Variable-diameter corrugated pipe and shaping method for same

A forming method and corrugated pipe technology, applied in the field of pipeline compensation, can solve the problems of using too many interface components of different-diameter pipelines, the inability to realize the connection of different-diameter pipelines, and increasing on-site welding and installation, so as to improve the forming success rate, uniform pressure, and The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

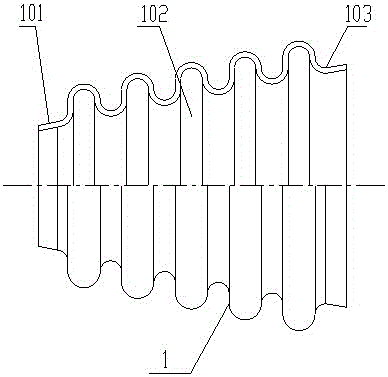

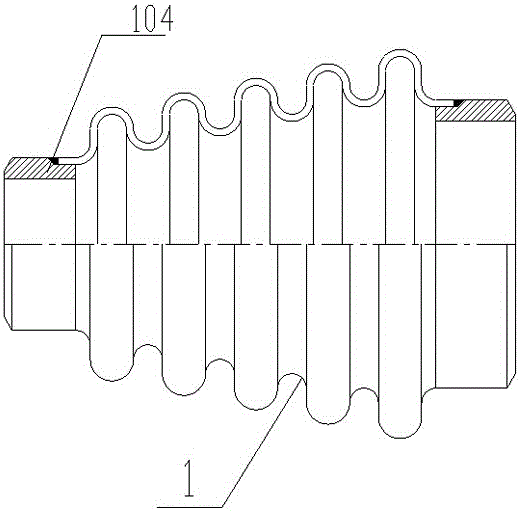

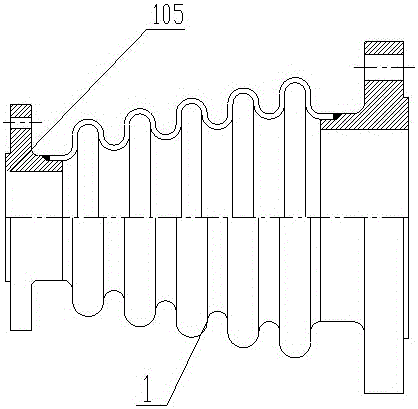

[0034] As shown in the figure, a variable-diameter corrugated pipe includes a small-diameter straight-side tapered pipe section 101, a large-diameter straight-side tapered pipe section 103, and a tapered corrugation arranged between the small-diameter straight-side tapered pipe section and the large-diameter straight-side tapered pipe section. Section 102, the crests and troughs of the tapered corrugated section gradually become larger from the small straight-sided tapered pipe section 101 to the large-diameter straight-sided tapered pipe section 103, and the overall shape is tapered, and the small end of the tapered corrugated section 102 is in this The position of the end trough is connected to the large end of the small diameter straight tapered pipe section 101 , and the large end of the conical corrugated section is connected to the small end of the large diameter straight tapered pipe section 103 at the position of the end wave trough.

[0035] The small-diameter straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com