Patch antenna having a non-feeding element formed on a side surface of a dielectric

a dielectric and side surface technology, applied in the field of digital radio receivers, can solve the problems of large interference of radiation elements, unsuitable antennas of planer-type (plane-type) such as patch antennas, and difficult to gain the directivity of the antenna in the low elevation mor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

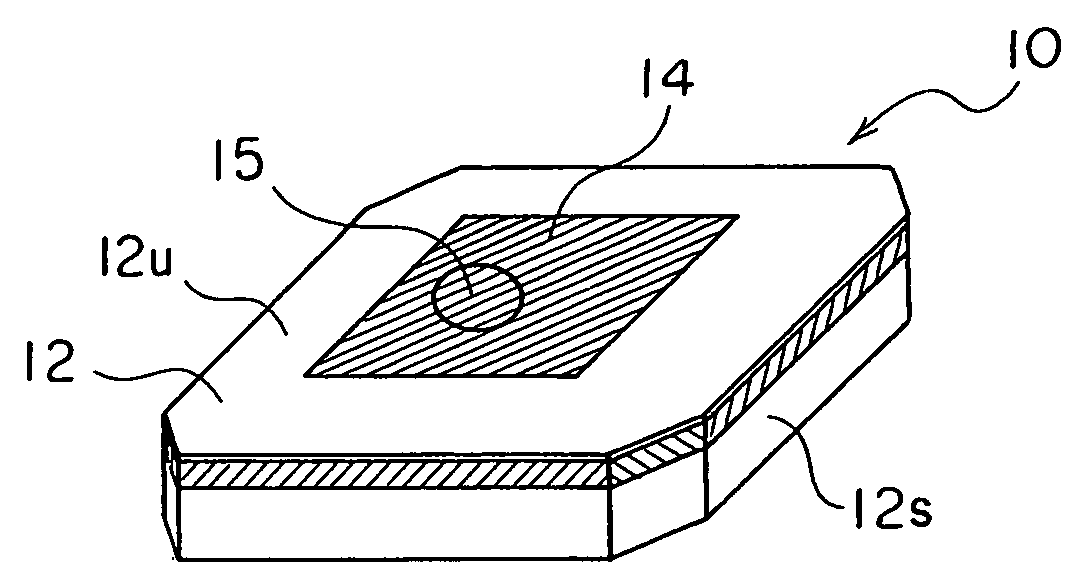

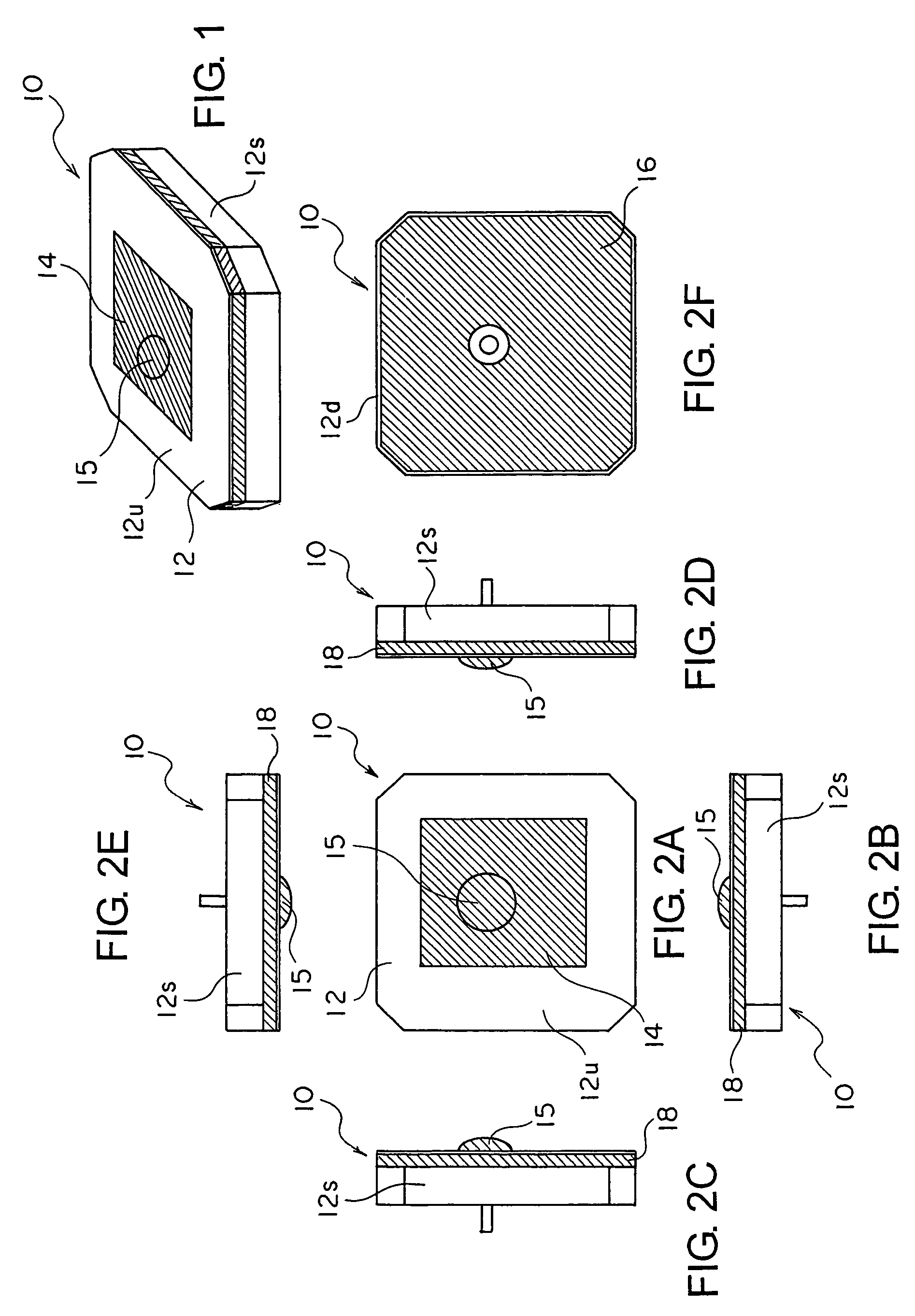

[0027]Referring to FIG. 1 and FIGS. 2A, 2B, 2C, 2D, 2E, and 2F, the description will proceed to a patch antenna 10 according to an embodiment of the present invention. FIG. 1 is a perspective view of the patch antenna 10. FIG. 2A is a plan view of the patch antenna 10. FIG. 2B is a front view of the patch antenna 10. FIG. 2C is a left-hand side view of the patch antenna 10. FIG. 2D is a right-hand side view of the patch antenna 10. FIG. 2E is a rear view of the patch antenna 10. FIG. 2F is a bottom view of the patch antenna 10.

[0028]The patch antenna 10 comprises a dielectric 12 having configuration of a substantially rectangular parallelepiped. In the example being illustrated, the dielectric 12 has a length, a width, and a thickness which are equal to 20 mm, 20 mm, and 4 mm, respectively. The dielectric 12 is made of a ceramic material or resin. The dielectric 12 has a top or upper surface 12u, a bottom surface 12d, and a side surface 12s. Practically, in the manner which is illus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com