Organic luminescent display

A light-emitting display, organic technology, applied in electroluminescent light sources, light sources, electric light sources, etc., can solve the problems of low optical utilization rate and light waste of organic light-emitting displays, and achieve the effect of improving optical utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

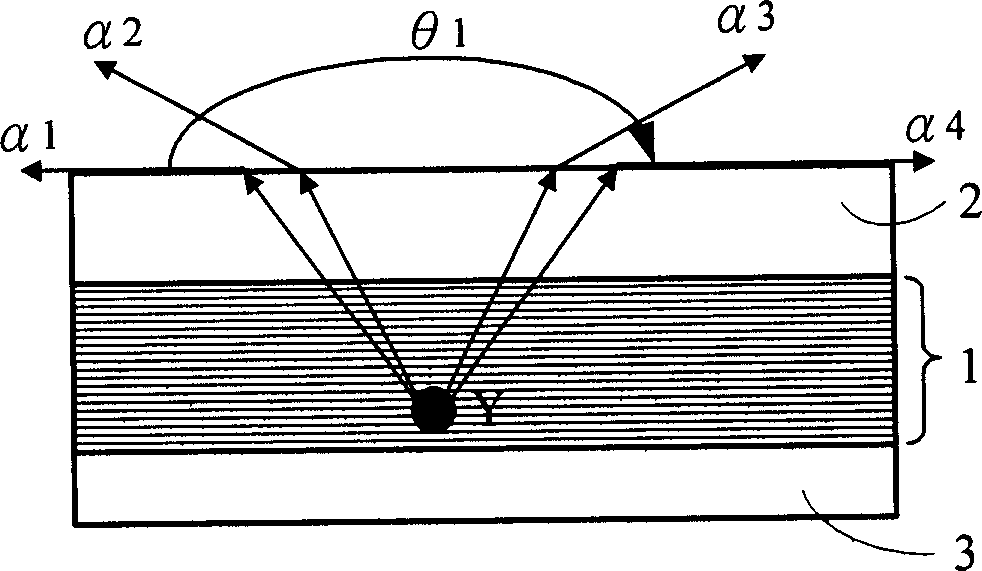

[0028] The present invention will be described in further detail below in conjunction with accompanying drawing.

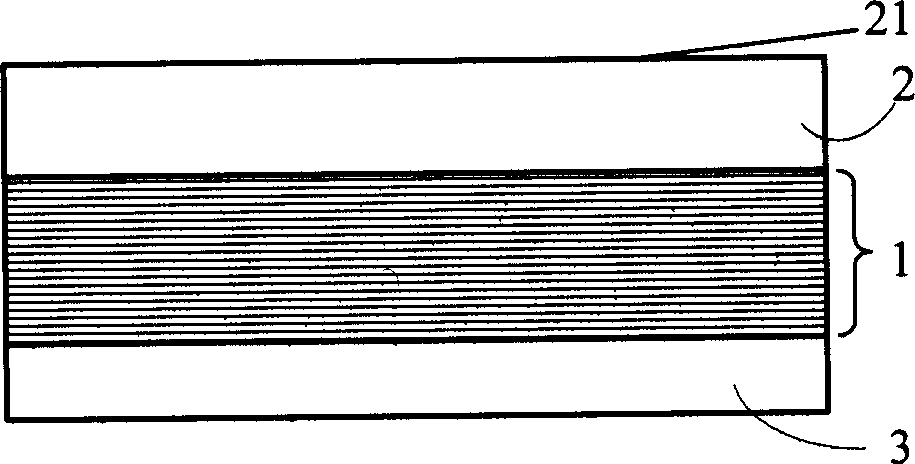

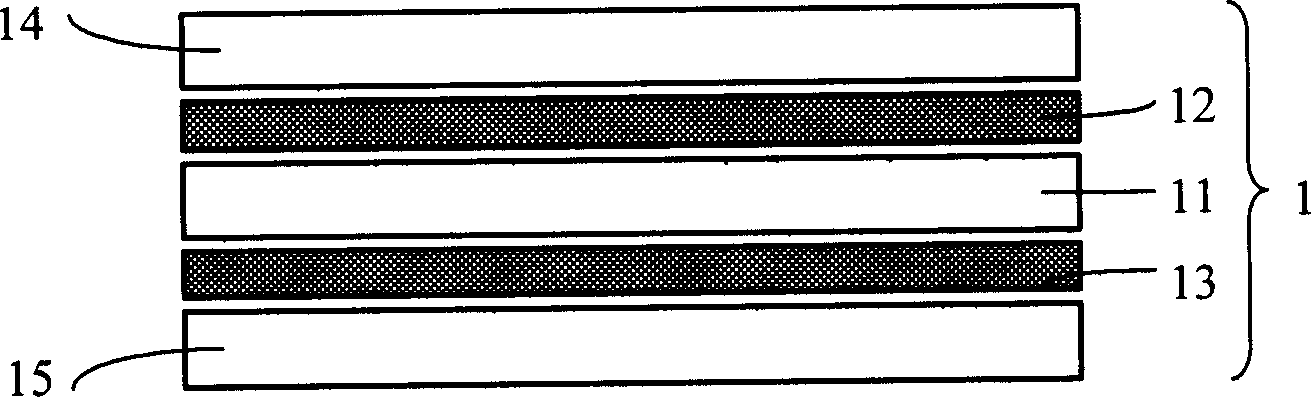

[0029] see Figure 4 , the organic light-emitting display provided by the present invention includes a light-emitting base layer 10, a light-transmitting layer 20, and an encapsulation protection layer 30; the light-emitting base layer 10 has self-luminous characteristics, and the light-emitting layer 20 includes a light-emitting surface 201; a prism film 40 is formed on On the light-emitting surface 201 , the above-mentioned prism film 40 is a single-layer structure, the upper surface of which contains a large number of prism structures 41 , and the opposite surface is combined with the light-emitting surface 201 .

[0030] The above-mentioned light-emitting base layer 10 includes an opposite first electrode and a second electrode, and an organic light-emitting layer located between the first and second electrodes; when the organic light-emitting display is in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com