction layer is different from second refraction layer in index of refraction, and the thickness of every first refraction layer and every second refraction layer is lambda o / 4n, and the light source which is incident from first pirsm can be divided into S polarized light and P polarized light, the S polarized light can be reflected to first pirsm by means of thin-film so as to prevent said S polarized light from being absorbed by polaroid, the second prism is placed on the thin-film, and the P polarized light can be transmitted through the thin- film and income to second prism,

Owner:AU OPTRONICS CORP

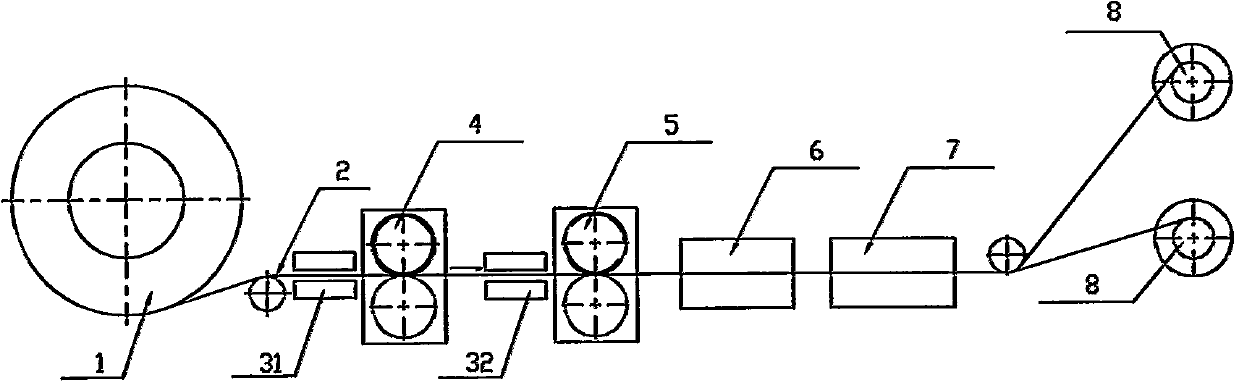

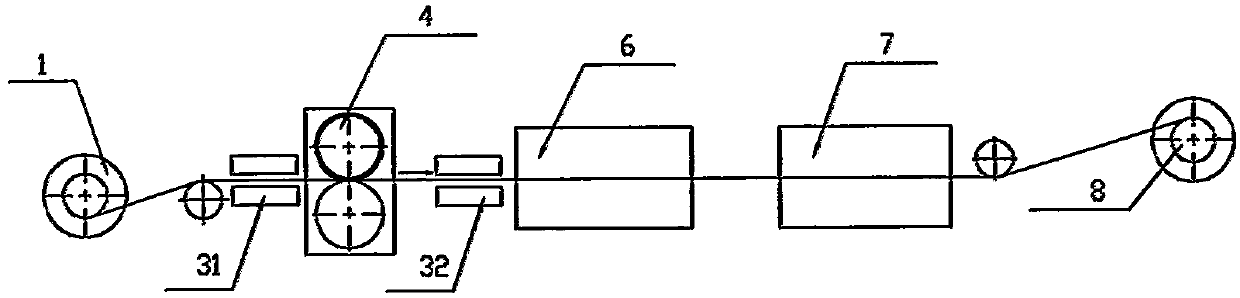

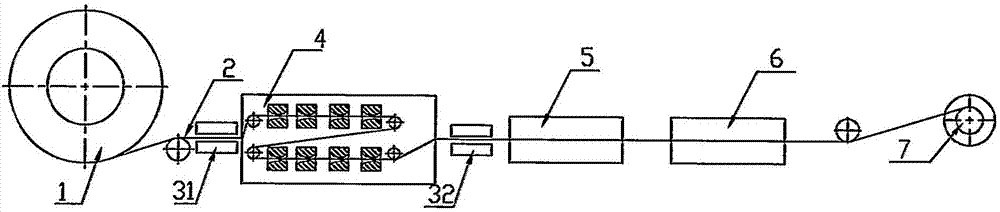

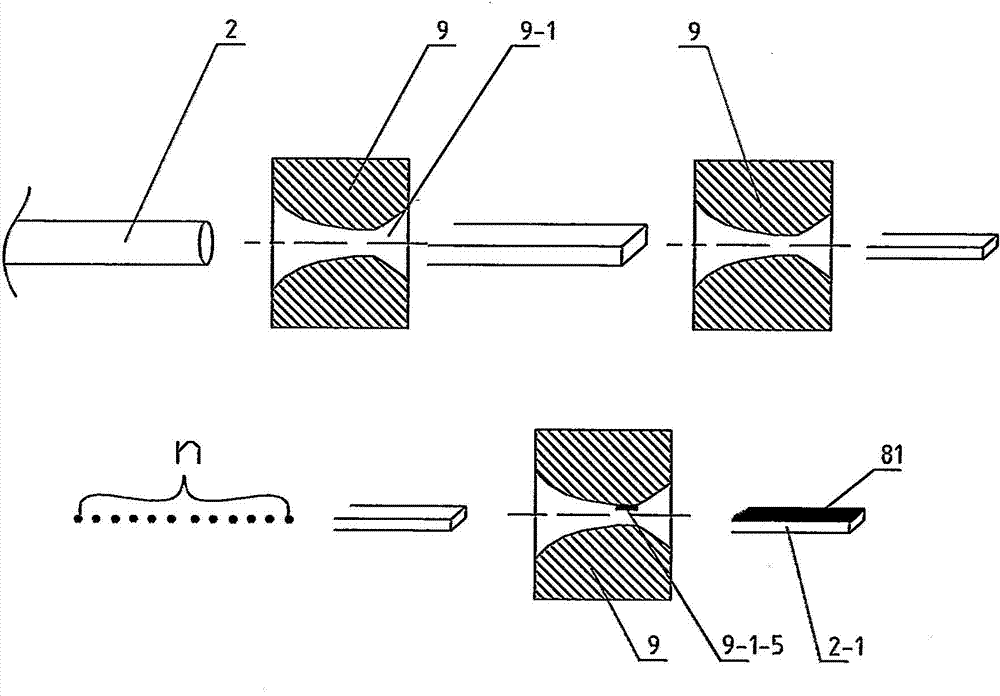

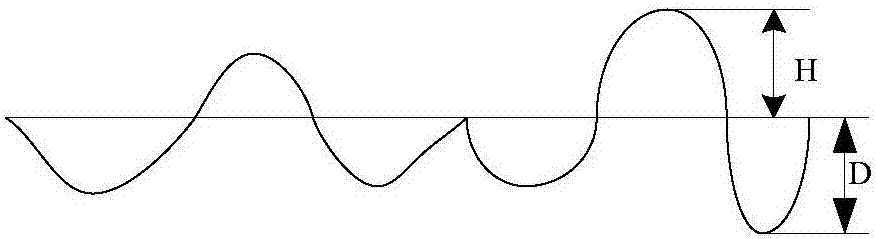

Method for manufacturing photovoltaic solder strip

InactiveCN103341703AIncrease productivityLower yield strengthWelding/cutting media/materialsSoldering mediaMicrometerWork in process

The invention discloses a method for manufacturing a photovoltaic solder strip. The method for manufacturing the photovoltaic solder strip includes the flowing steps: a, embossing a raw material, namely a copper strip, with a metal embossing process, forming a reflective groove structure on the surface of the copper strip, obtaining a first semi-finished product, b, conducting an annealing treatment on the first semi-finished product with an annealing process, forming a second semi-finished product, c, selecting proper coated metal, conducting electroplating on the second semi-finished product with an electroplating process, controlling the plating thickness and making the plating thickness to be ranged from 1 micrometer to 30 micrometers, and obtaining the needed photovoltaic solder strip. By means of the photovoltaic solder strip manufactured through the above method, the optical use ratio of a solar cell module can be improved, the manufacturing cost of the photovoltaic solder strip is reduced, the work efficiency of the photovoltaic solder strip is improved, and industrialized production is achieved.

Owner:TRINA SOLAR CO LTD

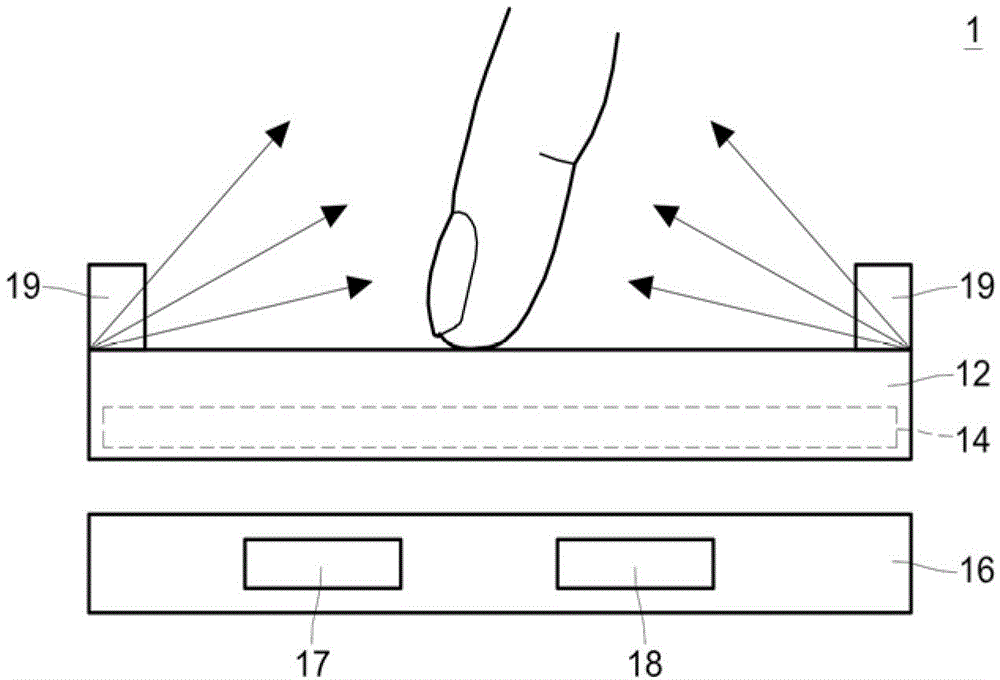

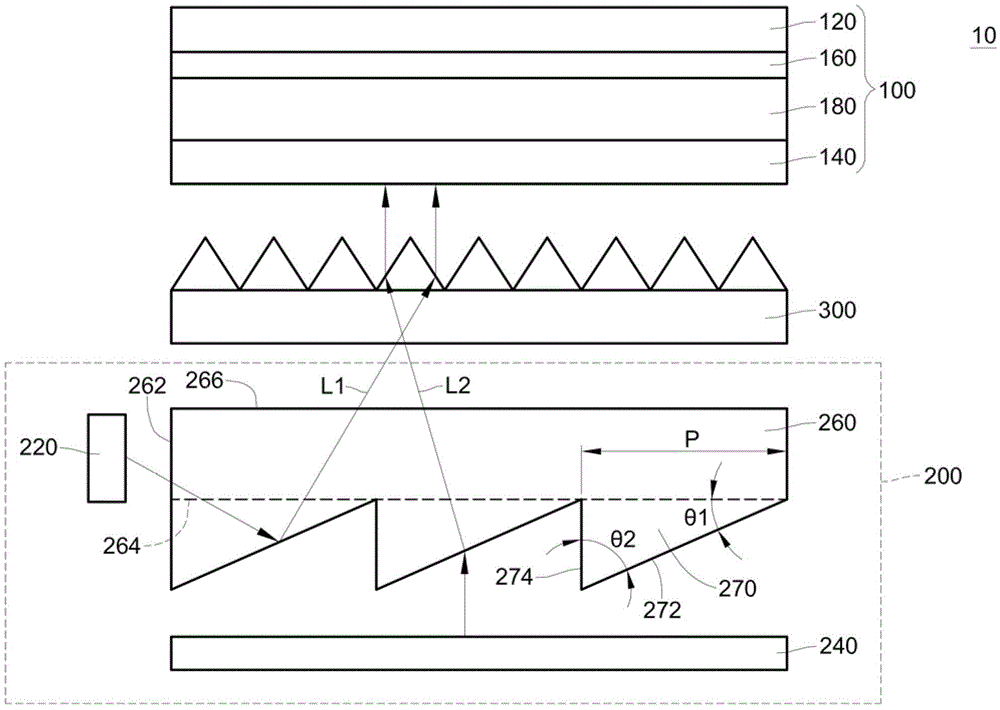

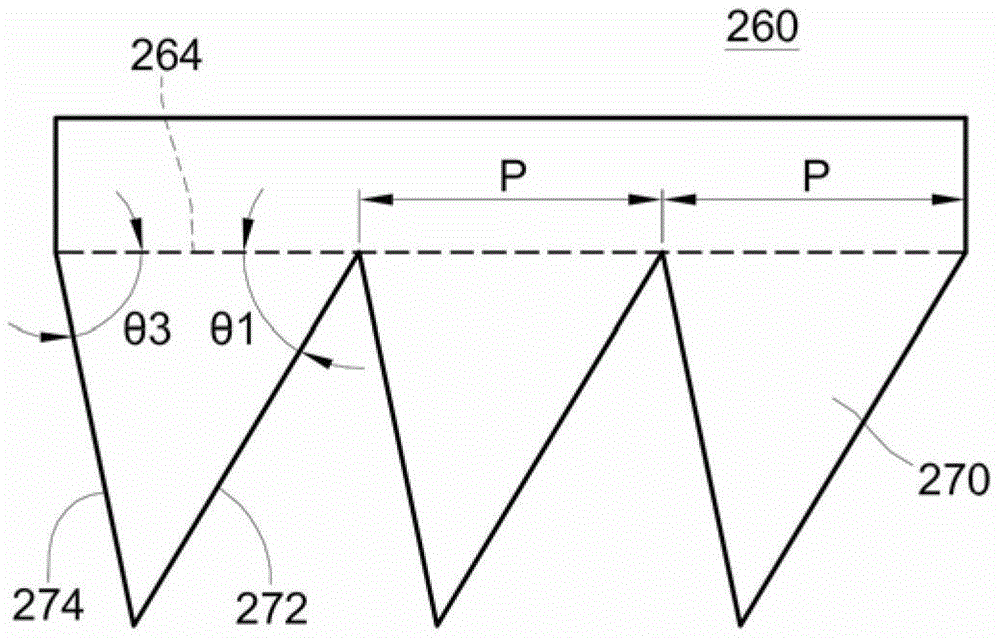

Touch control display device

InactiveCN103150062AGood collimationWiden perspectiveInput/output processes for data processingLight guideDisplay device

The invention relates to a touch control display device comprising a display module, a backlight module and a prismatic lens. The display module comprises a touch control sensing layer. The backlight module comprises a first light source, a second light source and a light guide plate. The first light source has a first wavelength and the second light source has a second wavelength which is less than the first wavelength. The light guide plate comprises a first incident light surface, a second incident light surface and an emergent light surface. The second incident light surface faces the emergent light surface and the first incident light surface is connected with the second incident light surface and the emergent light surface. The first light source is disposed on the first incident light surface and the second light source is disposed on the second incident light surface. The prismatic lens is disposed between the display module and the backlight module. According to the invention, the sensitivity of touch control is improved.

Owner:AU OPTRONICS CORP

Organic luminescent display

InactiveCN1791291AImprove optical utilizationReduce exit angleElectrical apparatusElectroluminescent light sourcesDisplay devicePrism

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

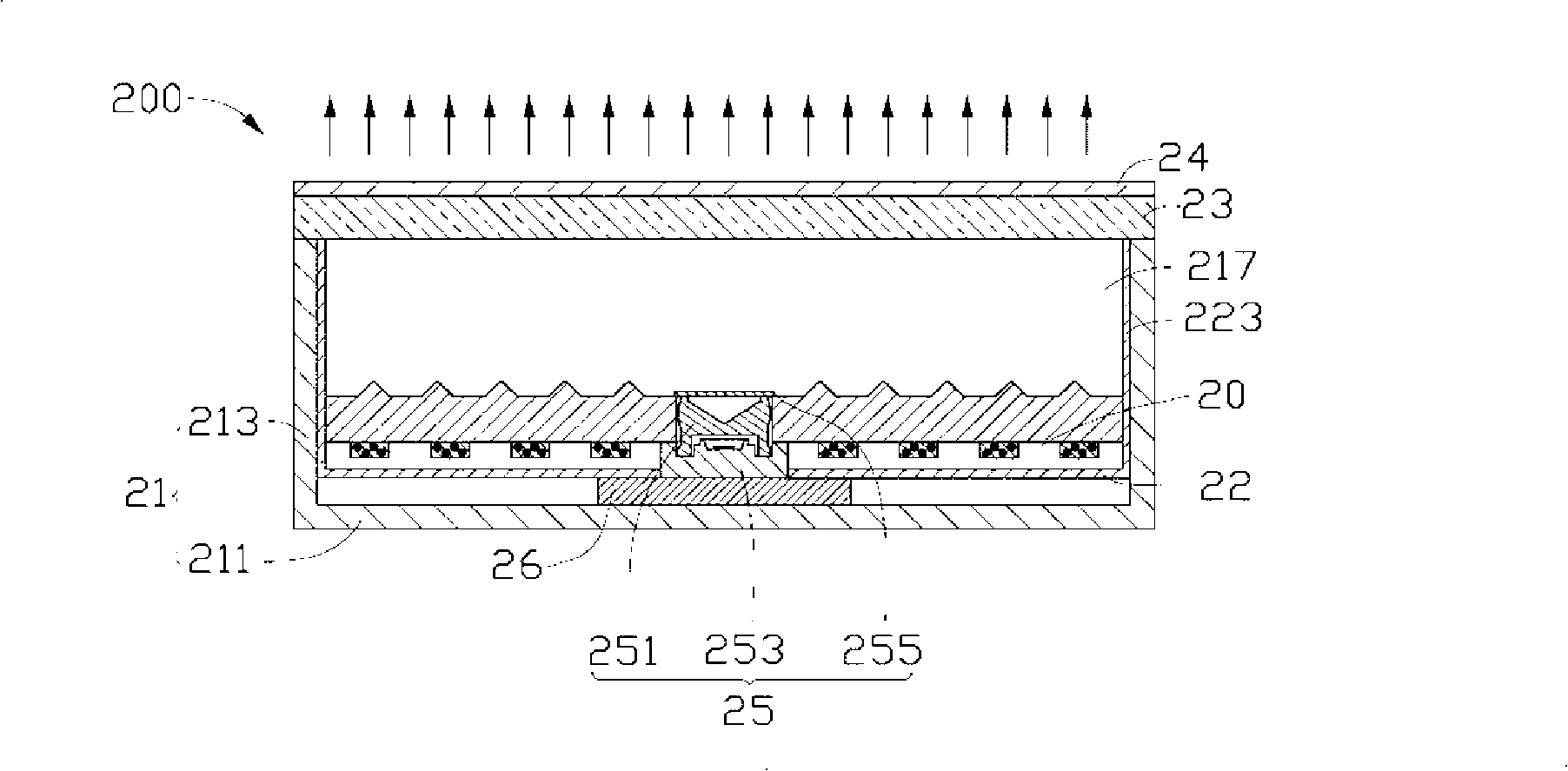

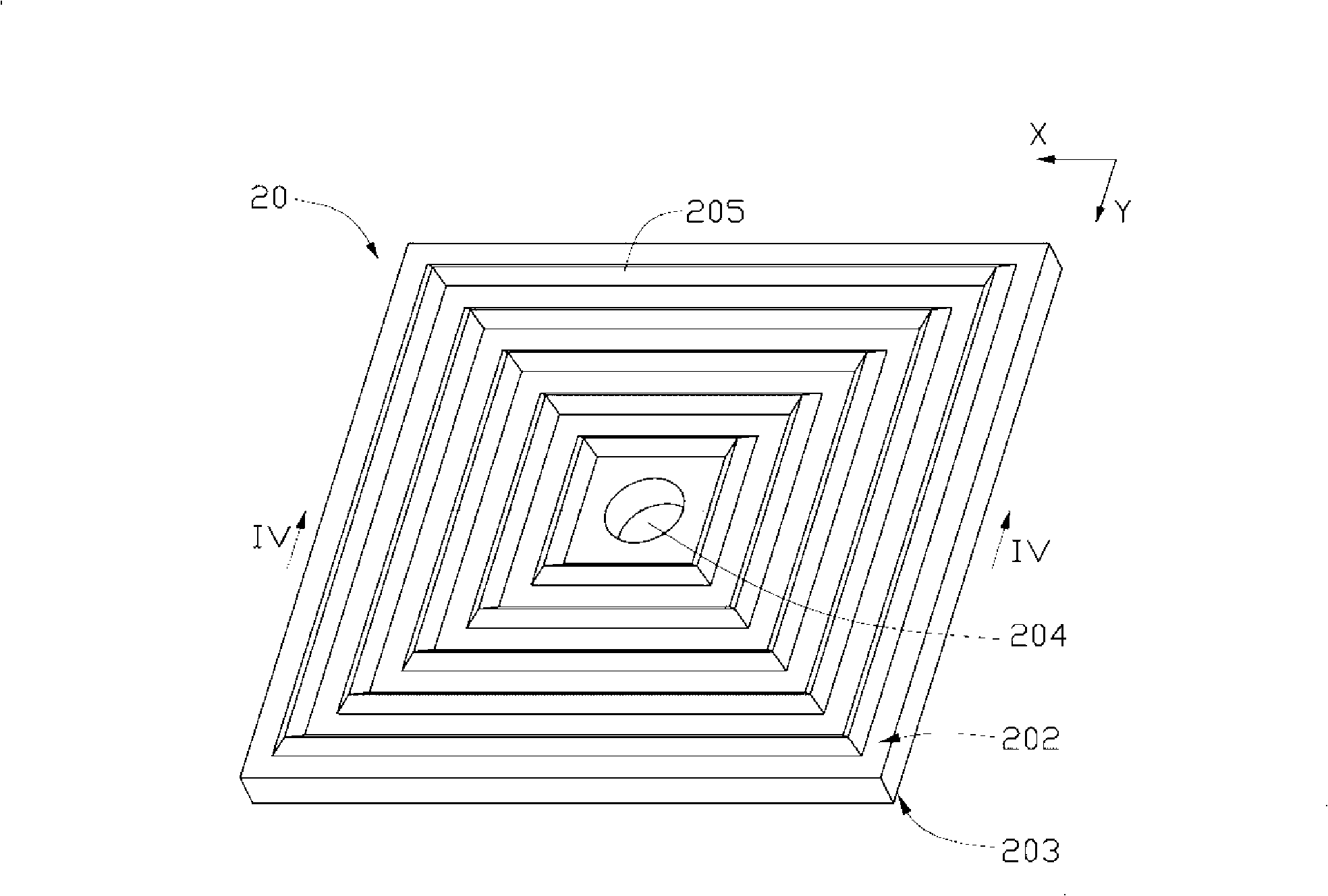

Back light module and optical plate

InactiveCN101344609AReduce thicknessReduce distanceOptical light guidesNon-linear opticsEngineeringLight source

