Back light module and optical plate

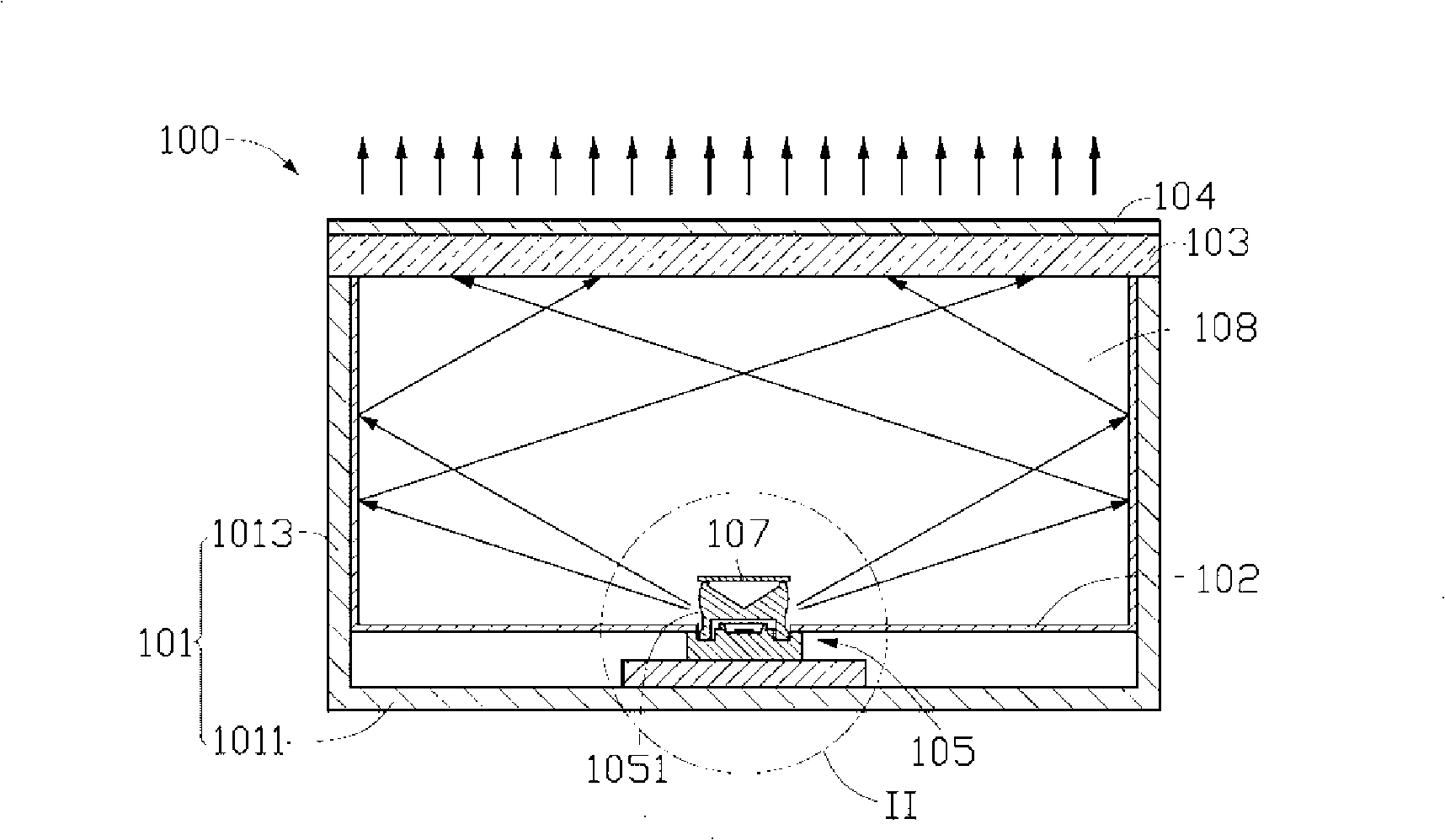

A backlight module and optical board technology, applied in optics, optical components, nonlinear optics, etc., can solve the problem of uneven light output from the backlight module 100

