Reflector lamp

A reflective cup and lens technology, which is applied in the field of spotlights, can solve the problems of low light utilization rate, achieve good lighting effect, improve light utilization rate, and improve the effect of optical utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

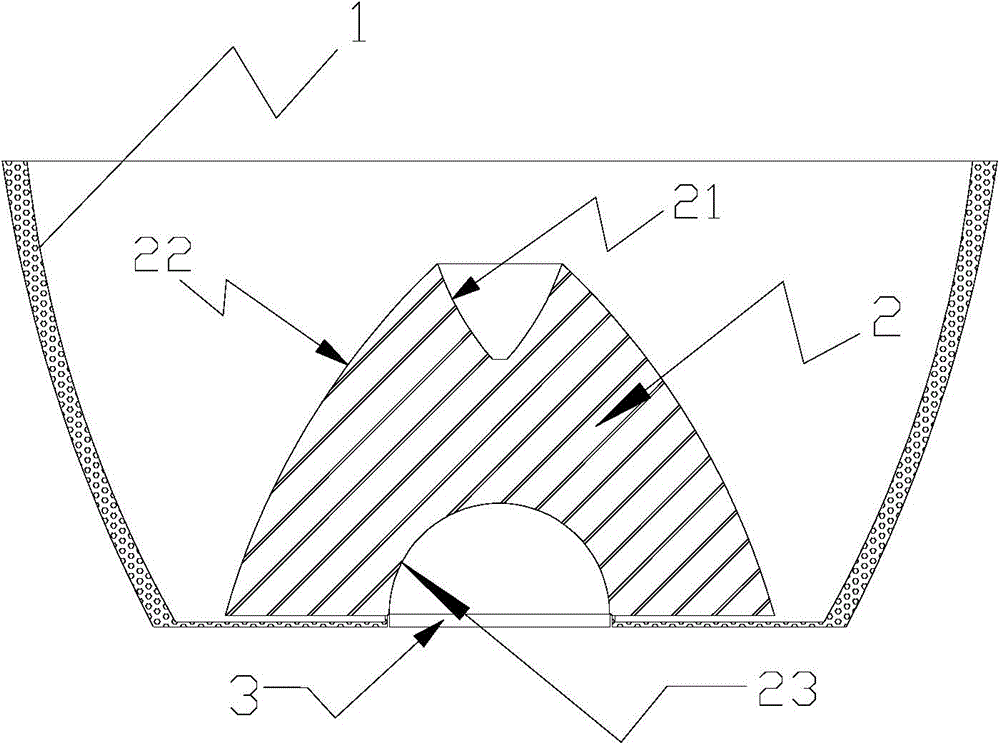

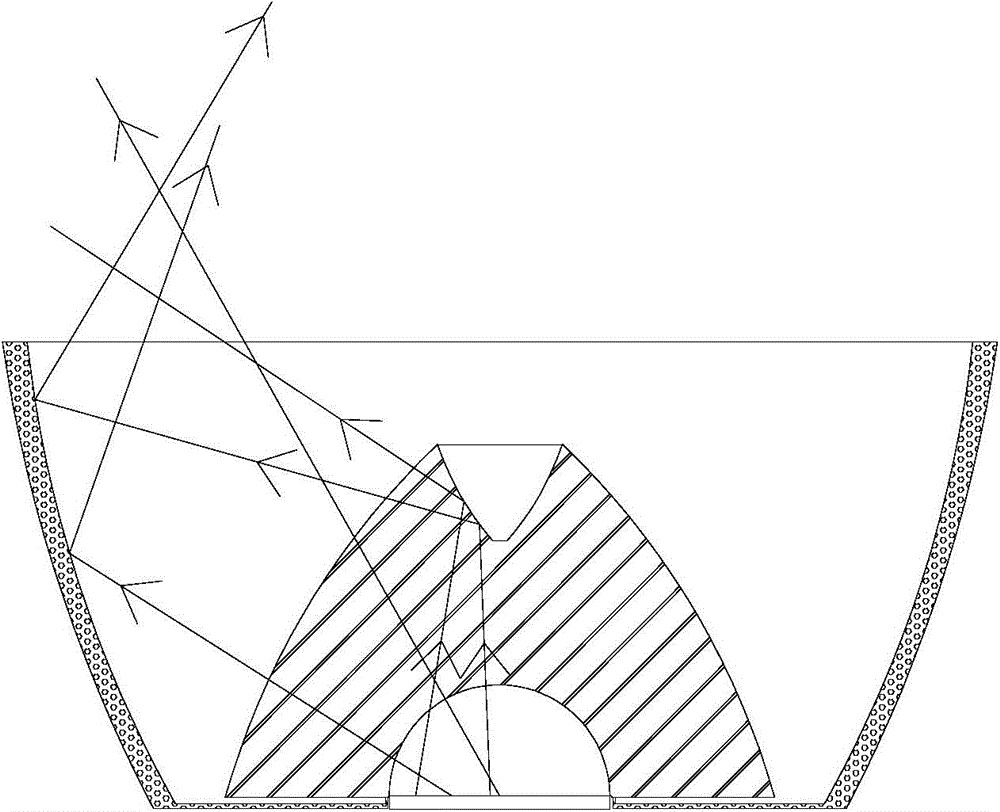

[0031] figure 1 A structural schematic diagram of the combined optical structure of the AR111 spotlight lens and reflector cup in this embodiment is given. The combined optical structure includes a reflective cup, a lens and an LED light source. Wherein, the lens 2 includes three different optically active surfaces: a light-reflecting surface 21 , a light-emitting surface 22 and a light-incoming surface 23 . The light entrance surface 23 is the inner arc surface of a hemisphere or ellipsoid located at the bottom of the lens, the light exit surface 22 is a frustum-shaped outer arc surface located on the outer surface of the lens, and the reflective surface 21 is located on the outer surface of the lens. The inner surface of the inverted truncated cone or cone at the top of the lens, the rotation axes of the light-incoming surface 23, the light-reflecting surface 22 and the light-emitting surface 21 coincide. Such as figure 1 As shown, the lens and the reflective cup are comb...