An optical plate comprises at least one optical plate unit that comprises a first surface and a second surface opposite to the first surface. A plurality of sealed V-shaped protuberances are formed on the first surface and a scattering layer is formed on the second surface and at least one light-source containing part is arranged at least on the first surface or the second surface. The invention also provides a backlight module adopting the optical plate and the backlight module has the advantage of even light-exiting.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

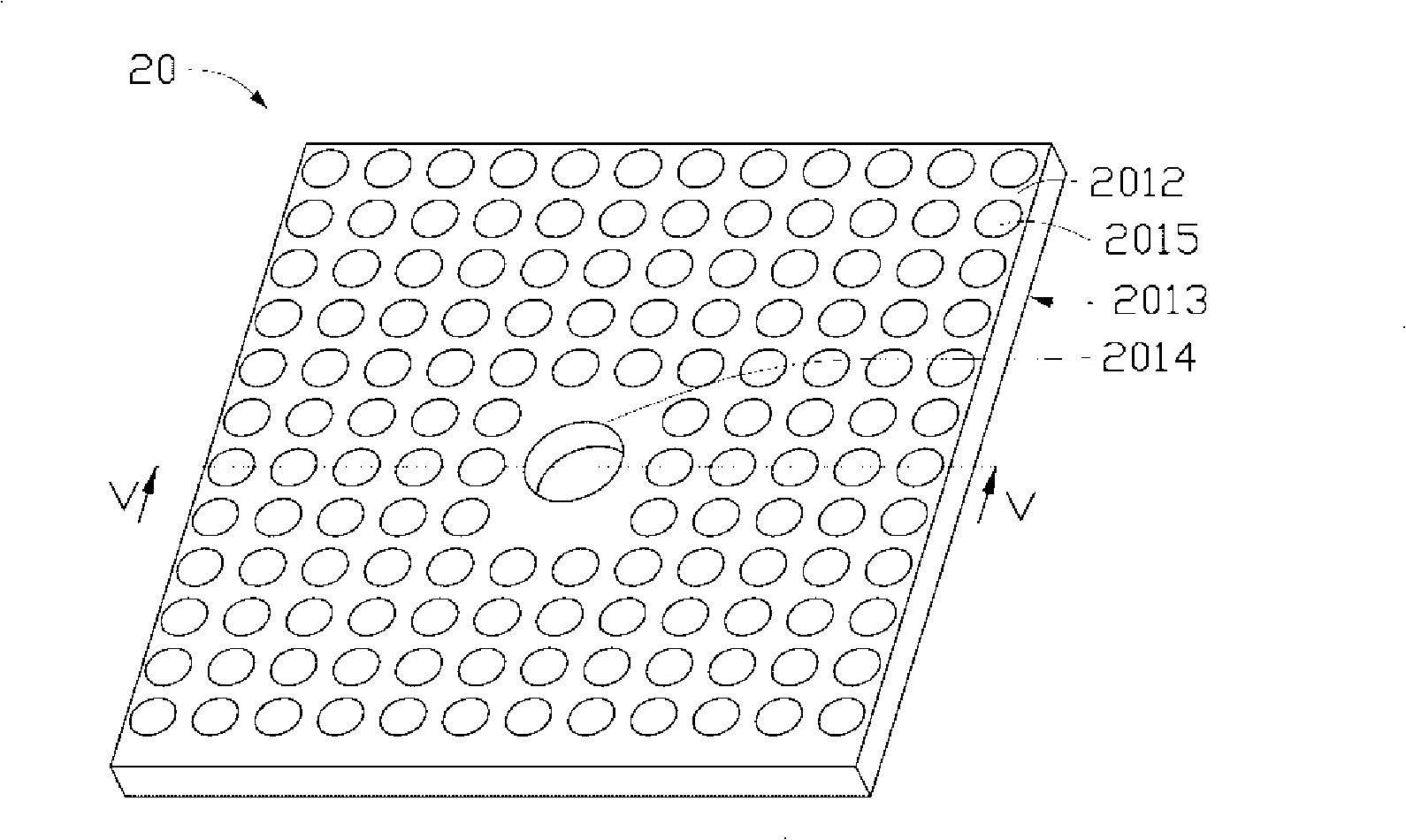

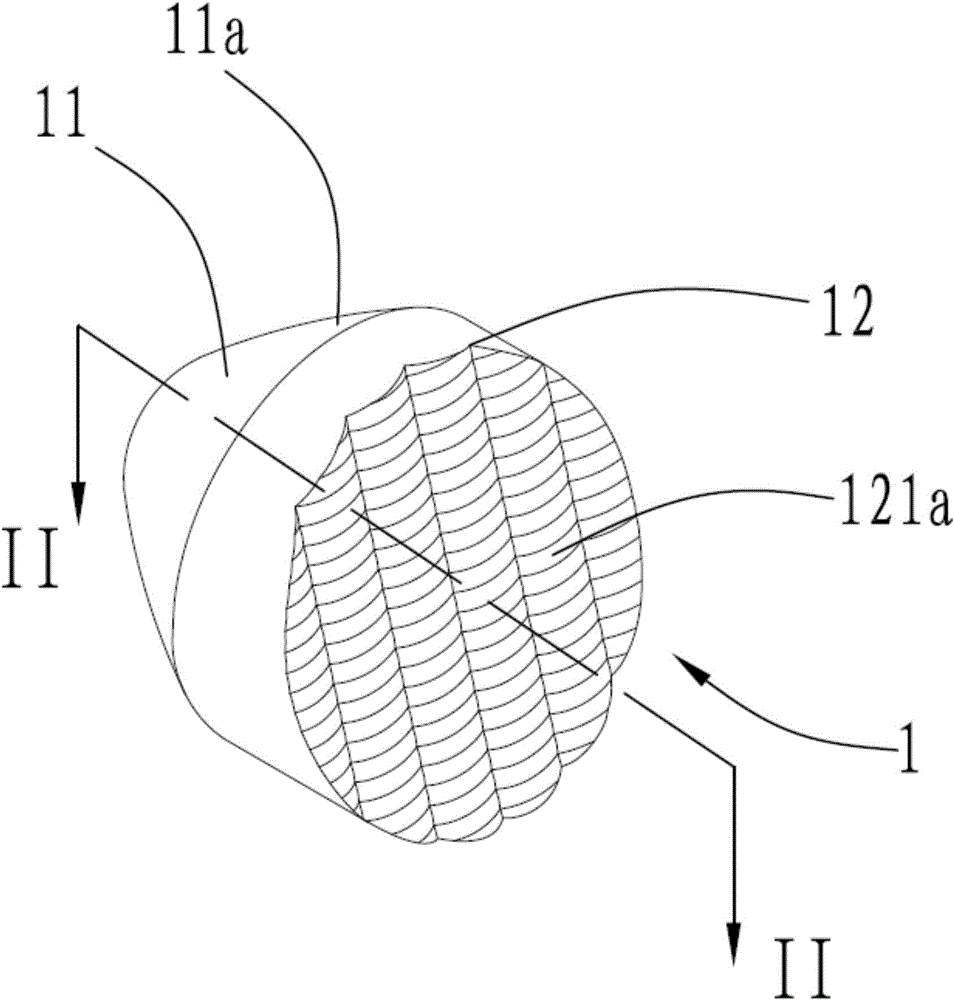

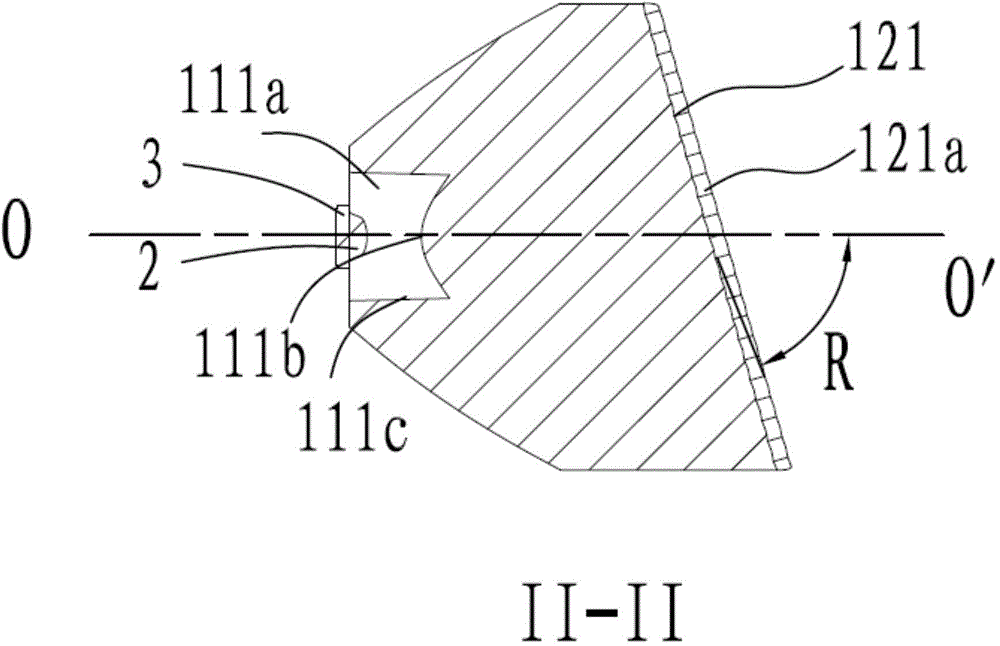

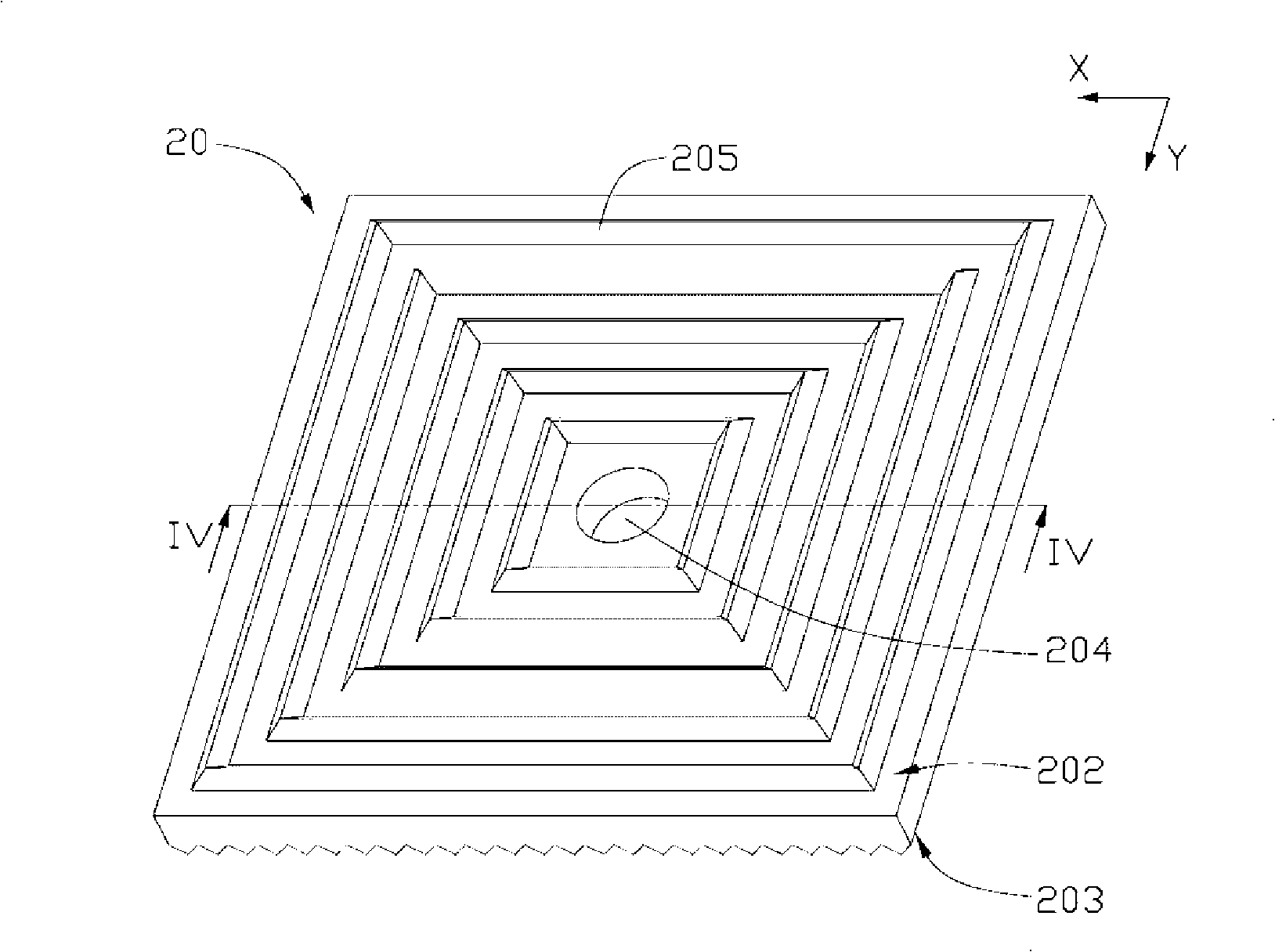

Back light module and optical plate

InactiveCN101295034AImprove optical utilizationReduce thicknessPlanar/plate-like light guidesNon-linear opticsEngineeringLight emission

The invention relates to a backlight module and an optical plate thereof. The optical plate comprises at least one optical plate unit which includes a first surface and a second surface opposite to the first surface. A plurality of tiny bulges are formed on the first surface, and each tiny bulge comprises at least three sides which are interconnected, the horizontal width of each side is gradually decreased along the direction which is far away from the first surface. A plurality of spherical bulges are formed on the second surface, and at least one of the first surface and the second surface is provided with at least one light source containing part. The backlight module adopting the optical plate has the advantage of even light emission.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

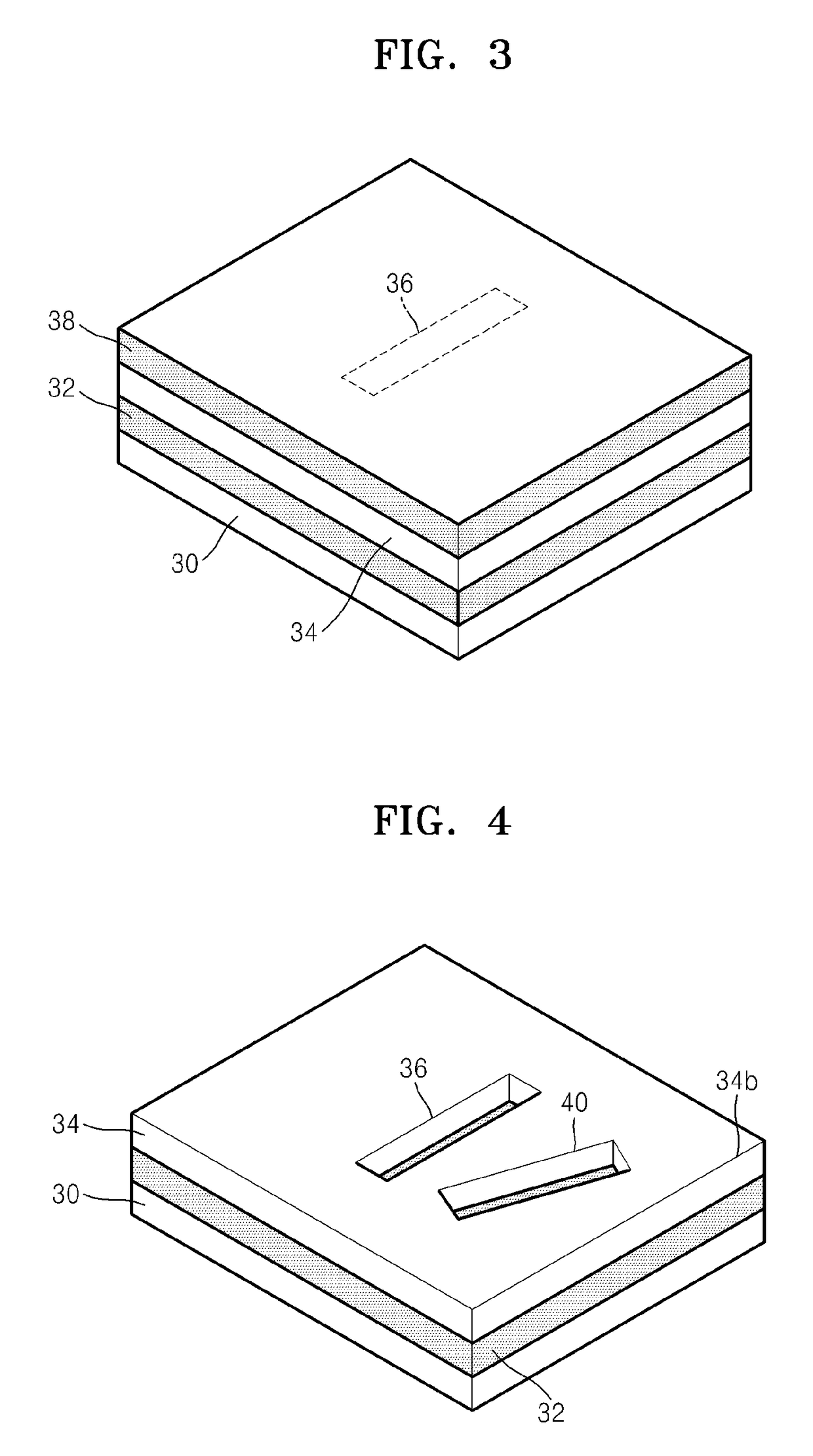

Tunable nano-antenna and methods of manufacturing and operating the same

ActiveUS9904077B2Solve narrow bandwidthImprove optical utilizationSimultaneous aerial operationsAntenna supports/mountingsOptoelectronicsNanometre