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

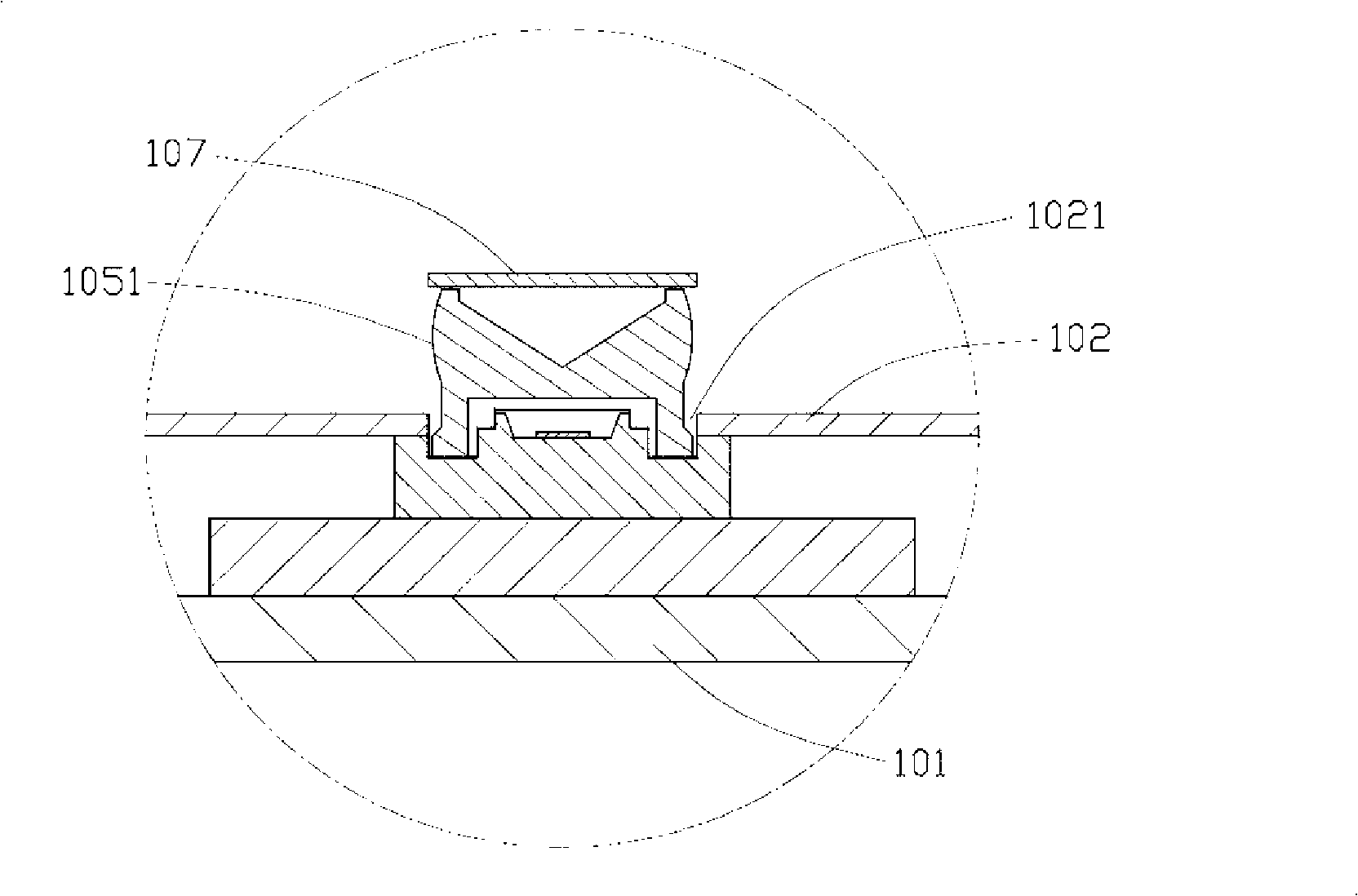

[0025] The backlight module and its optical plate of the present invention will be further described in detail below with reference to the drawings and embodiments.

