Processing method for photovoltaic solder strips as well as wire-drawing die and photovoltaic solder strip processing device used in method

A technology of photovoltaic welding tape and processing method, which is applied in the direction of wire drawing dies, etc., can solve the problem of high processing and production cost, and achieve the effects of speeding up production efficiency, reducing production cost and reducing yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments in conjunction with the accompanying drawings,

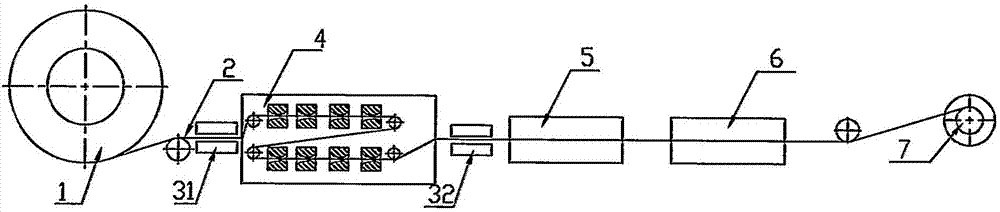

[0027] A method for processing a photovoltaic ribbon, the steps of the method are as follows:

[0028] a) Provide a raw copper rod 2;

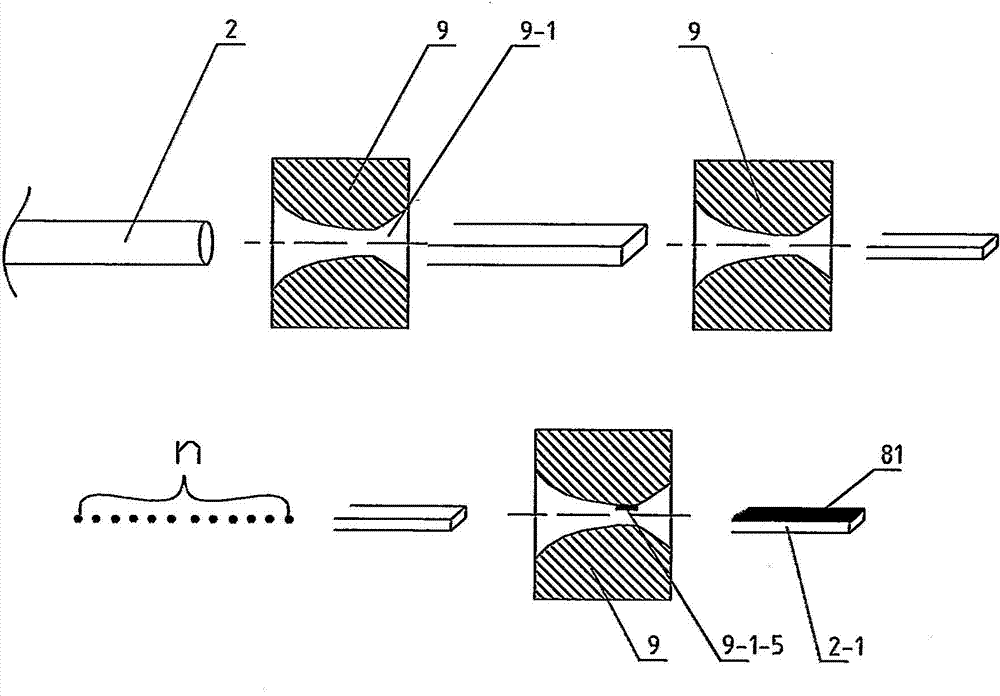

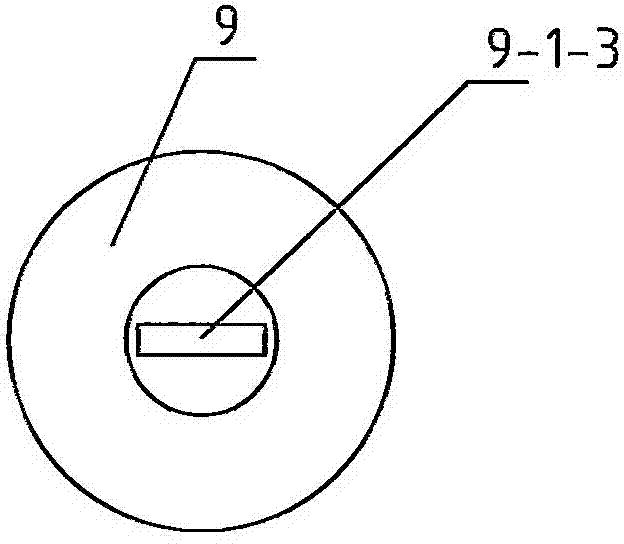

[0029] b) using the raw material copper rod 2 to form a copper strip of the required size by wire drawing through the wire drawing device 4 and forming a structure with reflective grooves on the surface of the copper strip to obtain the first semi-finished product;

[0030] c) Annealing the first semi-finished product by annealing process to form the second semi-finished product;

[0031] d) Reasonably select the coating metal, use the electroplating process to electroplate the second semi-finished product, and control the thickness of the coating to 1μm~30μm to obtain the required photovoltaic ribbon.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com