Machine vision illumination lens for generating customized light spots and design method of machine vision illumination lens

A machine vision and lens technology, used in lighting and heating equipment, lighting installations, design optimization/simulation, etc., to solve problems such as target image highlights, shadows, and feature mis-segmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical details of the present invention will be further described below in conjunction with the accompanying drawings.

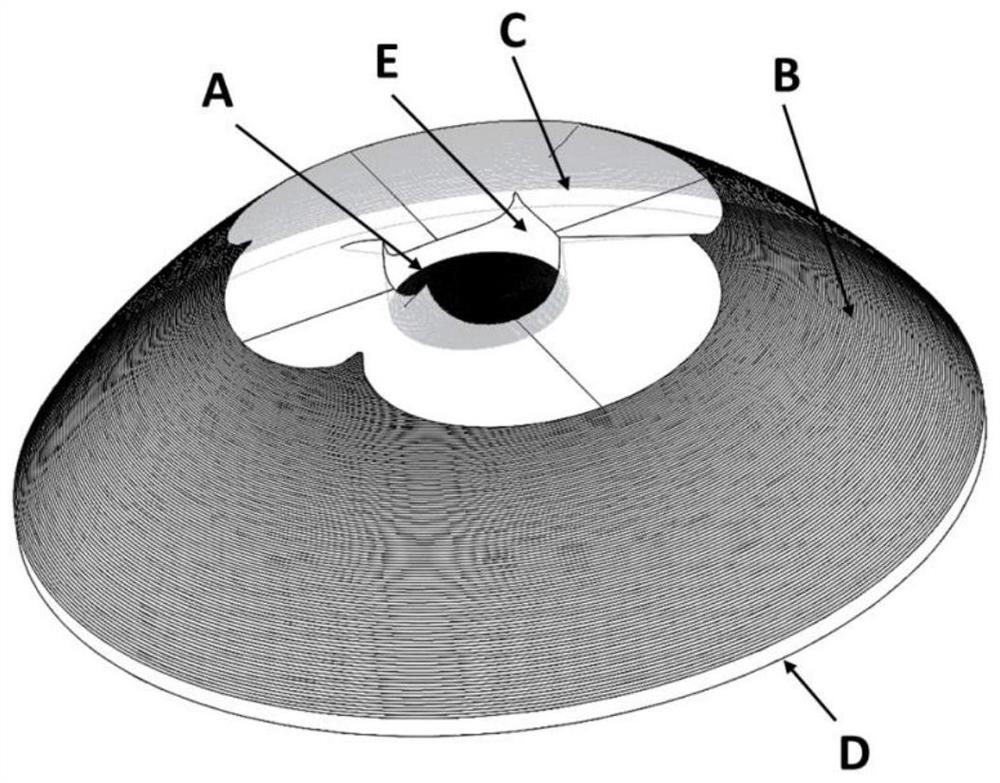

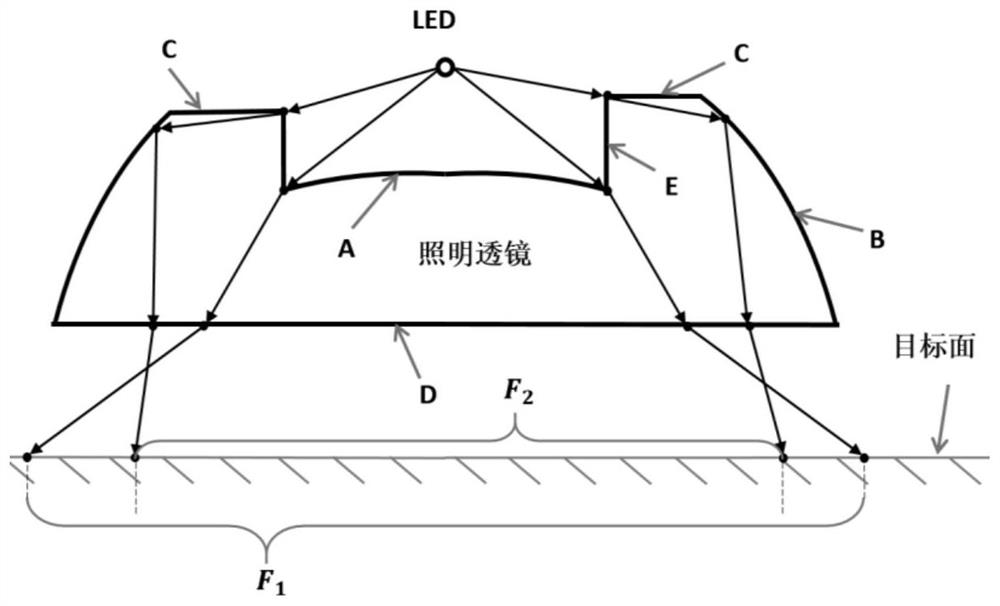

[0063] figure 1 It is a schematic diagram of the lighting lens of the present invention, and the lighting lens specifically includes a transmission aspheric surface A, a total