Owner:SAMSUNG ELECTRONICS CO LTD

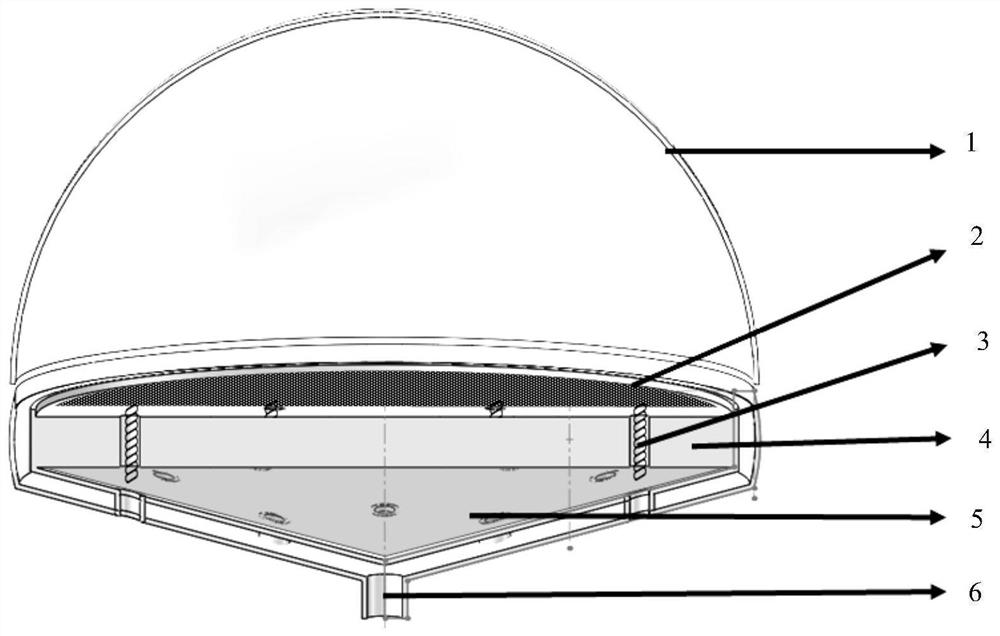

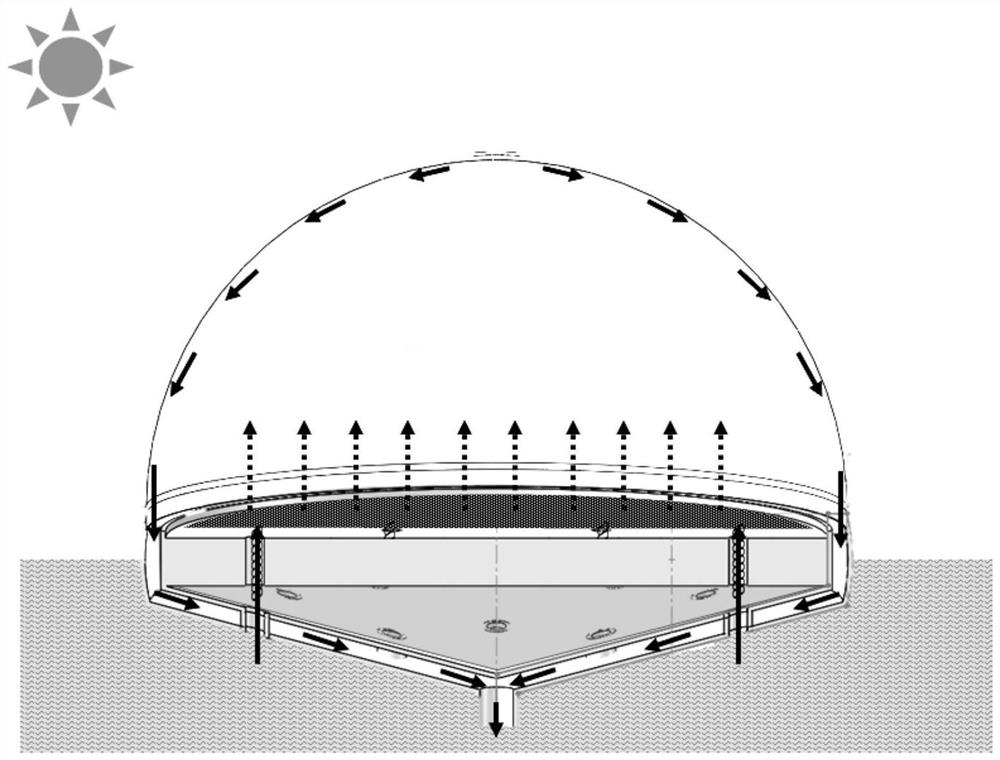

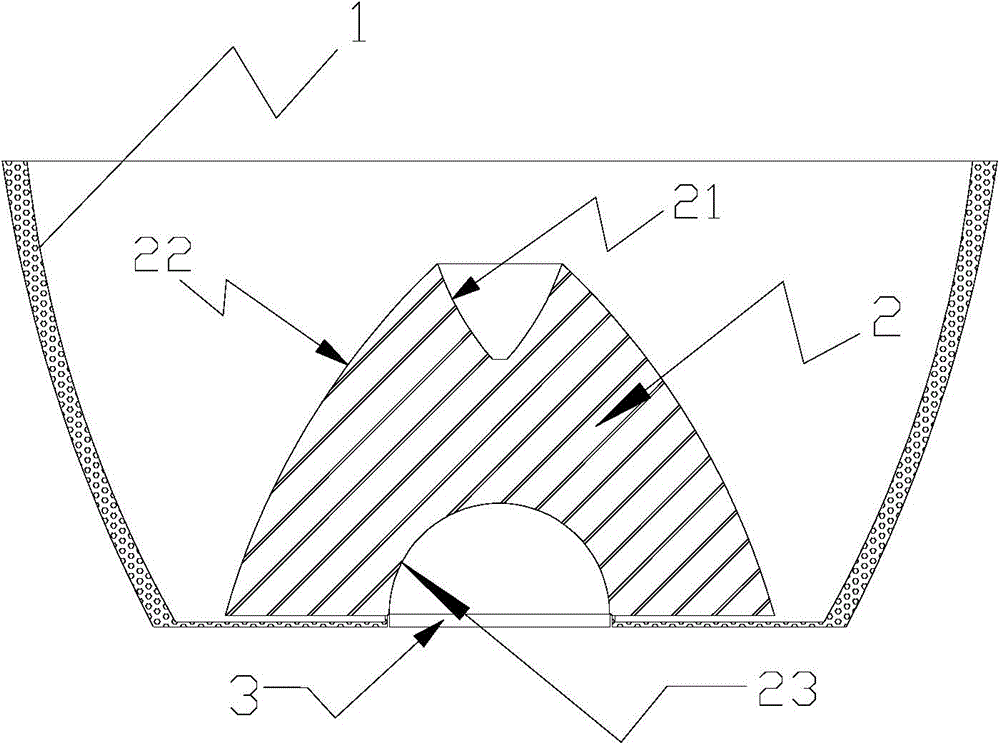

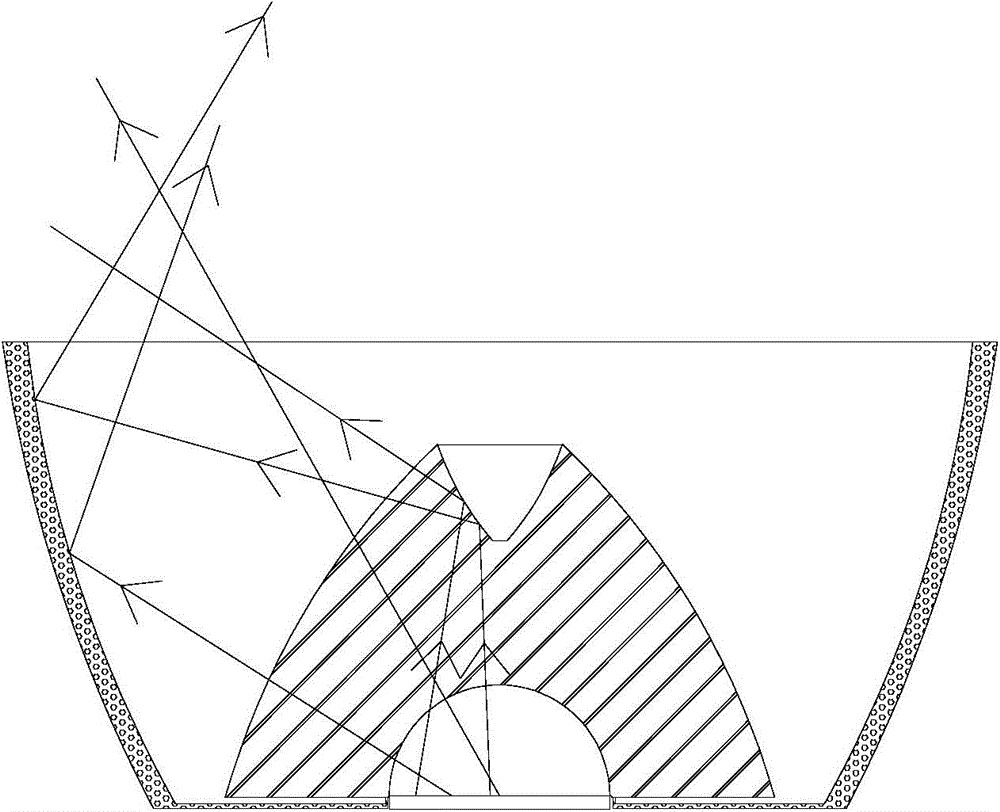

Portable solar photo-thermal evaporation seawater desalination distiller and method

PendingCN113896268ABuoyantReduce lossesGeneral water supply conservationSeawater treatmentInsulation layerThermal break

The invention relates to a portable solar photo-thermal evaporation seawater desalination distiller, which comprises a condensation structure, a photo-thermal conversion material, a water guide channel, a heat insulation layer, a seawater communication layer and a fresh water collection tank, wherein the condensation structure is arranged to be a structure facilitating downward sliding of condensed water, the photo-thermal conversion material is arranged on the lower portion of the condensation structure, the heat insulation layer is arranged on the lower portion of the photo-thermal conversion material, the through water guide channel is formed in the heat insulation layer, the lower edge of the condensation structure is communicated with the upper portion of the fresh water collection tank at the periphery of the heat insulation layer, the fresh water collection tank and the bottom surface of the heat insulation layer define the seawater communication layer, the bottom of the fresh water collection tank is provided with the fresh water discharge hole, and the bottom surface of the fresh water collection tank is provided with a through seawater communication hole. According to the invention, the condensation structure facilitating downward sliding of condensed water is arranged, the condensation structure is communicated with the conical fresh water collection tank, the seawater communication layer between the fresh water collection tank and the heat insulation layer can meet the requirement for continuous drawing of seawater, the floatable property is achieved, and high-efficiency seawater desalination is achieved.

Owner:ZHEJIANG ZHENENG TECHN RES INST

Projection screen and projection system

InactiveCN110824825AIncrease brightnessImprove brightness uniformityProjectorsFresnel lensProjection screen

The invention provides a projection screen and a projection system, which belong to the technical field of optical projection. The projection screen comprises a circular Fresnel lens layer, an imagingelement layer, an optical structure layer and a reflection layer, which are sequentially arranged in the thickness direction. The circular Fresnel lens layer is composed of a plurality of circular Fresnel lens structures with the circle centers at the same point. The optical structure layer is composed of a plurality of linear triangular optical structures which are arranged in rows. The cross section of the optical structure layer in the thickness direction is sawtooth-shaped. The vertex angle of each linear triangular optical structure far away from the imaging element layer ranges from 70degrees to 110 degrees. The projection system is composed of the projection screen and a projection device. The projection screen and the projection system, which are provided by the invention, have the advantages of high brightness, high light energy utilization rate, high image definition, good ambient light resistance, high contrast ratio and excellent projection display effect.

Owner:CHENGDU FSCREEN SCI TECH

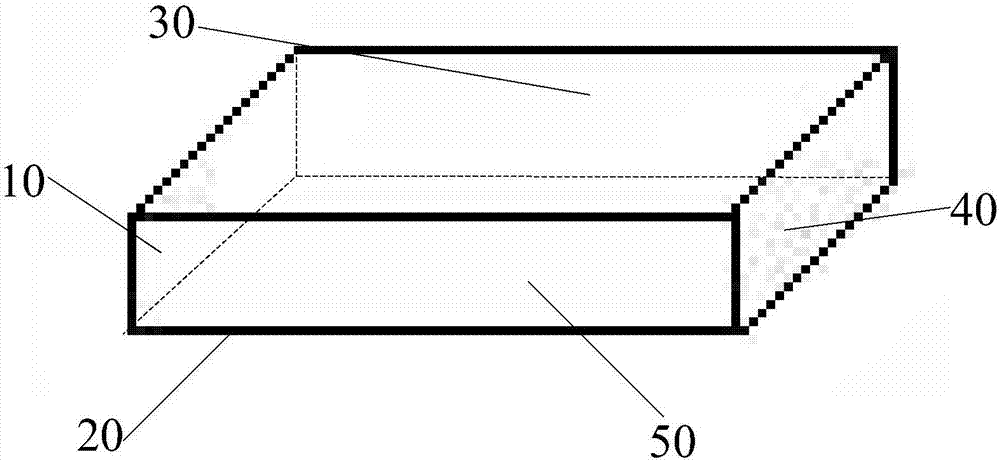

Reflector lamp

InactiveCN104633540AImprove lighting effectsImprove light utilizationPoint-like light sourceLight fasteningsLight effectsLight source

The invention provides a reflector lamp. The reflector lamp comprises a reflection cup, a lens and LED light source. An LED light source cavity is formed in the inner end of the lens, and the LED light source is located in the LED light source cavity; a concave reflection cavity is formed in the outer end of the lens, and the wall face of reflection cavity is a reflective face. The lens comprises three different optical acting faces, namely a light inlet face, the reflective face and a light outlet face, a first part of light emitted from the LED light source installed in the LED light source cavity can be projected out from the lens; a second part of the light is emitted to the reflective face, total reflection occurs, the totally reflected light is directly projected out partly, and the remaining part of the totally reflected light is projected out after being reflected by the reflection cup; a third part of the light is emitted to the lens, then projected to the reflection cup and projected out after being reflected. Therefore, by means of the reflector lamp, a good light effect is achieved, and the light use ratio is increased.

