Surface irregular high-power tin-plate copper strip of photovoltaic subassembly and manufacture method of surface irregular high-power tin-plate copper strip

A technology of tin-coated copper tape and photovoltaic modules, applied in photovoltaic power generation, cable/conductor manufacturing, electrical components, etc., can solve the problem of low heat-to-electricity conversion efficiency of solar photovoltaic modules, affecting the power of photovoltaic solar modules, poor heating effect, etc. problems, to achieve the effect of improving the photoelectric conversion efficiency, increasing the heating area, and improving the welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

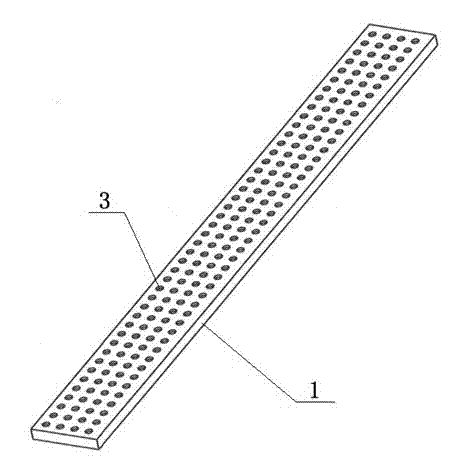

[0034] When the required surface profile of the tin-coated copper strip is elliptical, an embossing device is used to carry out surface profile treatment on the high-purity oxygen-free copper strip as a conductor: as Figure 4 Rolling wheels with oval raised patterns are used on the rolling machine as shown, the positions of the two rolling wheels are adjusted according to the desired depth of the pattern, and the high purity of the conductor is maintained under the drive of the motor (11) The oxygen-free copper strip (12) is rolled with a rolling wheel (13) at a speed of 10 m / min to 15 m / min to obtain the required oxygen-free copper strip (14) with elliptical pits on the surface .

[0035] Ultrasonic treatment is carried out to the high-purity oxygen-free copper strip of described surface special-shaped treatment again, and its main purpose is in order to degreasing and deoxidation; The ultrasonic cleaning agent used in the ultrasonic treatment process is organic For the sol...

Embodiment 2

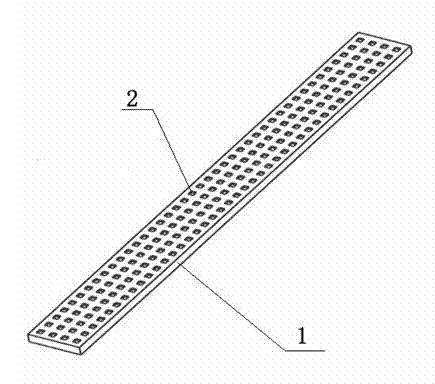

[0039] When the required surface irregular shape of the tin-coated copper strip is square, its processing steps are basically the same as that of the above-mentioned anisotropic pattern being oval, the difference lies in two points:

[0040] 1. Use a roller with a rectangular raised pattern on the roller press.

[0041] 2. In the process of hot-dipping tin, the dipping time is 8S, and the special-shaped high-power tin-coated copper strip with a rectangular pattern on the surface with a thickness of 28-32 microns on one side of the coating is obtained.

Embodiment 3

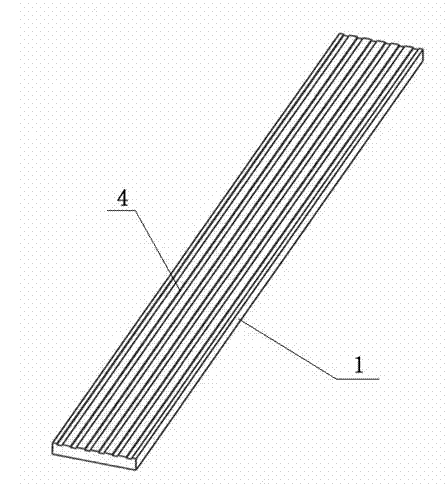

[0043] When the required surface profile of the tin-coated copper strip is a strip groove, its processing technology differs from that of Example 1 in two places, and the others are the same. These two differences are:

[0044] 1. Use a high-precision slow-moving wire cutting machine, and use imported tungsten steel cutting heads to process the mold into the required wire drawing mold. Such as Figure 5 Pass the high-purity oxygen-free copper strip (12) through the wire drawing die (15) as shown, and draw it at a speed of 4 m / s to 5 m / s through the wire drawing tractor (16) to obtain the required surface strips. Oxygen-free copper strip (17) with grooves.

[0045] 2. In the process of hot-dip tinning, the dipping time is 10 seconds, and a special-shaped high-power tin-coated copper strip with a strip pattern on the surface with a thickness of 36-40 microns on one side of the coating is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen content | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com