Small-sized device for connecting plane micropore for single-pore vacuum encapsulation and pipeline

A technology of vacuum filling and small devices, which is applied in capacitor manufacturing, electrical components, climate sustainability, etc. It can solve the problems of waste filling target liquid/gas, difficulty in vacuum filling, easy leakage of liquid/gas, etc., and achieve The device/equipment is beautiful, reduces air leakage, and reduces the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

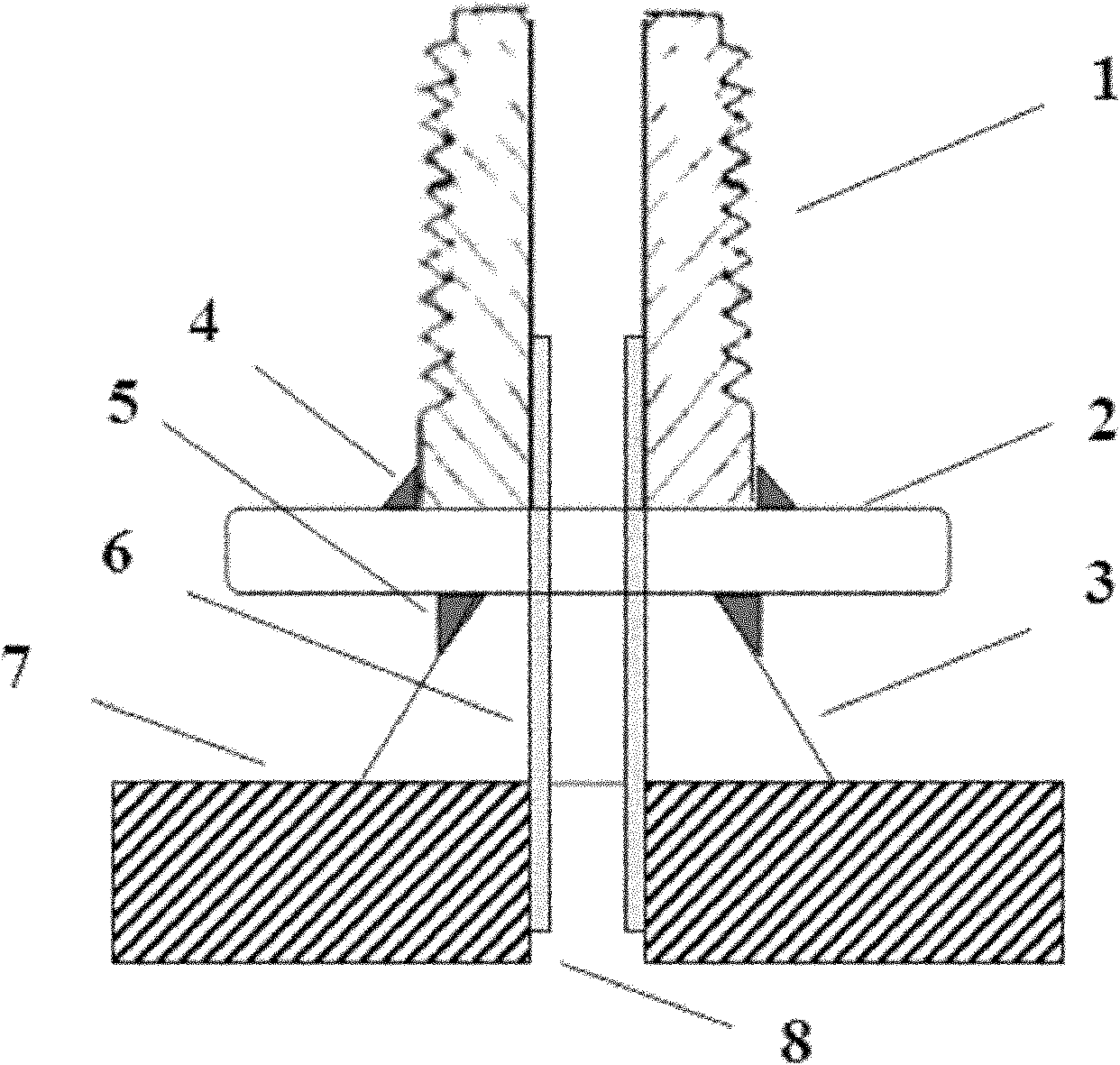

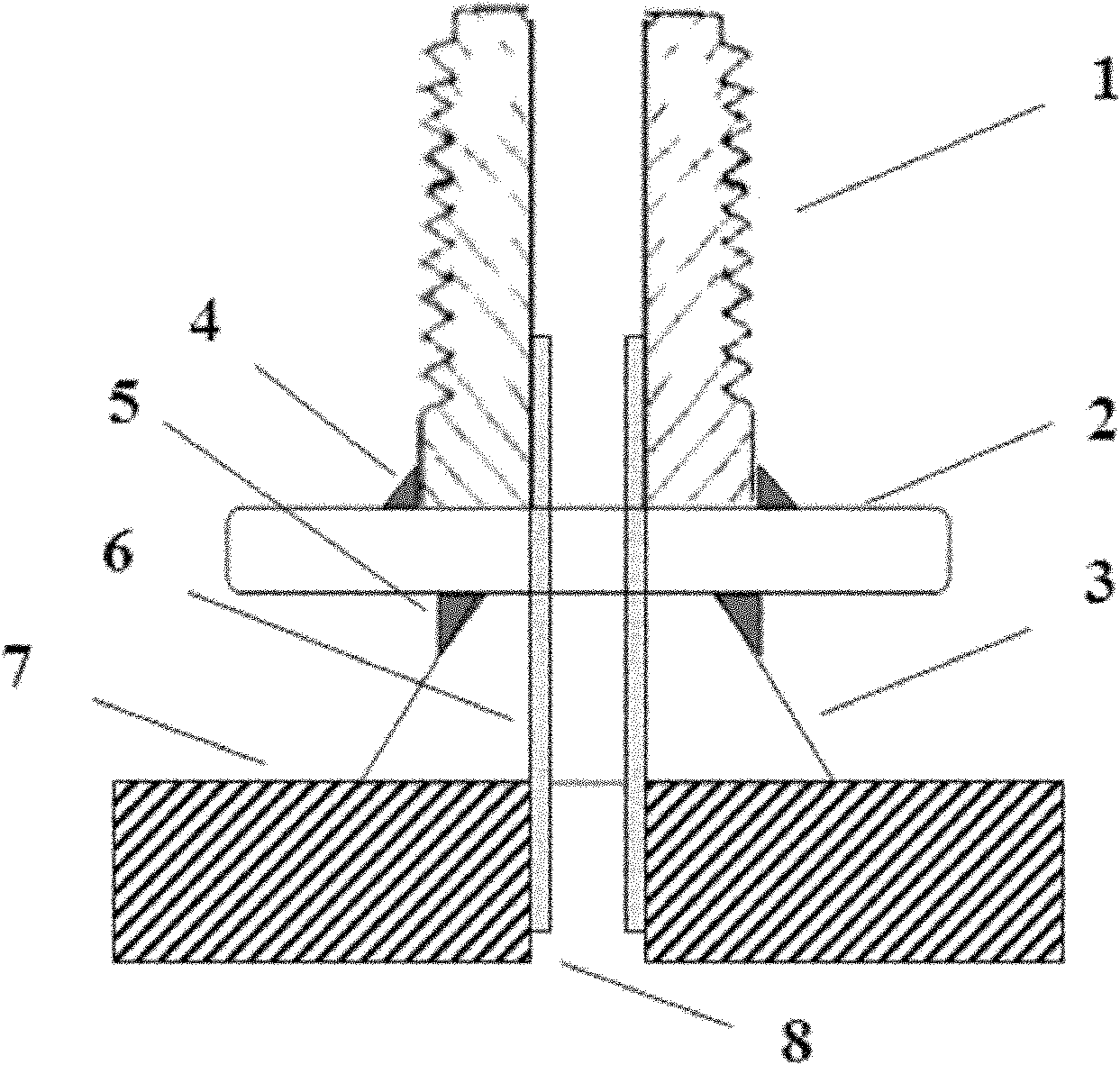

[0017] Such as figure 1 As shown, the small-sized connecting device used for the connection of the plane microhole and the pipeline for single-hole vacuum filling provided by the present invention includes a connecting rod 1, a suction cup 3 and a hole needle 6; the connecting rod 1 is a cylindrical structure; the suction cup 3 is tightly Connected to one end of the cylindrical structure, the tail end of the entry needle 6 passes through the suction cup 3 from the end where the suction cup 3 is located, and is inserted into the cylindrical structure, and the outer wall of the entry needle 6 is closely attached to the inner wall of the cylindrical structure; The outer wall of the needle head 6 is closely connected with the suction cup 3 . The outer wall of the cylindrical structure is provided with external threads; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com