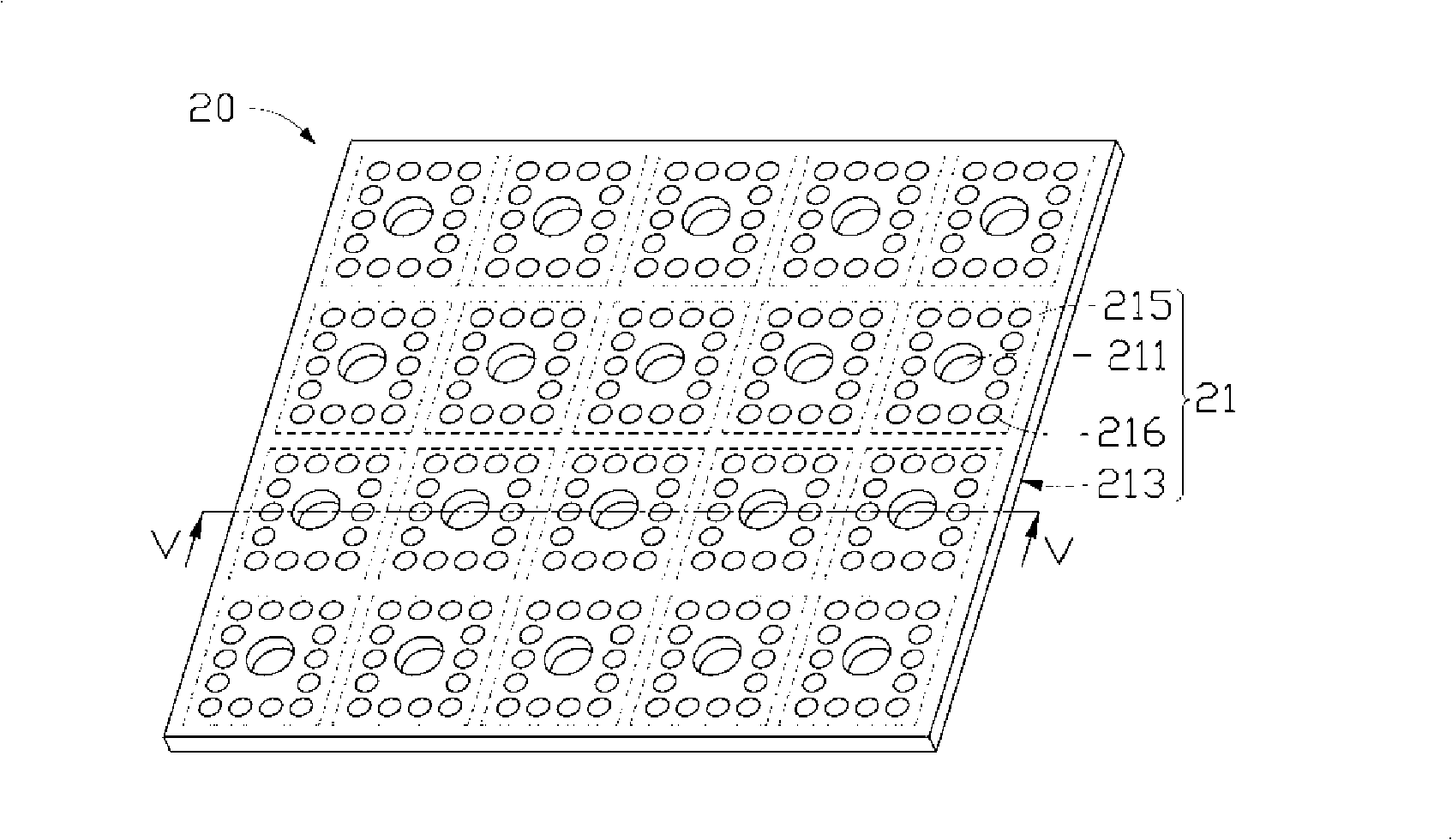

[0026] Please also refer to image 3 , Figure 4 and Figure 5 , the first preferred embodiment of the present invention provides an optical plate 20 . The optical plate 20 has a square shape and includes a plurality of optical plate units 21 arranged closely in an array. Each optical plate unit 21 includes a bottom surface 213 and a light emitting surface 215 opposite to the bottom surface 213 . A light source receiving portion 211 is defined at the center of the bottom surface 213 . In this embodiment, the light source receiving portion 211 is a through hole penetrating from the bottom surface 213 to the light emitting surface 215 . The bottom surface 213 is formed with a plurality of micro-protrusions 214 located around the light source containing portion 211 . The light emitting surface 215 forms a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com