Welding device and application

A welding equipment and equipment technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of large hidden dangers in welding quality and high welding cost, and achieve the effect of short welding time, lower production cost and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

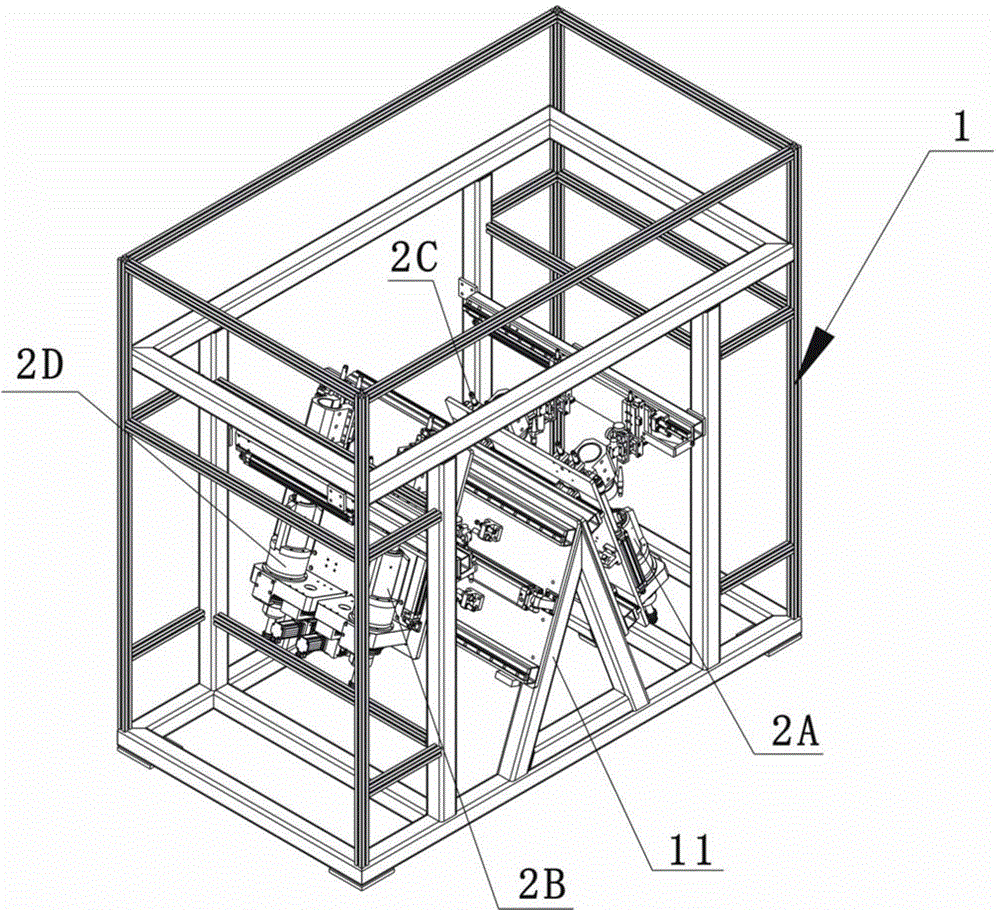

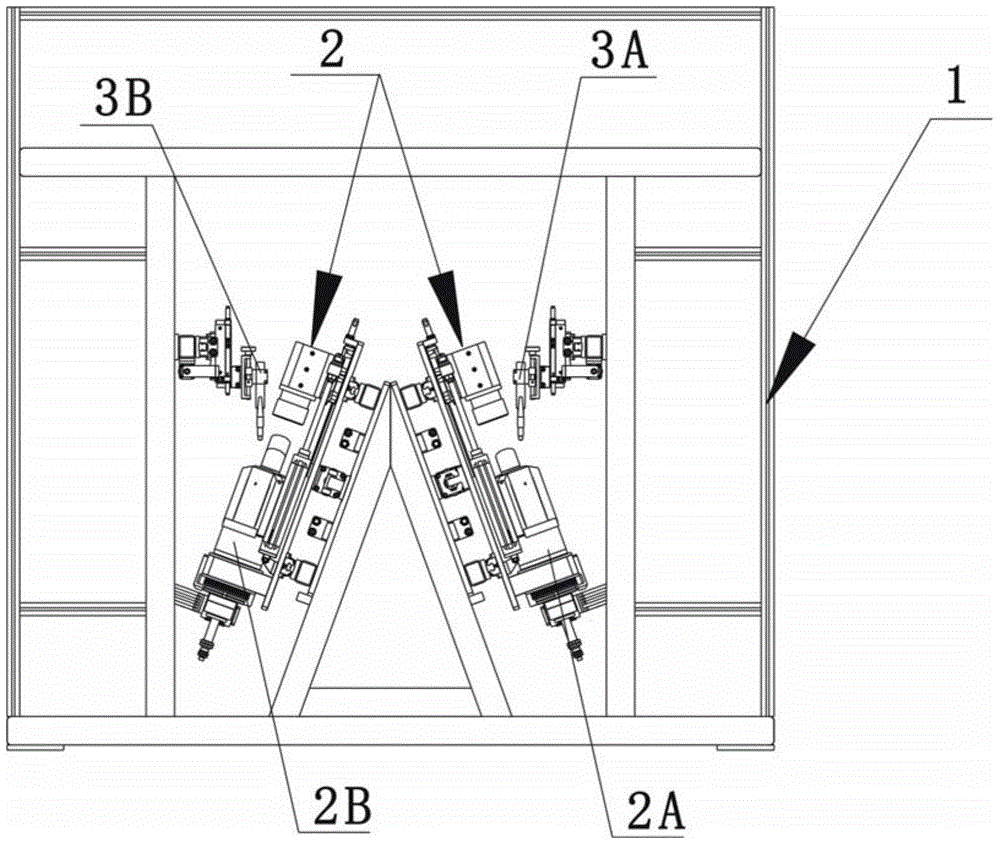

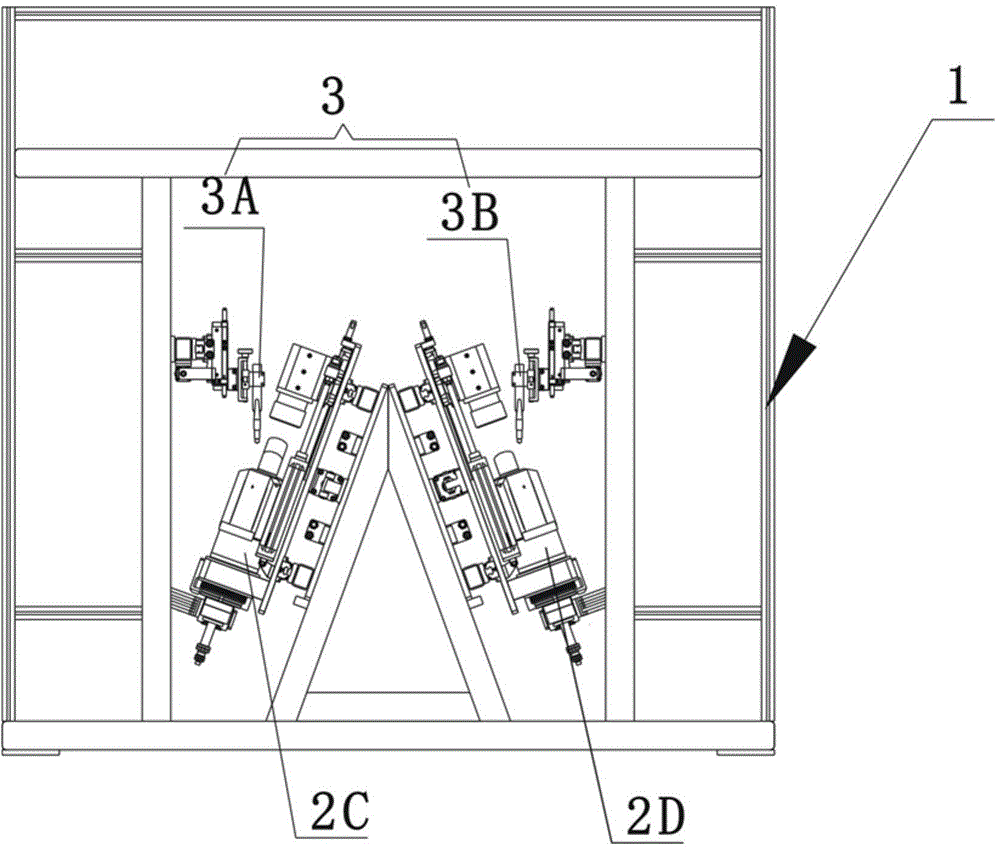

[0031] The welding equipment provided in this embodiment includes a frame 1 , at least one positioning and clamping mechanism 2 , at least one welding mechanism 3 , and at least one rotating mechanism 4 . At least one positioning and clamping mechanism 2 is arranged on the frame 1. The positioning and clamping mechanism 2 positions and clamps the welding workpiece 100. After clamping, the angle between the axis of the welding workpiece 100 and the horizontal plane is 2-178 degrees. Each welding mechanism 3 includes at least one welding torch 31, and at least one welding torch 31 welds the clamped welding workpiece. At least one rotating mechanism 4 drives the welding workpiece or at least one welding torch 31 to rotate around the axis of the welding workpiece during welding.

[0032] In this embodiment, the welding equipment also includes a wire feeding mechanism 5, the number of the wire feeding mechanism 5 is equal to the number of the welding mechanism 3 and is set in one-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com