Back light module and optical plate

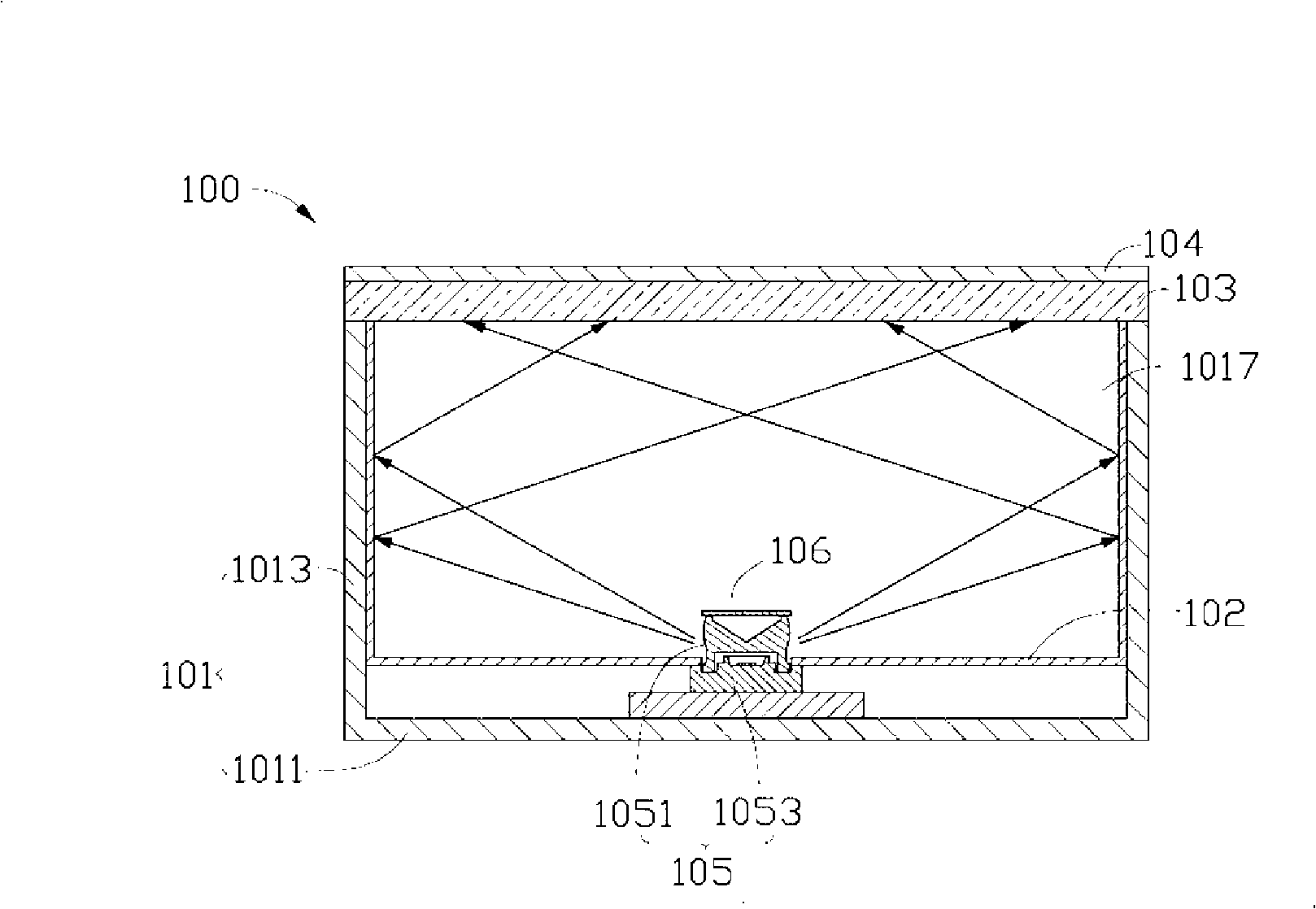

A backlight module and optical board technology, applied in optics, optical components, nonlinear optics, etc., can solve the problem of uneven light output from the backlight module 100

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The backlight module and its optical board of the present invention will be further described in detail below with reference to the drawings and embodiments.

