Full automatic assembling machine for T8LED lamp tube plugs

An assembly machine and fully automatic technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency, high wage costs, and increased production costs, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

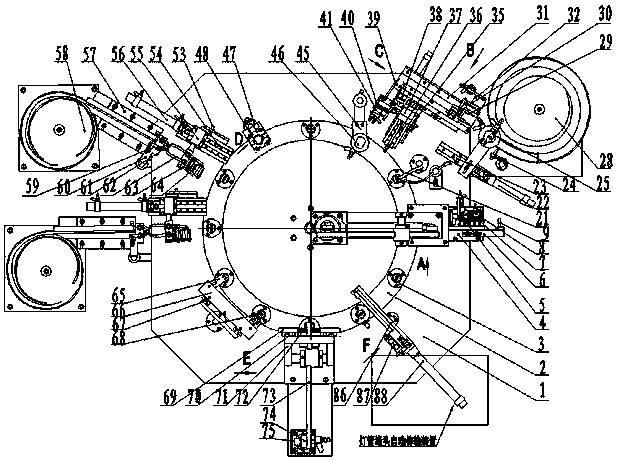

[0038] The technical solution of the patent of the present invention is: a fully automatic lamp needle pressing device for a T8LED lamp tube automatic production line, including a frame, a mechanical transmission mechanism, a steam control mechanism, an automatic positioning mechanism, a detection rotation mechanism, a copper belt feeding device, and a connection Sheet punching and automatic loading device, automatic feeding and loading device for plastic plugs, automatic feeding and loading device for lamp pins, automatic pressing device for lamp pins, connecting pieces and plugs, automatic unloading device for plugs .

[0039] The specific instructions are as follows:

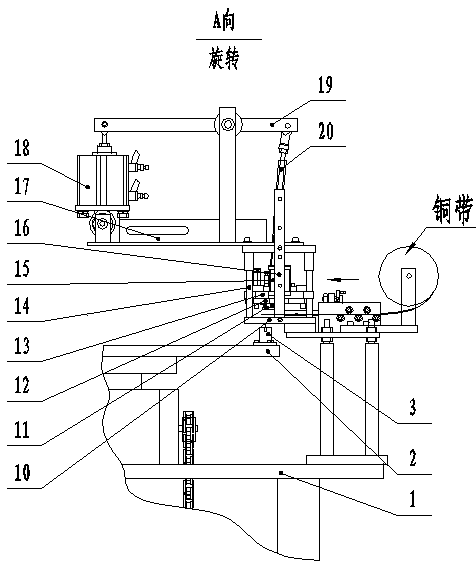

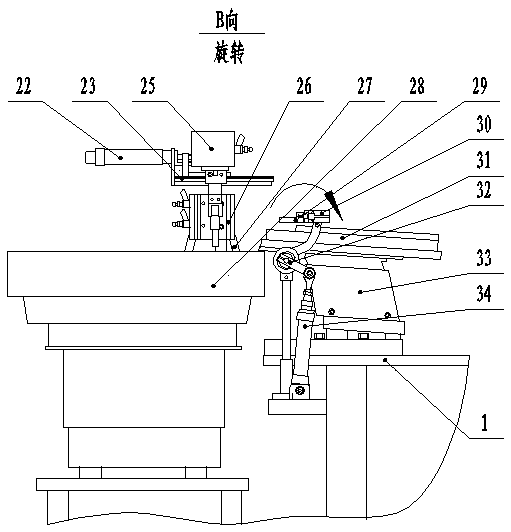

[0040] The structure of the lamp pressing machine for T8 LED tube automatic production line is shown in the figure: including frame 1, mechanical transmission device 2, plug seat 3, copper belt feeding fixed plate 4, copper belt feeding upper and lower rollers 5, copper belt feeding Fixing frame 6, copper st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com