Surface mechanical attrition treatment and ultrasonic wave collaborative assistance dissimilar metal TIG melting and brazing method

A surface mechanical grinding and dissimilar metal technology, which is applied in metal processing equipment, welding equipment, welding equipment, etc., can solve problems such as easy interference, difficult welding, and coarse joint structure, so as to improve composition and distribution, optimize joint performance, Optimizing the effect of joint organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

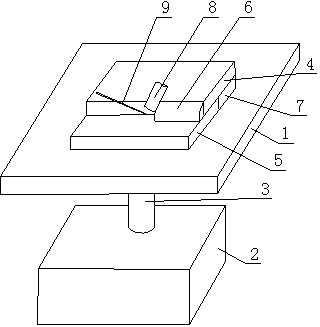

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032]During specific implementation, a method for TIG fusion-brazing of dissimilar metals assisted by surface mechanical grinding treatment and ultrasonic waves, including the step B of TIG fusion-brazing assisted by ultrasonic waves during welding, is characterized in that it also includes the low melting point before welding. Step A of performing surface mechanical grinding treatment on the base material.

[0033] Wherein, in step A, when the surface of the low-melting-point base material is mechanically ground, shot peening is used to remove oxides on the surface of the base material, and at the same time, the surface area of the low-melting-point base material is increased and a certain compressive stress is generated. The shot blasting process specifically includes the following steps: a. Take two low-melting-point base metal plates to be welded, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com