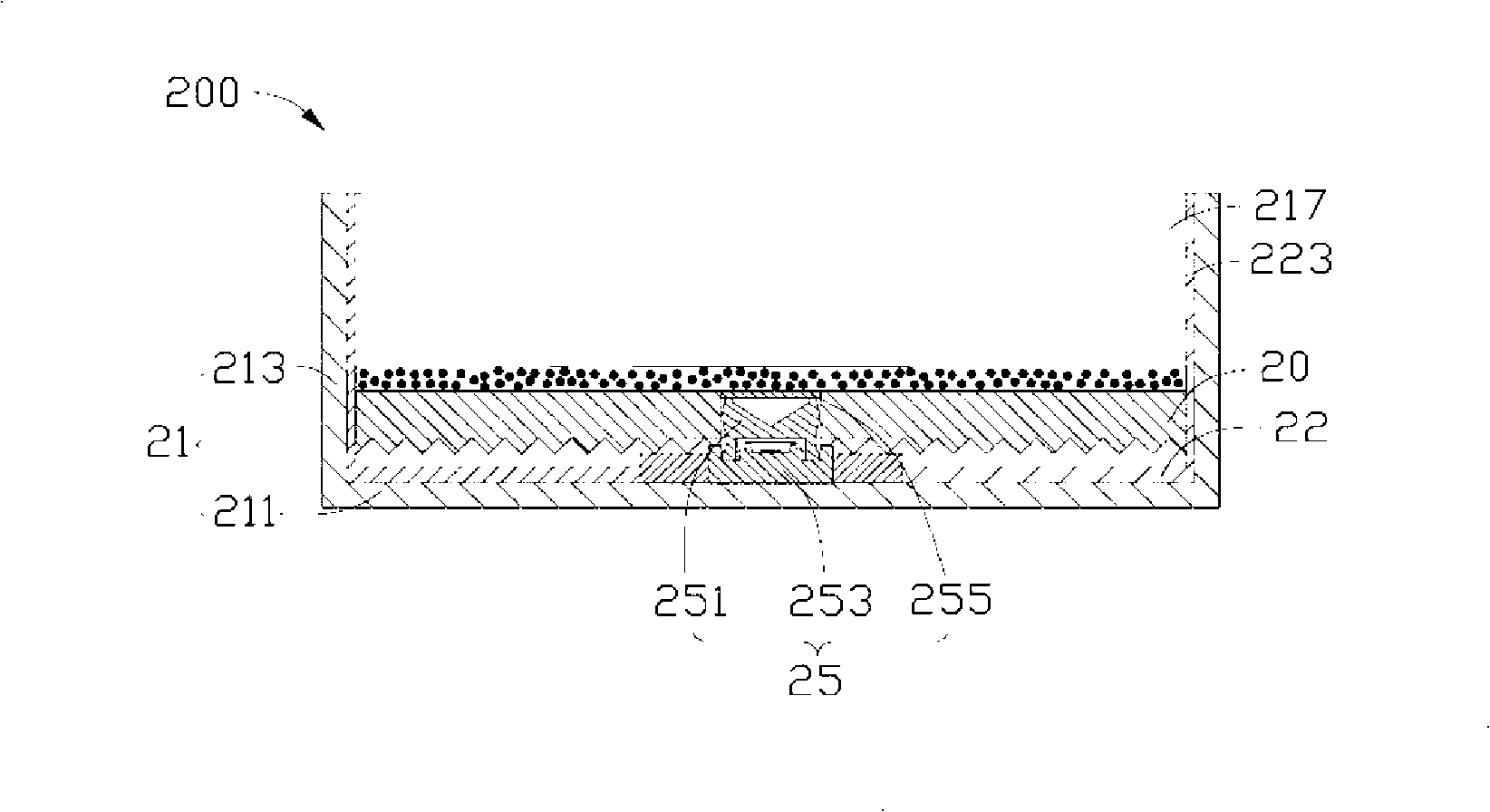

[0019] See figure 2 , shows the backlight module 200 of the preferred embodiment 1 of the present invention, which includes a frame 21 , a reflective plate 22 , an edge-type point light source 25 and an optical plate 20 . The frame 21 includes a rectangular bottom plate 211 and four sidewalls 213 vertically extending from the edge of the bottom plate 211 to the same side thereof and connected to each other. The four side walls 213 and the bottom plate 211 jointly form a cavity 217 for accommodating components such as the point light source 25 , the reflector 22 and the optical plate 20 .

