Diffuse reflection type tin-coated welding strip and method for producing same

A technology of tin-coated solder strips and production methods, which is applied in the fields of final product manufacturing, photovoltaic power generation, sustainable manufacturing/processing, etc., can solve the problems of reducing the probability of solar panels receiving a large amount of sunlight, and achieve stable physical indicators and improved The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described by specific examples below.

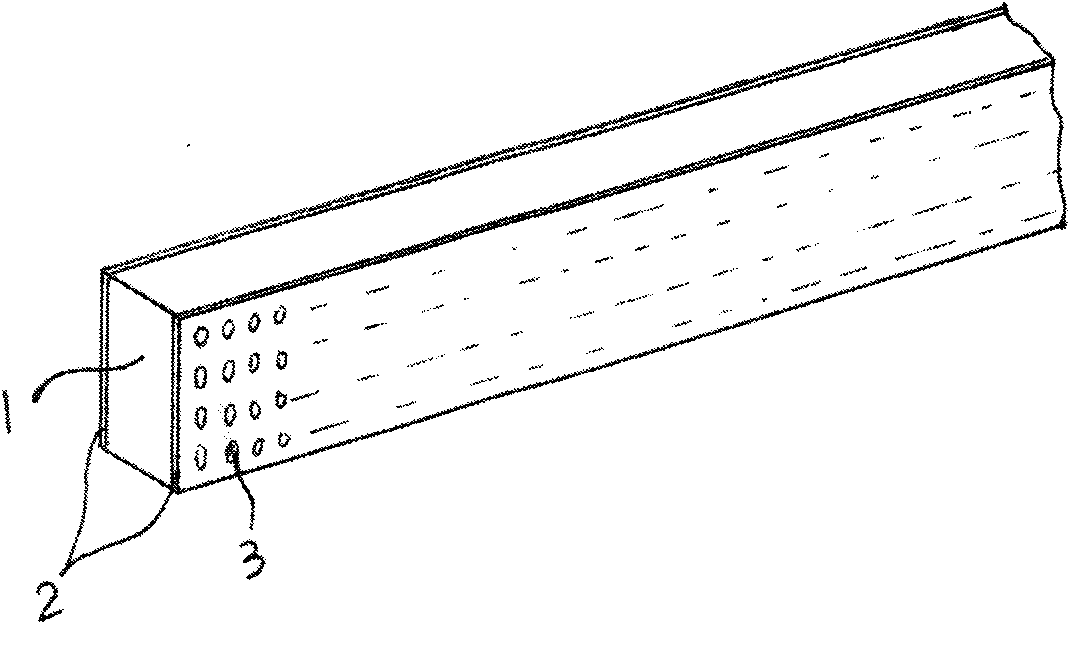

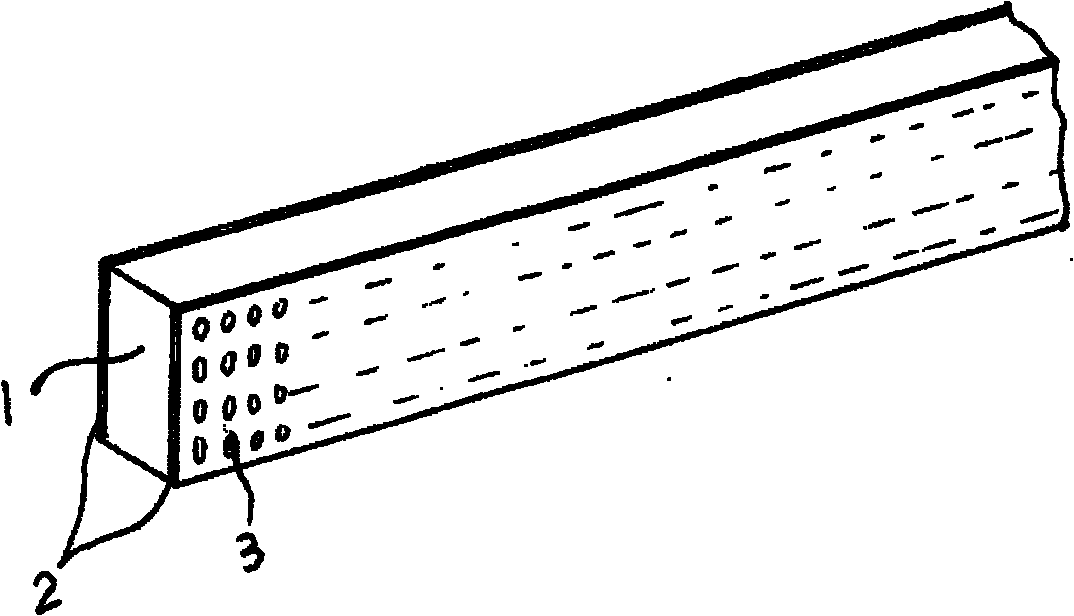

[0020] See figure 1 The diffuse reflection tin-coated solder strip includes copper strip 1 . There is a tin-coated layer 2 formed on the surface of the copper strip 1 by immersion plating. Pits 3 are distributed on the surface of the tin-coated layer 2 of the copper strip 1 . Therefore, the craters 3 on the surface of the tin-coated layer 2 can produce diffuse reflection of sunlight, so as to increase the acceptance of more light energy to the connected solar panels. In this embodiment, the distribution of the pits 3 on the surface of the tin-coated layer 2 is uniform. Likewise, the pits 3 on the surface of the tin-coated layer 2 are uniform pits.

[0021] In the present invention, the distribution of the pits 3 on the surface of the tin-coated layer 2 can be non-uniform besides the uniform distribution. Similarly, the craters 3 may be non-uniform craters in addition to uniformly distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com