Owner:ETI SOLID STATE LIGHTING ZHUHAI LTD

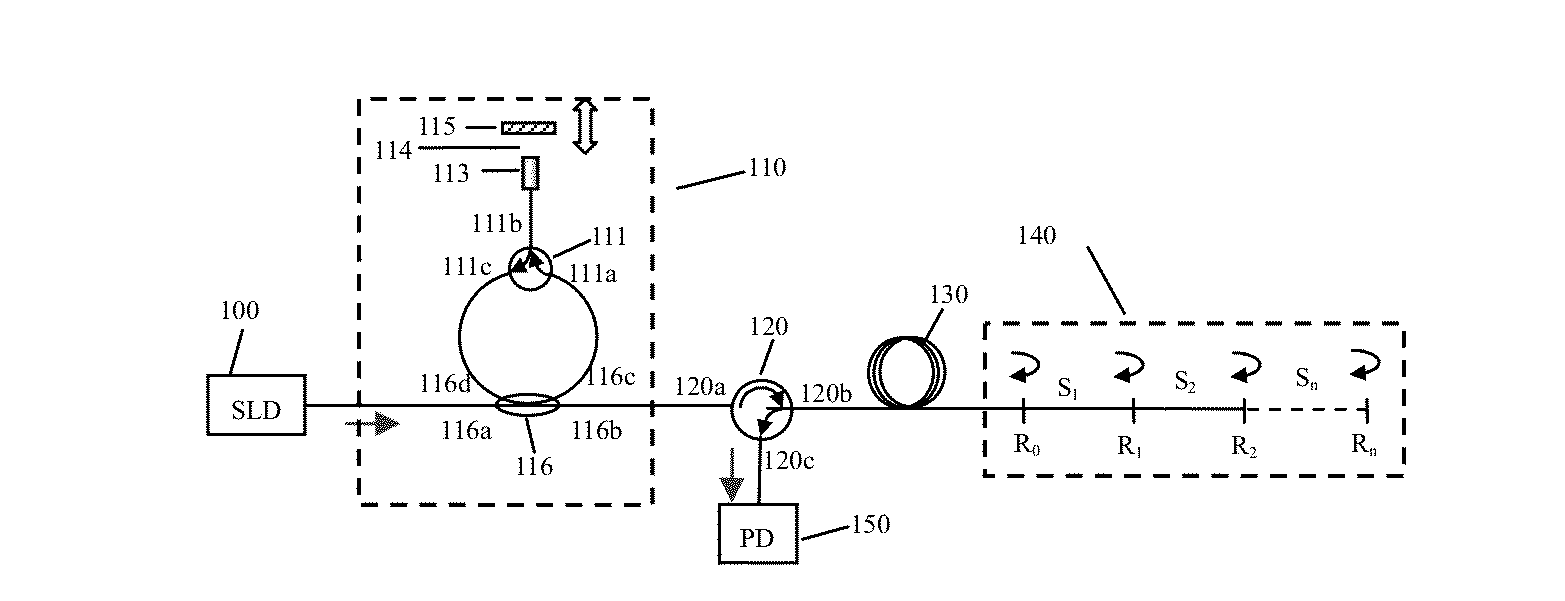

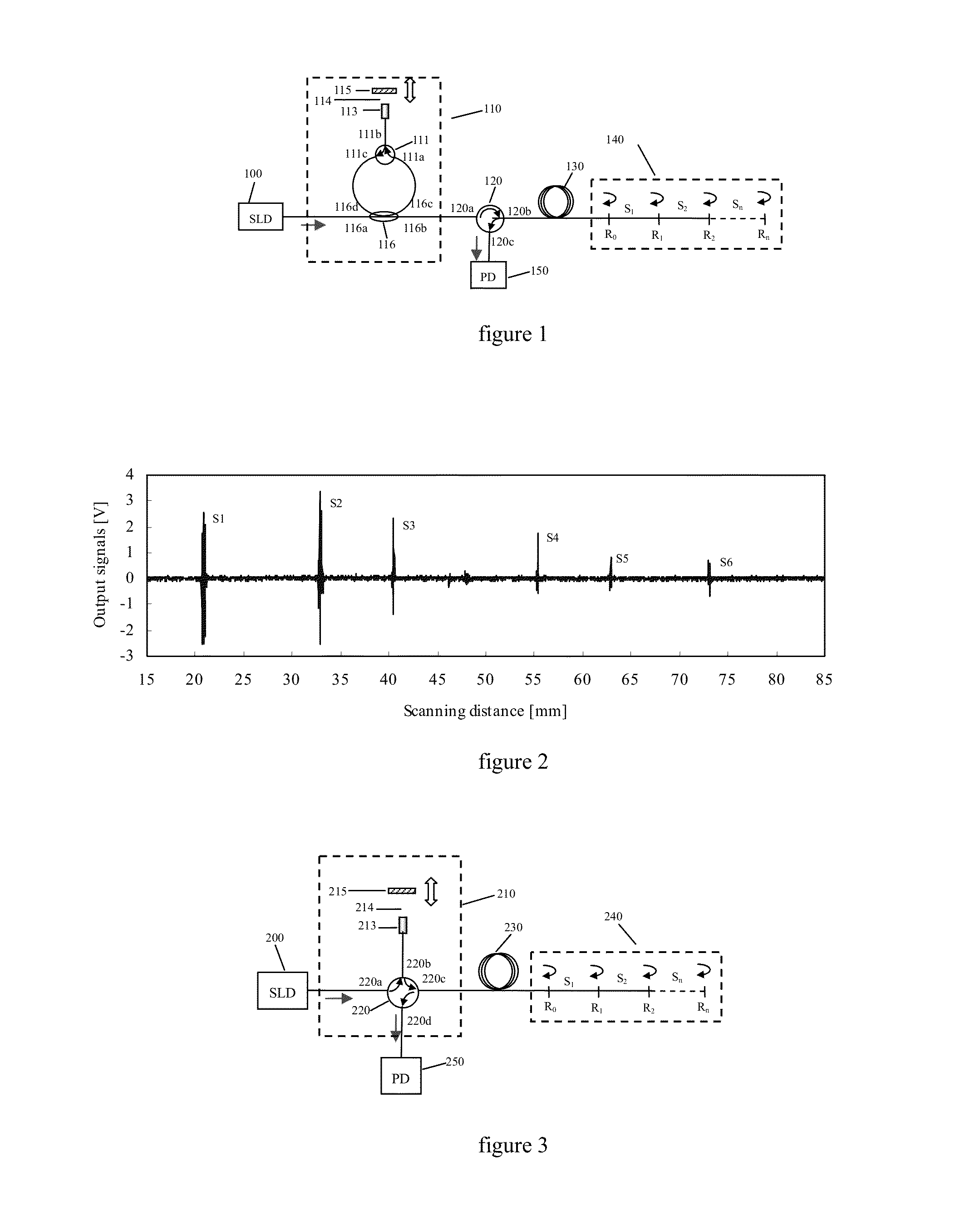

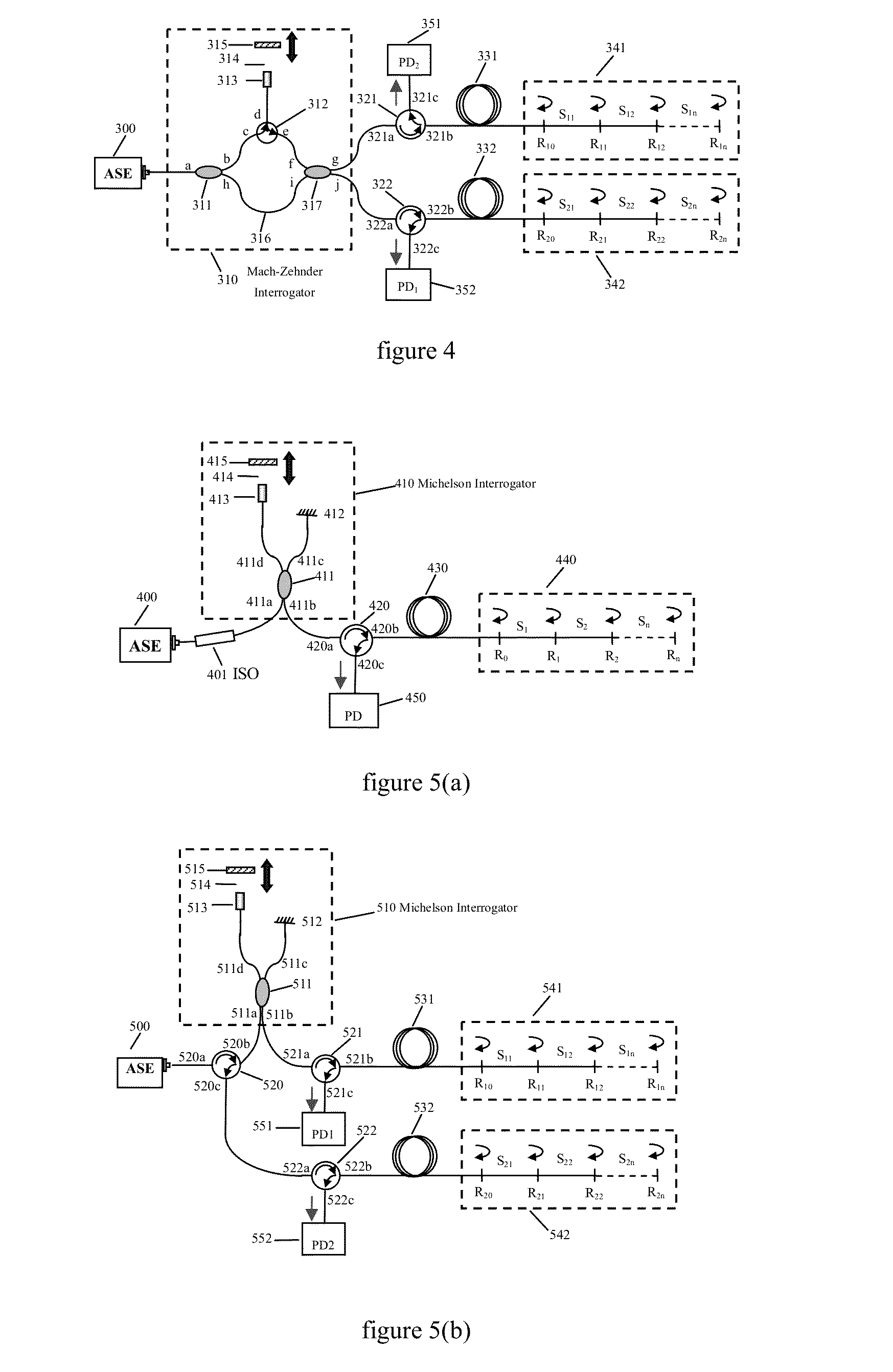

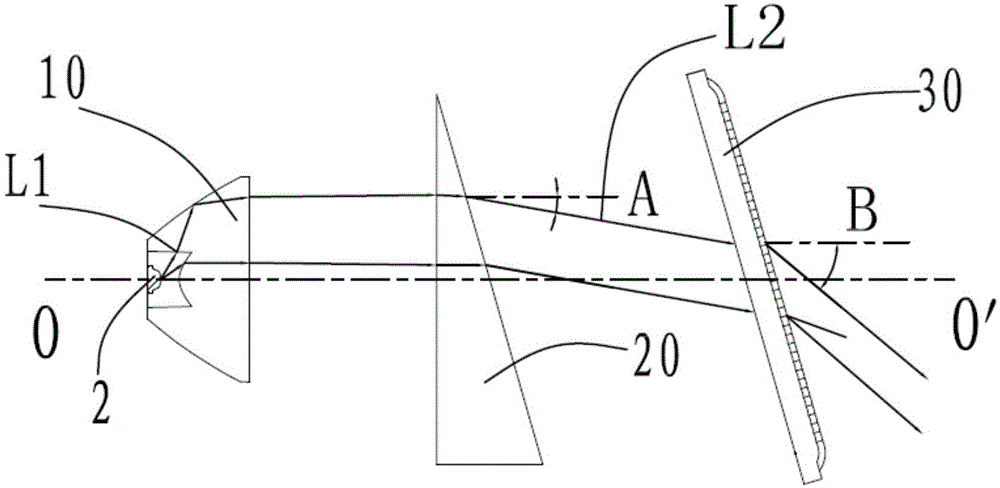

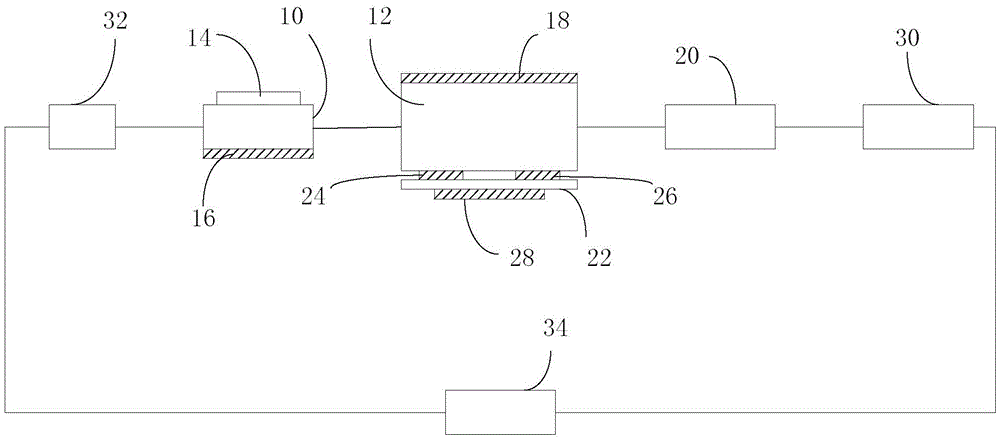

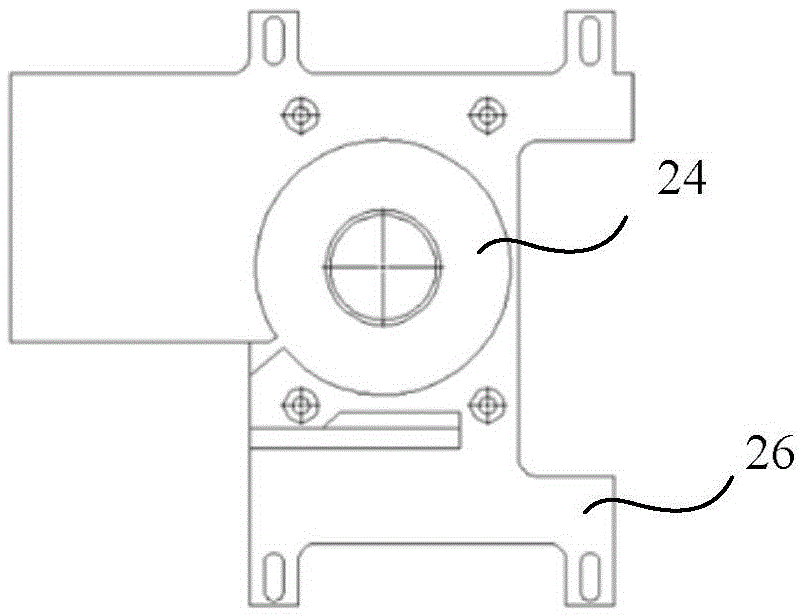

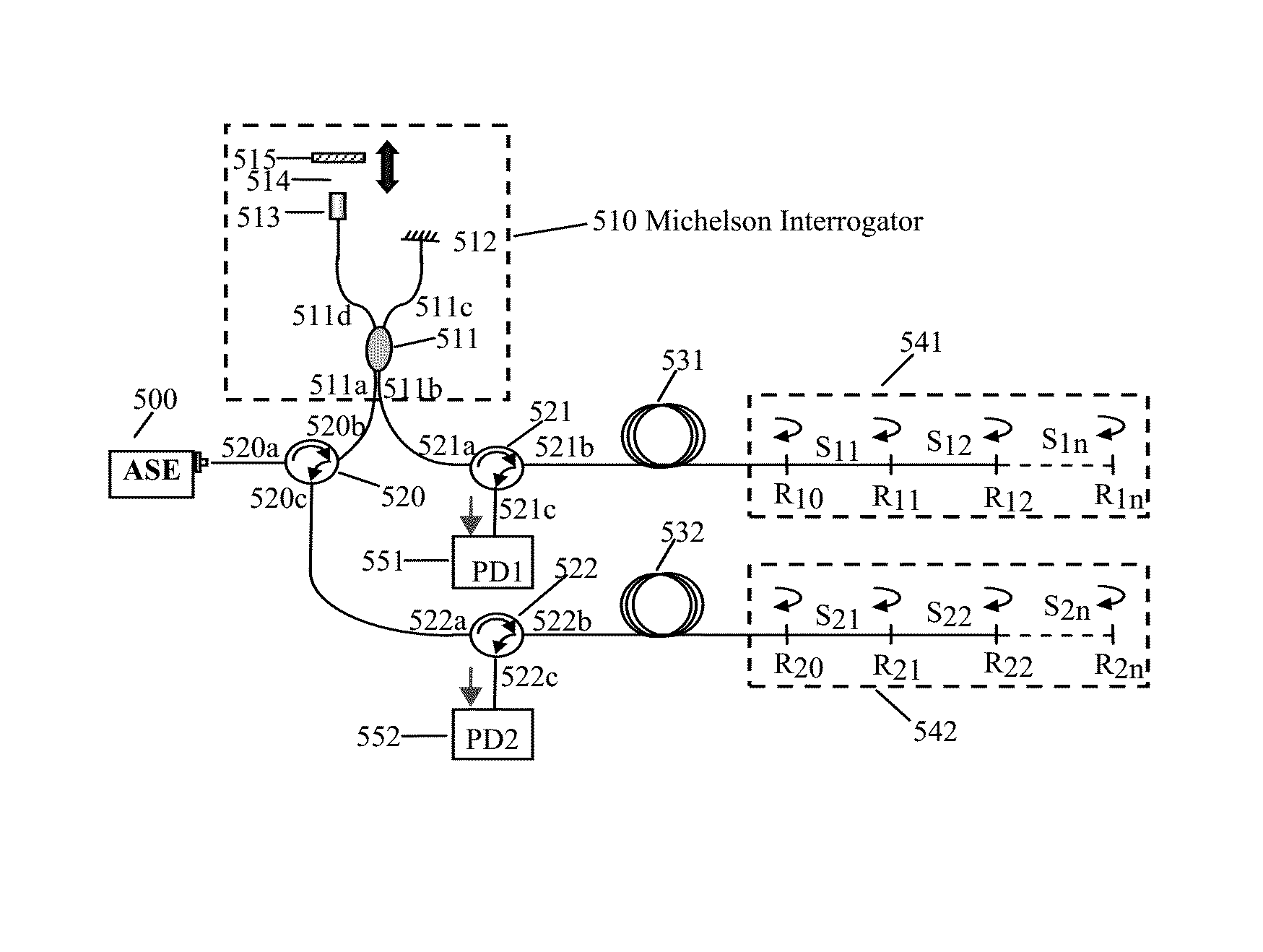

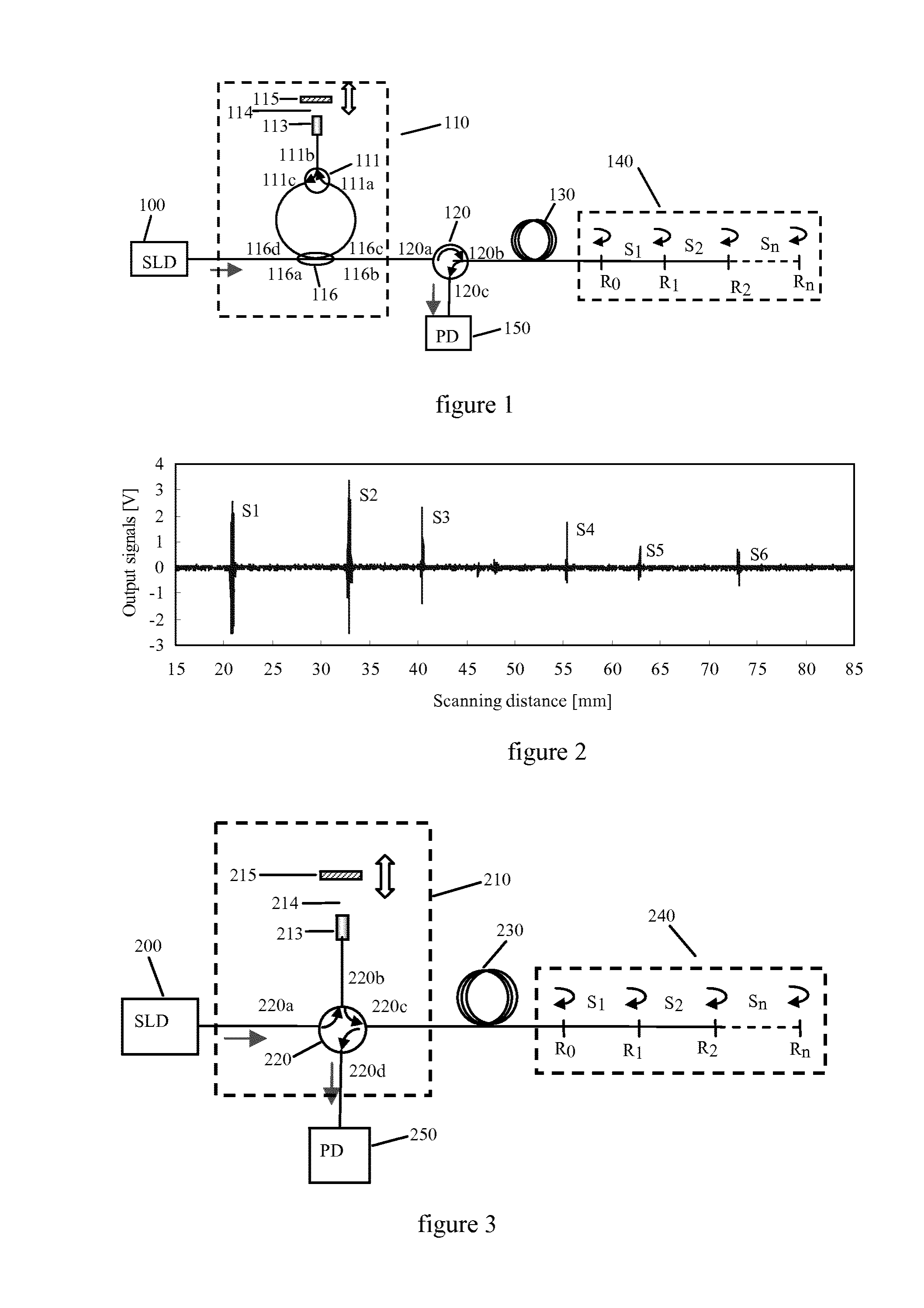

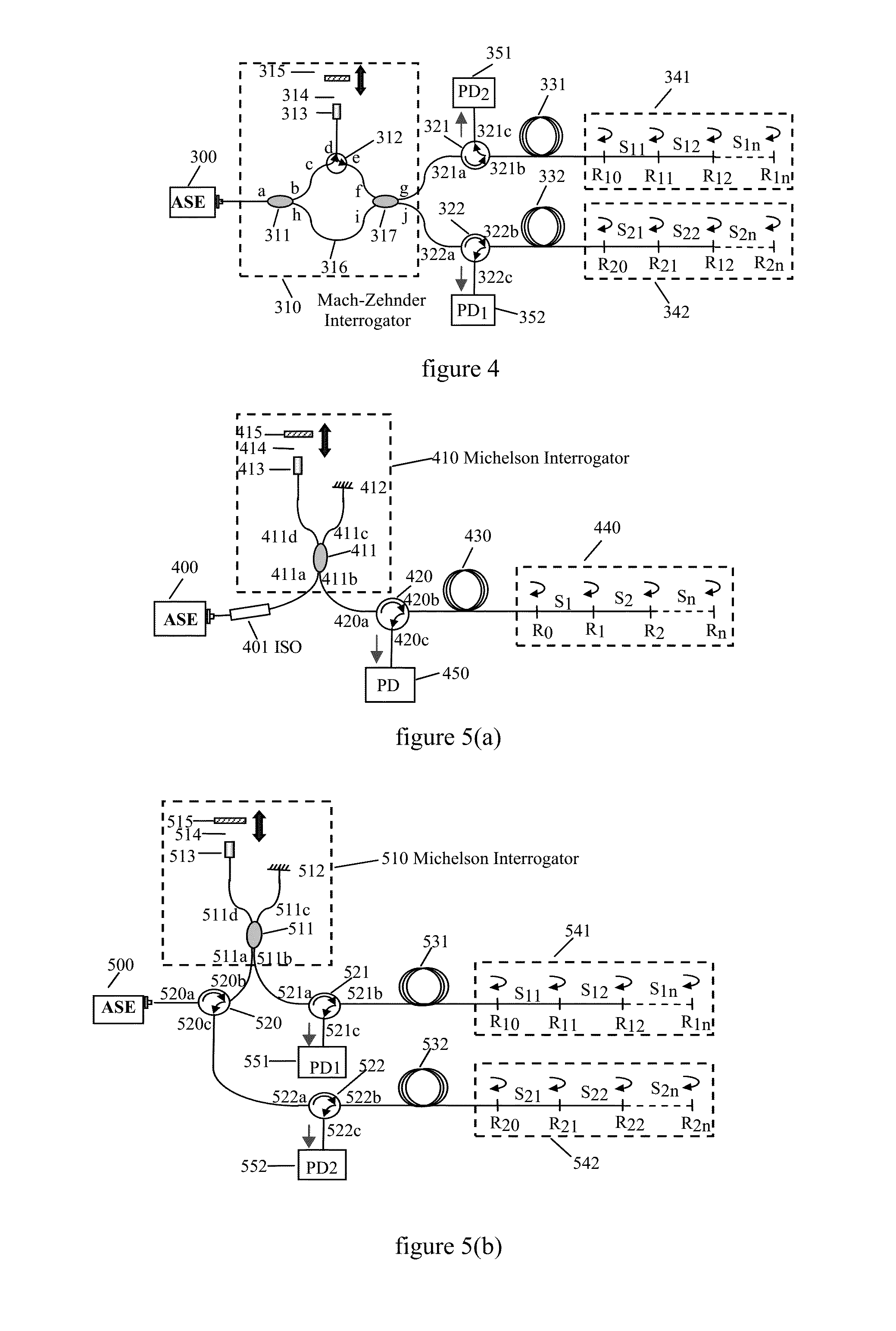

Multiple Optical Channel Autocorrelator Based on Optical Circulator

InactiveUS20130194580A1Increase powerLow efficiencyUsing optical meansOptical light guidesSensor arrayPhotovoltaic detectors

A multiple optical channel autocorrelator based on an optical fiber circulator includes a broad-band light source, at least an optical-fiber sensor array, an adjustable multiple light beams generator, at least an optical fiber circulator and at least a photoelectric detector. The optical-fiber sensor array is composed of the sensing fibers connected end to end. The online mirrors are formed by the connecting end faces of the adjacent fibers. The adjustable multiple light beams generator includes a fixed arm and an adjustable arm. The optical path difference between the fixed arm and the adjustable arm is adjustable in order to match the optical path of each sensor in the sensor array. The optical fiber circulator couples the signals generated by the multiple light beams generator to the sensor array, and couples the signals returned by the sensor array to the photoelectric detector. The photoelectric detector is connected to the optical fiber circulator. The multiple optical channel autocorrelator based on the optical fiber circulator can implement the real-time online measurement of the physical quantity of multipoint strain or deformation, and has advantages of low light source power loss, high efficiency and good stability.

Owner:HARBIN ENG UNIV

Back light module and optical plate

InactiveCN101295044AImprove optical utilizationLow costDiffusing elementsOptical light guidesLight emissionLight source

The invention relates to an optical plate which comprises at least one optical plate unit including a light-emitting surface, a bottom surface opposite to the light-emitting surface and a scattering layer formed on the light-emitting surface, wherein, a plurality of spherical bulges are formed on the bottom surface which is proided with a light source containing part. The invention also provides a backlight module which adopts the optical plate, and the backlight module has the advantage of even light emission.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Back light module and optical plate

InactiveCN101295040AImprove optical utilizationReduce thicknessPlanar/plate-like light guidesNon-linear opticsEngineeringLight emission

The invention relates to an optical plate which comprises at least one optical plate unit including a first surface and a second surface opposite to the first surface. A plurality of closed V-shaped bulges are formed on the first surface, a plurality of spherical grooves are formed on the second surface, and at least one of the first surface and the second surface is provided with a light source containing part. The invention also provides a backlight module which adopts the optical plate, and the backlight module has the advantage of even light emission.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

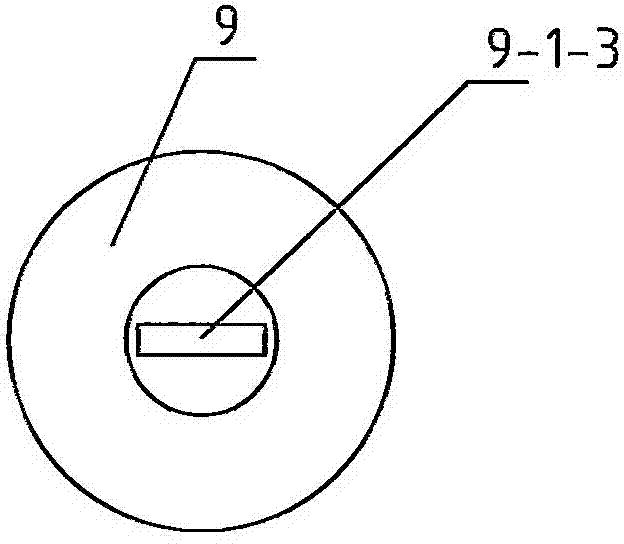

Processing method for photovoltaic solder strips as well as wire-drawing die and photovoltaic solder strip processing device used in method

The invention discloses a processing method for photovoltaic solder strips and a wire-drawing die and a photovoltaic solder strip processing device used in the method. The method comprises the following steps: a) providing a raw material copper bar; b) carrying out wire-drawing forming on the raw material copper bar through a wire-drawing device, so that a copper strip with a required size is formed, and the surface of the copper strip is formed into a structure with a reflective groove, thereby obtaining a first semi-finished product; c) carrying out annealing treatment on the first semi-finished product by using an annealing process so as to form a second semi-finished product; and d) reasonably selecting a coating metal, and carrying out electroplating treatment on the second semi-finished product by using an electroplating process, and controlling the thickness of the coating to be 1-30 mu m, thereby obtaining a required photovoltaic solder strip. By using the method, a reflective groove can be formed on the surface of a photovoltaic solder strip, so that the optical utilization rate of the photovoltaic solder strip and the power of a solar energy assembly are increased; the method improves the dimensional stability and production efficiency of photovoltaic solder strips, increases the reflective effect of photovoltaic solder strips, reduces the production cost of photovoltaic solder strips, and optimizes the process steps.

Owner:TRINA SOLAR CO LTD

Back light module unit and optical panel thereof

InactiveCN101299113AReduce thicknessIncrease exit lightOptical light guidesNon-linear opticsEngineeringLight emission

An optical board comprises at least one optical board unit which comprises a light emitting surface and a base surface opposite to the light emitting surface. The light emitting surface and the base surface are respectively formed with a plurality of micro-projections. Each micro-projection comprises at least three side surfaces connected with one another. The horizontal width of each side surface reduces along the direction away from the base surface of the micro-projection. The base surface is provided with at least one light source accommodation part. The invention also provides a backlight module which adopts the optical board and has the advantage of homogeneous light emission.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

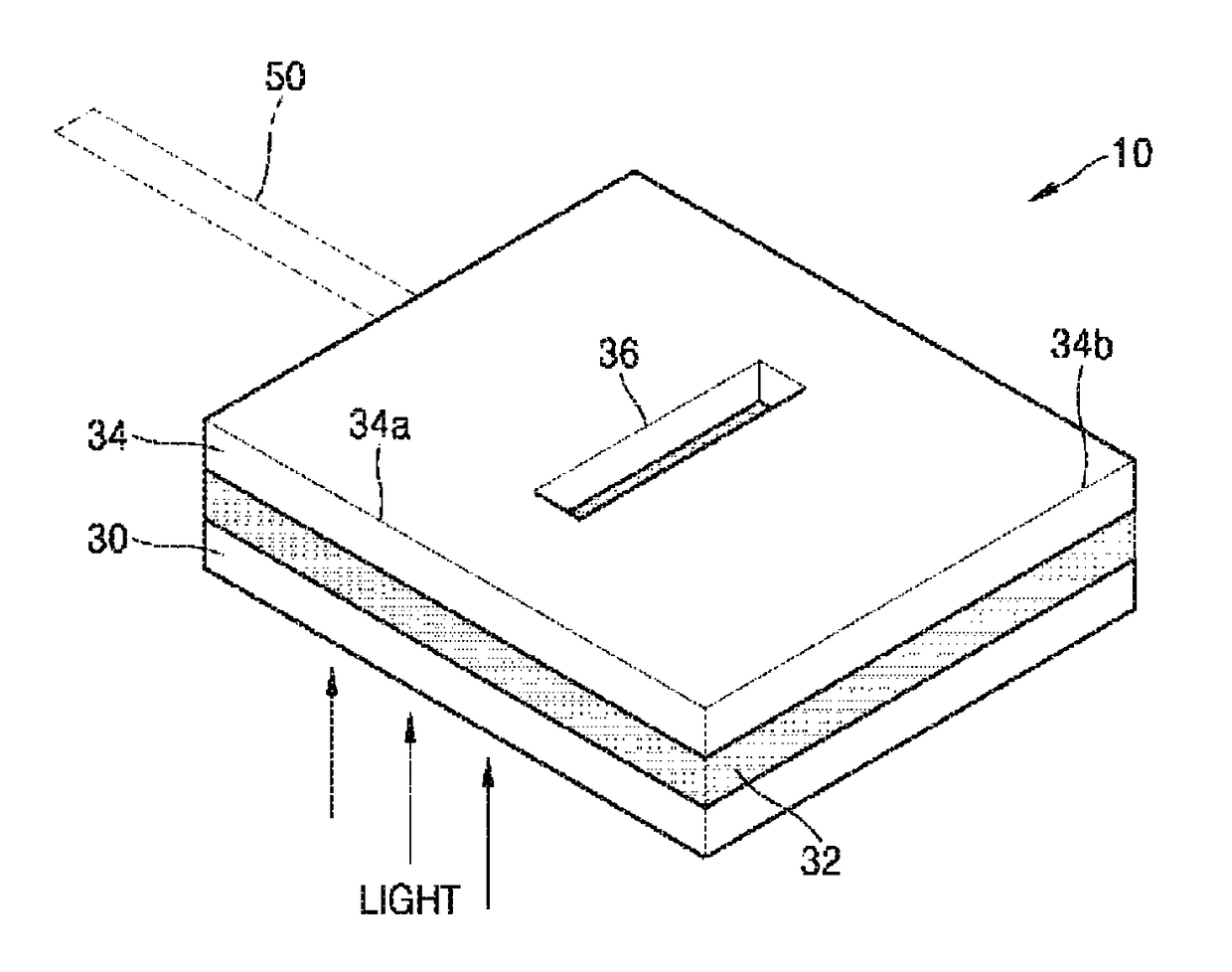

Optical film body and manufacturing method of optical film body and optical film primary body

ActiveCN103144326AExtended service lifeImprove optical utilizationOptical articlesOptical elementsOptical film

The invention discloses an optical film body and a manufacturing method of the optical film body and the optical film primary body. The manufacturing method of the optical film body comprises a first steps of manufacturing a pressed film primary body; a second step of placing a plane optical film manufactured in advance on the surface of the pressed film primary body, vacuumizing, and heating to soften the plane optical film; a third step of cooling the softened plane optical film, shaping the softened plane optical film, and manufacturing the optical film primary body; a fourth step of enabling a conducting layer to cover the surface of the optical film primary body and manufacturing an optical die; and a fifth step of manufacturing the optical film body through the optical die. Through the manufacturing method of the optical film body and the optical film primary body, the optical film body in a stereoscopic structure can be manufactured according to needs, and therefore the optical film can be widely applied to stereoscopic products, the optical film does not need to be adhered to a base body through adhesive sticker, the optical performance of the products is improved, and the service life of the products is prolonged.

