Metal plate rotating friction riveting method

A technology of rotating friction and metal sheets, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as high pressure and complex structure, and achieve the effect of simple rivet structure, simplified rivet structure, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

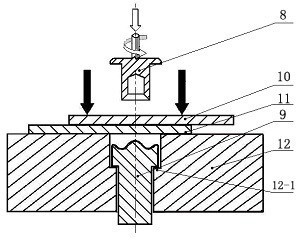

Method used

Image

Examples

Embodiment 1

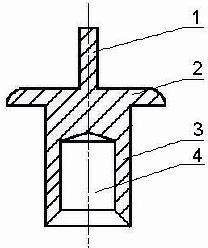

[0051] Example 1: For the connection of magnesium alloy plates. The model of the magnesium alloy plate is AZ31, and the size is 125×38×2mm; the size of the rivet is: the length of the clamping rod is 25mm, the diameter of the rivet cap is 10mm, the length of the semi-hollow rivet body is 6.5mm, and the inner and outer diameters of the rivet are 3.5mm and 3.5mm respectively. 5mm, depth 3mm. The overlapping length of the upper and lower magnesium plates is 25 mm; when riveting, the rivet speed is 3600 rpm.

[0052] After the riveting was completed, the shearing tensile test was carried out on the riveted joint. The results showed that the shear strength of the joint was (5.65±0.23) kN, which was significantly higher than that of the same material without heating self-riveting joint (4.32±0.09) kN and the shear strength (4.95 ± 0.12) kN of a joint that is self-riveted after heating the sheet to 180°C.

Embodiment 2

[0053] Example 2 : Used for the connection of magnesium alloy plate and aluminum alloy plate. The model of the magnesium alloy plate is AZ31, the size is 125×38×2mm; the model of the aluminum alloy plate is 6063, the size is 125×38×3mm; the size of the rivet is: the length of the clamping rod is 25mm, the diameter of the rivet cap is 10mm, and the semi-hollow The length of the rivet body is 7mm, the internal and external diameters of the rivet are 3.5mm and 5mm respectively, and the depth is 4mm; the magnesium alloy plate is used as the upper plate, the aluminum alloy plate is used as the lower plate, and the lap length of the upper and lower plates is 25mm; the rivet speed is 3600 rpm.

[0054] After the riveting was completed, a shearing tensile test was carried out on the riveted joints. The shear strength of the joint is (6.90±0.64) kN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com