Holing machine of cold cutting non-contact type

A non-contact, hole-opening machine technology, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, explosion generating devices, etc. It can solve the problems of inability to complete circular cutting motion, large bracket occupation area, tipping cutting surface, etc. problem, to achieve the effect of light weight, easy processing and adjustable cutting radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

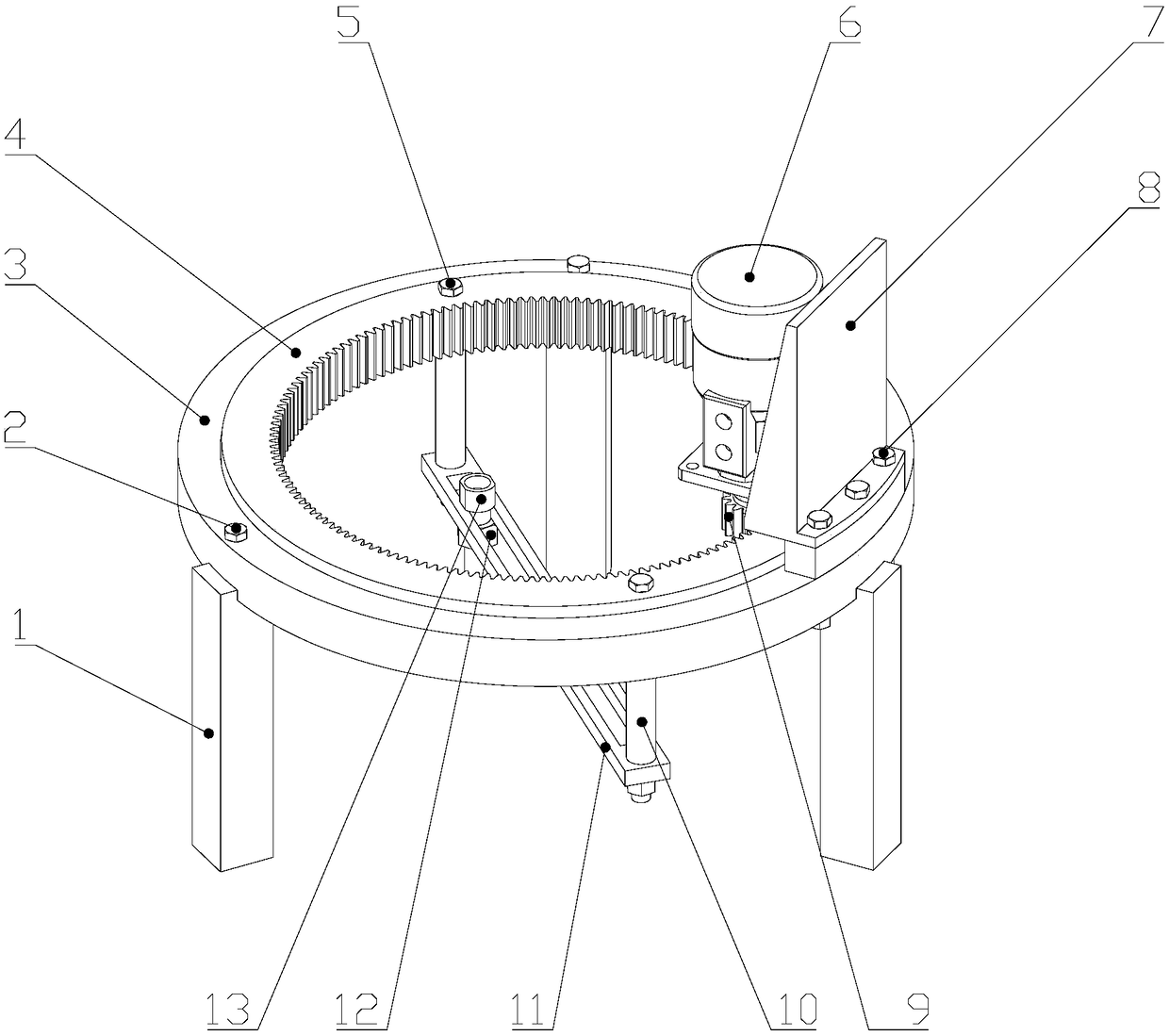

[0035] As shown in the accompanying drawings, the specific embodiment of the present invention, the cold cutting non-contact drilling machine includes: a leg 1, a rotary device, a motor fixing frame 7, a power unit, a nozzle installation device and a nozzle and a holder 13; the rotary device The lower part is equipped with at least three legs 1 through the fixing bolts 2; the motor fixing frame 7 is installed on the slewing device; the power device is installed on the motor fixing frame 7; the output end of the power device meshes with the inner ring teeth of the slewing device; the nozzle is installed The device is mounted on the bottom of the rotary device and can rotate with the rotary device; the nozzle and holder 13 are mounted on the nozzle installation device, and the cutting diameter can be adjusted on the nozzle installation device.

[0036] The slewing device includes: the slewing support outer ring 3 and the slewing support inner ring 4; the slewing support inner rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com