Owner:唐相平

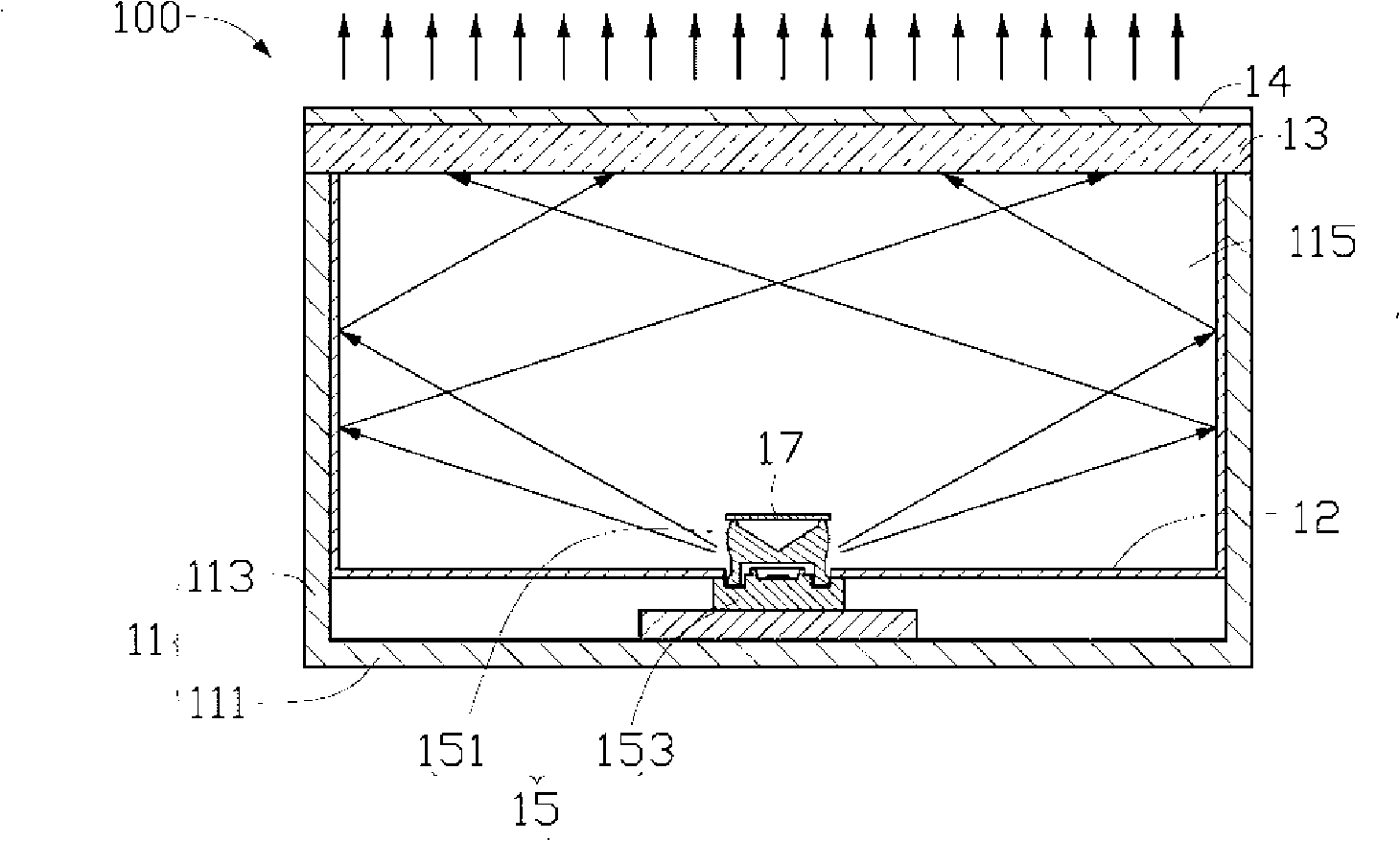

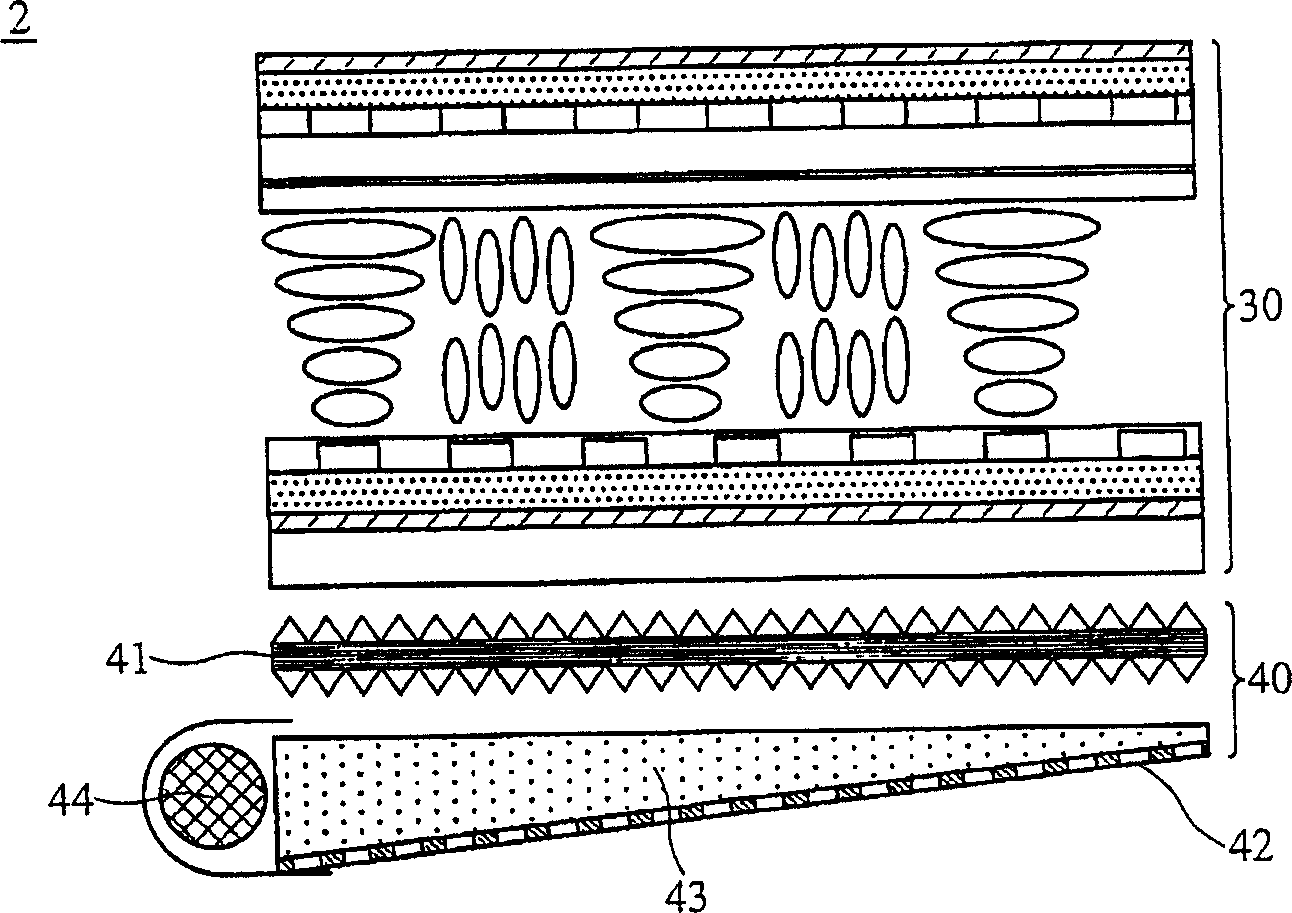

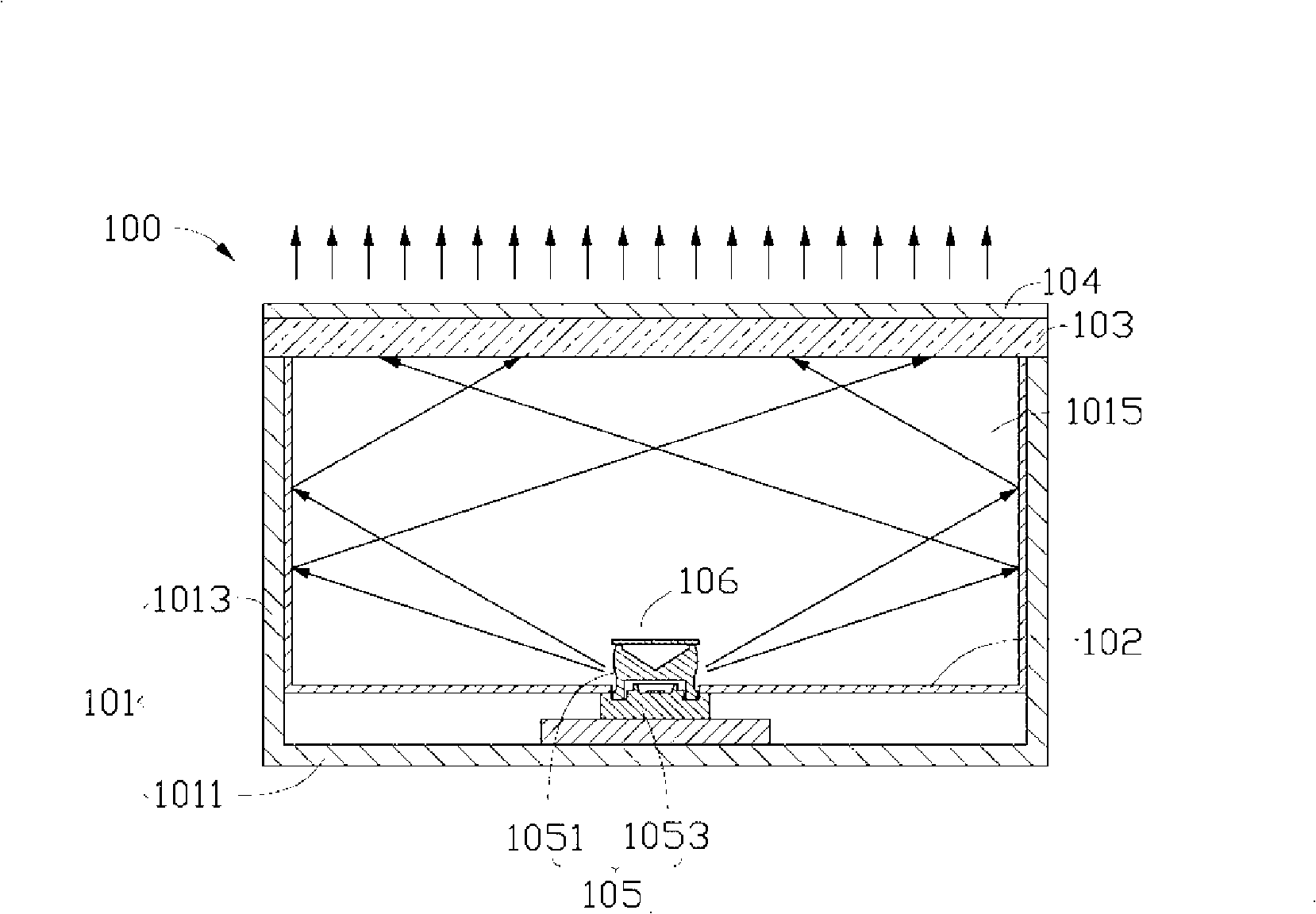

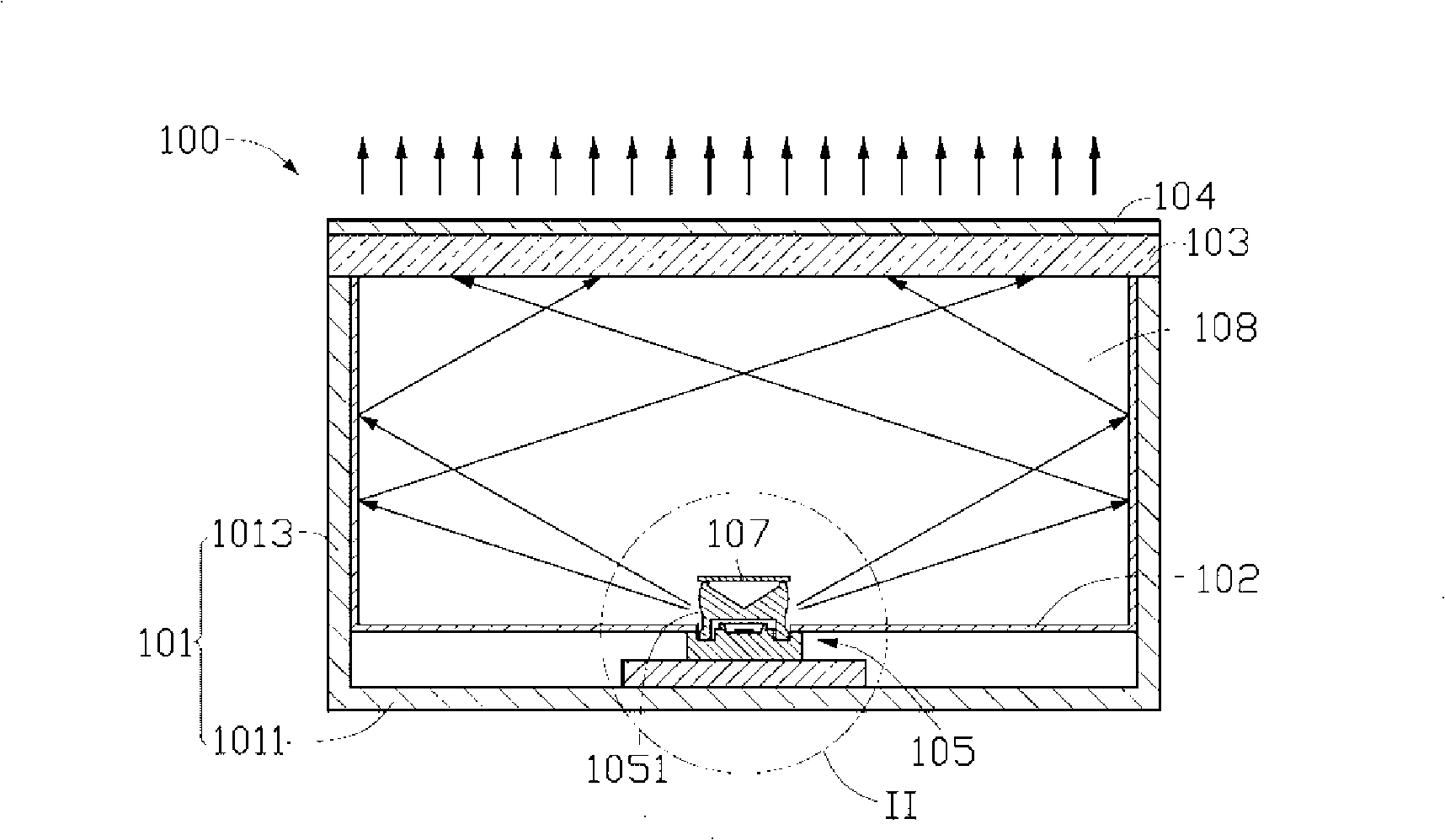

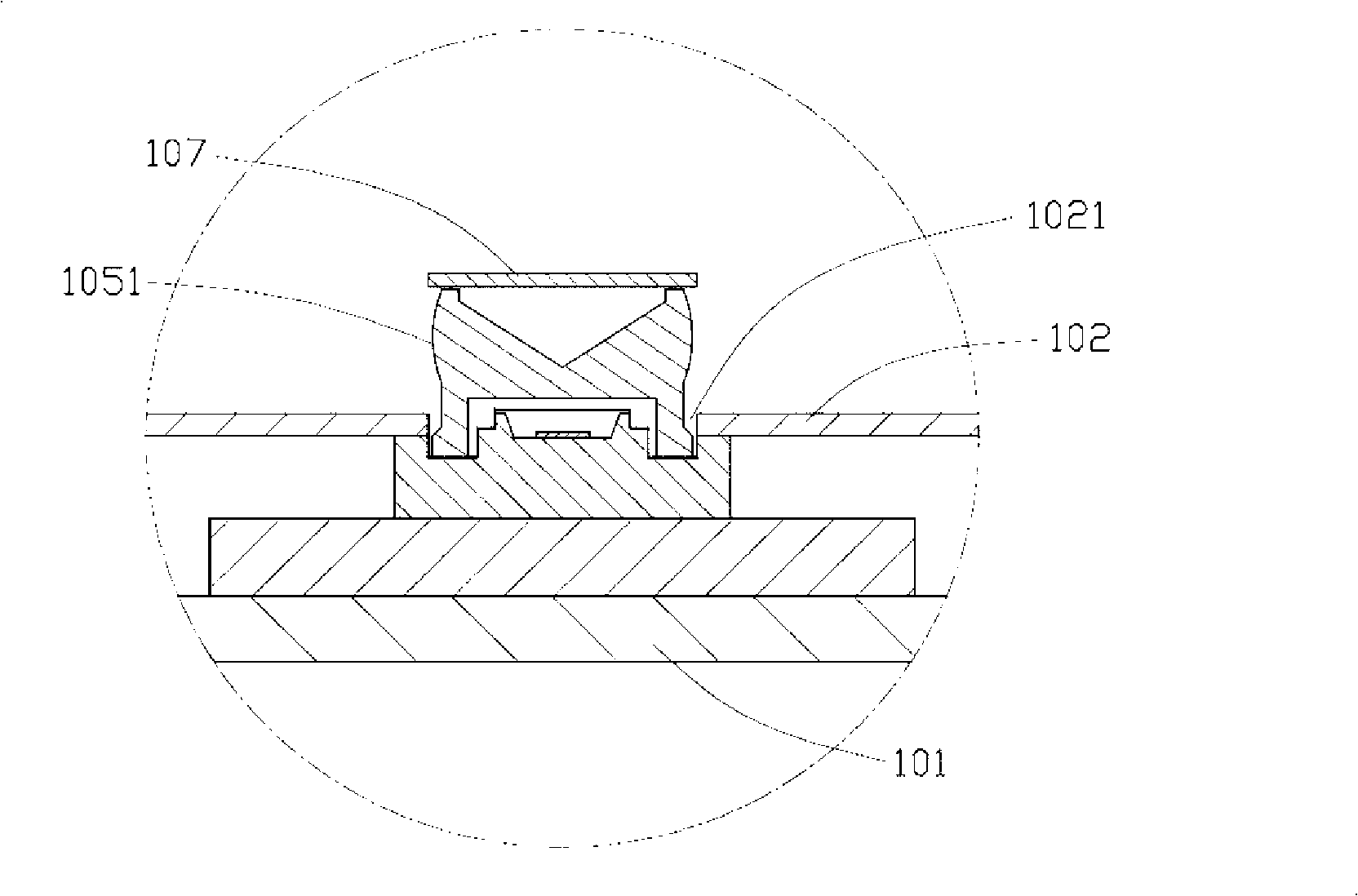

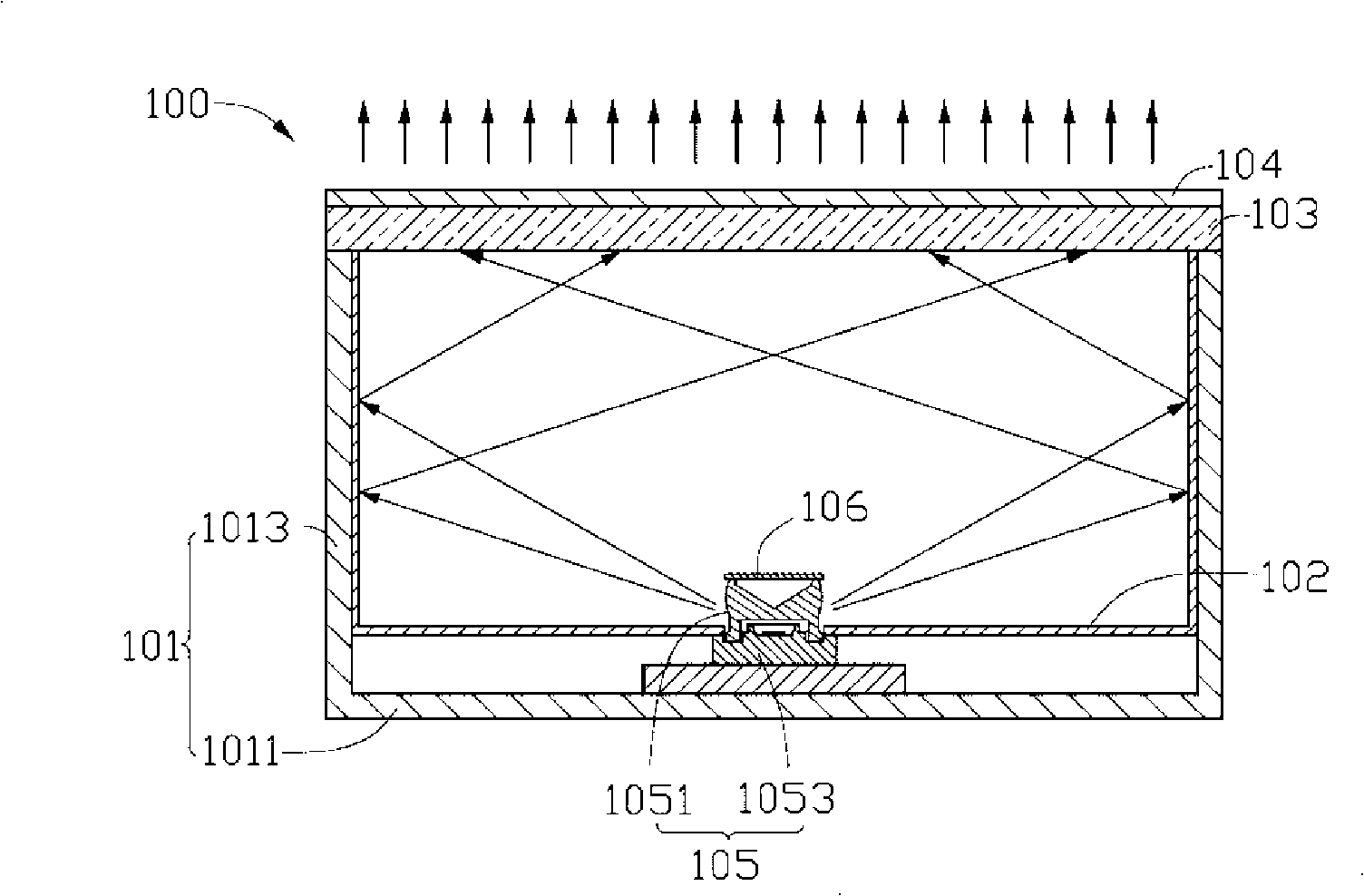

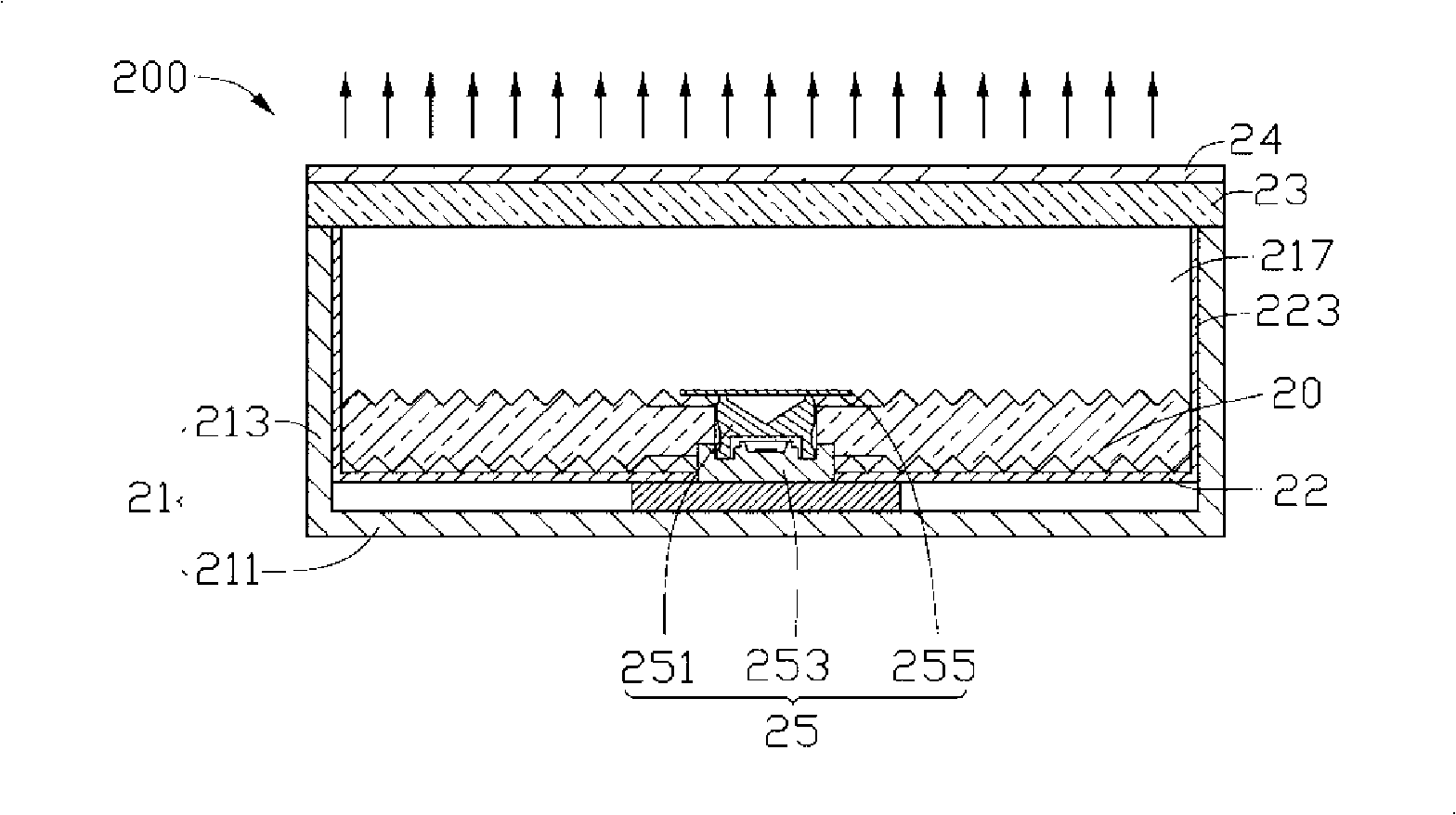

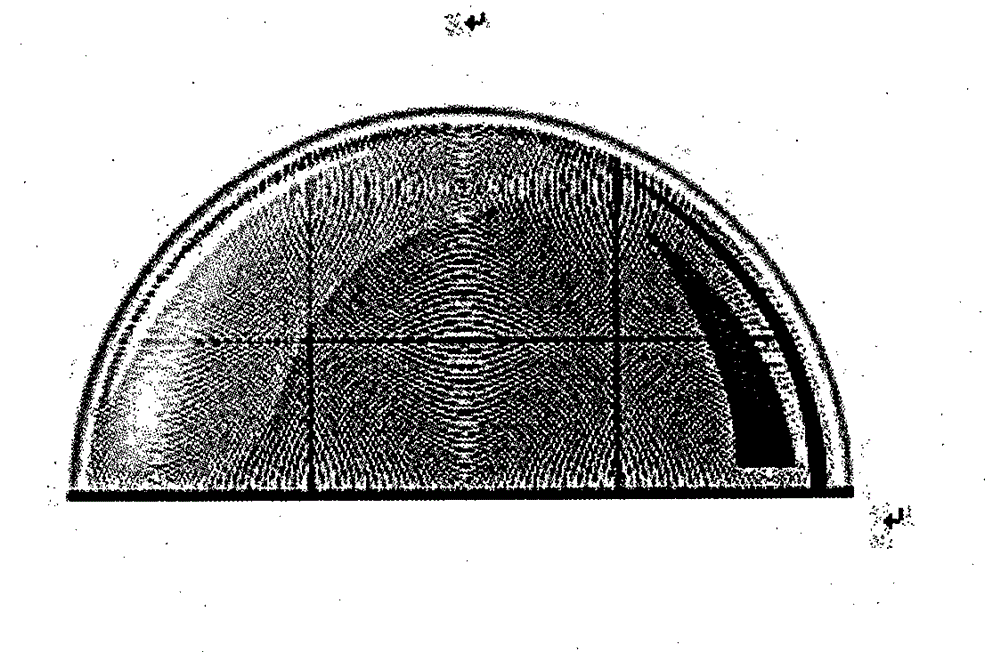

Backlight modules and liquid crystal devices

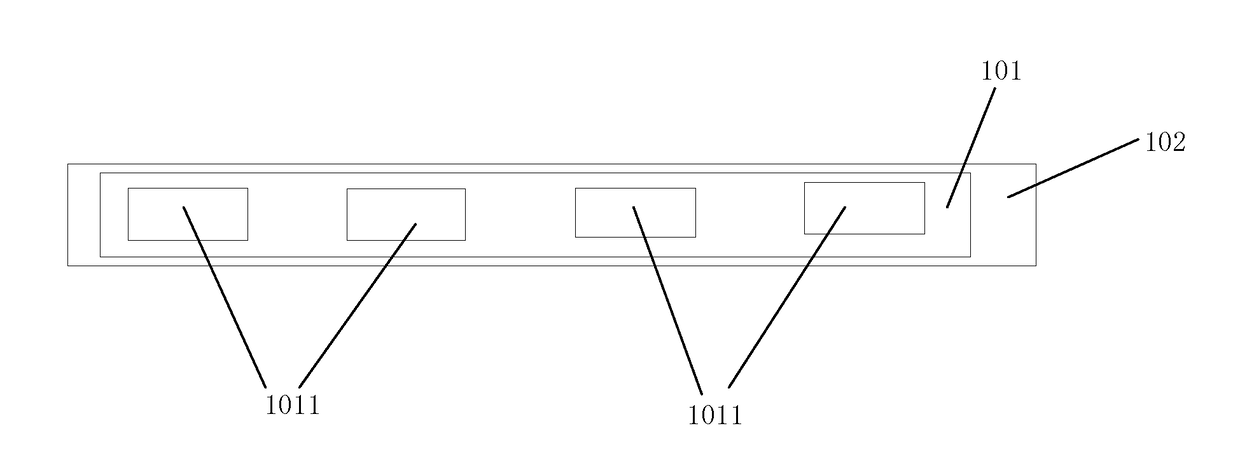

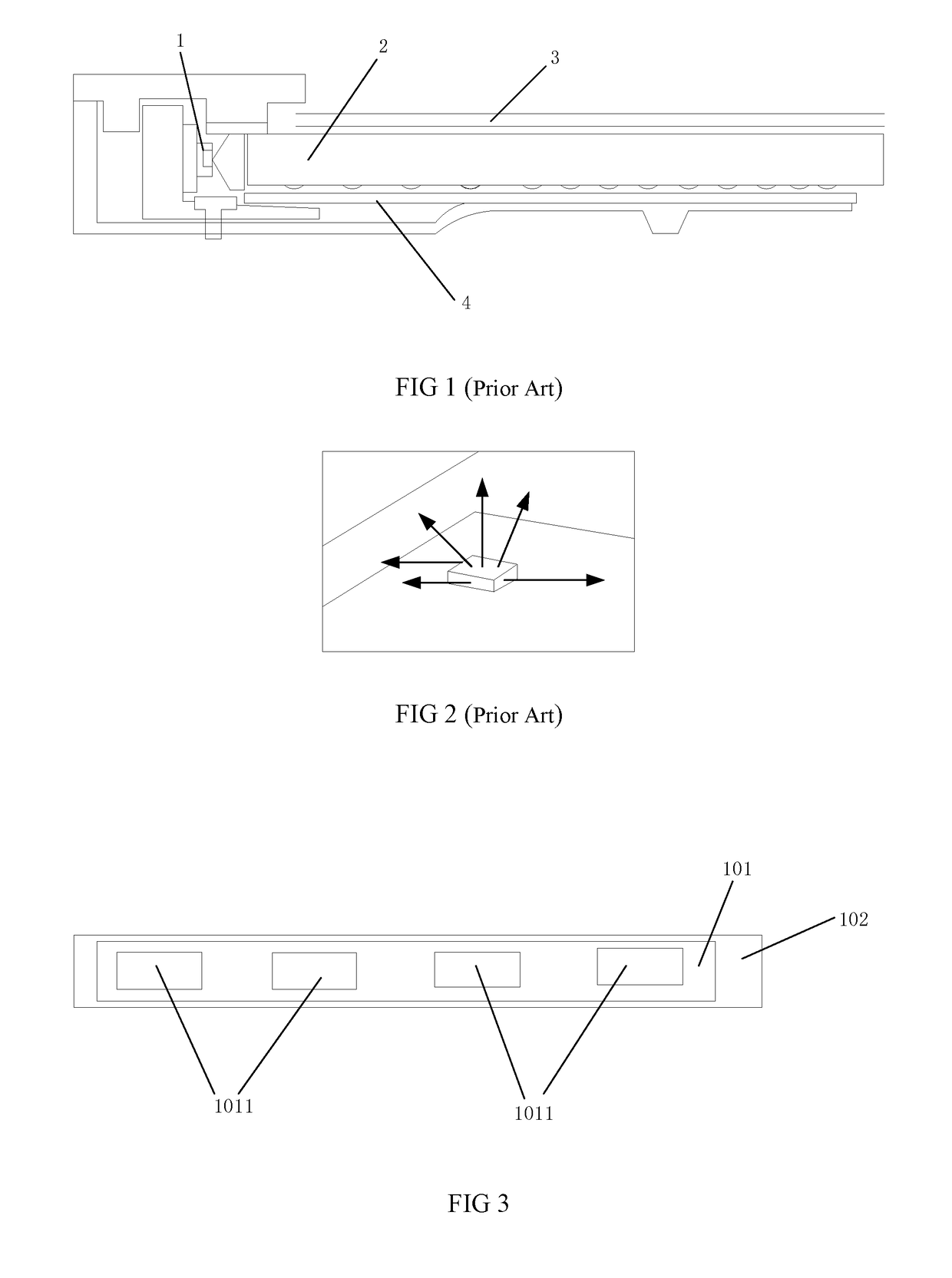

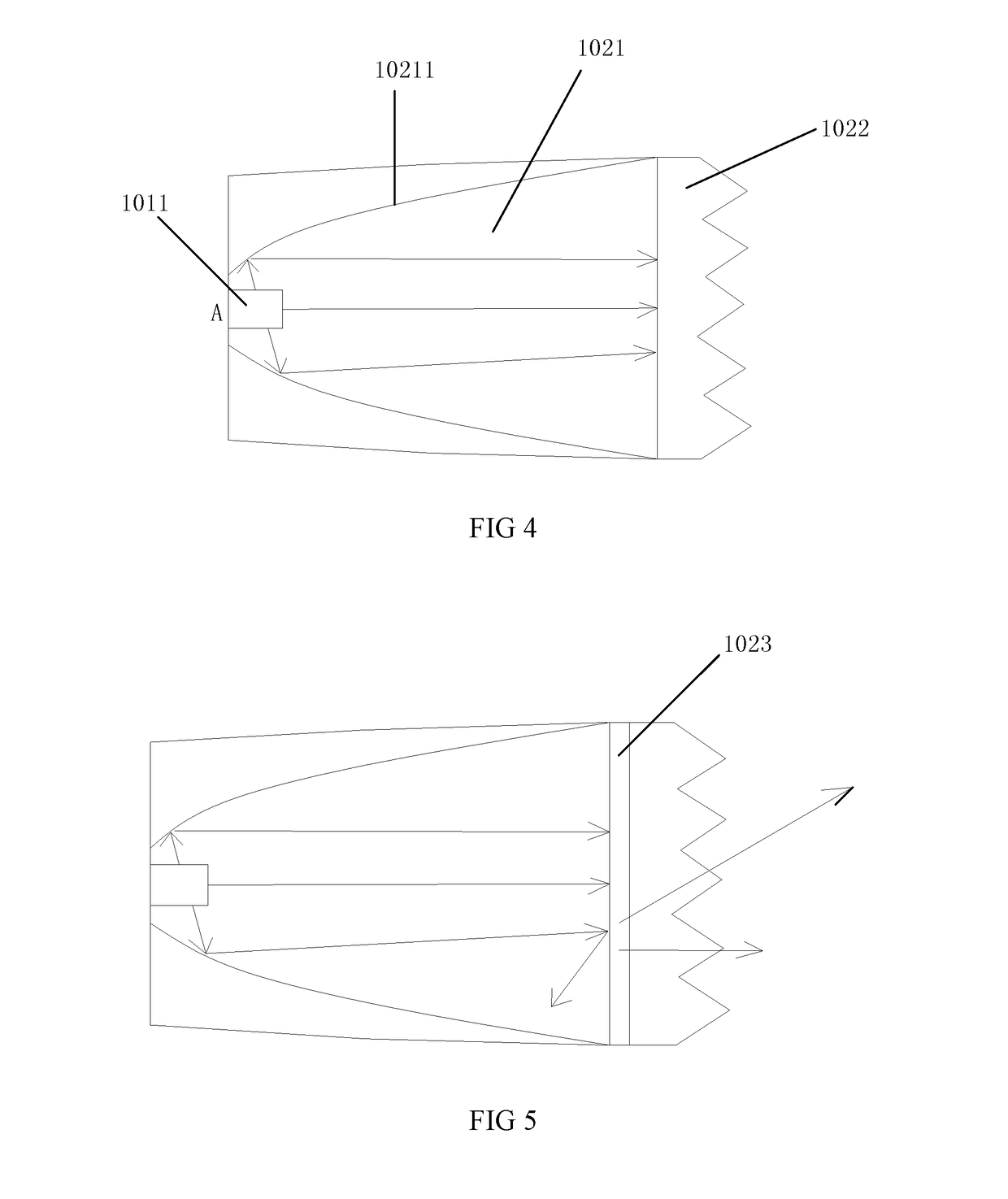

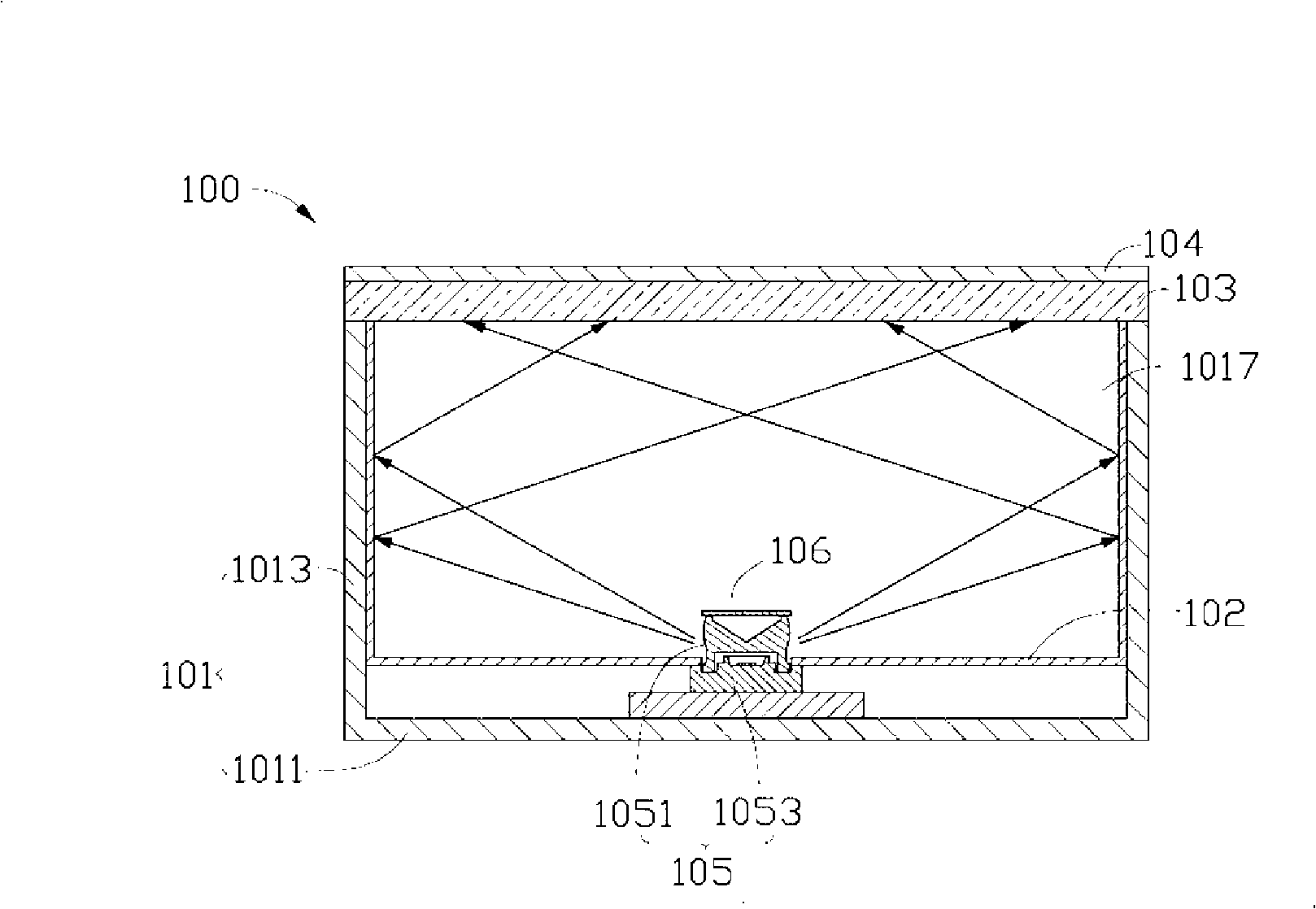

ActiveUS20180101063A1Low costImprove optical utilizationPlanar/plate-like light guidesRoad vehiclesEngineeringLED lamp

The present disclosure relates to a backlight module and a liquid crystal device. The backlight module includes a LED light source and a lens bar. The LED light source is arranged on the LED substrate and includes a plurality of LED lamps encapsulated by CSP. The lens bar is arranged in the front of the LED light source and includes a plurality of chambers. Internal walls of the chambers are parabola-shaped curved surfaces. Each of the LED lamps is arranged in a rim of a focal point formed by the parabola-shaped curved surface such that the curved surface above the LED lamps is symmetrical to that below the LED lamps. With such configuration, the LED light source encapsulated by the CSP may be incorporated in edge-type BLU so as to avoid the optical leakage issue.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Back light module and optical plate

InactiveCN101344610AImprove optical utilizationLow costOptical light guidesNon-linear opticsEngineeringLight source

An optical plate comprises at least one optical plate unit that comprises an exit face, a bottom face opposite to the exit face and a scattering layer formed on the exit face. A plurality of micro protuberances are formed on the bottom face and each micro protuberance includes at least three side faces which are mutually connected and the horizontal width of each side face decreases gradually along a direction far away from the bottom face; at least one light source containing part is arranged on the bottom face. The invention also provides a backlight module adopting the optical plate and the backlight module has the advantage of even light-exiting.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Lens and LED (light emitting diode) lamp with lens

InactiveCN104676467AImprove optical utilizationWide range of light outputPoint-like light sourceRefractorsAcute angleOptical axis

