Copper-aluminum connecting piece face-face penetrating fusion welding technique and preparation method

A connector, copper-aluminum technology, which is applied in the surface-surface infiltration and welding process and preparation field of copper-aluminum connectors, can solve the problem of coarse grains of substrates, affecting the physical properties, mechanical properties and electrochemical and chemical indicators of substrates and bonding surfaces, The copper-aluminum joint surface cannot form a continuous and firm joint surface, etc., so as to achieve the effect of high mechanical strength and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

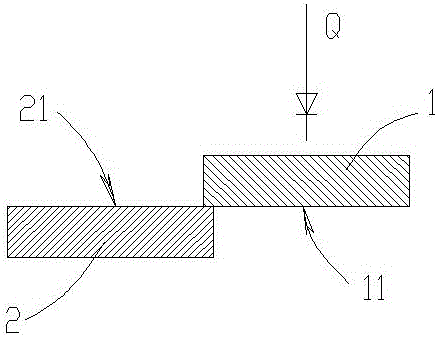

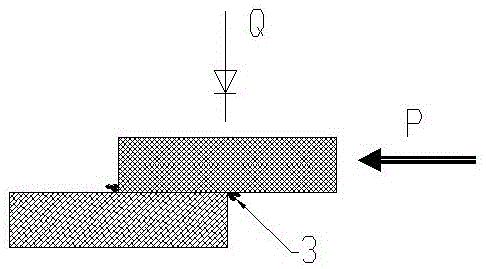

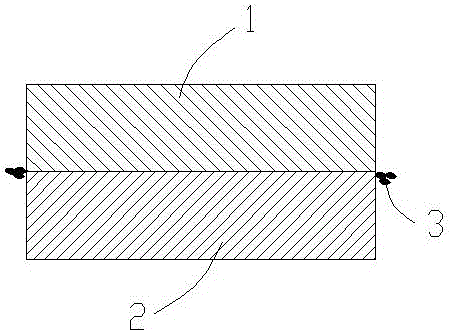

[0029] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0030] In this embodiment, a copper-aluminum connector surface-surface infiltration welding process is used. On the joint surface of the lead-aluminum connector, its main microstructure is a solid solution structure formed during the physical preparation process, which is provided by low-temperature friction and ultra-high pressure. Energy, so that the solid-phase aluminum and solid-phase copper atoms or molecules deviate from the equilibrium position for long-distance migration, thereby forming a solid-phase connection surface with physical connection properties. The result is that the total amount of solid solution in the bonding surface is > 95% or the total amount of compound + oxide + mixture in the firmly bonding surface is ≤ 5%.

[0031] The ultra-high pressure applied to the joint surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com