Embodiment 2

[0035] Such as Figure 4 As shown, the combined optical structure of the lens-reflector cup of this embodiment is different from that of Embodiment 1 in that: the shape of the reflector cup 1 is a concave arc surface rotating cup body. Preferably, the reflector cup 1 emits light corresponding to the spotlight The optical principle of the concave arc rotating cup with an angle greater than or equal to 30 degrees is the same as that of the first embodiment.

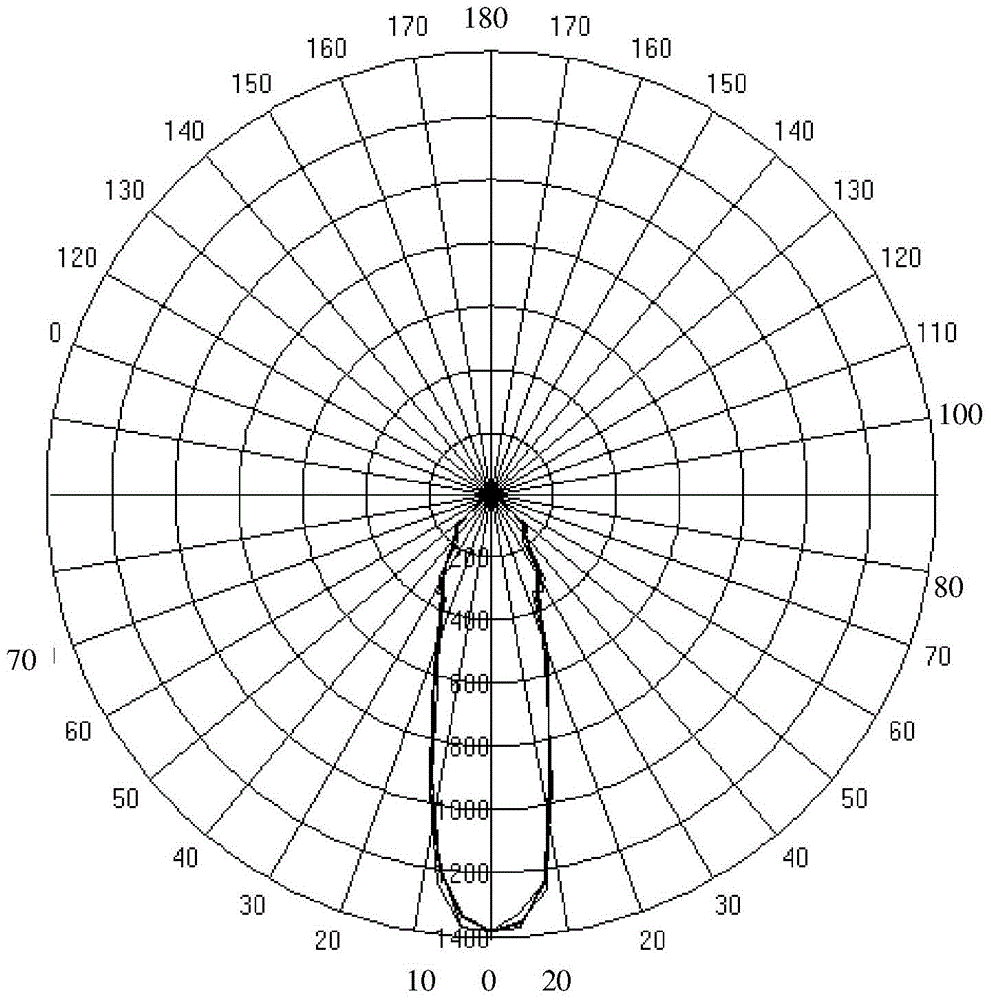

[0036] Figure 5 The light distribution curve of the second implementation is given. Similarly, from the curve, the spotlight of the second embodiment can achieve high-brightness and high-concentration light irradiation within the emission angle of 30 degrees, which can meet the optical effect of the AR111 spotlight lighting, and at the same time The curves indicate high optical utilization.

[0037] from Figure 4 with Figure 5 It can be clearly seen from the light distribution curve of the spotlight that the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com