Disclosed are a lens and an LED (light emitting diode) lamp with the lens. The lens comprises a light inlet end and a light outlet end, wherein the light input end is a revolving parabolic surface revolution solid which uses the optic axis as the rotation axis, the periphery of the light inlet end is a revolving parabolic surface, a light source containing cavity is formed in the small end of the light input end, a convex spherical surface is formed at a spherical cap of the light source containing cavity, an intersection angle between the end face of the light outlet end and the optic axis is an acute angle, a plurality of strip-shaped convex surfaces which are connected are arranged on the end face of the light outlet end, and light rays shot into the side wall of the light source containing cavity through the periphery of the light inlet end are reflected to the end face of the light outlet end through the periphery of the light inlet end. According to the lens and the LED lamp with the lens, the lens reflects the light rays through the periphery of the revolving parabolic surface, and converges the light rays through the convex spherical surface. Furthermore, the end face of the light outlet end is an oblique plane which forms the acute angle with the optic axis, the plurality of the strip-shaped convex surfaces which are connected are arranged, rectangular spots of 80 degrees*20 degrees are formed after the light rays are reflected through the end face of the light outlet end, an then are emitted out, and therefore a light outlet range is wide, the lens and the LED lamp with the lens are simple in structure and low in cost, and optical utilization rate of the LED lamp with the lens is improved.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

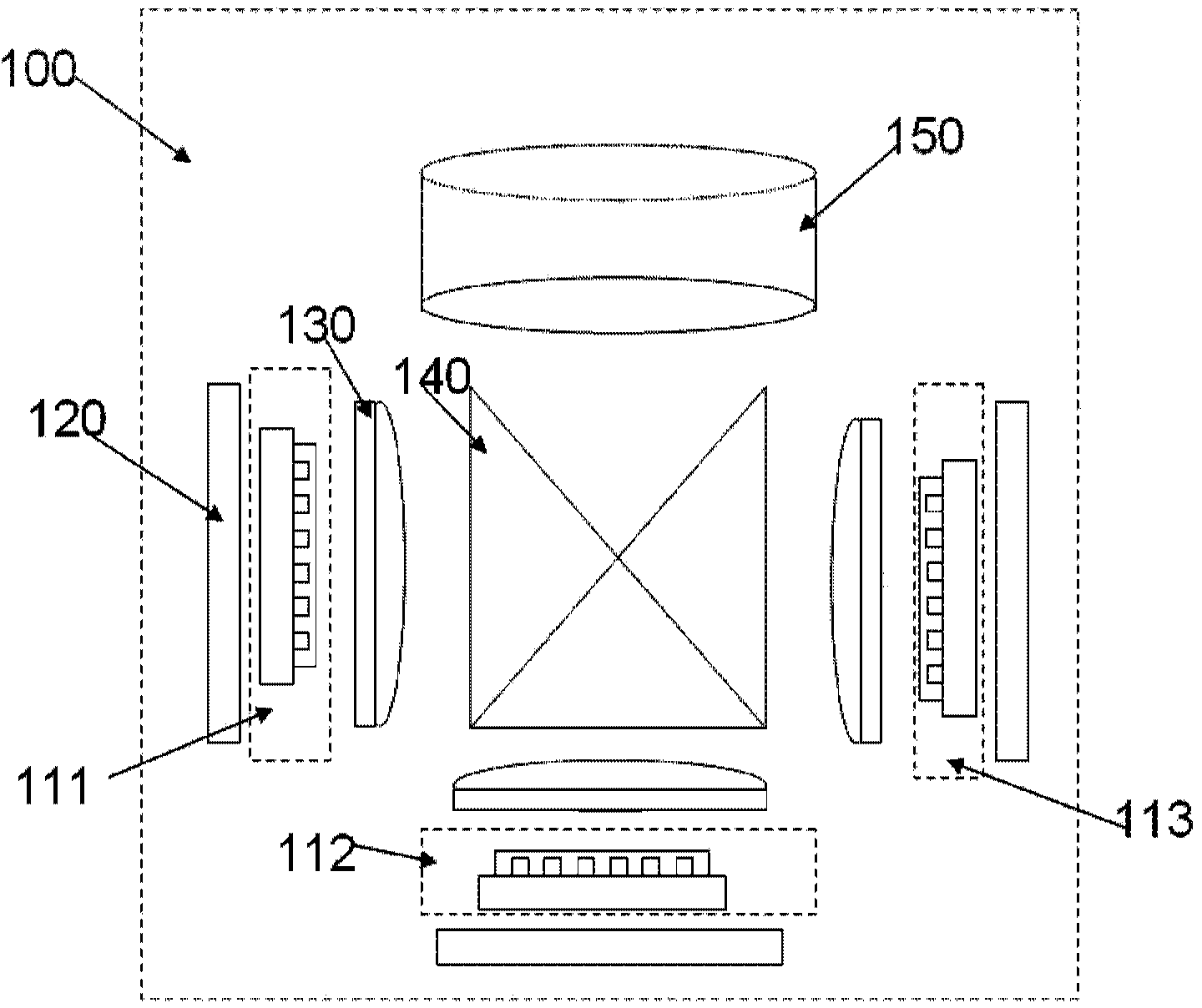

Microdisplay dynamic target simulation module

InactiveCN105549248AIncrease temperatureWork lessNon-linear opticsCooling/ventilation/heating modificationsDisplay deviceComputer module

The invention provides a microdisplay dynamic target simulation module which comprises a microdisplay, a microdisplay circuit driving board, heaters and a temperature controller. The microdisplay is connected with the microdisplay circuit driving board, the heaters are arranged on the back face of the microdisplay and the front face and the back face of the microdisplay circuit driving board respectively, and the temperature controller is connected between the heaters arranged on the front face and the back face of the microdisplay; the temperature controller detects the real-time temperature of the microdisplay, when the temperature is lower than first preset temperature, the temperature controller is switched on, and the heaters start to heat; when the temperature is higher than second preset temperature, the temperature controller is switched off, and the heaters stop heating. By means of the microdisplay dynamic target simulation module, the usage temperature of the microdisplay can be effectively widened, and the microdisplay can normally work in a low-temperature environment to dynamically simulate a target.