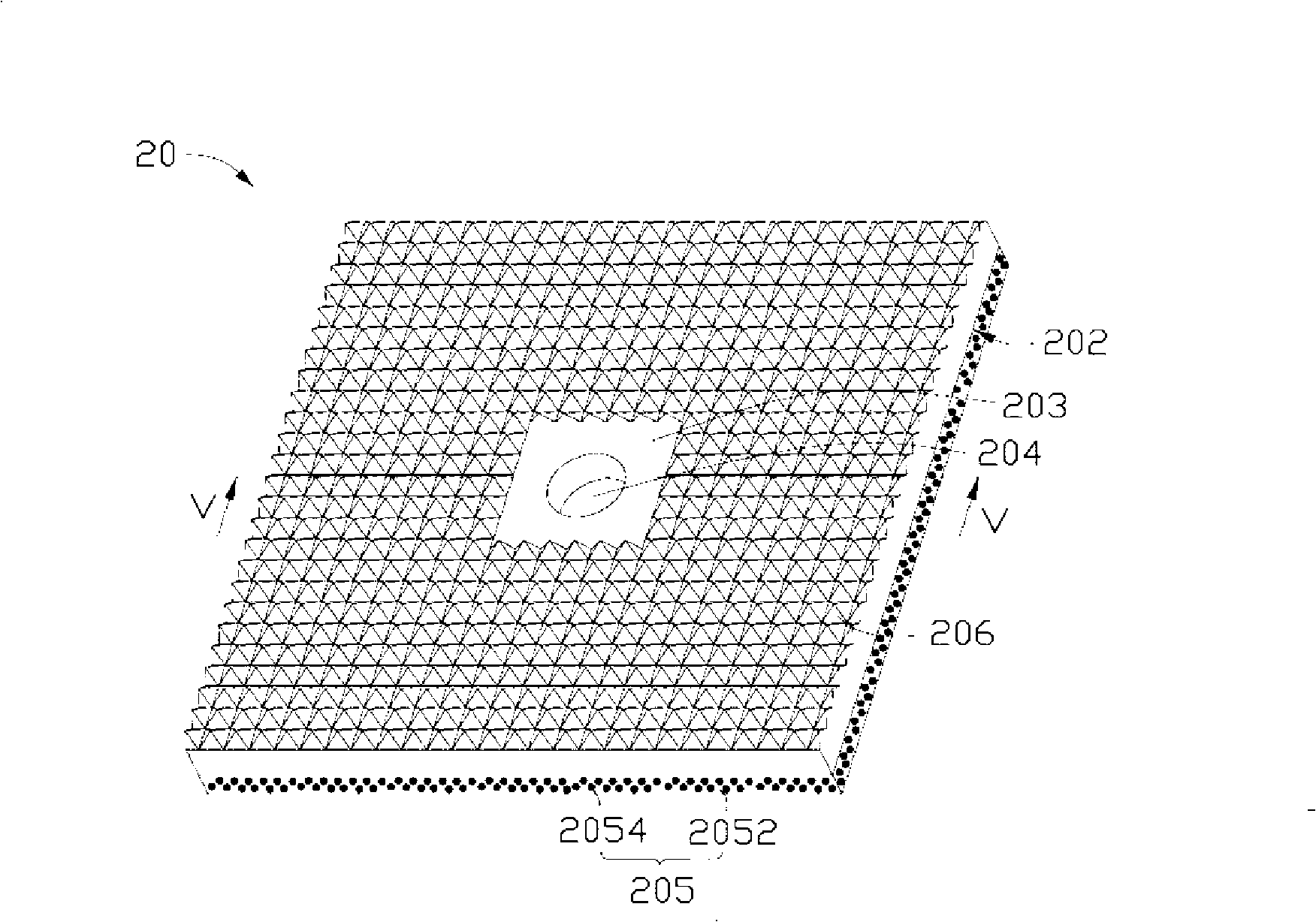

[0020] See image 3 , the optical plate 20 is a rectangular plate matched with the bottom plate 211 of the frame 21 , and includes a light emitting surface 202 and a bottom surface 203 opposite to the light emitting surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com