A kind of tin-based alloy and copper strip composite material and preparation method thereof

A tin-based alloy and composite material technology, applied in metal processing equipment, metal/alloy conductors, welding equipment, etc., can solve the problem that the uniformity is difficult to control, it is difficult to ensure the uniformity and consistency of the coating thickness, and it is easy to form a copper-tin alloy. and other problems, to achieve the effect of uniform coating thickness, avoiding re-oxidation, and firm and reliable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

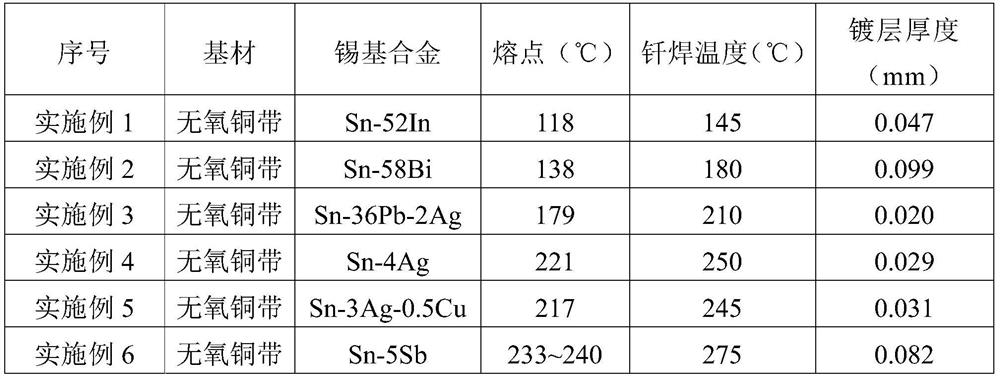

Embodiment 1

[0046] The composite material of tin-based alloy and copper strip is prepared, the copper strip is selected as oxygen-free copper, and the tin-based alloy is tin-indium alloy, wherein the weight percentages of tin and indium are 48% of tin and 52% of indium.

[0047] The tin-based alloy and copper tape composite material is prepared by the following method, which specifically includes the following steps:

[0048] Step 1: Choose an oxygen-free copper tape with a clean surface (thickness is 0.3mm, width is 2.5mm), the purity is higher than 99.99w%; two tin-indium alloy tapes with oil-free surface, of which the weight percentage of tin and indium For; tin 48%, indium 52%; the thickness of tin-indium alloy strip is 0.05mm, and the width is consistent with the copper strip.

[0049] Step 2: First, the copper tape selected in step 1 is pulled through acetone, soaked, heated (the temperature of acetone is 50° C.) and ultrasonic, and then dried with hot air. Then the copper strip so...

Embodiment 2

[0055] For the composite material of tin-based alloy and copper strip, the copper strip is selected as oxygen-free copper, and the tin-based alloy is tin-bismuth alloy, in which the weight percentages of tin and bismuth are; .

[0056] The traction speed is 30m / min, and the current frequency is 60KHz. Others are the same as in Example 1.

Embodiment 3

[0058] The composite material of tin-based alloy and copper strip, the copper strip is selected as oxygen-free copper, and the tin-based alloy is tin-lead-silver alloy, in which the weight percentages of tin, lead and silver are; 62% tin, 36% lead, 2% silver; tin and lead The thickness of the silver alloy strip is 0.02mm.

[0059] The traction speed is 15m / min, and the current frequency is 60KHz. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com