Owner:XIAN MICROMACH TECH CO LTD

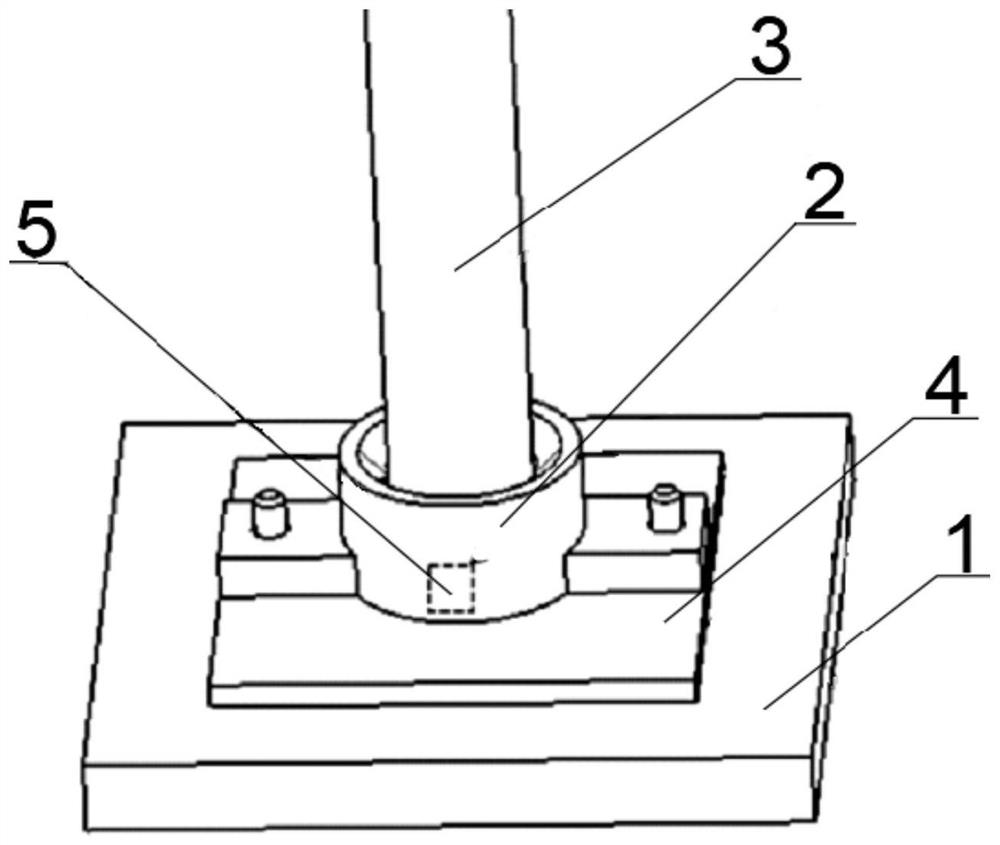

Light guide structure for realizing high brightness by low-power LED

PendingCN113606554AImprove optical utilizationImprove thermal conductivityVehicle headlampsElectric circuit arrangementsOptical reflectionLight guide

The invention discloses a light guide structure for realizing high brightness by a low-power LED. The light guide structure comprises a support and a light condenser, a PCBA is arranged on the top of the support, an LED lamp wick is installed on the top of the PCBA through an installation base, the light condenser is arranged on the outer side of the top of the PCBA, an optical reflection mirror face is glued in the light condenser, and a light guide column is arranged on the top of the light condenser in a sleeved mode. Compared with a conventional LED lighting light guide mode, the condenser is additionally arranged, the condenser can play a role in collecting light which cannot be directly emitted into the light guide and reflecting the light into the light guide again, meanwhile, the condenser can also reduce the effect that deviation exists between the position relation of a traditional light guide and an LED and actual assembly matching, and therefore the LED optical utilization rate is increased. The objective of low-power high brightness is achieved and the light guide structure is suitable for being widely popularized and used.

