Light source carrier board and side light source

A side-entry, carrier board technology, applied in optics, nonlinear optics, lighting devices, etc., can solve problems such as scratches on optical films, lower optical utilization efficiency, and component damage, so as to avoid damage and improve optical utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

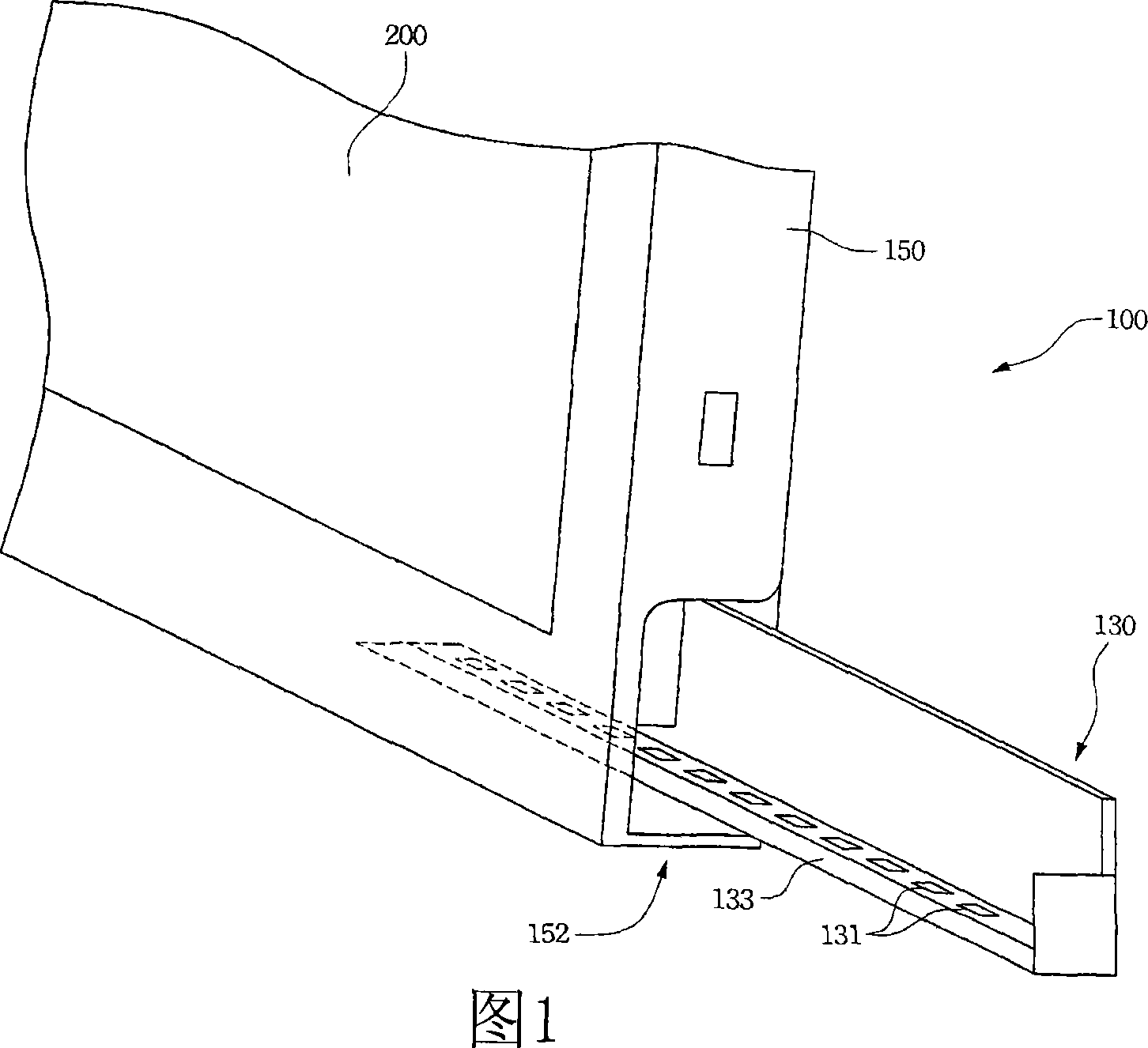

[0027] 1, which shows a three-dimensional schematic diagram of the side-lit light source structure of the present invention. The edge light source structure 100 mainly includes a light source carrier structure 130 and a plastic frame 150. The light source carrier board structure 130 includes a plurality of point light sources 131 disposed on the carrier board 133. The side corner of the plastic frame 150 has an opening 152 for the light source carrier structure 130 to be inserted therein. The optical film 200 may be a light guide plate, a reflection sheet, a light collection sheet, a diffusion sheet, or a combination thereof. The edge light source structure 100 provides a uniform backlight through the optical film 200.

