Device for manufacturing metal paste in double forcing and homogenizing mode and machining forming method thereof

A metal slurry and homogenization technology, which is applied in the field of non-ferrous metal casting and processing, can solve the problems that cannot be satisfied at the same time, and achieve the effects of easy control, better homogenization effect, and simple and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

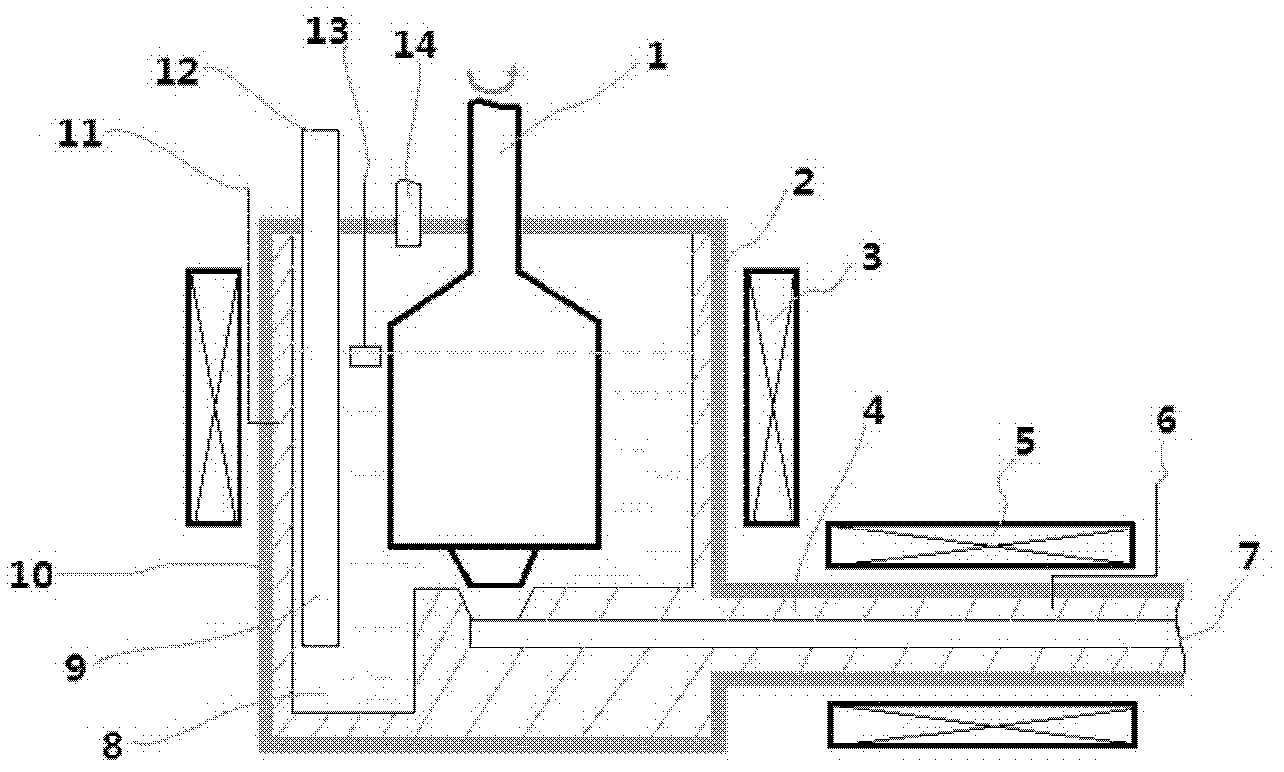

preparation example Construction

[0050] When preparing and processing a low-temperature homogeneous melt, the temperature of the molten metal in the prefabricated cavity 2 and the discharge pipe 4 must be controlled at the liquidus temperature T 0 ~T 0 Within the range of +50°C; when preparing and processing semi-solid slurry, the temperature of the metal slurry in the prefabrication chamber 2 and the discharge pipe 4 must be controlled at the solidus temperature T s ~T 0 In the range.

[0051] The slurry outlet 7 can be connected to any processing equipment, and the metal slurry provided by the slurry outlet 7 must be controlled at T s ~T 0 Processing and forming within the temperature range of +50°C. Processing equipment includes die-casting machines, casting-rolling machines, continuous casting machines, die forging machines and extrusion machines, etc.

[0052] In the processing and forming method for preparing metal slurry by double forced homogenization of the present invention, the metal slurry of...