Owner:北京海纳川海拉三河车灯有限公司

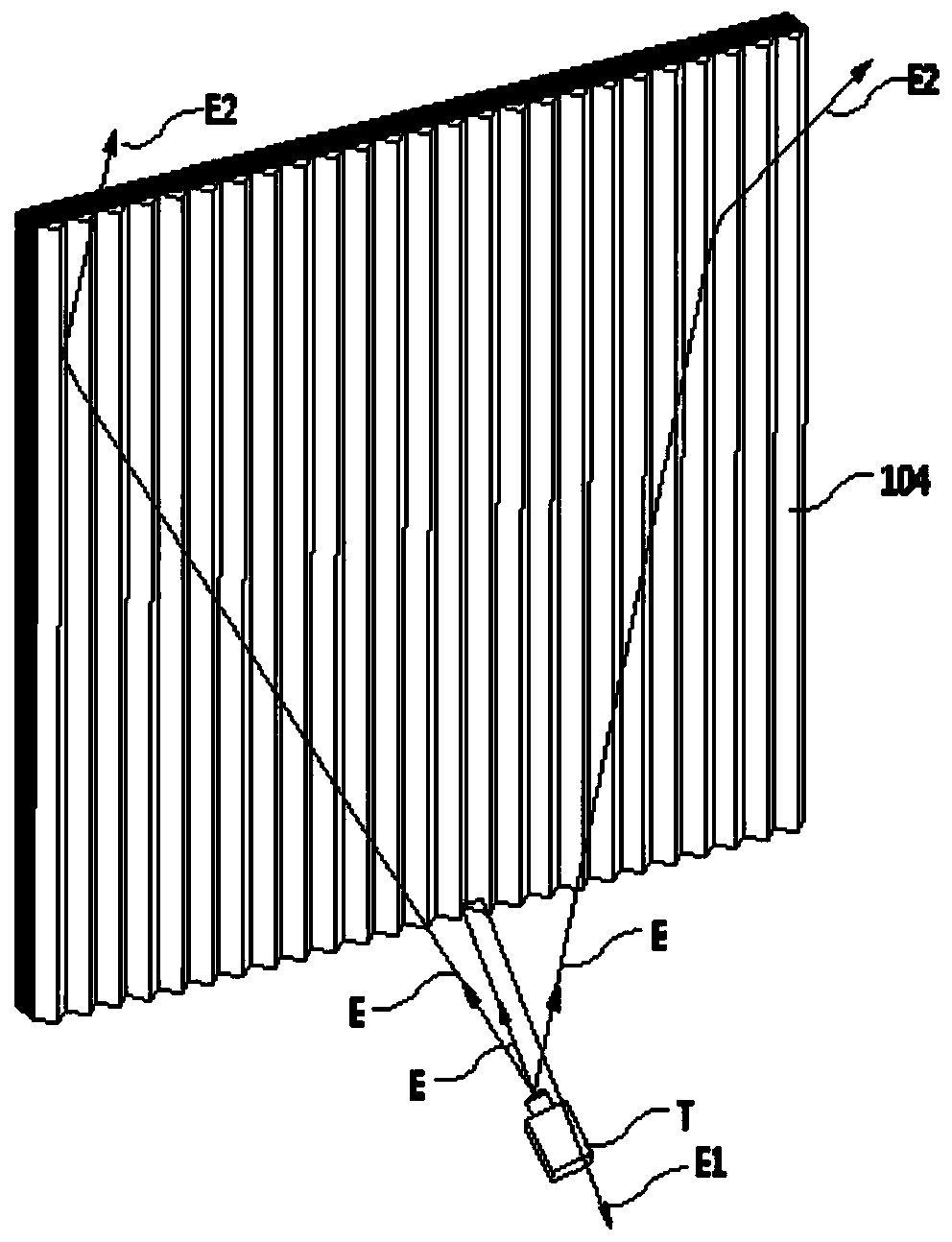

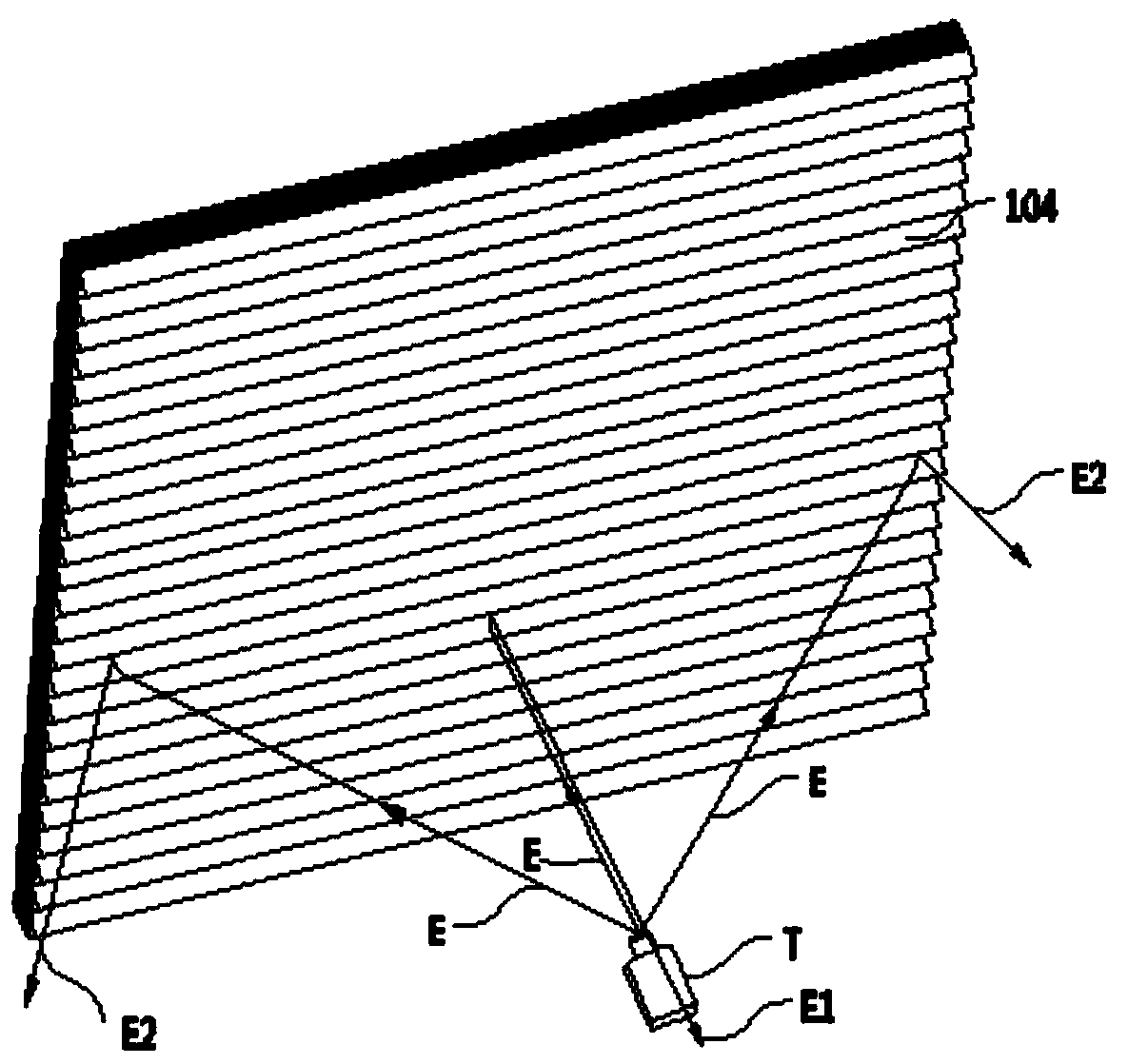

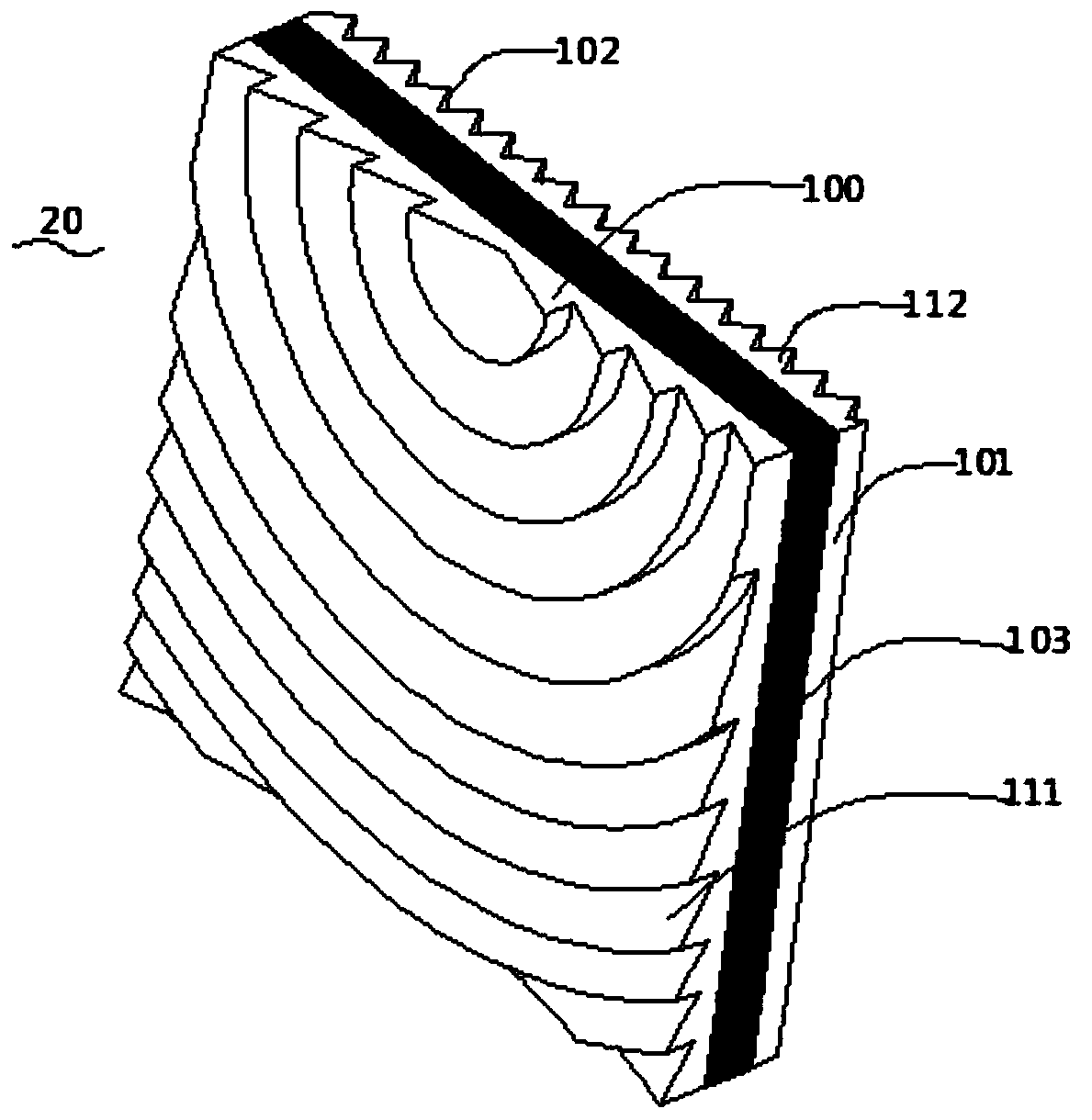

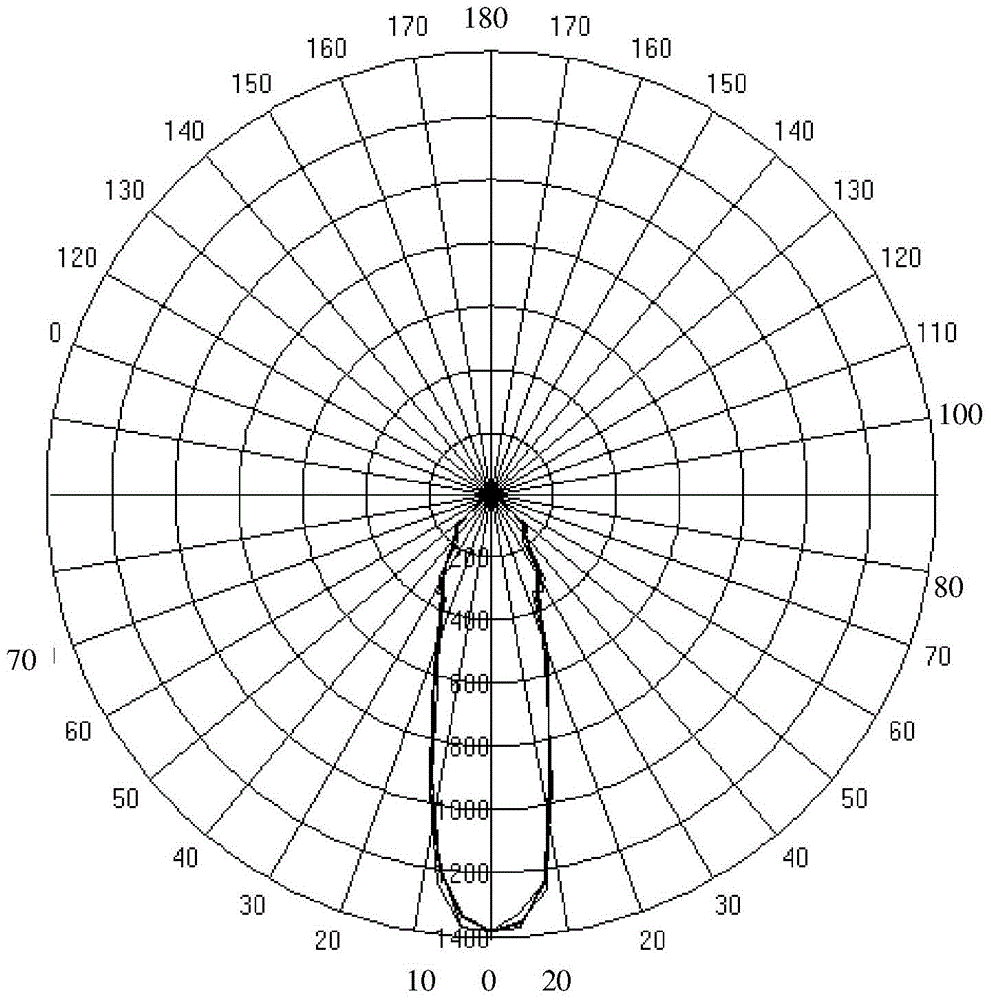

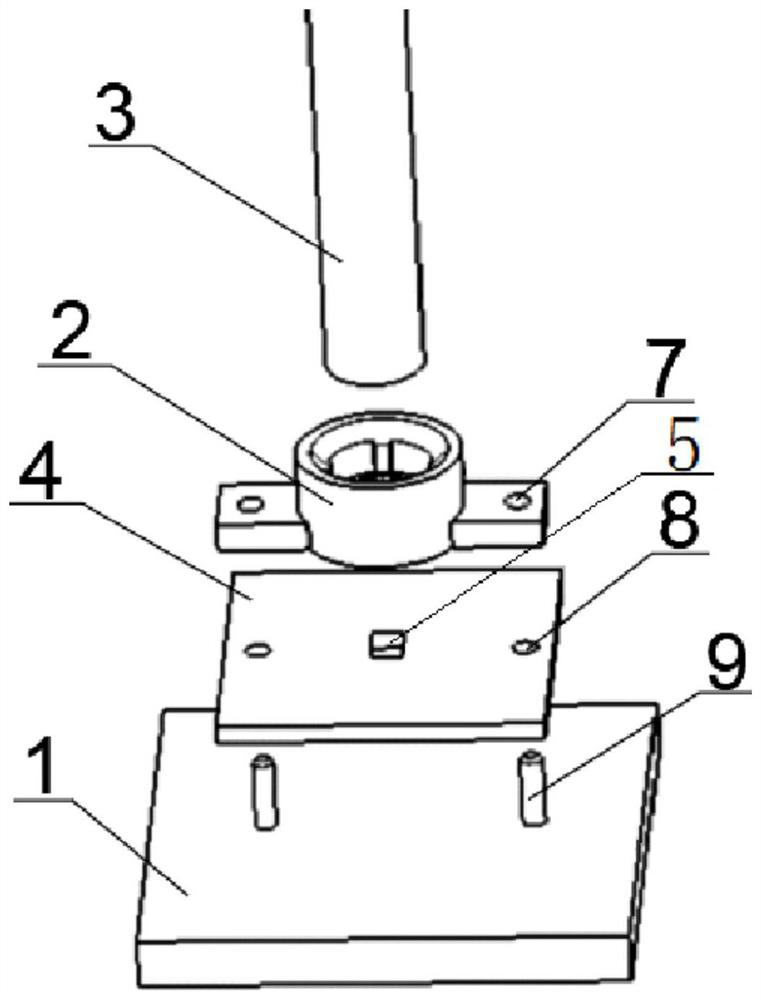

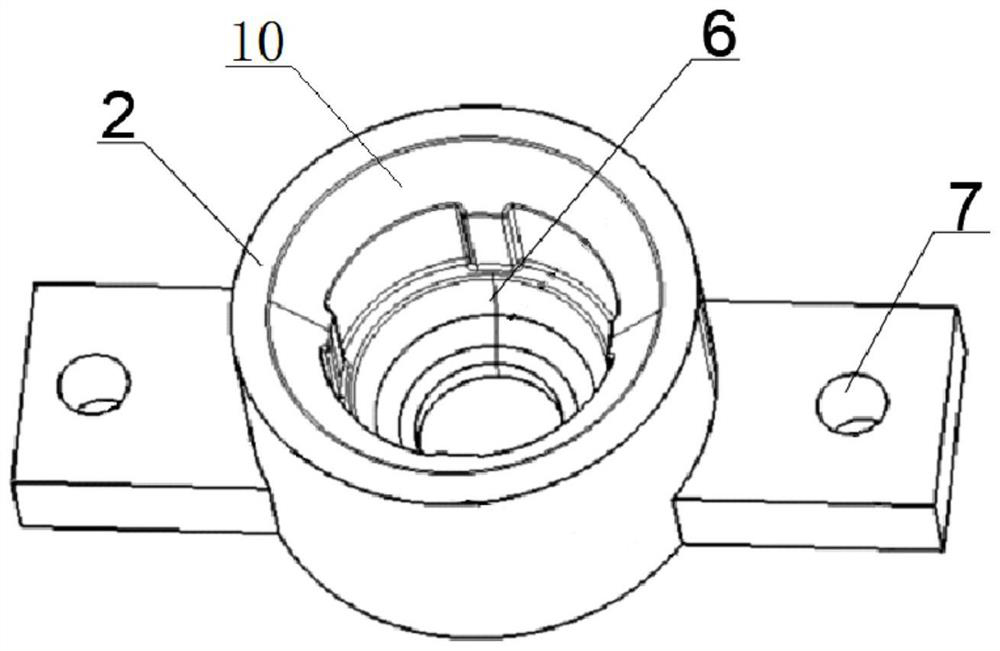

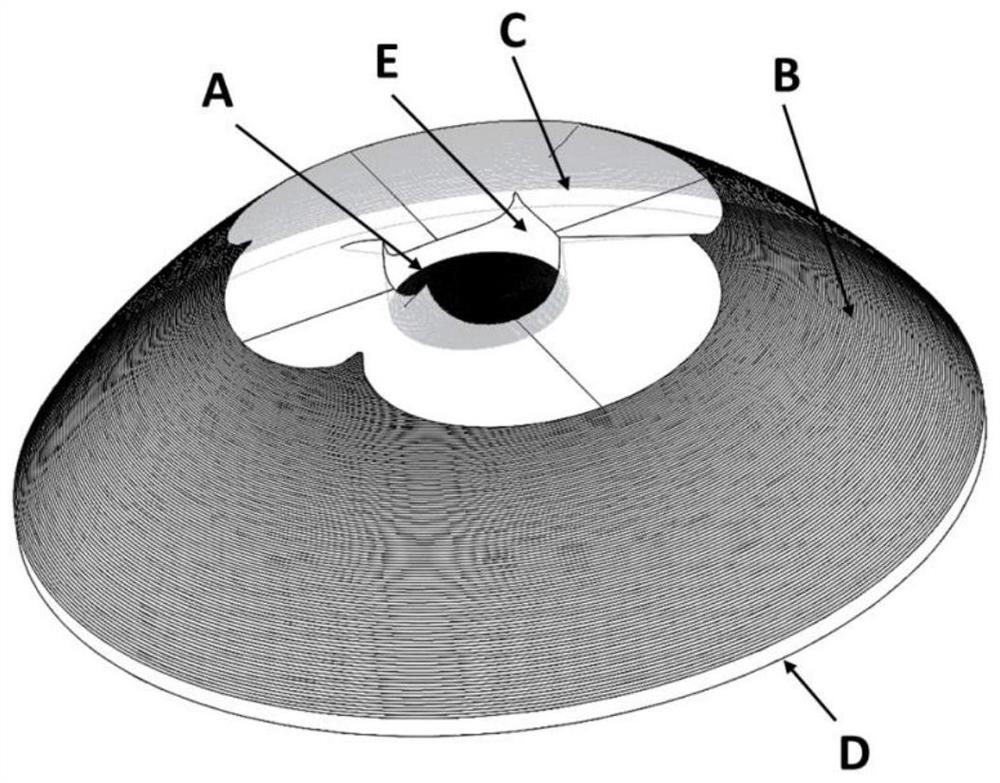

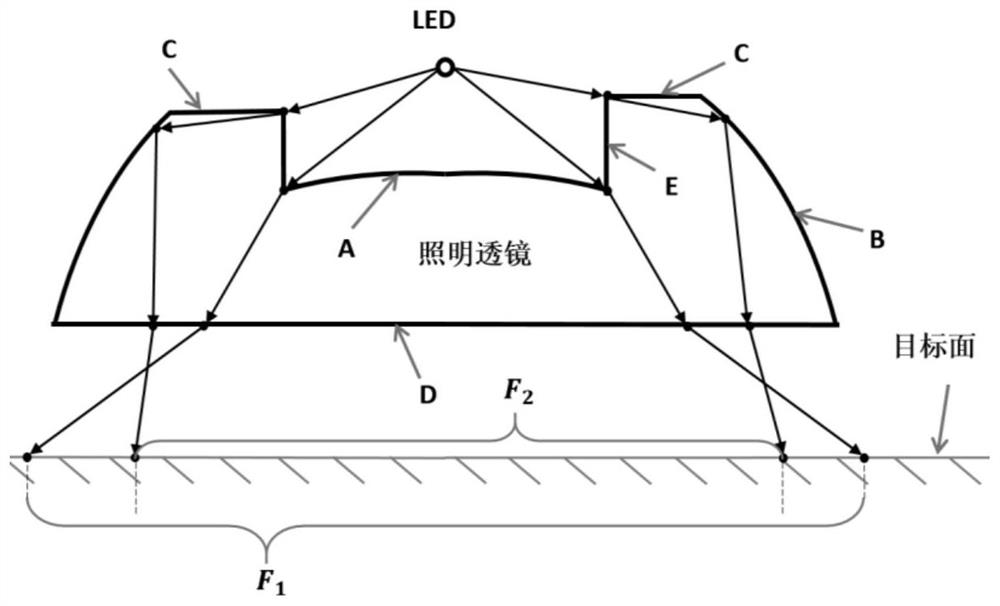

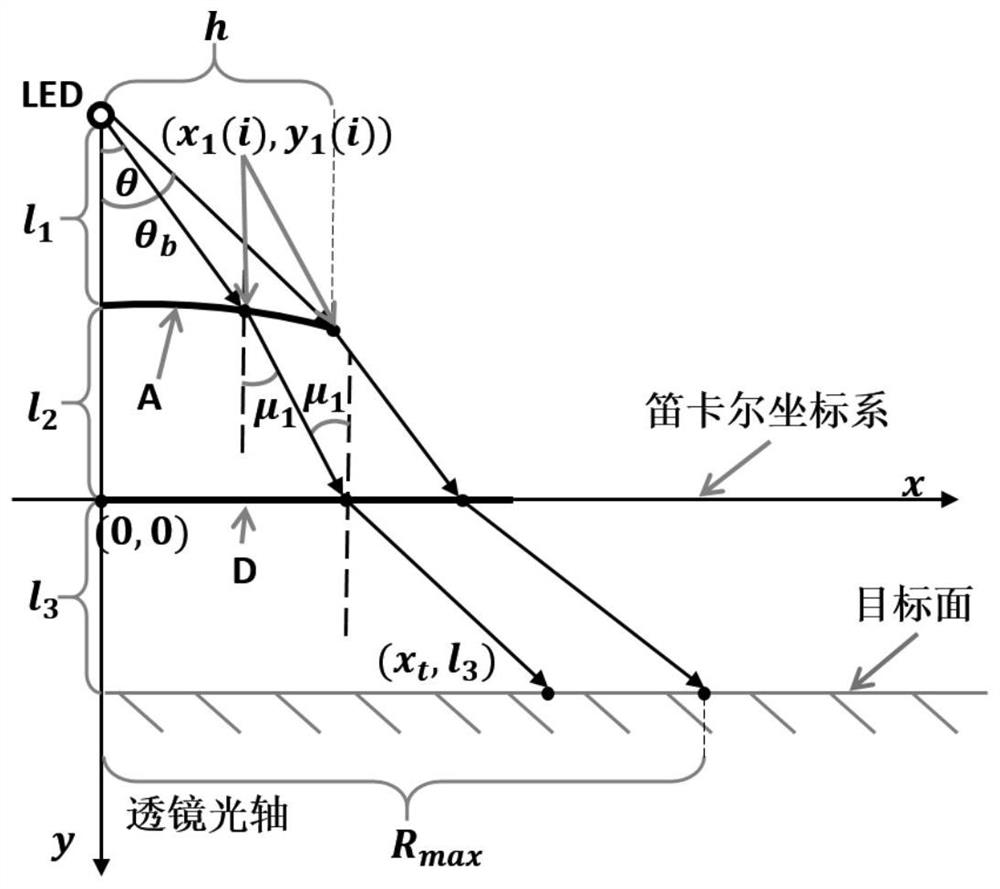

Machine vision illumination lens for generating customized light spots and design method of machine vision illumination lens

ActiveCN112050167ACompact structureImprove optical utilizationDesign optimisation/simulationComplex mathematical operationsOphthalmologyImaging quality

The invention belongs to the technical field of illumination design and machine vision, and particularly relates to a design method of an illumination lens for improving a vision detection system. According to the design method, a composite structure is adopted by a light distribution lens, two aspheric surfaces respectively perform total internal reflection light distribution and transmission light distribution on emergent light of a light source, so that the uniformity of irradiation distribution on a target surface is ensured, and bottom curved surfaces are used for customizing the shapes of uniform light spots on the target surface; and two groups of differential algebraic equations and a group of nonlinear equations are established in combination with the solid geometry relationship of the lens, and numerical solutions of the equations are processed into an illumination lens three-dimensional model and imported into optical tracing software for simulation. According to the designmethod, the uniform customized-shaped light spots can be generated, illumination can be customized in a targeted manner, the irradiation uniformity and the luminous flux utilization rate are high, anddifferent irradiance can be generated in different areas in the target surface according to the reflectivity design of a detection target, so that highlight or shadows in visual detection are inhibited, and the image quality of the visual detection is improved.

Owner:FUDAN UNIV

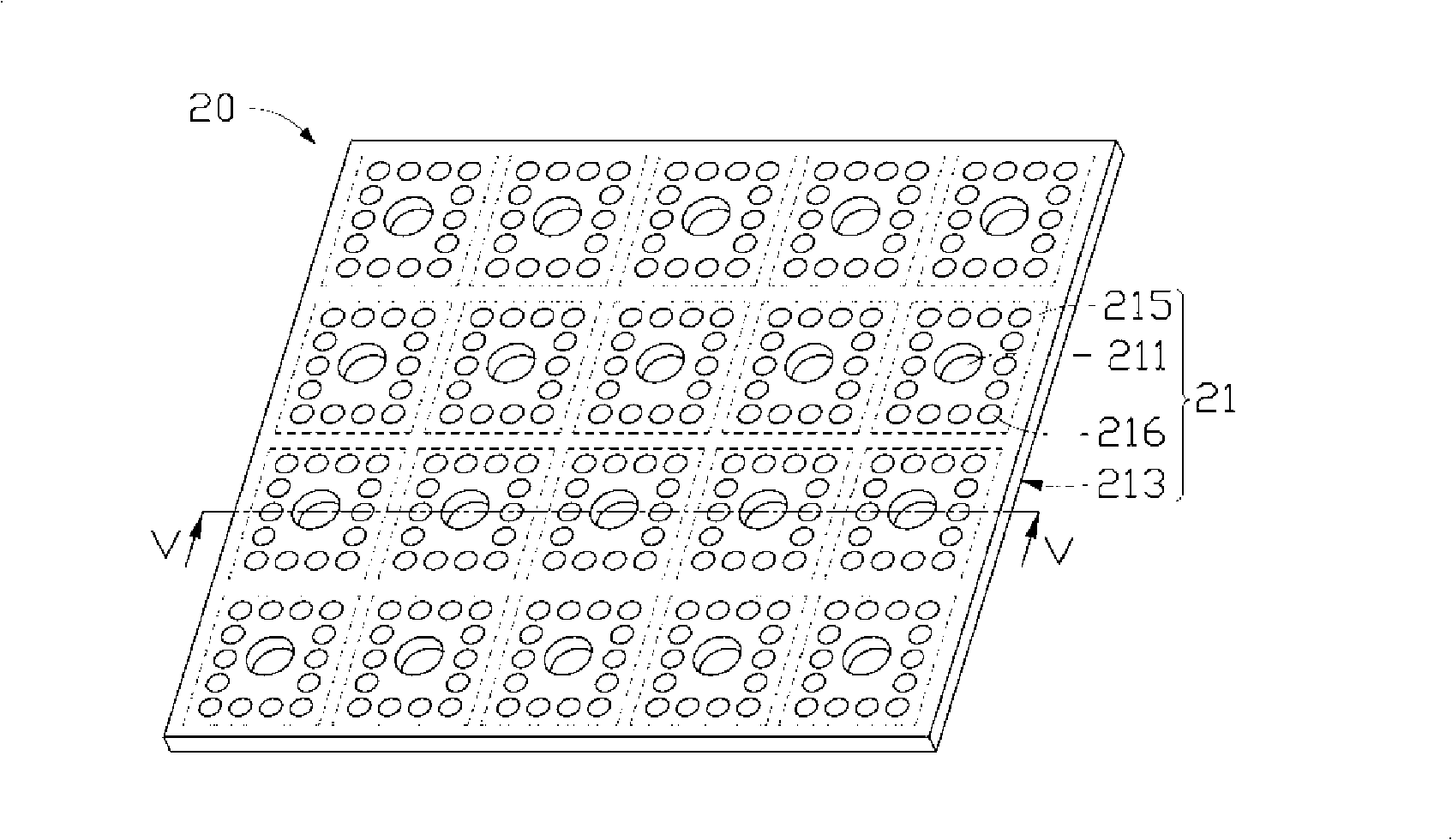

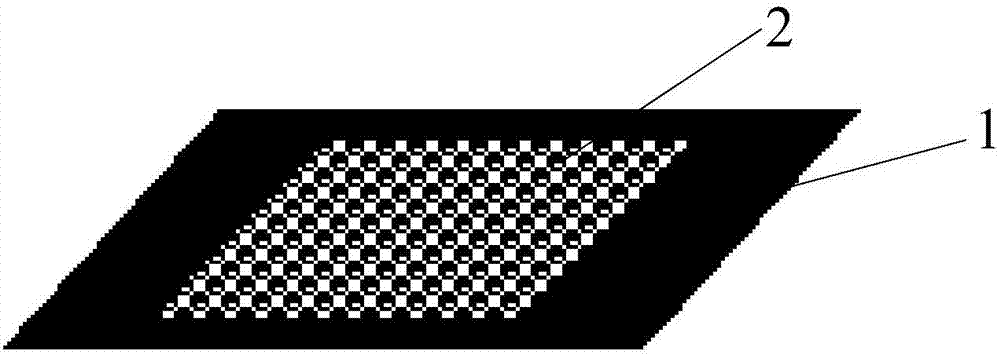

Light guide plate die, light guide plate and manufacturing method of light guide plate

PendingCN107089003AIncrease surface areaImprove optical utilizationOptical articlesFlat articlesEngineeringLight guide

The invention provides a light guide plate mold, a light guide plate and a preparation method thereof, belonging to the display field. The mold for the light guide plate includes a mold body and several shaped structures of light guide points arranged on the mold body. The light guide plate includes a plate body, and the plate body includes a light incident surface, a reflective surface intersecting the light incident surface, a light exit surface opposite to the reflective surface, and a light exit surface opposite to the light incident surface. The light-incident surface and the two opposite side faces, the light-incident surface is set facing the light source, and several light guide points are arranged on the reflective surface, and the shape of the light guide points is concave-convex-convex-concave-convex. In the present invention, the shaped structure of the light guide point is set to be concave-convex-convex-convex-convex, so that the shape of the light guide point on the light guide plate prepared based on the light guide plate mold is concave-convex-convex-concave-convex, that is, the shape of the light guide point is concave and convex. , compared with the light guide point including only the convex part, the optically effective utilization area can be enlarged.

Owner:SHANXI YUHAO NEW OPTICAL MATERIALS CO LTD

Back light module and optical plate

InactiveCN101295103AImprove optical utilizationReduce thicknessOptical light guidesNon-linear opticsEngineeringLight emission

The invention relates to an optical board which comprises at least one optical board unit, wherein, the optical board unit includes a first surface and a second surface opposite to the first surface, a plurality of closed V-shaped bulges are formed on the first surface; a plurality of V-shaped strip bulges are formed on the second surface, and at least one of the first surface and the second surface is provided with at least one containing part for light source. The invention also provides a backlight module adopting the optical board, which has the advantage of even light emission.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

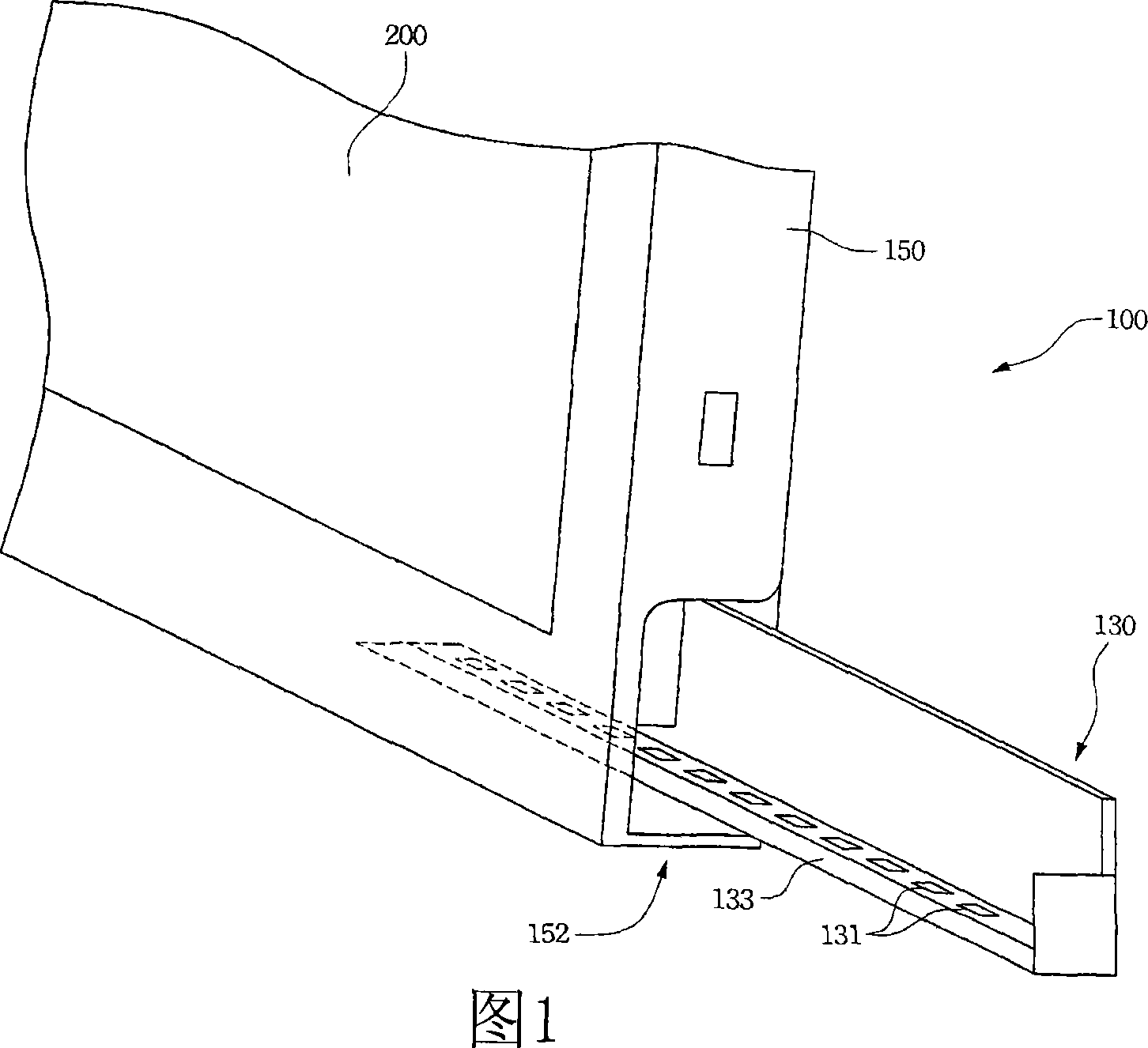

Light source carrier board and side light source

ActiveCN101144938AAvoid damageImprove optical utilizationLighting support devicesNon-linear opticsEngineeringBoard structure

The present invention discloses a light source carrier board structure, which includes a carrier board, a plurality of point light sources, a first side board, and a plurality of flanges. The point light sources are arranged on the carrier board. The first side board is essentially perpendicular to the carrier board, and arranged on a long side of the carrier board. The flanges are arranged on the first side board, and the extension direction of the flanges is essentially perpendicular to the carrier board. When the flanges of the side board with the light source carrier board structure is used to avoid the light source configure, the point light source contacts with the optical film piece directly. Hereon, the present invention also discloses a side entry type light source structure. The light source carrier board structure and the side entry type light source structure of the present invention can prevent the components or the optical film piece from being damaged, and can improve the optical utilization rate.

Owner:AU OPTRONICS CORP

Virtual reality display device

InactiveCN110161692AImprove optical utilizationIncrease display brightnessOptical elementsDisplay devicePolarizer

The invention provides a virtual reality display device. The device includes an OLED display panel and an optical system. The optical system is arranged between the OLED display panel and a user observation side. The optical system includes a first linear polarizer arranged between the OLED display panel and the user observation side, a first reflective and transmissive optical film arranged between the first linear polarizer and the OLED display panel and a first 1 / 4 wave plate arranged between the first reflective and transmissive optical film and the OLED display panel. According to the invention, through the arrangement of the first reflective and transmissive optical film and the first 1 / 4 wave plate, linear polarized light which cannot pass through the first liner polarizer is converted into linear polarized light which can pass through the first liner polarizer to enter the subsequent optical system, which improves the optical utilization of the virtual reality display device and improves the display brightness of the virtual reality display device.

Owner:SEEYA OPTRONICS LTD

Multiple Optical Channel Autocorrelator Based on Optical Circulator

InactiveUS20160187119A1Increase powerLow efficiencyUsing optical meansOptical light guidesSensor arrayPhotovoltaic detectors

Owner:HARBIN ENG UNIV

Projection display system based on full-color light-emitting diode matrixes

InactiveCN104181760AImprove optical utilizationReduce power consumptionProjectorsOptical pathWavelength

The invention discloses a projection display system based on full-color light-emitting diode matrixes. The projection display system comprises three light-emitting diode matrix modules, heat dissipation elements, light collection elements, a light mixing element and a projection element. The light-emitting diode matrix modules comprise the three light-emitting diode display matrixes with different wave lengths. The heat dissipation elements serve as accessories of the three light-emitting diode matrixes and are used for dissipating heat. The light collection elements are placed in front of optical paths of the light-emitting diode matrixes and used for collecting light and guiding the light into the light mixing element. The light mixing element is used for mixing the three types of light emitted by the three light-emitting diode matrixes to form a full-color image. The projection element is placed in front of the light mixing element and used for adjusting the image quality and the image size. The active light-emitting display system is realized, passive control elements in the traditional display technology are eliminated, and therefore the optical utilization rate is increased, and the power consumption of the display system is lowered.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com