Copper alloy contact reaction brazing method and used active connecting agent

A technology of contact reaction and active connection, which is applied in the direction of welding/welding/cutting objects, welding media, welding equipment, etc., can solve the problems of corrosion resistance decline, high welding temperature, and difficult melting of copper materials, so as to reduce the welding temperature, Guaranteed mechanical properties and low brazing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

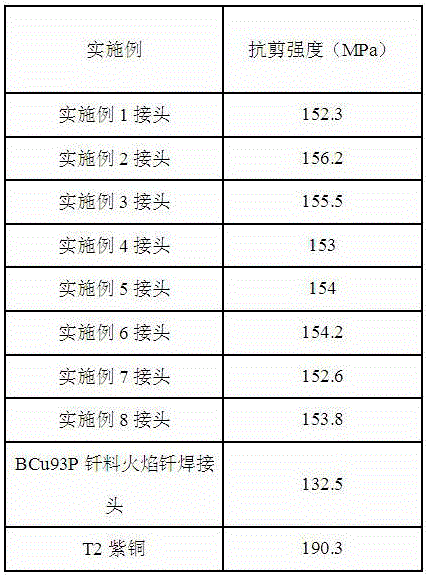

Examples

Embodiment 1

[0035] A copper alloy contact reaction brazing method, comprising the following steps:

[0036] Step 1. Take 78% of red P powder with a purity of 99% and a particle size range of 300um-100um, 12% of B powder, and add 10% of binder at the same time, and stir the three evenly to prepare a paste-like active linker ,spare;

[0037] Step 2, clean the surface of the copper alloy block to be welded, and coat the active linker prepared in step 1 with a thickness of 12um, and set aside;

[0038] Step 3. Combine the copper alloy block to be welded in step 2 into a butt joint. After the combination is completed, fix and compress it on the jig. The contact surface of the jig and the copper alloy block is pre-coated with solder resist, and then placed on the In the vacuum chamber of the welding furnace, when the welding pressure is 0.085 MPa-0.02MPa and the vacuum degree is 1.3×10 -3 Under the condition of Pa, high-purity argon gas with a purity of 99.999% is introduced into the vacuum c...

Embodiment 2

[0040] A copper alloy contact reaction brazing method, comprising the following steps:

[0041] Step 1. Take 79% of red P powder and 11% of B powder with a purity of 99% and a particle size range of 300um-100um, and add 10% of binder at the same time, and stir the three evenly to prepare a paste-like active linker ,spare;

[0042] Step 2, clean the surface of the copper alloy block to be welded, and coat the active linker prepared in step 1 with a thickness of 8um, and set aside;

[0043] Step 3. Combine the copper alloy block to be welded in step 2 into a butt joint. After the combination is completed, fix and compress it on the jig. The contact surface of the jig and the copper alloy block is pre-coated with solder resist, and then placed on the In the vacuum chamber of the welding furnace, when the welding pressure is 0.085 MPa-0.02MPa and the vacuum degree is 1.3×10 -3 Under the condition of Pa, high-purity argon gas with a purity of 99.999% is introduced into the vacuum...

Embodiment 3

[0045] A copper alloy contact reaction brazing method, comprising the following steps:

[0046] Step 1. Take 80% of red P powder with a purity of 99% and a particle size range of 300um-100um, and 10% of B powder. At the same time, add 10% of binder, and stir the three evenly to prepare a paste active linker ,spare;

[0047] Step 2, cleaning the surface of the copper alloy block to be welded, and coating the active linking agent prepared in step 1 with a thickness of 10 μm, and set aside;

[0048] Step 3. Combine the copper alloy block to be welded in step 2 into a butt joint. After the combination is completed, fix and compress it on the jig. The contact surface of the jig and the copper alloy block is pre-coated with solder resist, and then placed on the In the vacuum chamber of the welding furnace, when the welding pressure is 0.085 MPa-0.02MPa and the vacuum degree is 1.3×10 -3 Under the condition of Pa, high-purity argon gas with a purity of 99.999% is introduced into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com