Cable connecting terminal and cable

A terminal and cable technology, which is applied to the end parts of multi-core cables, conductive connections, circuits, etc., can solve problems such as failures and accidents, increase in temperature rise, and increase in contact resistance between cables and terminals. The effect of good connection performance, high strength and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

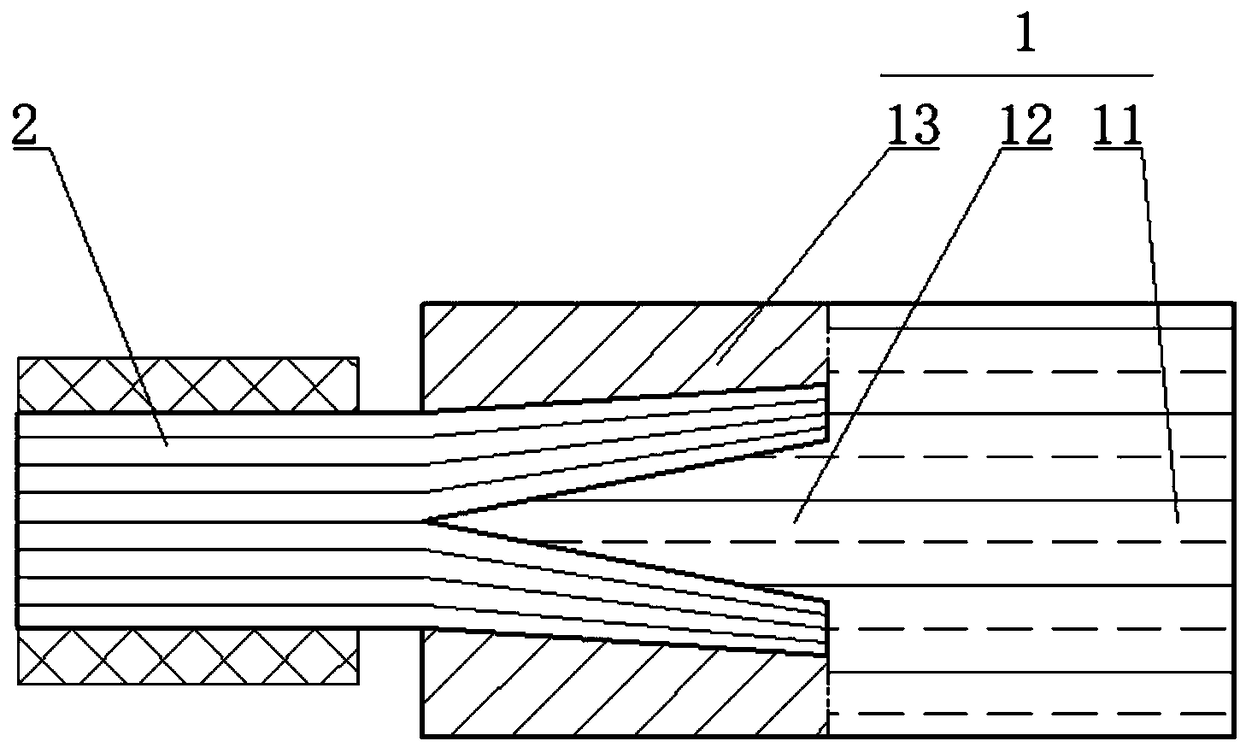

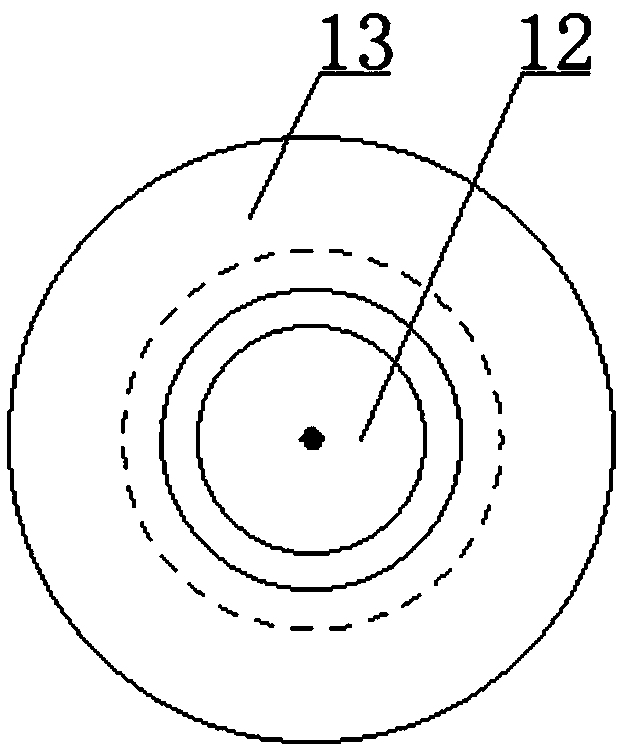

[0037] Such as figure 1 As shown, the cable terminal 1 includes a fixedly connected working end 11 and a clamping section. The mandrel 12 of the clamping section is integrally formed with the working end 11 and is made of red copper. The working end 11 can be an in-line terminal, a pin type, a nose type or a right-angle type, etc.

[0038] The sleeve 13 is made of aluminum alloy, coaxially arranged with the mandrel 12, and fixedly connected with the working end 11 by means of friction welding. Other welding methods can also be used, or the inner diameter of the sleeve 13 is matched with the outer diameter of the working end 11, and then crimped or welded by electromagnetic pulse.