Embodiment 1

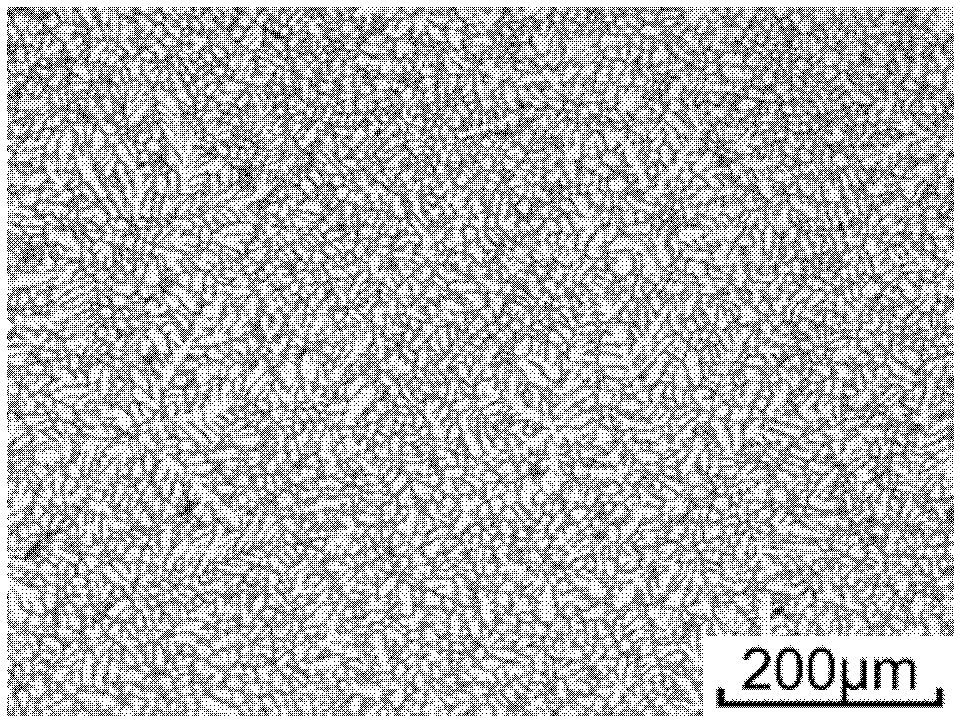

[0058] This embodiment is that the method of the present invention is applied to double-roll horizontal rheological casting and rolling AZ31 magnesium alloy plate

[0059] First start the heating equipment of the device, that is, the thermocouples 6 and 11, so that the valve head of the control rod 1 is in the closed position downward. Set the temperature of the prefabricated chamber 2 to 645°C and the temperature of the discharge pipe 4 to 635°C. When the temperature in the prefabricated cavity 2 and the discharge pipe 4 reaches and stabilizes at the set temperature, the protective gas is sent from the air pressure pipe 14, and the AZ31 magnesium alloy liquid at 650°C is injected from the liquid inlet pipe 9, and the liquid level is determined by the liquid level. Sensor 13 monitors in real time. When the liquid level reaches 2 / 3 of the height of the prefabricated chamber 2, the main coil 3 is started to stir electromagnetically and the control rod 1 rotates to stir. Lift t...

Embodiment 2

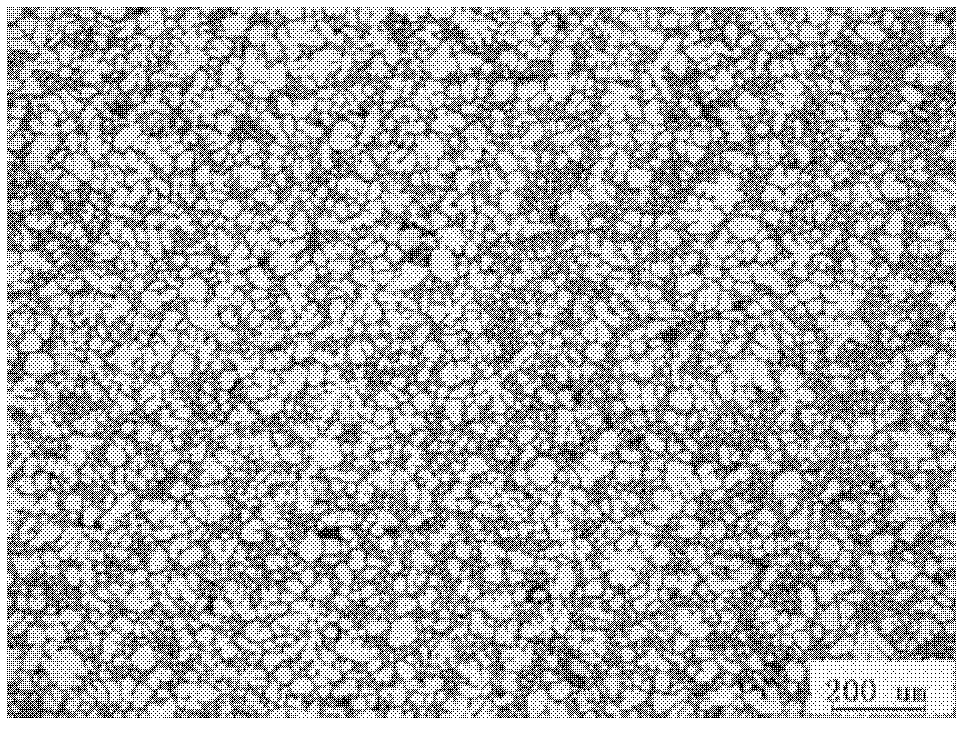

[0062] This embodiment is that the method of the present invention is applied to rheological die-casting AZ91D magnesium alloy castings

[0063] First start the heating equipment of the device, that is, the thermocouples 6 and 11, so that the valve head of the control rod 1 is in the closed position downward. Set the temperature of the prefabricated chamber 2 to 605°C and the temperature of the discharge pipe 4 to 595°C. When the temperature in the prefabricated cavity 2 and the discharge pipe 4 reaches and stabilizes at the set temperature, the protective gas is sent from the air pressure pipe 14, and the AZ91 magnesium alloy liquid at 610°C is injected from the liquid inlet pipe 9, and the liquid level is determined by the liquid level. Sensor 13 monitors in real time. When the liquid level reaches 2 / 3 of the height of the prefabricated cavity 2, the main coil 3 is started to stir electromagnetically and the control rod 1 rotates to stir. Lift the control rod 1 to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com