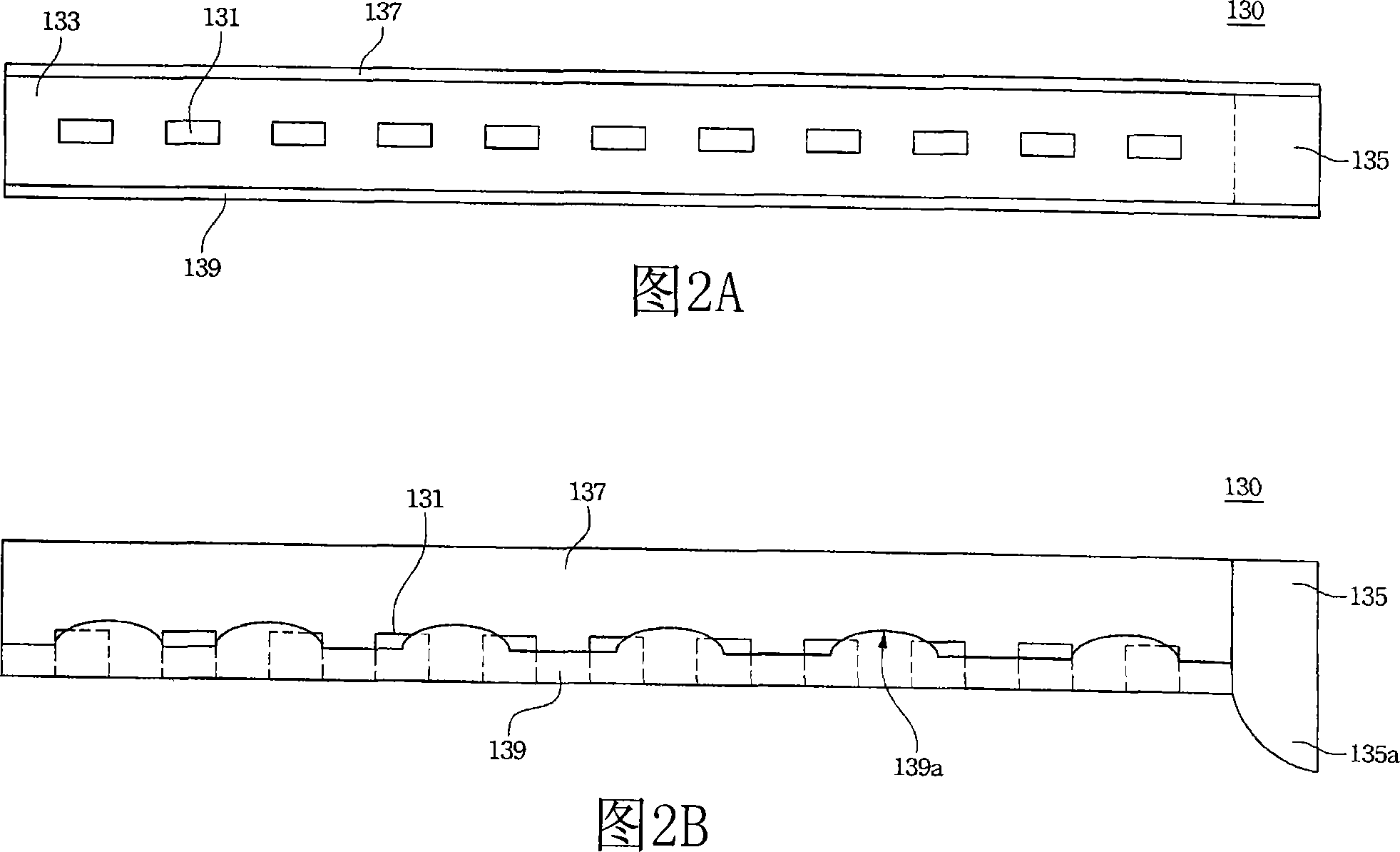

[0028] Refer to FIG. 2A and FIG. 2B together. 2A is a top view of the light source carrier structure of the present invention, and FIG. 2B is a side view thereof. The light source carrier board structure 130 has a plurality of point light sources 131 disposed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com