[0039] Take the working end 11 as the root of the mandrel 12 and the sleeve 13, and the other end as the head.

[0040] The outer peripheral surface of the mandrel 12 is conical, and the inner peripheral surface of the sleeve 13 is conical, forming a cylindrical accommodating space between them. ...

Embodiment 2

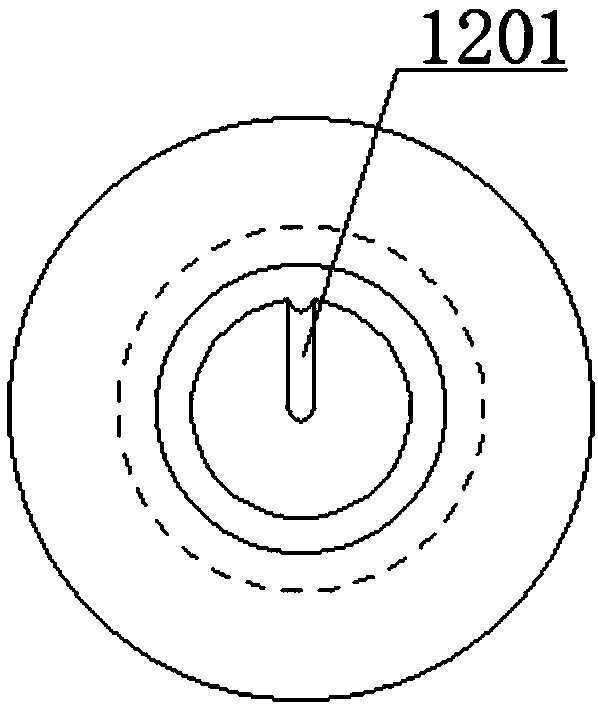

[0043] Based on Example 1, such as image 3 As shown, the outer periphery of the mandrel 12 includes a longitudinal escape groove. In this way, the front end of the mandrel 12 is in the shape of a circular arc. When the conductive wire bundle extends into the accommodation space, the conductive wire at the central axis is embedded in the avoidance groove, and the whole conductive wire bundle is stretched by the mandrel 12 and evenly scattered into the accommodation space. space.

Embodiment 3

[0045] Such as Figure 4 As shown, the wall thickness of the sleeve 13 is uniform, so that the sleeve 13 can be formed by stamping and forging a straight cylinder, which is convenient to manufacture. Friction welding with the working end 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com