internal reflection aspheric surface B, a curved bottom surface C, a lens exit surface D and a transmission cylindrical surface E; the surface shape of the lens exit surface D As a plane, the LED light passes through the transmission aspheric surface A, the total internal reflection aspheric surface B, the bottom curved surface C and the transmission cylindrical surface E after light distribution, and finally exits from the lens exit surface D to the target surface.

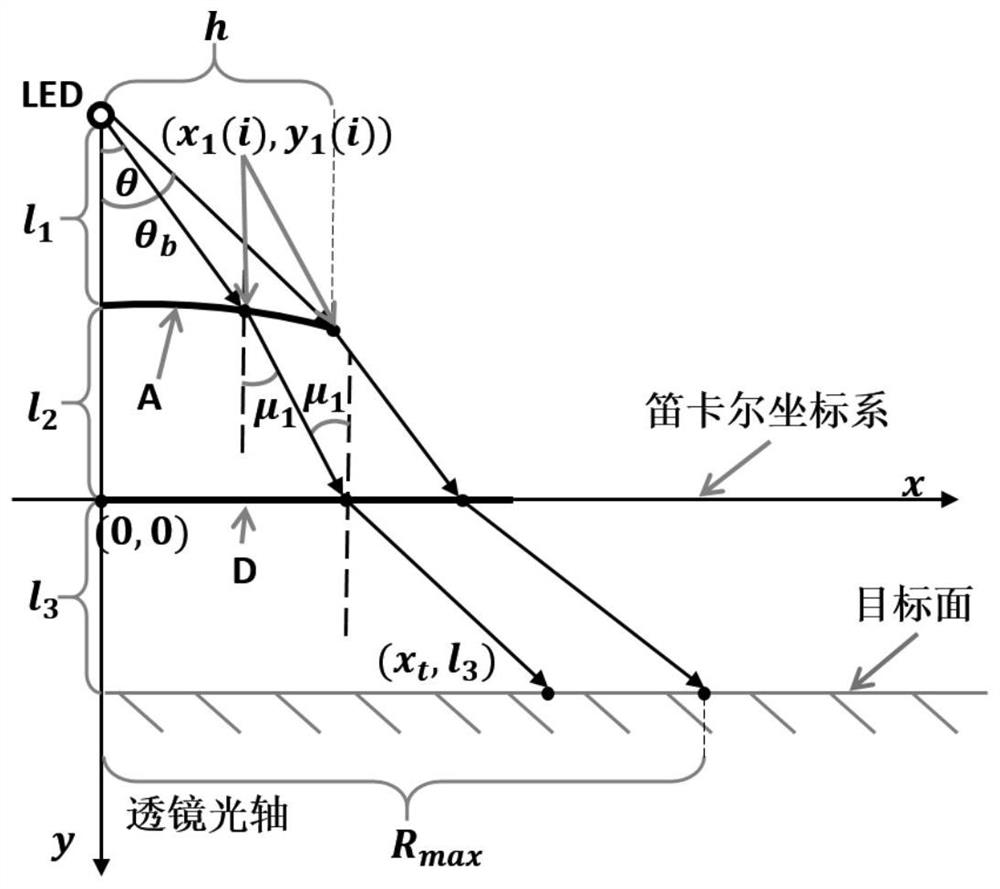

[0064] figure 2 It is a schematic cross-sectional view of the lighting lens according to the present invention. The transmission aspheric surface A distributes the light emitted by the LED at a small angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com